June 16, 2024 By Usman Ahmed 12 minutes read

Capacitors are one of the most fundamental components in the world of electronics. If you’ve ever wondered how electronic devices like your smartphone or laptop manage to store and release energy so efficiently, capacitors are a big part of the answer.

A capacitor is a device that stores electrical energy in an electric field, allowing it to be released when needed.

This ability to quickly store and discharge energy makes capacitors vital in various applications, from filtering noise in audio systems to stabilizing voltage in power supplies.

This article is here to guide you through the diverse world of capacitors. We’ll delve into twelve different types of capacitors, explaining how each works, where they’re used, and their advantages and disadvantages. By the end, you’ll have a comprehensive understanding of choosing the right capacitor for any equipment.

A capacitor consists of two conductive plates separated by an insulating material called a dielectric. When a voltage is applied across the plates, an electric field is created, and electrical energy is stored in the dielectric. This stored energy can then be released when the circuit requires it.

Imagine a capacitor as a small, rechargeable battery that can charge and discharge rapidly. Electrons accumulate on one plate when connected to a power source, creating a negative charge. At the same time, the other plate loses electrons, developing a positive charge.

The dielectric material between the plates prevents the charges from crossing over, thus storing energy in the electric field. When the capacitor is connected to a load, the stored energy is released, providing a burst of current to the circuit.

Understanding a capacitor’s performance involves knowing a few key parameters:

Capacitance: This is the primary measure of a capacitor’s ability to store charge, expressed in Farads (F). Higher capacitance means more energy storage.

Voltage Rating: Every capacitor has a maximum voltage it can handle before breaking down, known as the voltage rating. Exceeding this rating can cause the capacitor to fail, sometimes catastrophically.

Equivalent Series Resistance (ESR): This represents the capacitor’s internal resistance. Lower ESR values are preferred because they result in less energy loss.

Tolerance: This indicates the variation in capacitance from the stated value. It’s usually expressed as a percentage, and it tells you how accurate the capacitor is.

