1. Introduction to Molded Case Circuit Breakers (MCCB)

1.1 Understanding the Role of MCCBs in Electrical Systems

Molded Case Circuit Breakers (MCCBs) are fundamental components in electrical distribution networks, providing essential protection against overcurrents and short circuits. These devices are designed to interrupt electrical faults effectively, preventing damage to circuits and ensuring the safety of both equipment and personnel.

MCCBs are widely used in industrial, commercial, and residential applications where reliability and efficiency are paramount.

1.2 Why MCCBs Are Essential for Circuit Protection

Electrical systems are constantly exposed to potential hazards such as excessive current flow, short circuits, and ground faults. Without appropriate circuit protection, these conditions can lead to severe damage, fire hazards, and costly downtimes. MCCBs serve as a robust solution by automatically disconnecting the circuit when an anomaly is detected, thereby mitigating risks and enhancing system stability.

1.3 Key Features That Differentiate MCCBs from Other Circuit Breakers

MCCBs are distinguished by their versatility and advanced protection mechanisms. Unlike Miniature Circuit Breakers (MCBs), which are suited for lower current ratings, MCCBs handle higher capacities and offer adjustable trip settings. Additionally, MCCBs incorporate both thermal and magnetic trip units, enabling precise fault detection and response. Their modular design allows for seamless integration into diverse electrical infrastructures.

