August 5, 2024 By Hasan 12 minutes

5S is a concept, which is all about making workplaces more efficient, organized, and fun. Imagine walking into a room where everything is messy, with papers everywhere, tools scattered around, and no clear path to move through.

Now, imagine a room where everything is neatly arranged, you know exactly where to find what you need, and there’s plenty of space to work comfortably. That second room sounds a lot better, right? That’s the magic of 5S. In this article we will discuss in detail about the strategies on how to implement 5s in an organization.

5S is a system that helps us keep things organized, clean, and ready for action. It originally comes from Japan and is often used in factories, offices, and even schools to make workspaces super efficient. The best part? You can use it anywhere!

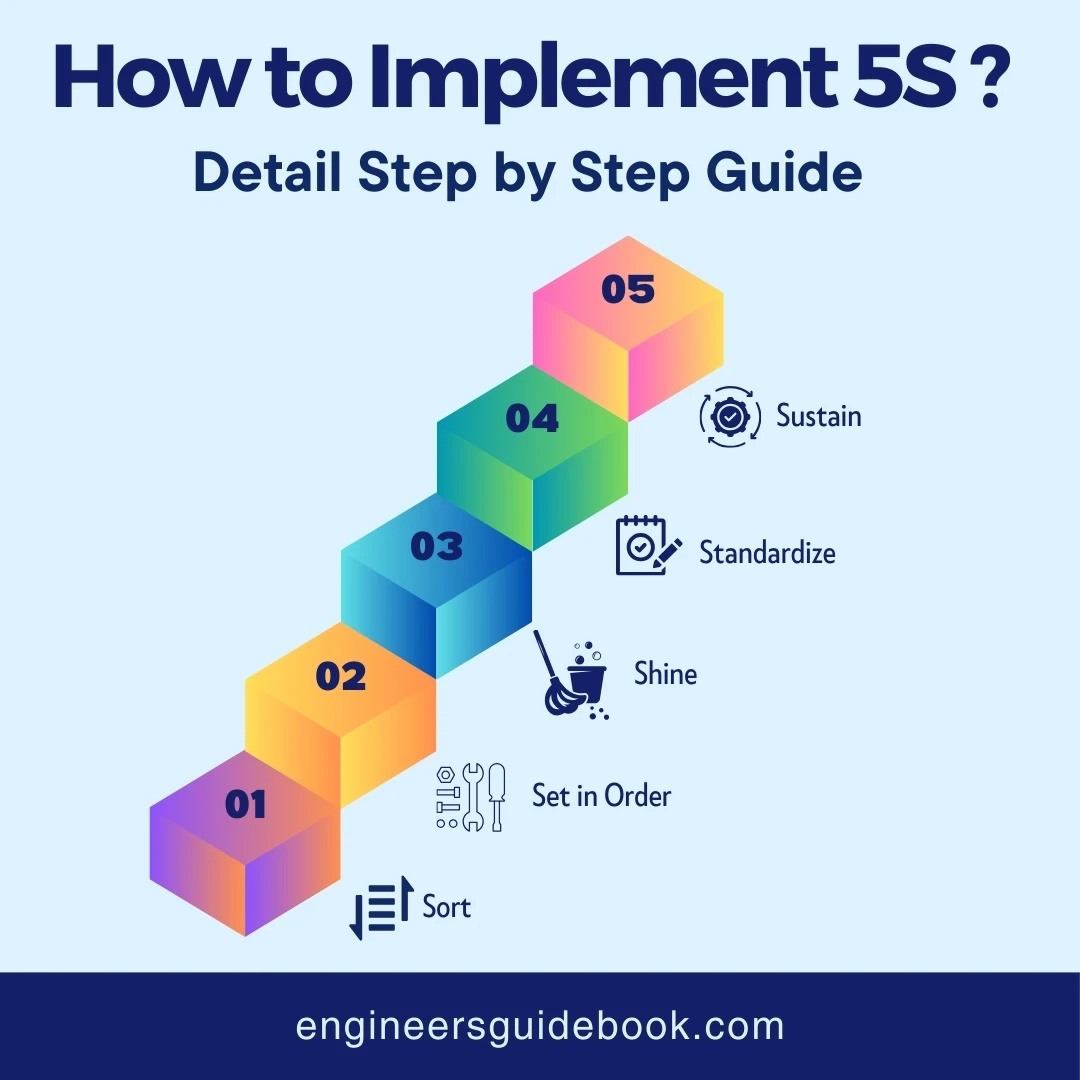

The name 5S comes from five Japanese words that all start with the letter “S”: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. These words translate to Sort, Set in Order, Shine, Standardize, and Sustain in English. Each step is like a building block that helps create a perfect work environment. Let’s break them down:

Read More About 5s: What is 5S methodology? The ultimate 5s guide

This step is all about getting rid of things you don’t need. Imagine you’re cleaning your room and finding old toys or clothes you never use. You decide to keep only what’s important. That’s sorting!

The second step of the 5S methodology, Set in Order, involves organizing and arranging items in a systematic way so that they are easy to find, use, and return to their designated places.

Keeping everything clean and shiny is what this step is all about. You clean your workspace regularly, just like you tidy up your room every week.

Once everything is organized and clean, you want to keep it that way. Standardizing means creating routines or habits that help you maintain the neatness you’ve achieved.