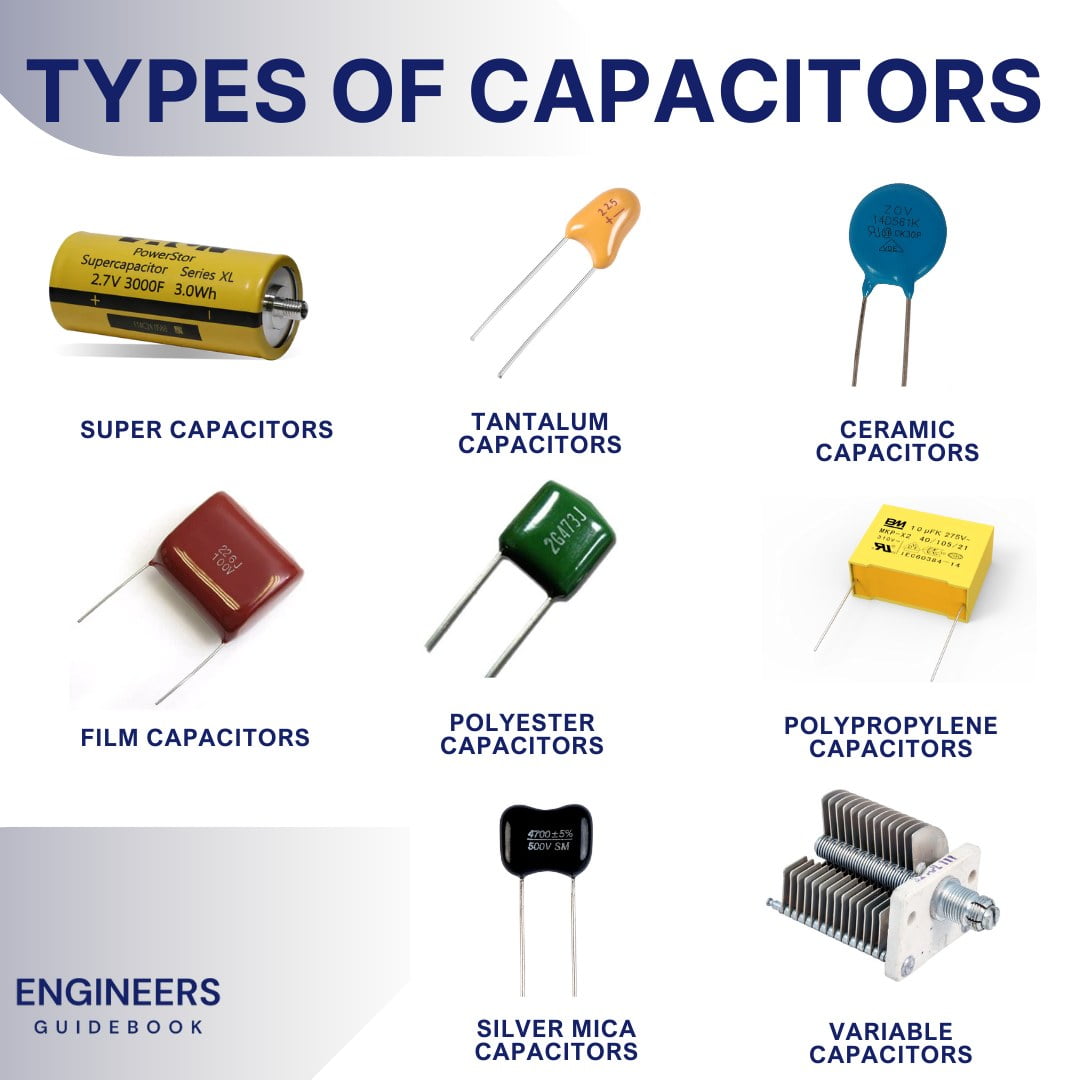

Capacitors come in various shapes, sizes, and materials, each tailored to specific applications and requirements. In this section, we’ll explore twelve different types of capacitors, breaking down their working principles, applications, advantages, and disadvantages.

Working Principle

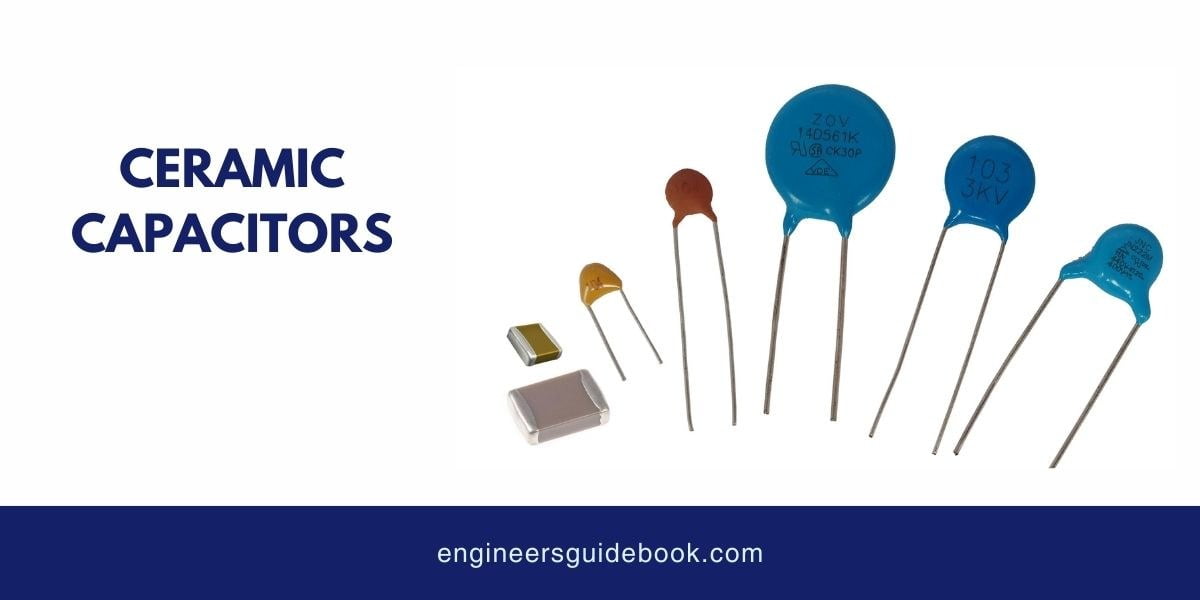

Ceramic capacitors are among the most common types of capacitors used today. They are made from a ceramic material that serves as the dielectric. The conductive plates are typically metal and layered onto the ceramic. When a voltage is applied, the ceramic dielectric polarizes, allowing the capacitor to store energy.