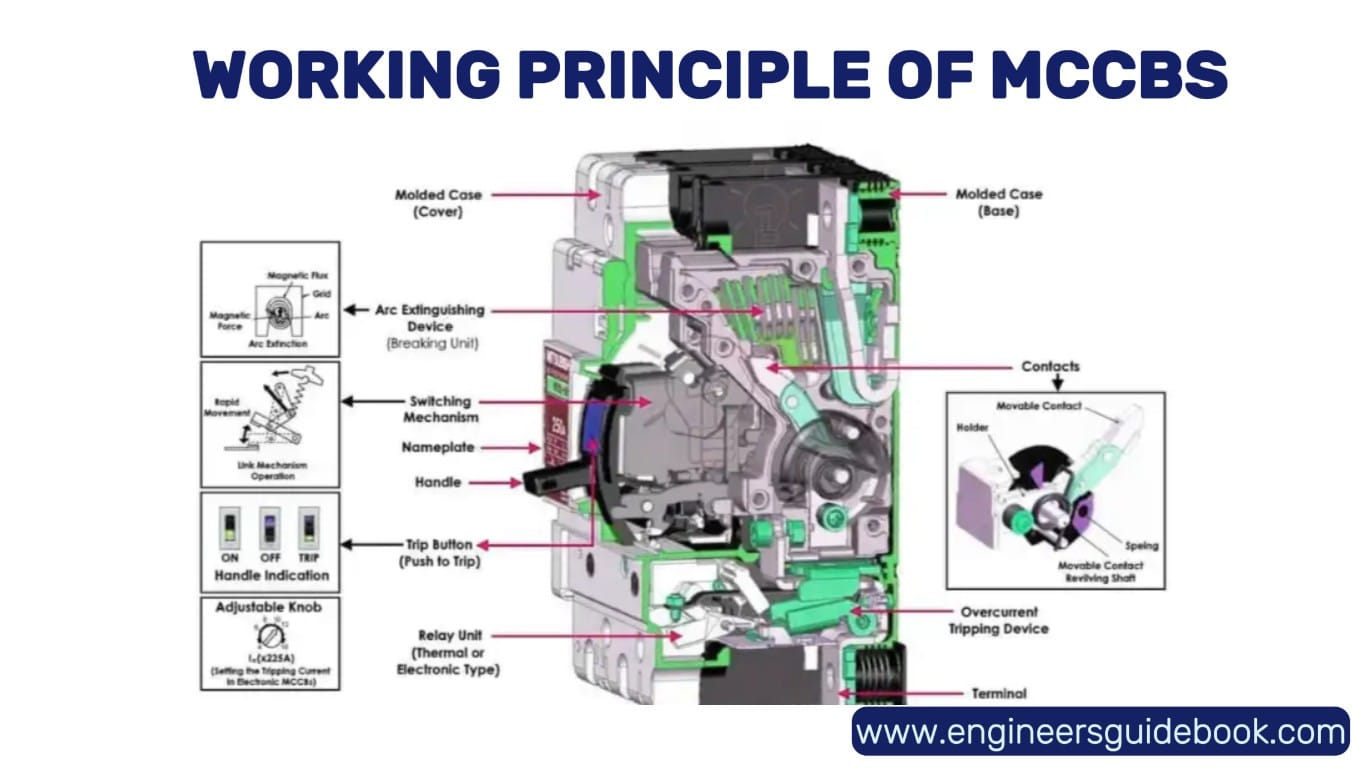

2. Working Principle of MCCBs

2.1 The Mechanism Behind MCCB Operation

MCCBs function by utilizing a combination of thermal and magnetic mechanisms to detect and interrupt electrical faults. Under normal operating conditions, electrical current flows uninterrupted through the MCCB. However, when an abnormal surge occurs, the internal trip unit activates, causing the breaker to open and halt the current flow.

2.2 Thermal and Magnetic Protection Explained

The thermal protection element consists of a bimetallic strip that bends when exposed to excessive heat generated by prolonged overcurrent. This deformation triggers the trip mechanism, cutting off power to prevent overheating. Meanwhile, the magnetic protection element consists of an electromagnet that reacts instantly to sudden short circuits by inducing a strong magnetic field, forcing the circuit breaker to trip immediately.

2.3 Arc Extinguishing

When a circuit breaker interrupts a fault, an electric arc is generated between its contacts. To prevent further damage, MCCBs are equipped with arc chutes that rapidly extinguish the arc. These chutes consist of a series of metal plates that cool and divide the arc into smaller segments, effectively dissipating the energy and ensuring safe operation.

2.4 Trip Mechanisms and Their Importance in Safety

MCCBs utilize various trip mechanisms tailored for different applications. These include thermal-magnetic trip units, electronic trip units, and microprocessor-based trip units. Each mechanism provides specific advantages, such as precision, adjustable settings, and advanced fault detection, ensuring optimal protection for electrical systems.

3. Types and Classifications of MCCBs

3.1 Classification Based on Rated Current and Voltage

MCCBs are categorized based on their rated current and voltage capacities. Low-voltage MCCBs are commonly used in residential and commercial settings, whereas high-voltage MCCBs are employed in industrial power distribution systems. Selecting the appropriate MCCB rating is crucial for maintaining electrical safety and efficiency.

3.2 Types of MCCBs Based on Application Needs

3.2.1 Standard MCCBs for General Industrial Use

Standard MCCBs are widely utilized in industrial environments to safeguard machinery and electrical panels from overcurrents and short circuits. These breakers offer reliable protection and are designed to handle high inrush currents commonly encountered in motor-starting applications.

3.2.2 Current-Limiting MCCBs for Enhanced Safety

Current-limiting MCCBs are engineered to restrict fault current magnitude within a predefined threshold, reducing potential damage to downstream equipment. By limiting peak fault currents, these breakers enhance overall system reliability and improve the longevity of electrical components.

3.2.3 Adjustable MCCBs for Flexible Protection

Adjustable MCCBs provide the flexibility to modify trip settings based on specific application requirements. These breakers allow users to fine-tune protection parameters, ensuring compatibility with various loads and operating conditions. This adaptability makes them ideal for dynamic electrical systems requiring precise control over fault response times.

4. Key Specifications and Ratings of MCCBs

4.1 Rated Current (In)

The rated current of an MCCB defines the maximum continuous current it can handle without tripping. Choosing an MCCB with the appropriate rated current is essential to prevent nuisance tripping while ensuring adequate protection against overload conditions.

4.2 Breaking Capacity

Breaking capacity refers to the maximum fault current an MCCB can safely interrupt without sustaining damage. A higher breaking capacity indicates a greater ability to handle severe fault conditions, making it a critical parameter when selecting MCCBs for high-power installations.

4.3 Rated Voltage

The rated voltage of an MCCB must align with the system voltage to ensure safe and efficient operation. Using an MCCB with an incompatible voltage rating can lead to insulation breakdown, reduced performance, and potential safety hazards.

4.4 Frame Size and Its Impact on Installation

Frame size determines the physical dimensions and maximum current capacity of an MCCB. Larger frame sizes accommodate higher current ratings and additional features, making them suitable for heavy-duty applications. Proper selection of frame size ensures seamless integration within electrical panels and switchgear assemblies.

