July 23, 2024 By Sadia Khan 5 minutes read

In today’s competitive business environment, organizations continually seek ways to enhance quality and optimize processes. One powerful methodology that has emerged to meet these demands is Six Sigma.

One powerful methodology that has emerged to meet these demands is Six Sigma. Originating in the manufacturing sector, Six Sigma has evolved into a comprehensive approach applicable across various industries, including healthcare, finance, and technology.

This article will delve into the basics of Six Sigma, including its principles, methodologies, and practical applications, offering a thorough grounding in this vital discipline.

At its core, Six Sigma aims to improve quality management by systematically identifying and eliminating defects in processes, thus ensuring that products and services meet customer expectations.

Six Sigma is not just a set of tools; it represents a philosophy and culture of continuous improvement aimed at reducing process variation and enhancing quality.

Developed by Motorola in the 1980s, the term “Six Sigma” refers to the statistical concept that aims to limit defects to fewer than 3.4 per million opportunities. This remarkable goal reflects a commitment to excellence that organizations strive to achieve.

Moreover, Six Sigma emphasizes the importance of customer satisfaction. By understanding and addressing customer needs, organizations can tailor their processes and outputs to align closely with expectations.

The Six Sigma methodology is structured around systematic frameworks that guide organizations in their quest for quality improvement. The most widely recognized frameworks within Six Sigma are DMAIC and DMADV, each serving distinct purposes depending on the nature of the project.