Working Principle

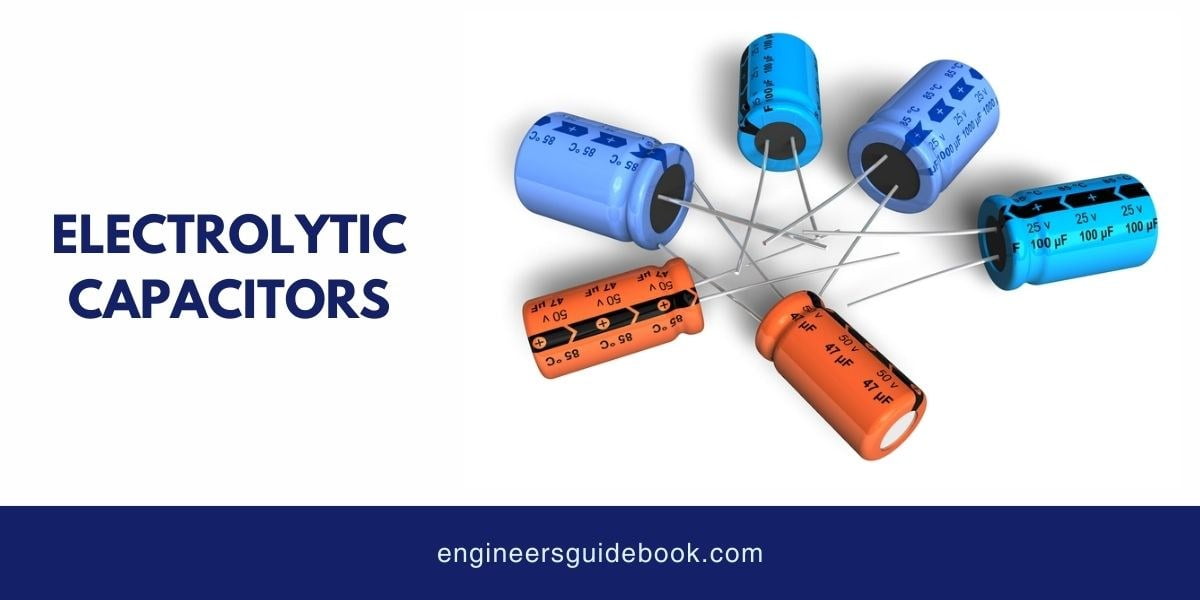

Electrolytic capacitors use an electrolyte as the dielectric material. The conductive plates are usually made of aluminium or tantalum, and the electrolyte is either a liquid or solid. Due to their higher capacitance values, these capacitors can store much more energy than ceramic capacitors.

Working Principle

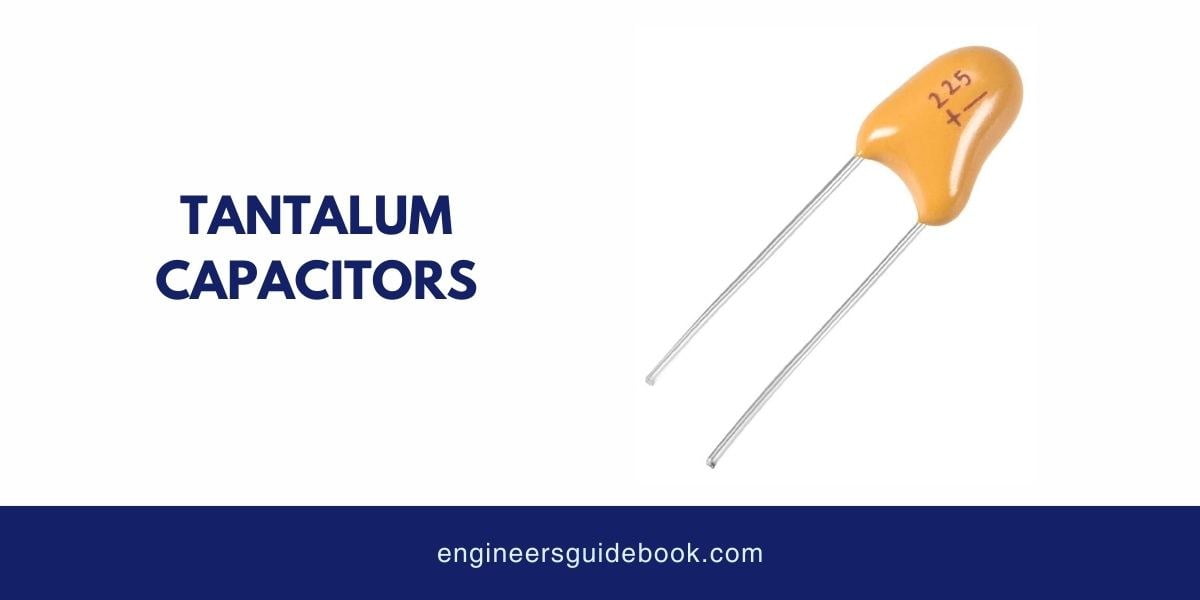

Tantalum capacitors are electrolytic capacitors that use tantalum as an anode. A thin oxide layer acts as the dielectric, and a conductive material, often manganese dioxide, serves as the cathode. Tantalum capacitors are known for their reliability and stability.

