August 14, 2024 By Amber raza 6 minutes read

Imagine being able to control the speed of an electric motor as easily as you turn the volume knob on your radio. That’s essentially what a Variable Frequency Drives (VFD) does. At its core, a VFD is a type of motor controller that drives an electric motor by varying the frequency and voltage of its power supply.

But why would you want to control a motor’s speed? Well, in many applications, the speed of a motor needs to be adjusted to match the demands of the system it’s powering.

For example, think about a conveyor belt in a manufacturing plant. Sometimes, the belt needs to move quickly to keep up with production, and other times it needs to slow down to ensure safety. A Variable Frequency Drives (VFD) allows for this flexibility, making it an essential tool in modern engineering.

It starts by taking the fixed AC power from your main supply and converting it into DC power. This process is handled by a component called a rectifier. Once the power is in DC form, it passes through a DC bus that filters and smooths the current, ensuring a stable flow.

Next, the magic happens in the inverter section. The inverter takes the clean DC power and converts it back into AC power, but the frequency and voltage can vary this time. By adjusting these parameters, the VFD controls the speed of the motor. It’s like turning the dial on a fan to make it spin faster or slower but with much more precision and control.

It’s important to examine the underlying principles of a variable frequency drive (VFD) to really understand how it operates.

In simple terms, frequency refers to how many times an AC power signal cycles in one second, measured in Hertz (Hz). The speed of an AC motor is directly proportional to the frequency of the power supply. So, if you increase the frequency, the motor speeds up; if you decrease it, the motor slows down.

A VFD manipulates this frequency to control motor speed. By varying the frequency of the power supplied to the motor, the VFD can precisely adjust how fast the motor spins.

This ability to fine-tune motor speed is what makes VFDs so valuable in various applications.

One of the key techniques used by VFDs to control motor speed is called Pulse Width Modulation (PWM). Don’t let the technical name scare you—it’s actually quite simple once you break it down.

PWM is a method where the VFD creates a series of rapid on-and-off pulses in the DC power, which are then converted back into AC power.

The width of these pulses determines the average voltage and frequency of the power supply. By controlling the pulse width, the VFD can effectively adjust the motor’s speed and torque.