5. Applications of MCCBs in Various Industries

5.1 MCCBs in Industrial Power Distribution

Industrial facilities rely on MCCBs to protect critical electrical infrastructure, including transformers, motor control centers, and distribution panels. These breakers play a pivotal role in preventing system failures and minimizing production downtime caused by electrical faults.

5.2 Role of MCCBs in Commercial and Residential Electrical Systems

In commercial and residential settings, MCCBs provide robust protection for electrical distribution networks. They safeguard lighting circuits, HVAC systems, and power outlets from overcurrent and short-circuit conditions, ensuring safe and reliable operation.

5.3 MCCBs in Renewable Energy Installations

Renewable energy systems, such as solar and wind power installations, incorporate MCCBs to protect inverters, battery storage units, and grid connections. These breakers help manage fluctuating power levels and prevent damage caused by electrical faults.

5.4 MCCBs in Motor Protection and Control Circuits

MCCBs are extensively used in motor control applications to protect electric motors from overloads and short circuits. Their ability to withstand high inrush currents makes them indispensable in industrial automation, conveyor systems, and pumping stations.

6. Selection Criteria for Choosing the Right MCCB

6.1 Understanding Load Requirements Before Selection

Before selecting an MCCB, it is imperative to analyze the electrical load it will be protecting. This includes determining the maximum current the circuit will carry under normal operation and accounting for potential surges. Overlooking this step can lead to incorrect sizing, resulting in nuisance tripping or inadequate protection.

6.2 Breaking Capacity and Fault Current Considerations

Breaking capacity refers to the maximum fault current an MCCB can safely interrupt without sustaining damage. It must be higher than the prospective short-circuit current of the system. Selecting an MCCB with insufficient breaking capacity can lead to catastrophic failures, posing serious safety hazards.

6.3 Choosing the Right Trip Unit for Different Applications

MCCBs come with various trip units, including thermal-magnetic and electronic types. Thermal-magnetic trip units are ideal for general applications, while electronic trip units offer adjustable settings for precise protection. Selecting the appropriate trip unit ensures optimal performance based on the application’s specific needs.

6.4 Environmental Factors and Their Impact on MCCB Performance

Environmental conditions such as temperature, humidity, and exposure to dust or corrosive substances can affect MCCB performance. MCCBs used in harsh environments must have protective enclosures or coatings to prevent premature failure and ensure long-term reliability.

7. Installation and Maintenance Best Practices

7.1 Proper Installation Techniques to Ensure Reliability

A well-executed installation is key to MCCB reliability. Proper torque settings for connections, secure mounting, and adherence to manufacturer guidelines are essential to avoid overheating, arcing, and malfunctions.

7.2 Common Mistakes to Avoid During MCCB Installation

Errors such as incorrect wiring, inadequate spacing for heat dissipation, and failure to follow polarity requirements can lead to operational issues. Awareness of these mistakes helps in achieving a safe and effective installation.

7.3 Regular Maintenance and Inspection Protocols

Periodic maintenance, including visual inspections, thermal imaging, and functional testing, helps in detecting early signs of deterioration. Cleaning terminals and checking for wear ensures continued protection and extends the lifespan of MCCBs.

7.4 Troubleshooting Common MCCB Issues

Issues such as nuisance tripping, overheating, or failure to trip require systematic troubleshooting. Understanding the root causes, whether it be overload conditions, poor connections, or internal damage, is essential for restoring proper functionality.

8. Advantages and Limitations of MCCBs

8.1 Benefits of Using MCCBs for Circuit Protection

MCCBs offer superior protection against overloads and short circuits. They provide high reliability, adjustable settings for flexibility, and ease of maintenance, making them a preferred choice in diverse electrical systems.

8.2 Limitations

Despite their advantages, MCCBs have limitations, such as size constraints in compact installations and potential costs for high-rated models. In some cases, fuses or other protective devices may be more suitable, especially where rapid disconnection is required.