The last step is about making 5S a part of your daily life. It’s like brushing your teeth every day – you do it without thinking because it’s a good habit.

5S helps businesses and workplaces avoid chaos and confusion, making it easier for everyone to do their jobs efficiently.

Efficiency: When everything is in its place, you spend less time looking for things and more time getting work done.

Safety: A clean and organized workplace is safer because there’s less clutter to trip over or cause accidents.

Productivity: With 5S, workers are happier and more motivated because they can work in a pleasant environment.

Quality: Products and services are often better when created in an organized space, leading to satisfied customers.

Teamwork: 5S encourages everyone to work together to maintain the space, fostering a sense of community and collaboration.

The first step in the 5S process is Sort, which is all about identifying what you need and what you don’t.

The goal of sorting is to go through everything and keep only what’s necessary. This way, you make space for the things that really matter.

Sorting is like clearing the path to success. Here’s why it’s essential:

Reduces Clutter: By removing unnecessary items, you create a more organized and efficient space.

Increases Focus: With fewer distractions, you can concentrate better on your tasks.

Saves Time: You’ll spend less time searching for things and more time getting things done.

Improves Safety: Removing unneeded items can reduce the risk of accidents and make the workspace safer.

Sorting might sound simple, but doing it effectively requires some planning. Here’s a step-by-step guide to help you sort like a pro:

Identify the Area: Choose a specific area to sort, like your desk, a cabinet, or even a digital space like your computer files. Focusing on one area at a time makes the process more manageable.

Gather Everything: Pull out all the items from the area you’ve chosen. This gives you a clear view of everything you have and makes it easier to decide what to keep and what to let go.

Ask Key Questions: As you go through each item, ask yourself questions like:

Decide What to Keep: Based on your answers, decide which items are essential. These are the things you’ll keep. Be honest with yourself about what you really need.

Remove Unnecessary Items: Anything that doesn’t make the cut should be removed. This can mean recycling old papers, donating items in good condition, or discarding broken things.

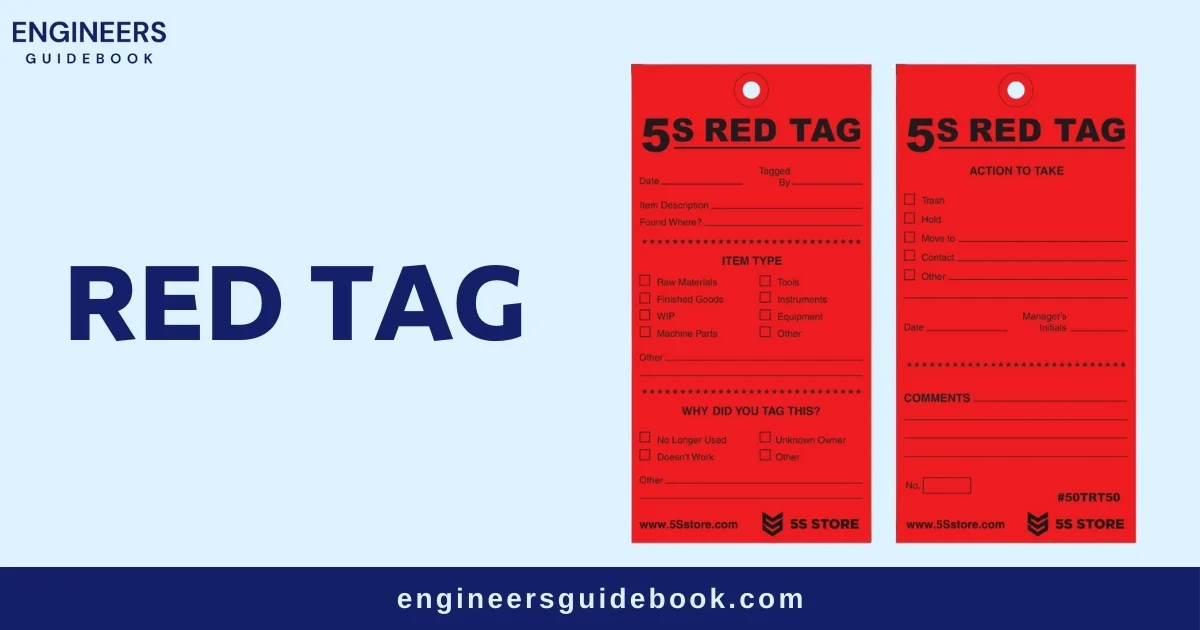

One popular method used in sorting is the Red Tag Method. This is especially useful in larger spaces like offices or classrooms. Here’s how it works:

Red Tagging: Place a red tag on items that you’re unsure about or don’t use often. This can be a piece of red paper or a sticker. Write the date on the tag to track how long the item has been unused.

Let’s look at how sorting might work in a school art room. Imagine there are bins filled with old paints, brushes, papers, and other materials. Here’s how sorting could help:

Step 1: Pull out all the materials and lay them out on a table.

Step 2: Sort the items into categories like paints, brushes, and papers.

Step 3: Examine each category. Are the paints still usable, or have they dried out? Are the brushes in good condition, or are some broken?

Step 4: Keep only the materials that are in good shape and regularly used for projects.

Step 5: Donate or recycle the materials that aren’t needed anymore.