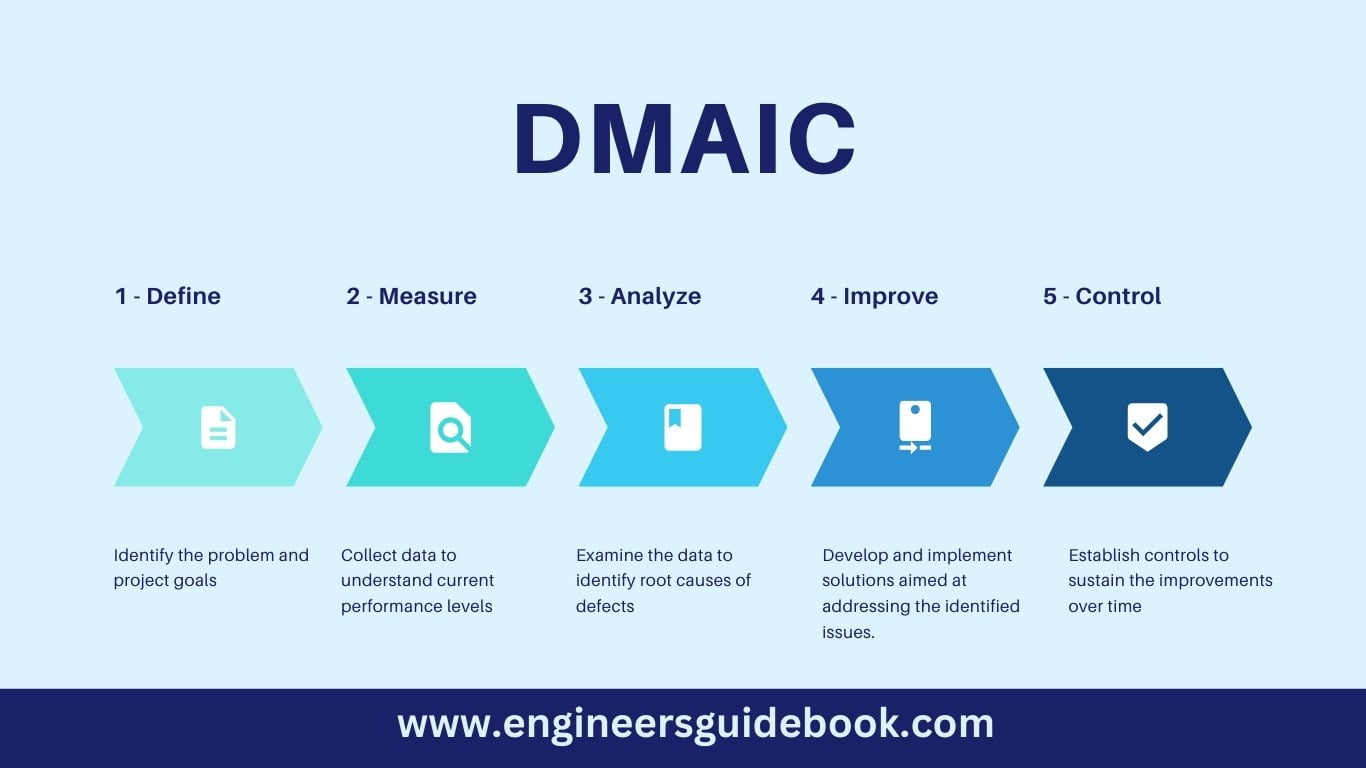

DMAIC stands for Define, Measure, Analyze, Improve, and Control. This framework is primarily used for existing processes that need enhancement. The steps are as follows:

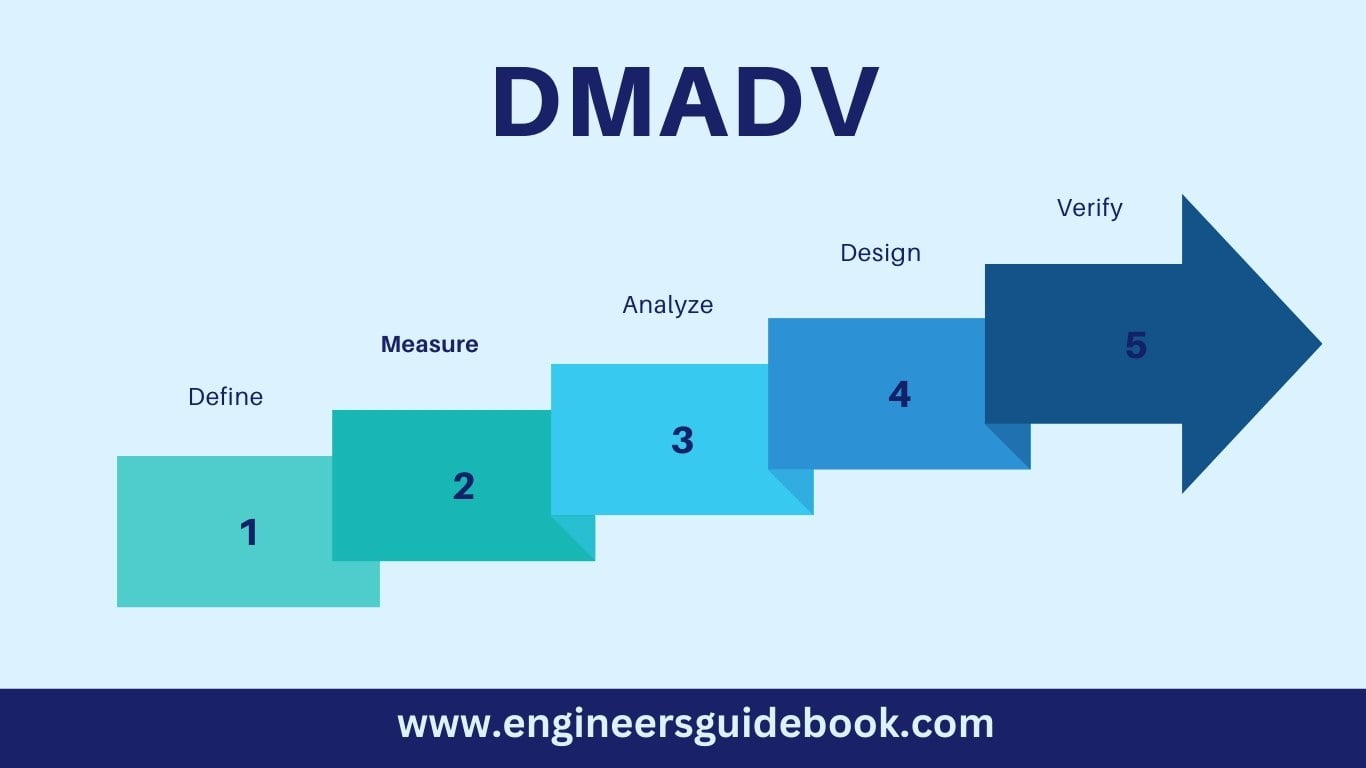

DMADV (Define, Measure, Analyze, Design, Verify) is utilized for new processes or products. This framework focuses on designing quality into the process from the outset:

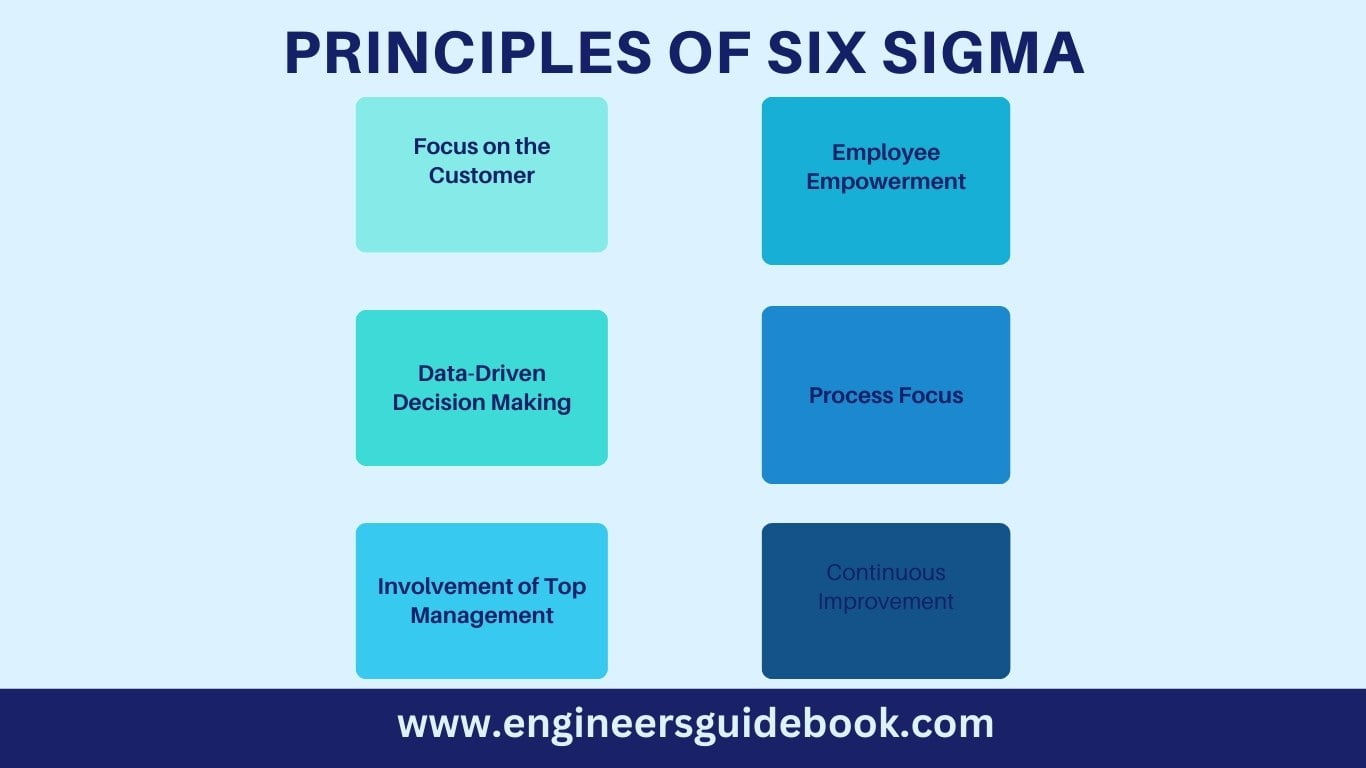

The principles of Six Sigma are the guiding philosophies that underpin the methodology, ensuring that organizations effectively enhance quality and achieve their goals.