Working Principle

Film capacitors use a thin plastic film as the dielectric, with metal foil or a metalized film serving as the conductive plates. The dielectric film is wound into a tight roll or stacked to create a compact component. The type of plastic used in the film, such as polyester, polypropylene, or polystyrene, influences the capacitor’s characteristics.

Working Principle

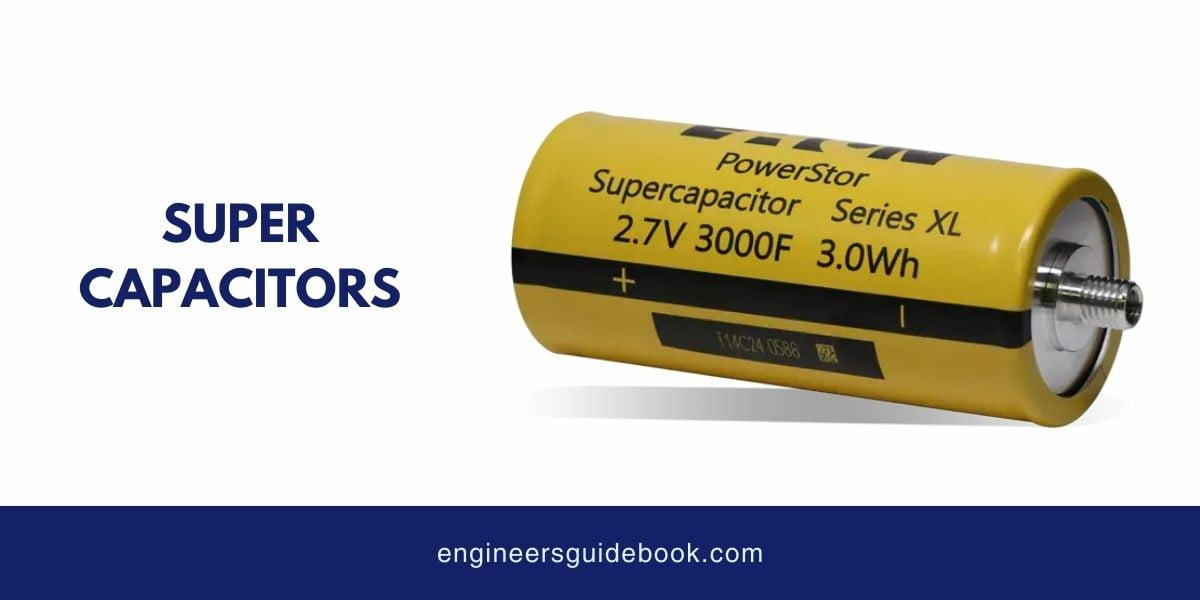

Supercapacitors, also known as ultracapacitors, are designed to store much more energy than traditional capacitors. They achieve this by using materials like activated carbon, which has a high surface area, and an electrolyte to create a double-layer capacitance. The result is a capacitor with a very high capacitance value, often several farads or more.

Working Principle

Mica capacitors use mica, a natural mineral, as the dielectric material. The mica sheets are stacked between metal plates, creating a stable and reliable capacitor. Mica capacitors are known for their precision and are often used in applications where accuracy is crucial.

Working Principle

Polyester capacitors, also known as Mylar capacitors, use polyester film as the dielectric material. The conductive plates are either aluminum or metalized film, and the dielectric is usually rolled into a compact cylindrical shape.

Polyester capacitors are known for their reliability and cost-effectiveness, making them popular in a variety of general-purpose applications.

Working Principle

Polypropylene capacitors use polypropylene film as the dielectric material. The dielectric is wound into a roll or stacked and encased in a plastic or metal housing. Polypropylene capacitors are known for their excellent electrical characteristics, making them ideal for high-performance applications.