Now that we’ve sorted through everything and cleared out the clutter, it’s time to move on to the next exciting step: Set in Order.

This step is all about arranging the things you need in a neat and organized way, so you can find them quickly and easily whenever you need them.

Setting things in order is like putting the pieces of a puzzle together. It helps ensure everything is in the right place and ready to use. Here’s why this step is crucial:

Boosts Efficiency: When everything has a designated spot, you waste less time searching for what you need.

Reduces Stress: An organized space feels calmer and less chaotic, making it easier to focus on your tasks.

Improves Workflow: A well-organized area ensures a smooth flow of work, allowing tasks to be completed faster.

Enhances Safety: Proper arrangement of items reduces the chances of accidents or mishaps in the workspace.

Organizing your space might sound like a big task, but it can be a fun and rewarding process. Here’s a step-by-step guide to help you set things in order:

Create Zones: Start by dividing your workspace into zones based on the type of work you do. For example, in a classroom, you might have zones for reading, art, and science projects.

Assign Places: Give each item a specific home. Decide where each tool, book, or supply belongs, and make sure it always goes back to that spot after use.

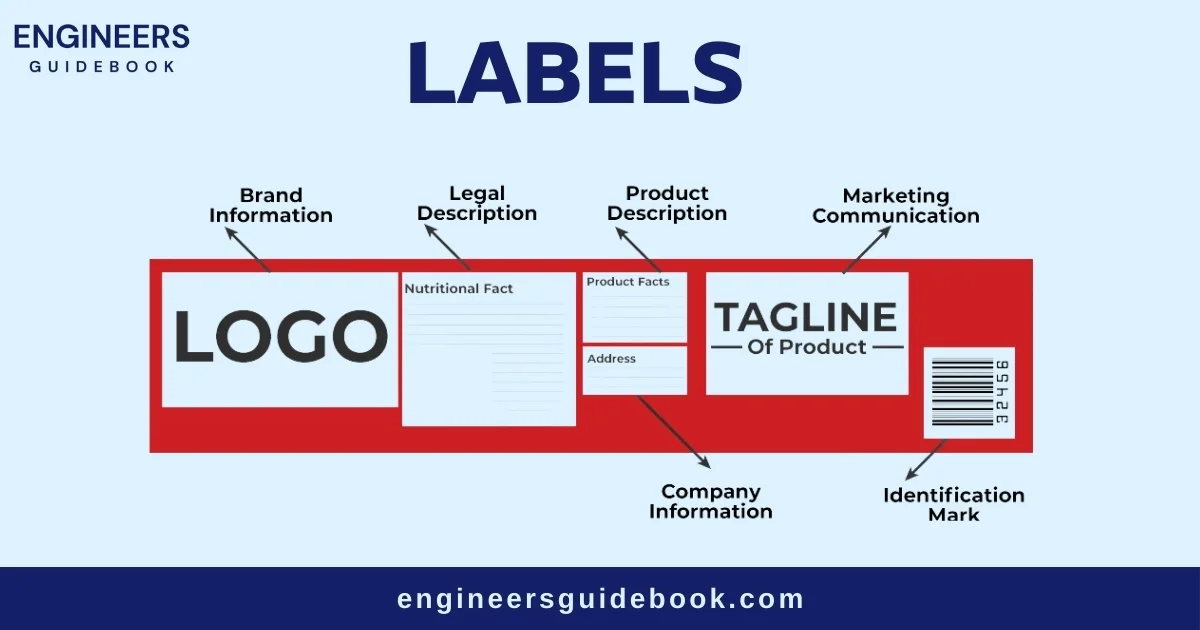

Use Labels: Labels are your best friends when it comes to organization. Clearly label shelves, drawers, and containers so you and others know where everything belongs. This can be especially helpful in shared spaces.

Organize Vertically: Use wall space wisely by adding shelves or pegboards to hang tools and supplies. Vertical organization helps save floor space and keeps things within easy reach.

One of the key aspects of setting things in order is visual management. This involves using visual cues to help people understand how things should be arranged. Here are some ways to incorporate visual management:

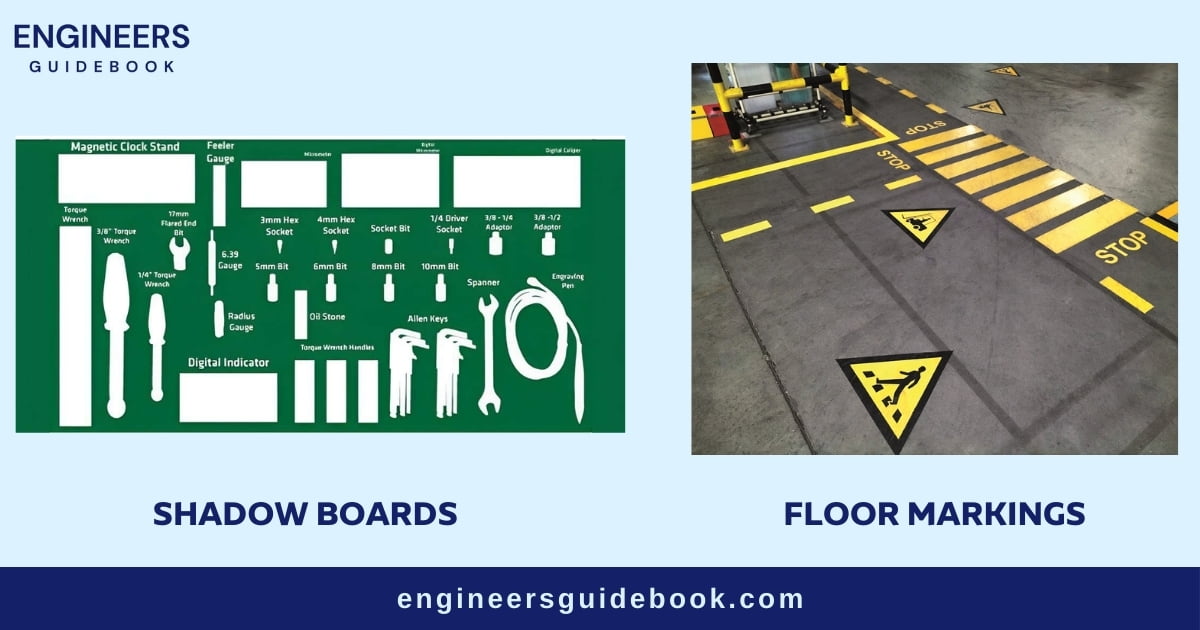

Shadow Boards: Use shadow boards to outline where tools should be placed. This makes it obvious when something is missing or out of place.

Floor Markings: In larger spaces like factories or workshops, use floor markings to define work areas and pathways. This keeps everything organized and improves safety.

Signage: Place signs and posters with instructions or reminders around your workspace. This helps keep everyone informed and on the same page.

Imagine you’re in a school science lab filled with beakers, test tubes, and various chemicals. Here’s how setting in order might work:

The third step of 5S: Shine! This step is all about keeping your workspace clean, tidy, and shining like new.

Imagine you’re walking into a room where everything sparkles, and there’s not a speck of dust to be found. That’s the kind of environment we’re aiming to create with this step.

Keeping your workspace clean isn’t just about making it look nice. It has many benefits that can improve your work and your mood:

Enhances Appearance: A clean and shiny space looks welcoming and professional, boosting your confidence and enthusiasm for work.

Prevents Damage: Regular cleaning helps maintain equipment and tools, preventing wear and tear and extending their lifespan.

Improves Health: A clean environment reduces the spread of germs and allergens, keeping you healthier and more productive.

Increases Safety: A tidy space minimizes the risk of accidents, like slipping on spills or tripping over debris.

Cleaning your workspace might seem like a never-ending task, but with the right approach, it can become an easy and enjoyable routine. Here’s how to shine effectively:

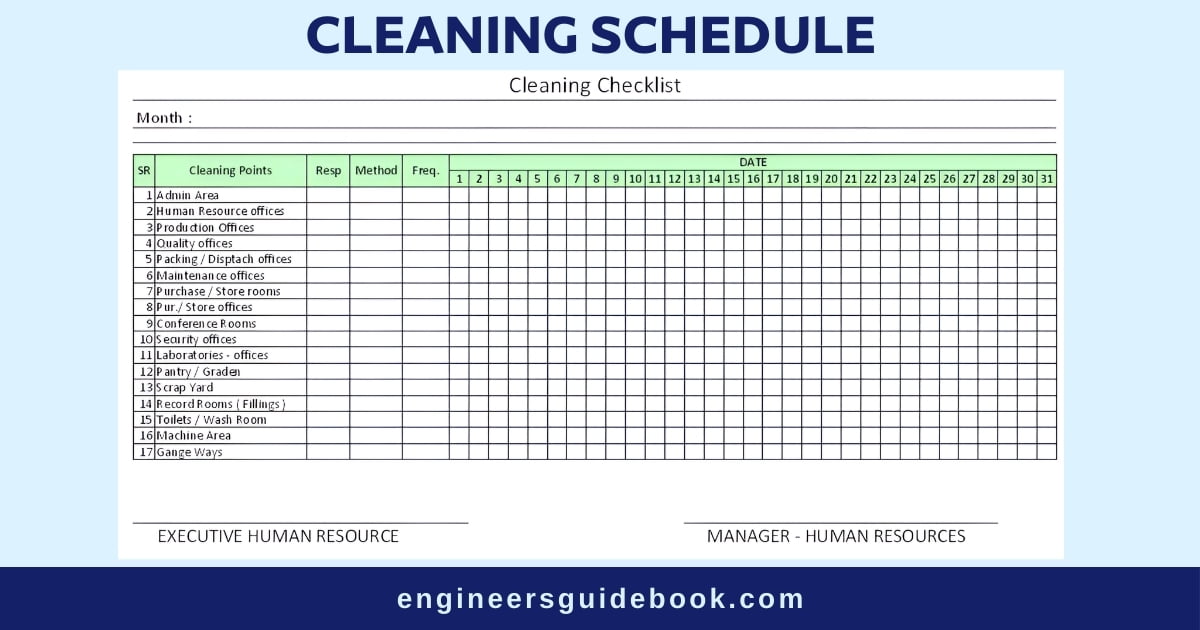

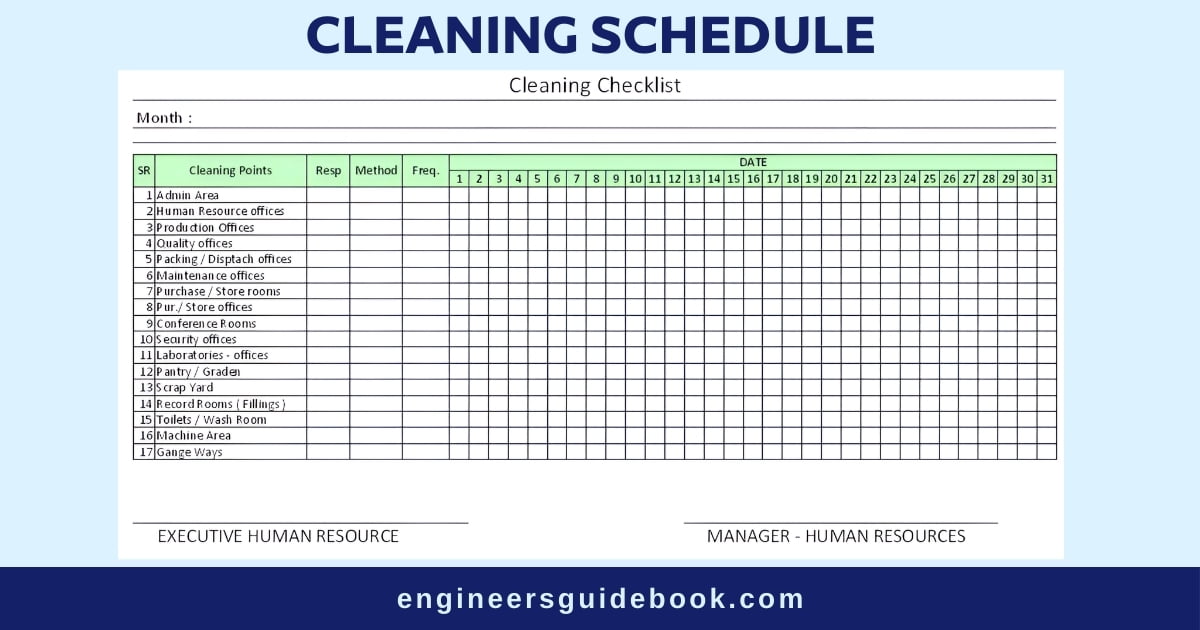

Create a Cleaning Schedule: Decide how often each area needs to be cleaned. Some spaces might need daily attention, while others can be cleaned weekly or monthly.

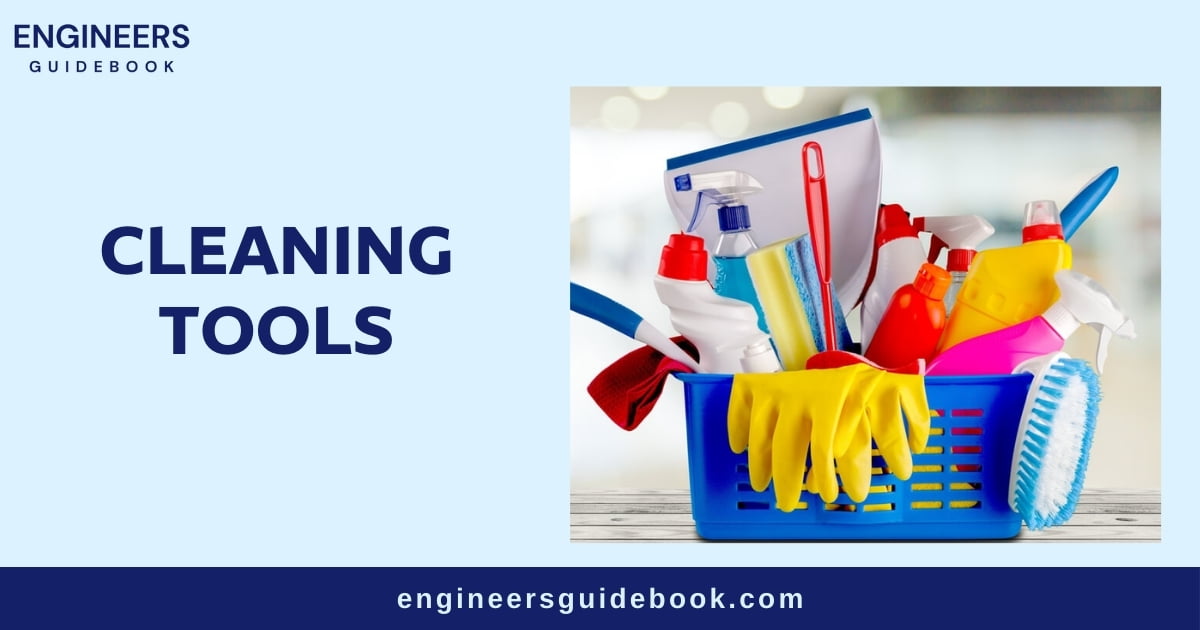

Gather Cleaning Supplies: Keep a stock of cleaning supplies, like cloths, disinfectants, and brushes, in an easily accessible spot. This way, you’re always prepared to tackle any mess.

Assign Responsibilities: In shared spaces, assign cleaning tasks to different people. This ensures everyone contributes to keeping the area clean and takes ownership of their surroundings.

Clean as You Go: Make cleaning a habit by tidying up as you work. For example, put away tools after using them, wipe up spills immediately, and throw away trash promptly.