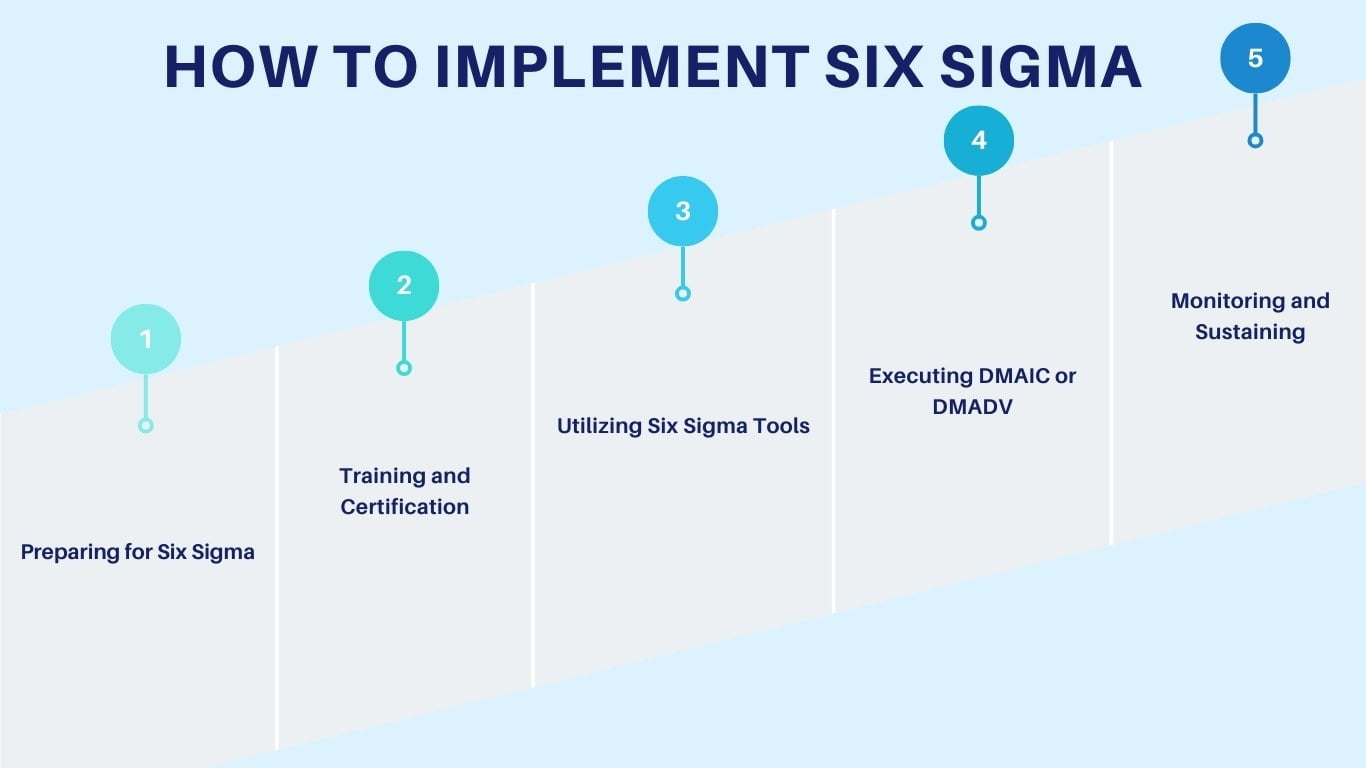

Here’s a step-by-step guide to help engineering students and professionals navigate the implementation of Six Sigma effectively.

Before diving into Six Sigma projects, it’s essential to lay a solid foundation. Begin by identifying key projects that could benefit from Six Sigma methodologies.

This involves assessing current processes and pinpointing areas with high defect rates or inefficiencies. Once potential projects are identified, establish a dedicated Six Sigma team composed of individuals with diverse skills and insights.

Training is critical to the successful implementation of Six Sigma. Various Six Sigma certifications include White, Yellow, Green, Black, and Master Black belts, each representing different proficiency levels. Engineering students should consider pursuing these certifications to gain a deeper understanding of Six Sigma principles and tools.

Organizations often provide training programs tailored to their specific needs, ensuring that team members are equipped to tackle quality challenges.

A variety of tools are available to support Six Sigma projects. Statistical analysis tools, such as control charts, process maps, and Pareto charts, help teams visualize data and identify trends. Quality control techniques, including failure mode and effects analysis (FMEA) and root cause analysis, enable teams to diagnose issues effectively.