Working Principle

Paper capacitors use paper as the dielectric material, which is impregnated with oil or wax to improve its insulating properties. The conductive plates are typically made of aluminium or tinned foil, and the capacitor is encased in a plastic or metal housing. Although less common today, paper capacitors are widely used in older electronic equipment.

Working Principle

Variable capacitors are designed to allow adjustment of the capacitance value within a certain range. They typically consist of a set of fixed and movable plates, with the capacitance varying as the distance between the plates changes. This type of capacitor is often used in tuning circuits where precise control over the capacitance is required.

Working Principle

Silver mica capacitors use mica as the dielectric material, with silver applied to the conductive plates. The mica sheets are stacked or rolled, and the silver layers are deposited to create a highly stable and precise capacitor. Silver mica capacitors are known for their excellent performance in high-frequency applications and their ability to maintain a stable capacitance over time.

Working Principle

Glass capacitors use glass as the dielectric material, with metal or metallized plates acting as the conductors. The glass dielectric provides exceptional insulation and stability, making these capacitors highly reliable in demanding applications. Glass capacitors are often used in environments where extreme temperatures, radiation, or other harsh conditions are present.

Capacitors are incredibly versatile components used in a wide range of applications across various engineering fields.

One of the primary applications of capacitors is power supply filtering. In electronic devices, capacitors smooth out fluctuations in the power supply. They act as reservoirs, storing energy when the supply voltage is high and releasing it when the voltage drops. This helps maintain a stable DC output, which is crucial for the proper functioning of sensitive electronic components.

Capacitors are widely used in signal coupling and decoupling applications. In coupling, capacitors allow AC signals to pass from one stage of a circuit to another while blocking any DC components. This is essential in audio and RF circuits to ensure that only the desired signal is transmitted. Decoupling capacitors, on the other hand, are used to isolate different stages of a circuit, preventing unwanted noise or interference from affecting the performance of sensitive components.

Capacitors are also used for energy storage in various applications. Unlike batteries, capacitors can charge and discharge rapidly, making them ideal for applications that require quick bursts of energy. Supercapacitors, particularly, are used in energy storage systems where high capacitance and fast charge/discharge cycles are needed.

Capacitors are essential components in RF and high-frequency applications, where they are used for tuning, filtering, and impedance matching. The precise capacitance and low loss characteristics of certain capacitors, such as silver mica and ceramic capacitors, make them ideal for these applications.

Capacitors play a crucial role in timing circuits, where they are used to create time delays or oscillations. By combining a capacitor with a resistor, engineers can create an RC time constant, which determines how quickly a capacitor charges or discharges. This principle is used in various timing and oscillator circuits.

Selecting the right capacitor for your project can be a critical decision that impacts your design’s overall performance and reliability.

The capacitance value, measured in Farads (F), determines how much charge the capacitor can store. Depending on your circuit’s requirements, you may need a capacitor with a low or high capacitance value. For instance, power supply filters typically require high capacitance, whereas coupling capacitors might need lower values.

The voltage rating of a capacitor is the maximum voltage it can handle before it risks breaking down. It’s crucial to select a capacitor with a voltage rating higher than the maximum voltage your circuit will encounter to ensure safe and reliable operation.

The physical size and shape of the capacitor can be a limiting factor, especially in compact or densely packed designs. Some types of capacitors, like electrolytic and film capacitors, are bulkier than others, like ceramic capacitors.

Different capacitors have varying degrees of temperature stability. If your application operates in extreme temperatures, such as in automotive or aerospace environments, you’ll need a capacitor that maintains its performance across a wide temperature range.

ESR is the internal resistance within the capacitor that causes power loss and heat generation. Low ESR is generally preferred, especially in high-frequency or high-current applications, to minimize energy loss and improve efficiency.

The cost of capacitors can vary widely based on type, material, and specifications. While choosing the most affordable option is tempting, it’s important to balance cost with performance and reliability. In critical applications, the higher upfront cost of a reliable capacitor can save costs in the long run by preventing failures.

As technology continues to evolve, so does the demand for capacitors that can meet the increasingly complex requirements of modern electronic systems. The future of capacitor technology is being shaped by advancements in materials science and manufacturing techniques.

One of the most exciting areas of capacitor development is the exploration of new dielectric materials.

High-K Dielectrics: Materials with high dielectric constants (High-K) are being developed to increase the capacitance per unit volume, creating smaller, more efficient capacitors.