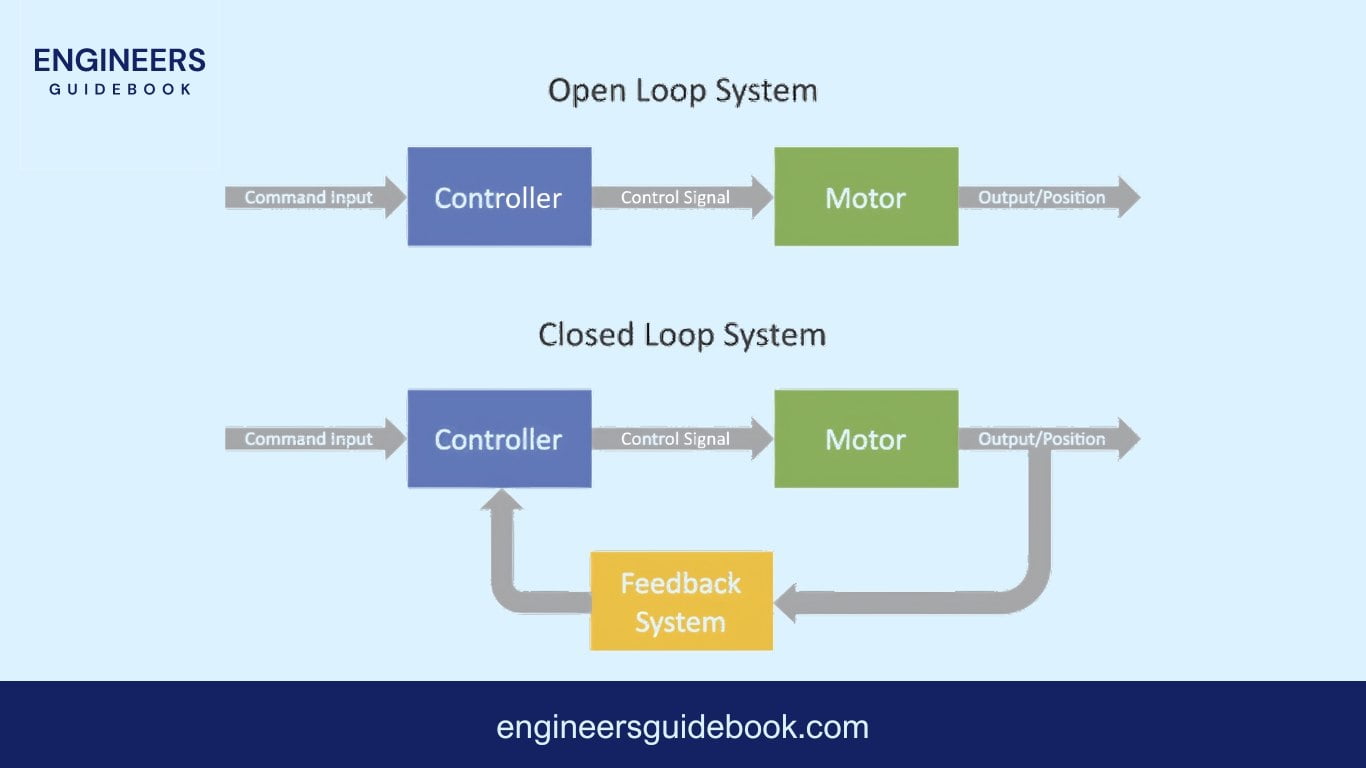

There are two main methods for controlling motor speed using VFDs: open-loop and closed-loop control.

Open-loop control: is the simpler of the two. In this method, the VFD sends a set frequency to the motor without any feedback. It’s like setting your cruise control on the highway without any adjustments, regardless of changes in terrain or load.

Closed-loop control, on the other hand, involves constant feedback. Sensors monitor the motor’s speed and provide data to the VFD, which then makes real-time adjustments to maintain the desired speed. This method is more accurate and is used in applications where precision is crucial.

A critical aspect of VFD operation is energy conversion. As mentioned earlier, a VFD converts AC power to DC and back to AC. This highly efficient conversion process allows the VFD to improve the motor system’s power factor.

The power factor measures how effectively electrical power is being used. A poor power factor means more energy is wasted, leading to higher electricity costs.

Variable Frequency Drives (VFDs) come in various types, each designed to meet specific needs and applications. Understanding the differences between these types is crucial for selecting the right drive for your project.

Voltage Source Inverters (VSIs) are the most widely used type of VFDs. As the name suggests, VSIs use a constant voltage source to convert DC power back into AC power. These drives are highly efficient and are ideal for applications where the motor speed needs to be adjusted over a wide range.

VSIs are commonly used in conveyor systems, fans, and pumps. Their popularity comes from their simplicity and reliability. However, they do have some limitations, particularly when handling high starting currents.

Current Source Inverters (CSIs) operate similarly to VSIs but with one key difference: they use a constant current source instead of a constant voltage source. This makes CSIs particularly suited for applications where precise control of motor torque is required.

CSIs are often found in high-power applications such as large compressors and heavy-duty industrial machinery. They are known for their robustness and ability to handle high loads. However, they are typically more complex and expensive than VSIs, making them less common in everyday applications.

Pulse Width Modulation (PWM) drives are among the most versatile and widely used VFDs. PWM is a technique where the VFD rapidly switches the inverter on and off, creating a series of pulses that control the motor’s speed. By adjusting the width of these pulses, the VFD can precisely control the output voltage and frequency.

PWM drives are efficient and can produce smooth motor control with minimal harmonics. This makes them suitable for a broad range of applications, from HVAC systems to process control in manufacturing. The combination of high performance and flexibility makes PWM the go-to choice for many engineers.

Direct Torque Control (DTC) is a more advanced type of VFD that offers highly accurate motor torque and speed control. Unlike traditional drives, which control voltage and frequency indirectly, DTC drives manage these parameters directly, allowing for faster response times and better performance.

DTC drives are particularly useful in applications requiring precise motor control, such as robotics, CNC machines, and other high-performance industrial equipment. While DTC drives offer superior power, they are more complex and typically more expensive, making them ideal for specialized applications where precision is critical.