Additionally, process mapping is a valuable tool for visualizing workflows, allowing teams to identify bottlenecks and inefficiencies.

Depending on the nature of the project—whether improving an existing process or designing a new one—teams should apply the DMAIC or DMADV framework.

This structured approach ensures that all aspects of the process are addressed methodically, leading to sustainable improvements.

Once improvements have been implemented, it’s crucial to monitor the results continuously. Establish control measures to ensure that the changes are effective and that the process remains stable.

Regularly review performance metrics and solicit feedback from team members to identify any areas that may require further refinement.

The implementation of Six Sigma offers an array of benefits that can significantly enhance organizational performance and customer satisfaction.

One of the primary goals of Six Sigma is to meet and exceed customer expectations. By systematically identifying and eliminating defects in processes, organizations can deliver higher-quality products and services.

Six Sigma methodologies focus on process optimization, which leads to increased efficiency. By identifying and eliminating waste, organizations can streamline their operations, reduce lead times, and enhance productivity.

The financial implications of implementing Six Sigma can be substantial. By reducing defects and improving process efficiency, organizations can lower costs associated with rework, waste, and customer complaints.

The potential for significant cost savings makes Six Sigma an attractive investment for businesses of all sizes.

Involving employees in Six Sigma initiatives empowers them to contribute to the improvement process. When team members feel valued and engaged, morale increases.

Originally developed within the manufacturing sector, Six Sigma remains a cornerstone of quality management in this industry.

By utilizing DMAIC methodologies, manufacturers can reduce defects, optimize production processes, and enhance product quality.

Techniques such as statistical process control (SPC) are commonly employed to monitor and control manufacturing processes, ensuring they remain within specified limits.

The healthcare industry has increasingly adopted Six Sigma to improve patient care and operational efficiency.

Hospitals and clinics utilize Six Sigma to streamline processes, reduce wait times, and enhance patient outcomes.

For instance, by analyzing patient flow and identifying bottlenecks, healthcare providers can improve service delivery, ultimately leading to higher patient satisfaction and better health outcomes.

In the financial sector, Six Sigma is applied to enhance operational efficiency and reduce errors. For example, banks and financial institutions use Six Sigma methodologies to streamline processes such as loan approvals and account management.

By minimizing errors and improving turnaround times, organizations can enhance customer service and maintain a competitive edge.

Service-oriented businesses, including hospitality and retail, leverage Six Sigma principles to improve customer experiences.

By analyzing service processes and identifying areas for improvement, these organizations can enhance service quality, reduce customer complaints, and foster loyalty.

The IT sector employs Six Sigma to improve software development processes and enhance project management.

By utilizing tools such as root cause analysis and process mapping, IT professionals can identify inefficiencies in software development lifecycles, leading to faster delivery times and higher-quality products.

While Six Sigma offers numerous benefits, implementing this methodology is not without its challenges.

One of the most significant challenges in implementing Six Sigma is overcoming resistance to change. Employees may be hesitant to adopt new processes or methodologies, particularly if they are comfortable with existing practices.

To combat this resistance, organizations must foster a culture of open communication, emphasizing the benefits of Six Sigma and involving employees in the change process. Training and support can also help ease the transition.

A successful Six Sigma implementation relies on the knowledge and skills of the team members involved.

If employees lack sufficient training or understanding of Six Sigma principles, the program may falter.

Organizations must invest in comprehensive training programs to ensure that team members are well-equipped to apply Six Sigma methodologies effectively.

For Six Sigma initiatives to succeed, they must align with the overall goals and objectives of the organization.

If projects are pursued without a clear connection to strategic priorities, they risk becoming disconnected from the organization’s mission. Engaging top management in the planning process can help ensure that Six Sigma efforts are aligned with broader business objectives.

Six Sigma relies heavily on data-driven decision-making. If organizations do not have robust data collection and analysis processes in place, they may struggle to identify root causes of defects or inefficiencies.

Investing in data management systems and training employees to utilize statistical analysis tools can enhance the effectiveness of Six Sigma projects.