Let’s see how shining might work in a classroom setting. Here’s how you can keep the room bright and clean:

This step is about creating routines and standards that ensure the organization and cleanliness we’ve achieved continue in the long run. Think of it as setting up habits that make staying organized second nature.

Standardizing helps maintain consistency and makes it easier to keep things in order. Here’s why it’s a crucial part of the 5S process:

Ensures Consistency: The workspace remains organized and efficient when everyone follows the same procedures.

Reduces Mistakes: Clear standards help prevent errors by providing clear guidelines for how things should be done.

Saves Time: Standard procedures eliminate guesswork, making tasks quicker and more straightforward.

Facilitates Training: New team members can quickly learn the ropes when there are clear standards to follow.

Standardizing might sound complicated, but it’s about creating simple and clear guidelines for everyone to follow. Here’s how to standardize effectively:

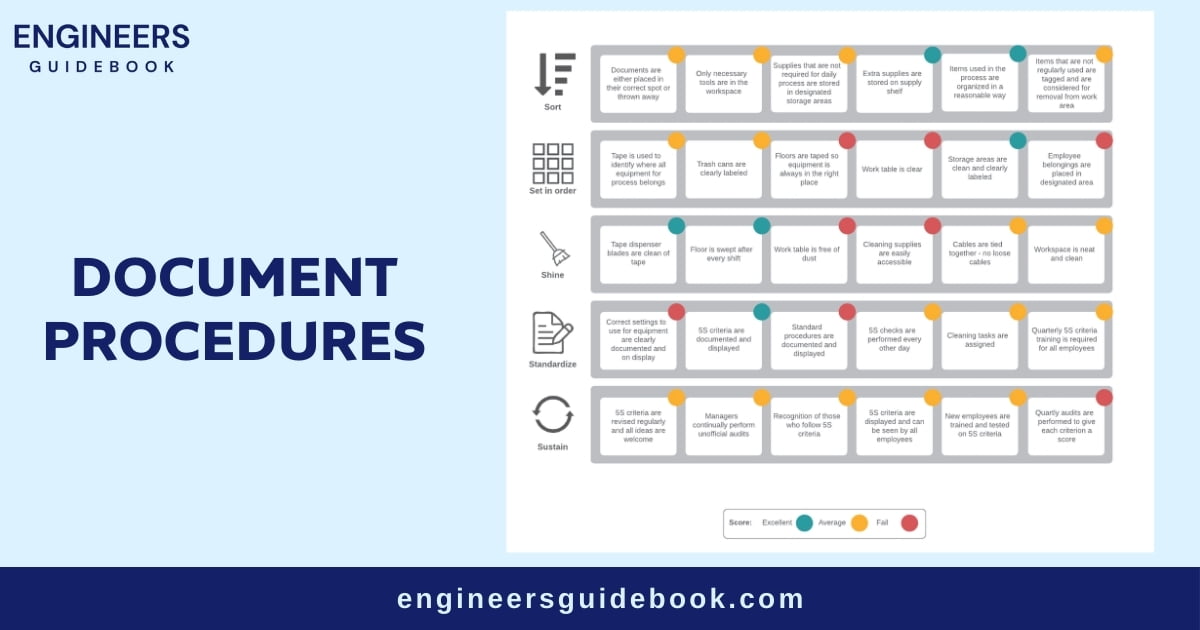

Document Procedures: Write down the steps for organizing, cleaning, and maintaining each area. Use simple language and include visuals if possible.

Create Checklists: Develop checklists for tasks that need to be completed regularly, like daily cleaning routines or weekly inspections.

Use Visual Aids: Incorporate visual aids like charts, diagrams, and signs to reinforce standards and remind everyone of their responsibilities.

Set Up Routines: Establish routines for when tasks should be done, such as cleaning at the end of the day or restocking supplies every Monday.

Involve the Team: Encourage everyone to contribute to creating and maintaining standards. When people are involved in the process, they’re more likely to follow through.

Let’s see how standardizing might work in a school library. Here’s how you can set up standards to keep the library organized and welcoming:

Step 1: Document procedures for shelving books, checking out materials, and returning items to their proper places.

Step 2: Create checklists for daily tasks, like tidying up reading areas, restocking returned books, and updating the catalog.

Step 3: Use signs and labels to indicate where different genres and materials belong.

Step 4: Establish routines for regular inventory checks and book repairs.

Step 5: Involve students and staff in maintaining library standards by assigning roles and responsibilities.

We’ve reached the final step in the 5S process: Sustain. This step is all about making sure the habits and standards we’ve put in place become part of our everyday routine. It’s like turning all the steps we’ve learned into a lifestyle that helps keep everything organized and efficient.

Sustaining is the key to making sure that the benefits of 5S last over time. Without this step, it’s easy to slip back into old habits. Here’s why sustaining is crucial:

Maintains Gains: Ensures that the improvements made during the first four steps continue to deliver results.

Builds Habits: Turns organization and cleanliness into habits that are automatic and easy to maintain.

Fosters Discipline: Encourages a culture of discipline and responsibility, where everyone takes ownership of their space.

Supports Continuous Improvement: Provides a foundation for ongoing improvements and adaptations as needs change.