8.3 Comparing MCCBs with Other Circuit Protection Devices

| Type of Breaker | Current Rating | Protection | Applications |

|---|

| Miniature Circuit Breaker (MCB) | Low Current (up to 100A) | Protection against overloads and short circuits | Residential and light commercial circuits |

| Molded Case Circuit Breaker (MCCB) | Higher Current (up to 2500A) | Protection against overloads, short circuits, and ground faults | Industrial and heavy-duty applications |

| Residual Current Circuit Breaker (RCCB) | Varies (Typically low to medium current) | Protection against earth leakage or ground faults | Sensitive environments, wet areas, and safety-critical systems |

9. Latest Innovations and Trends in MCCB Technology

9.1 Smart MCCBs: The Future of Circuit Protection

Advancements in MCCB technology have led to the development of smart MCCBs with built-in communication capabilities. These devices provide real-time diagnostics, predictive maintenance insights, and remote control functionality.

9.2 Integration with IoT for Real-Time Monitoring

Modern MCCBs are now integrated with IoT platforms, allowing engineers to monitor electrical parameters remotely. This enhances system efficiency, reduces downtime, and prevents unexpected failures.

9.3 MCCB Advancements in Energy Efficiency and Sustainability

Energy-efficient MCCBs minimize power losses and contribute to sustainable operations. Innovations in design and materials have improved thermal management, ensuring lower energy consumption and reduced environmental impact.

10. Conclusion

MCCBs are indispensable components in electrical protection systems. Their selection, installation, and maintenance directly influence system reliability and safety.

Understanding MCCB operation, selection criteria, and emerging technologies ensures informed decision-making. Investing in the right MCCB enhances safety and performance.

As electrical infrastructures evolve, selecting MCCBs with advanced features ensures adaptability. Future-proofing through smart MCCBs and IoT integration will drive efficiency and reliability in modern electrical networks.

11. FAQ

1. What is the primary function of an MCCB?

- Answer: The primary function of a Molded Case Circuit Breaker (MCCB) is to provide overcurrent protection to electrical circuits. It protects against both overloads and short circuits, preventing damage to electrical equipment and reducing the risk of fire hazards.

2. How do MCCBs differ from MCBs?

- Answer: MCCBs (Molded Case Circuit Breakers) are designed for higher current ratings (up to 2500A) and are typically used in industrial and commercial settings, while MCBs (Miniature Circuit Breakers) are used for lower current ratings (up to 100A) in residential and light commercial applications. MCCBs also offer adjustable trip settings, unlike MCBs.

3. What is the breaking capacity of an MCCB?

- Answer: The breaking capacity of an MCCB refers to the maximum fault current that it can safely interrupt without causing damage. This capacity is crucial for ensuring that the breaker can handle extreme short-circuit conditions in a system without failing.

4. How does an MCCB work to prevent electrical hazards?

- Answer: An MCCB operates using thermal and magnetic trip mechanisms. The thermal element responds to prolonged overload conditions, while the magnetic element reacts to short circuits. When either condition is detected, the MCCB trips, disconnecting the circuit and preventing potential damage or fire.

5. Can MCCBs be used for motor protection?

- Answer: Yes, MCCBs are widely used for motor protection. They can be equipped with special trip units that protect motors from overloads, short circuits, and phase failures, ensuring the longevity and safety of motors in various industrial applications.

6. What is the difference between thermal and magnetic trip units in MCCBs?

- Answer: The thermal trip unit in an MCCB provides protection against overloads by using a bimetallic strip that bends when heated by excessive current. The magnetic trip unit protects against short circuits by using an electromagnet that activates the breaker when a high surge of current occurs instantaneously.

7. Are MCCBs adjustable?

- Answer: Yes, many MCCBs come with adjustable settings for trip currents and time delays. This flexibility allows for precise protection tailored to the specific needs of a system, providing better control over when the breaker will trip under overload or short-circuit conditions.

8. What factors should be considered when selecting an MCCB?

- Answer: When selecting an MCCB, factors to consider include the rated current, breaking capacity, voltage rating, frame size, and environmental conditions. It’s important to match the MCCB to the electrical load and potential fault conditions of the system, as well as ensure the breaker is suitable for the specific application (e.g., industrial, residential, or motor protection).

One Response

Hello this is kind of of off topic but I was wondering if blogs use WYSIWYG editors or

if you have to manually code with HTML. I’m starting a

Very Nice Blog and data is very comprehensive