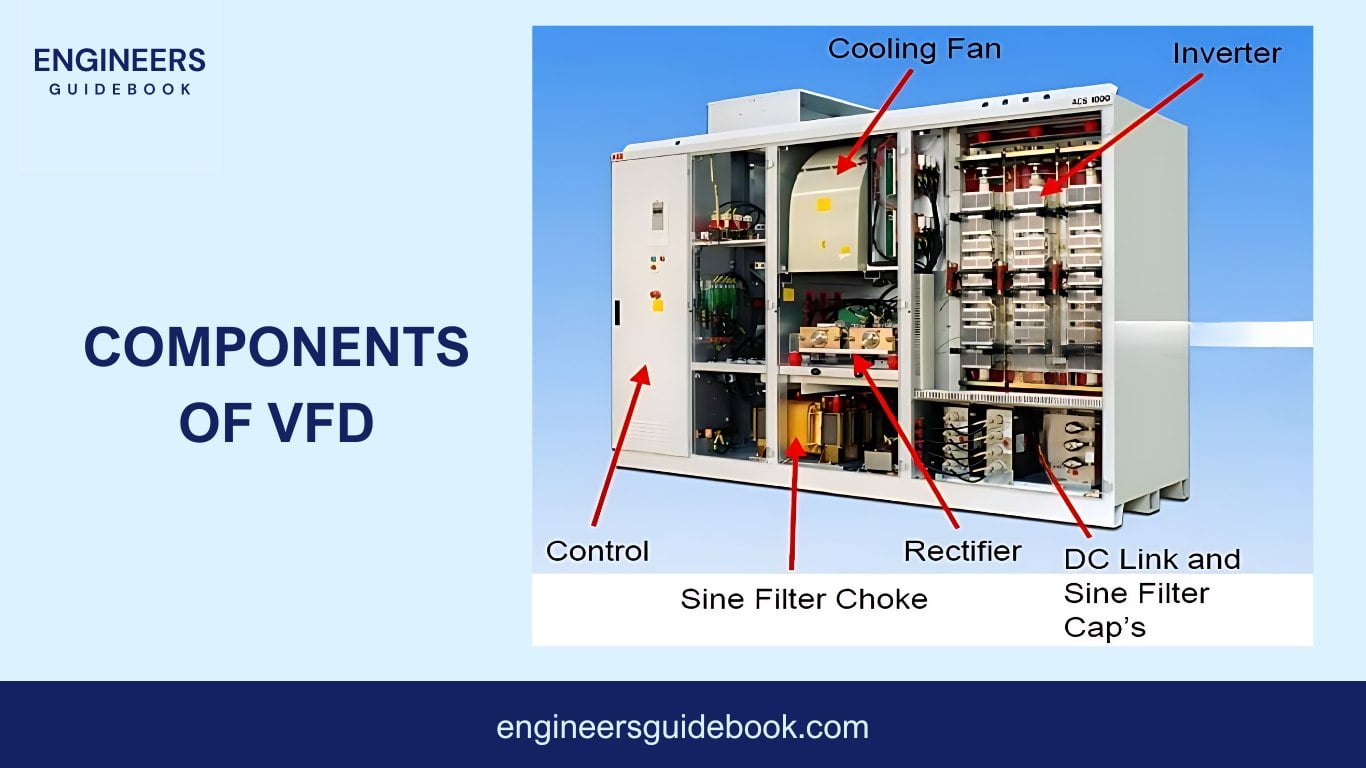

Understanding the key components of variable frequency drives (VFDs) is important to fully appreciate how these devices work.

The rectifier is the first major component in a VFD. Its primary function is to convert the incoming AC power from the electrical grid into DC power. This conversion is essential because the DC power is easier to control and modify. The rectifier is typically made up of diodes or thyristors, which allow current to flow in only one direction, effectively converting the AC signal into a pulsating DC signal.

There are two main types of rectifiers used in VFDs: uncontrolled and controlled. Uncontrolled rectifiers use diodes and are simpler but less flexible, while controlled rectifiers use thyristors, allowing for more precise control over the DC output.

Once the AC power is converted to DC by the rectifier, it flows into the DC bus. The DC bus serves as a storage and filtering stage. It smooths out the pulsating DC power from the rectifier, ensuring a stable and clean DC voltage. This is crucial because any fluctuations in the DC bus voltage can lead to unstable motor operation and inefficiency.

The DC bus typically contains capacitors and inductors that help filter out any ripples in the DC voltage. By maintaining a consistent voltage level, the DC bus ensures that the subsequent stages of the VFD can operate smoothly.

The inverter is where the real magic happens. After the power is stabilized by the DC bus, the inverter converts the DC power back into AC power, but this time with a controlled frequency and voltage. This controlled AC power is then fed to the motor, allowing for precise speed and torque control.