Organizations may be tempted to seek quick wins when implementing Six Sigma, overlooking the long-term commitment required for sustained improvement.

It’s essential to view Six Sigma as an ongoing journey rather than a one-time project. Encouraging a continuous improvement mindset among employees will help maintain momentum and drive lasting change.

As the birthplace of Six Sigma, Motorola’s implementation of this methodology serves as a benchmark for success. In the 1980s, the company faced significant quality issues that impacted customer satisfaction and market share.

By adopting Six Sigma principles, Motorola focused on reducing defects and enhancing product quality.

The result was a remarkable improvement in manufacturing processes, leading to a 90% reduction in defects over a five-year period.

Under the leadership of former CEO Jack Welch, GE adopted Six Sigma in the 1990s to drive operational excellence across its diverse portfolio of businesses.

By emphasizing a culture of quality and continuous improvement, GE achieved significant cost savings, estimated at $12 billion over five years. The company’s commitment to Six Sigma not only improved internal processes but also enhanced customer satisfaction, solidifying GE’s reputation as a leader in innovation and quality.

The financial institution adopted Six Sigma to enhance operational efficiency and customer service.

By analyzing its loan approval processes, Bank of America identified areas for improvement, leading to reduced turnaround times and enhanced customer experiences.

The successful implementation of Six Sigma principles has allowed the bank to maintain a competitive advantage in the financial services sector.

In conclusion, Six Sigma represents a powerful methodology that enables organizations to enhance quality management and drive continuous improvement across various sectors.

By understanding the basics of Six Sigma, including its principles, methodologies, and real-world applications, engineering students and professionals can equip themselves with the tools needed to make meaningful contributions to their organizations.

By implementing structured frameworks like DMAIC and DMADV, organizations can systematically identify and eliminate defects, streamline processes, and ultimately achieve operational excellence.

By mastering Six Sigma principles and methodologies, engineering students can position themselves as valuable assets in their fields, ready to tackle quality challenges and contribute to the success of their organizations.

The basic principles of Six Sigma include a focus on the customer, data-driven decision-making, involvement of top management, employee empowerment, process focus, and a commitment to continuous improvement.

The primary goal of Six Sigma is to reduce defects and improve quality in processes, ultimately enhancing customer satisfaction and operational efficiency.

To start with Six Sigma, consider pursuing training and certification programs, identifying key projects within your organization, and forming a dedicated Six Sigma team to lead initiatives.

Six Sigma tools include statistical analysis tools (e.g., control charts, Pareto charts), quality control techniques (e.g., root cause analysis, failure mode effects analysis), and process mapping tools.

Yes, many resources, including online courses, books, and certification programs, are available for individuals interested in learning Six Sigma independently.

The term “Six Sigma” refers to the statistical concept of achieving fewer than 3.4 defects per million opportunities, representing a high level of quality.

Six Sigma and TQM both focus on quality improvement, but Six Sigma emphasizes a data-driven, structured approach to problem-solving, while TQM encompasses a broader philosophy of continuous improvement involving all employees.

Lean focuses on waste reduction and process flow improvement, while Six Sigma emphasizes reducing process variation and defects through statistical analysis. Together, Lean Six Sigma combines these approaches for comprehensive process improvement.

Six Sigma certification involves training and testing on Six Sigma methodologies and tools. Certifications are offered in levels, known as belts, including Yellow Belt, Green Belt, Black Belt, and Master Black Belt, each representing increasing expertise.

Six Sigma belts represent different levels of expertise and responsibility. Yellow Belts support projects, Green Belts lead smaller projects, Black Belts manage complex projects, and Master Black Belts provide strategic direction and mentorship.

Yes, Six Sigma can be tailored for small businesses by focusing on key processes and using simplified tools. It helps small businesses improve efficiency, reduce costs, and enhance customer satisfaction.

A project charter is a formal document that defines a Six Sigma project’s objectives, scope, and participants. It serves as a roadmap, providing direction and ensuring alignment with organizational goals.

Hasan, an Industrial Engineer with a PhD from Georgia Tech, specializes in operational efficiency and lean manufacturing. His research on optimizing production workflows has significantly impacted the manufacturing industry.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.