Graphene-Based Capacitors: Graphene, a material known for its exceptional electrical conductivity and mechanical strength, is being explored as a potential material for capacitors. Graphene-based capacitors could offer higher energy storage capabilities and faster charge/discharge rates, making them ideal for applications in energy storage and fast-charging systems.

Embedded Capacitors: These capacitors are built into the PCB substrate, reducing the need for discrete components and saving valuable board space. Embedded capacitors also improve the circuit’s overall performance by reducing parasitic inductance and resistance.

Flexible and Printed Capacitors: With the rise of wearable electronics and flexible devices, there is an increasing need for capacitors that can bend, stretch, and conform to different shapes. Flexible and printed capacitors, made from materials like conductive polymers and printed inks, are emerging as solutions for these applications.

The future of capacitor technology is bright, with numerous advancements on the horizon that promise to enhance the performance, efficiency, and versatility of these critical components. As engineers and designers continue to push the boundaries of what’s possible in electronics, capacitors will remain at the forefront of innovation, enabling the development of new technologies and applications that will shape the world for years to come.

A capacitor is an electronic component that stores and releases electrical energy. It consists of two conductive plates separated by a dielectric material. When voltage is applied, it stores energy in an electric field, which can be discharged when needed.

Common types include ceramic, electrolytic, tantalum, film, supercapacitors, mica, polyester, polypropylene, paper, variable, silver mica, and glass capacitors. Each type has unique properties suited for specific applications.

Capacitors are used in power supply filtering, signal processing, energy storage, timing circuits, and RF applications. They stabilize voltage, filter noise, and store energy in various electronic circuits.

Choose based on capacitance, voltage rating, ESR, and application requirements. Consider the environment, size constraints, and required stability to ensure optimal performance.

Electrolytic capacitors offer high capacitance and are used for power supply filtering but have polarity sensitivity. Ceramic capacitors are smaller, stable at high frequencies, and used for decoupling, but they offer lower capacitance.

Capacitance, measured in Farads (F), indicates a capacitor’s ability to store charge. It is measured by applying a known voltage and observing the charge stored.

Capacitors can fail due to overvoltage, overheating, aging, physical damage, or exposure to harsh environmental conditions, leading to reduced performance or total failure.

Capacitors store energy in the electric field between their plates when charged. This energy is released as current when the capacitor is discharged into a circuit.

ESR (Equivalent Series Resistance) is the internal resistance of a capacitor that causes energy loss as heat. Low ESR is crucial for efficient operation, especially in high-frequency or high-current circuits.

Supercapacitors store significantly more energy than regular capacitors and charge/discharge rapidly. They are used in energy storage and backup power applications but have lower voltage ratings compared to traditional capacitors.

Capacitors store energy electrostatically in an electric field, allowing rapid charging and discharging, but they hold less energy over a shorter period. Batteries store energy chemically, providing a larger, slower release of power over a longer time.

The dielectric material in a capacitor is an insulating substance placed between the conductive plates. It increases the capacitor’s ability to store charge by reducing the electric field’s strength between the plates, thereby enhancing capacitance.

In AC circuits, capacitors can block DC while allowing AC to pass, making them useful for filtering and coupling applications. In DC circuits, capacitors are used to store energy, smooth voltage fluctuations, and filter out noise.

Usman Ahmed, a PhD in Electrical Engineering from Harvard University, is at the forefront of research in smart grid technology. His work on optimizing electrical distribution networks is highly regarded in the academic and professional circles.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.

8 Responses

I want to see

Just wish to say your article is as astonishing. The clearness on your post is just spectacular and i can assume you’re an expert

on this subject. Fine along with your permission allow me to take

hold of your feed to keep updated with impending post.

Thanks one million and please continue the enjoyable work.

I’m curious to find out what blog system you happen to be working with?

I’m experiencing some small security issues with my latest blog and

I would like to find something more safe. Do you have any solutions?

continuously i used to read smaller articles which as well clear their motive, and that is also happening with this article

which I am reading at this time.

This is the perfect website for everyone who really wants to find out about this topic.

You know so much its almost hard to argue with you (not that I actually would

want to…HaHa). You certainly put a new spin on a topic that has been discussed for many years.

Great stuff, just great!

i think it is all ai generated. Ai Garbige

I’m extremely impressed with your writing skills as well

as with the layout on your blog. Is this a paid theme or did you

customize it yourself

Very nice post. I just stumbled upon your weblog and wished to mention that I have really enjoyed surfing around your blog posts. In any case I’ll be subscribing in your rss feed and I hope you write once more soon!