The inverter accomplishes this conversion using semiconductor switches, such as Insulated Gate Bipolar Transistors (IGBTs) or Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs). These switches rapidly turn on and off, creating a series of high-frequency pulses that approximate the desired AC waveform.

Filters and inductors play a vital role in minimizing electrical noise and protecting the VFD and motor from potential damage. The rapid switching action of the inverter can create high-frequency harmonics, which are undesirable because they can cause overheating and inefficiency in the motor.

To mitigate these issues, VFDs often include input and output filters. Input filters reduce the harmonics fed back into the power supply, while output filters smooth out the waveform before it reaches the motor. Inductors, on the other hand, limit the rate of change of current, providing additional protection against spikes and surges.

The control unit is the brain of the VFD. It monitors and adjusts the drive’s operation to ensure the motor performs as required. The control unit processes inputs from the operator and feedback from the motor, adjusting the inverter’s output to achieve the desired speed and torque.

Variable Frequency Drives (VFDs) have become indispensable in many industries because they control motor speed and torque precisely.

Pumps: Pumps are essential in industries like water treatment, oil and gas, and chemical processing. VFDs help control the flow rate by adjusting the pump speed, reducing energy consumption, and extending the life of the equipment.

Fans and Blowers: HVAC systems in factories, warehouses, and processing plants often rely on large fans to circulate air. VFDs allow these fans to run at variable speeds, reducing energy use when full airflow is not required.

Conveyors and Material Handling Systems: In manufacturing and distribution, conveyors are used to move products through different stages of production or packaging. VFDs allow for smooth acceleration and deceleration of conveyor belts.

HVAC Systems: In commercial buildings, VFDs are used to control the speed of fans, pumps, and compressors in heating, ventilation, and air conditioning (HVAC) systems. By adjusting motor speed to match the actual demand, VFDs can significantly reduce energy consumption and improve indoor air quality.

Elevators and Escalators: VFDs are essential in operating elevators and escalators, providing smooth and efficient movement. By controlling the speed and torque of the motors, VFDs ensure that elevators start and stop gently.

Variable Frequency Drives (VFDs) offer numerous benefits that make them essential in many industrial and commercial applications.

One of the most significant advantages of using VFDs is the potential for energy savings. By controlling the speed of motors to match the exact demand of the application, VFDs can reduce energy consumption by up to 50% or more in some cases.

VFDs offer precise motor speed and torque control, translating into better process control. This flexibility allows for smoother operation, reduces the risk of mechanical stress, and enables more accurate adjustment of system parameters.

Starting and stopping motors at full speed can cause wear and tear on mechanical components. VFDs help mitigate this by providing soft start and stop functions, gradually increasing or decreasing the motor speed.

VFDs contribute to a quieter operating environment by reducing the speed of motors when full speed isn’t necessary. This is especially important in HVAC systems, where fans running at lower speeds produce less noise.

One of the primary disadvantages of VFDs is their initial cost. VFDs can be expensive to purchase and install, particularly for large or complex systems. Additionally, integrating VFDs into existing systems may require significant modifications, adding to the overall cost.

VFDs can introduce harmonic distortion into the electrical system, which can interfere with the operation of other equipment. Harmonics are unwanted frequencies that can cause overheating in motors and transformers, reducing efficiency and potential equipment failure.

While VFDs can reduce the mechanical wear on equipment, they themselves are complex electronic devices that require regular maintenance. The failure of a VFD can lead to significant downtime, and repairs can be costly.

Proper installation and maintenance are critical to ensuring the reliable and efficient operation of Variable Frequency Drives (VFDs). A well-installed and maintained VFD can save energy, reduce downtime, and extend equipment life.

Selecting the right VFD for your application is the first step in ensuring optimal performance. The VFD must be appropriately sized to match the motor’s power requirements. Undersized VFDs can lead to overheating and premature failure, while oversized VFDs may result in unnecessary energy consumption and higher costs.

The environment in which the VFD is installed plays a significant role in its longevity and performance. VFDs are sensitive to temperature, humidity, and dust. Ideally, they should.

Proper wiring and grounding are crucial for VFDs’ safe and efficient operation. Incorrect wiring can lead to electrical noise, interference, and even damage to the VFD or motor. Follow the manufacturer’s wiring diagrams and use the recommended wire sizes and types.