Sustaining might sound challenging, but with a few strategies, it can become a natural part of daily life. Here’s how to sustain effectively:

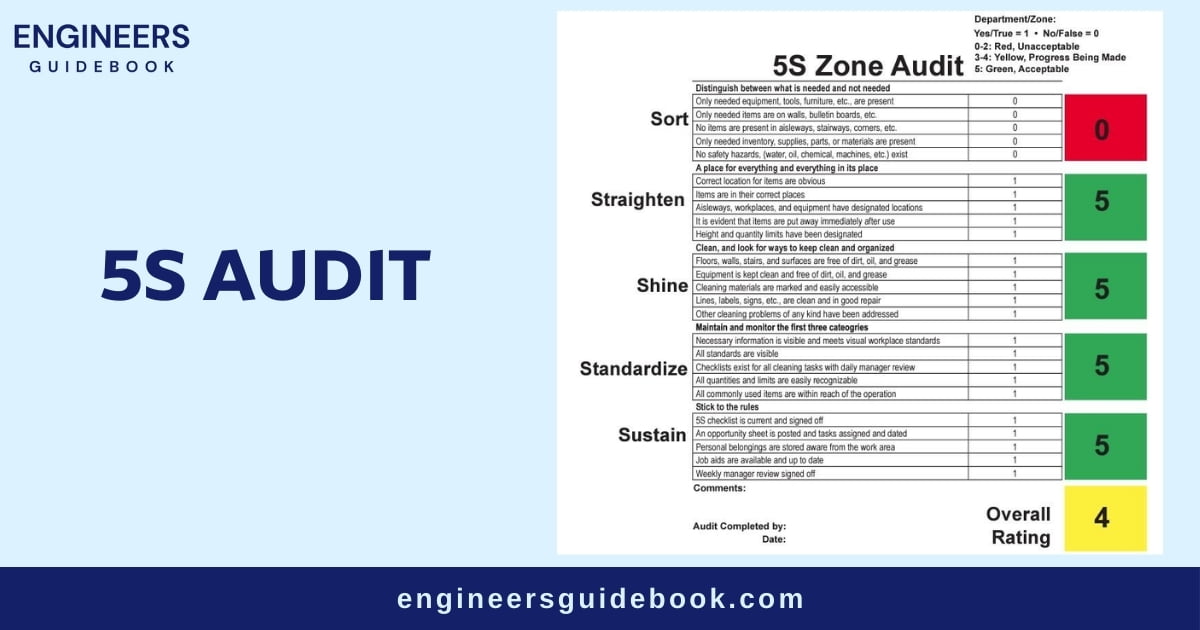

Regular Audits: Conduct regular audits or inspections to ensure that standards are being followed and to identify areas for improvement.

Continuous Training: Provide ongoing training and education to reinforce the importance of 5S and update everyone on any changes or improvements.

Encourage Involvement: Keep everyone engaged by encouraging them to suggest improvements or report issues. This involvement fosters a sense of ownership and pride.

3. Celebrate Success: Recognize and reward efforts to maintain 5S standards. Celebrating successes keeps everyone motivated and committed.

4. Adapt and Improve: Be open to change and improvement. As you sustain 5S, look for new ways to enhance efficiency and organization.

Let’s explore how sustaining might work in a school cafeteria setting. Here’s how you can keep the cafeteria running smoothly and efficiently:

Implementing the 5S methodology can significantly improve organization and efficiency, but like any new system, it can also present its own set of challenges.

Understanding these challenges and knowing how to overcome them is crucial for successful 5S implementation.

Challenge: People are often resistant to change, especially if they are used to doing things a certain way. Implementing 5S means adopting new habits and routines, which can be met with skepticism or reluctance.

Solution:

Challenge: Without strong support from management, 5S initiatives can struggle to gain traction and sustain momentum. Management plays a crucial role in setting the tone and providing resources.

Solution:

Challenge: After the initial excitement of implementing 5S, it’s easy for enthusiasm to wane, and old habits to creep back in. Maintaining momentum is essential for long-term success.

Solution:

To ensure that 5S is delivering the desired results, it’s important to measure its impact. This involves tracking key performance indicators (KPIs) and using feedback to make continuous improvements.

Here are some KPIs to consider when evaluating the success of 5S:

Efficiency Improvements: Track metrics such as reduced time to complete tasks, decreased search times for tools and materials, and faster production cycles.

Safety Enhancements: Monitor the number of workplace accidents, near misses, and safety-related incidents to see if 5S has improved safety.

Quality Improvements: Measure the quality of products or services by tracking defect rates, customer complaints, and rework.

Employee Engagement: Assess employee satisfaction and engagement through surveys and feedback. A more organized and efficient workplace can lead to higher morale and job satisfaction.

Waste Reduction: Track the amount of waste generated and identify reductions in material and resource waste.

Whether you’re organizing a classroom, a workspace, or even your digital life, these practical tips and tricks can help you apply the 5S methodology effectively and achieve the best results.

Tip: Begin with a small area to implement 5S, such as a single desk or a drawer, before moving on to larger spaces.

Why It Works: Starting small makes the process more manageable and allows you to build momentum. It helps you develop a deeper understanding of the 5S steps and gain confidence before tackling bigger projects.

Tip: Involve everyone who uses the space in the 5S process. Encourage collaboration and input from team members, students, or family members.

Why It Works: When everyone participates, there’s a greater sense of ownership and responsibility. It fosters teamwork and ensures everyone is on the same page about maintaining the space.