VFDs generate heat during operation; adequate cooling is necessary to prevent overheating and maintain reliability. Ensure that the VFD is installed with sufficient ventilation to dissipate heat. Avoid placing VFDs in confined spaces or near heat sources.

While Variable Frequency Drives (VFDs) offer numerous benefits in terms of energy savings and operational efficiency, ensuring their safe operation is paramount.

VFDs can introduce harmonic distortion into the electrical system, which can have several negative effects on both the VFD and other equipment in the facility. Harmonics are unwanted frequencies that can cause overheating, increased losses, and interference with sensitive equipment.

Harmonic distortion occurs when the VFD converts AC to DC and back to AC, particularly during the switching operations in the inverter section. These switching operations generate harmonics that can propagate through the electrical system, affecting other devices.

To mitigate harmonic distortion, several techniques can be employed:

Electromagnetic Compatibility (EMC) is crucial when installing and operating VFDs. EMC refers to the VFD’s ability to operate without causing or being affected by electromagnetic interference (EMI).

EMC compliance ensures that the VFD does not emit excessive EMI that could interfere with other nearby electronic devices. It also ensures that the VFD is resistant to EMI from external sources, which could affect its operation.

To achieve EMC compliance, the following measures can be taken:

The landscape of Variable Frequency Drives (VFDs) is continuously evolving, with new technologies and innovations poised to shape the future of motor control.

Wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are revolutionizing the design and performance of VFDs. These materials offer superior electrical properties to traditional silicon-based semiconductors, including higher voltage tolerance, faster switching speeds, and lower energy losses.

The evolution of control algorithms is another area where significant progress is being made in VFD technology. Advanced algorithms, such as vector control and direct torque control (DTC), are becoming more sophisticated, offering improved accuracy and responsiveness in motor control.

As the demand for more compact and efficient systems grows, the trend toward miniaturization in VFD technology is becoming increasingly important. Advances in semiconductor technology, cooling techniques, and packaging allow VFDs to become smaller while increasing their power density.

Throughout this article, we’ve explored the fundamentals and advanced aspects of Variable Frequency Drives (VFDs), from their basic operating principles to their diverse applications across industries. We’ve delved into the components that make VFDs function, examined the benefits and challenges of using these devices, and looked ahead to the future trends shaping their evolution.

VFDs are undeniably a cornerstone of modern industrial and commercial operations, offering significant energy savings, improved process control, and enhanced equipment longevity. As technology continues to advance, VFDs are becoming even more integral to achieving efficiency and sustainability in various fields, from manufacturing to renewable energy.

A VFD is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of its power supply.

A VFD converts incoming AC power to DC and then back to AC with adjustable frequency and voltage, which controls the motor’s speed.

VFDs offer energy savings, improved process control, reduced wear on motors, and lower operational costs by matching motor speed to demand.

VFDs are used in various applications, including HVAC systems, pumps, conveyors, fans, and renewable energy systems.

VFDs are typically used with three-phase AC motors, but they can also be used with certain types of single-phase motors if compatible.

A VFD controls motor speed and torque throughout the operation, while a soft starter only reduces the inrush current and gradually increases motor speed during startup.

By adjusting the motor speed to match the actual demand, a VFD reduces energy consumption compared to running the motor at full speed all the time.

The main components are the rectifier, DC bus, inverter, and control unit, which work together to adjust the motor speed.

Common types include Voltage Source Inverters (VSIs), Current Source Inverters (CSIs), Pulse Width Modulation (PWM) drives, and Direct Torque Control (DTC) drives.

VFD sizing depends on the motor’s power rating (horsepower or kilowatts), voltage, current, and the specific application requirements.

Disadvantages include initial cost, potential harmonic distortion, and the need for proper maintenance and environmental controls.

Yes, VFDs can introduce harmonic distortion into the electrical system, which can affect other equipment and reduce efficiency.

Regenerative braking allows a VFD to capture excess energy from the motor during deceleration and feed it back into the power grid or use it within the system.

Amber Raza, who earned her PhD in Electrical Engineering from the University of California, Berkeley, is an expert in wireless communication systems. Her innovative research in 5G technology is paving the way for next-generation connectivity.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.

One Response

Hello There. I found your blog using msn. This is

a really well written article. I’ll be sure

too bookmark iit and come back tto rread more of your useful info.