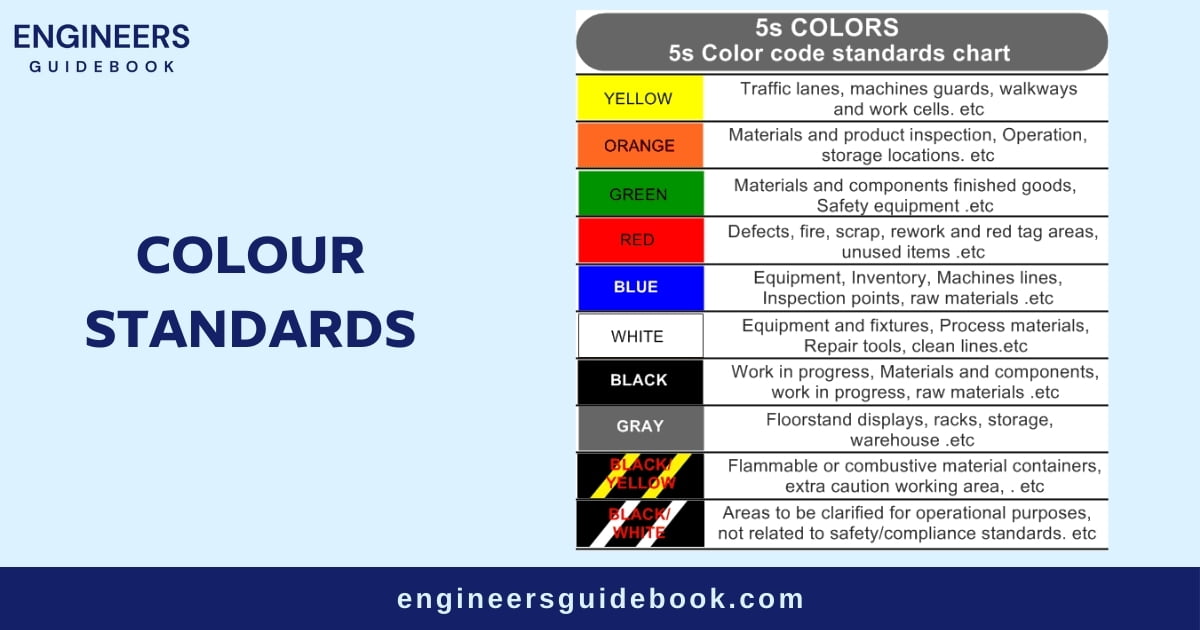

Tip: Incorporate visual management tools like color-coded labels, charts, and diagrams to make the organization intuitive and easy to understand.

Why It Works: Visual cues clearly guide where things belong and how they should be arranged. They make it easy to spot items that are out of place and ensure consistency in the organization.

Implementing the 5S methodology is a powerful way to transform any environment into an organized, efficient, and productive space.

By following the steps of Sort, Set in Order, Shine, Standardize, and Sustain, you can create a workspace that supports success and well-being for everyone involved.

5S is not just about tidying up; it’s about fostering a culture of continuous improvement, where everyone takes responsibility for maintaining standards and finding ways to improve processes.

Whether you’re applying 5S in a manufacturing plant, an office, a school, or even at home, the benefits are clear: increased efficiency, enhanced safety, improved quality, and greater employee engagement.

As you embark on your 5S journey, remember that it’s an ongoing process that requires commitment and collaboration.

The primary goal of 5S is to create an organized, efficient, and safe work environment by following the five principles: Sort, Set in Order, Shine, Standardize, and Sustain.

By implementing these steps, 5S aims to improve productivity, reduce waste, and enhance overall work quality.

Absolutely! While 5S originated in manufacturing, it can be applied in various settings, including offices, schools, hospitals, and homes.

The principles of 5S are versatile and can help organize and improve efficiency in any environment.

The time required to implement 5S varies depending on the size and complexity of the area being organized. It can take anywhere from a few days to several weeks to complete the initial implementation.

However, maintaining 5S is an ongoing process that requires regular attention and commitment.

Common challenges in implementing 5S include resistance to change, lack of management support, and maintaining momentum. To overcome these challenges:

5S contributes to sustainability by promoting efficient use of resources and reducing waste. By organizing materials and optimizing processes, 5S helps minimize the environmental impact of operations. Additionally, 5S encourages recycling, responsible disposal of materials, and energy-efficient practices.

5S supports continuous improvement by fostering a culture of evaluation and enhancement.

By regularly reviewing and updating 5S practices, organizations can identify areas for improvement and implement innovative solutions.

This mindset of continuous improvement leads to ongoing growth and success.

Yes, 5S can be customized to meet the unique needs of different industries and environments.

While the core principles remain the same, organizations can adapt 5S practices to align with their specific goals, challenges, and workflows. This flexibility makes 5S applicable in diverse settings.

Leadership plays a crucial role in the success of 5S implementation. Influential leaders set the tone for the organization by modeling 5S principles and providing guidance and support.

They communicate the importance of 5S, allocate necessary resources, and encourage employee involvement and collaboration.

Successful 5S implementation can be found in various industries and settings. For example:

Hasan, an Industrial Engineer with a PhD from Georgia Tech, specializes in operational efficiency and lean manufacturing. His research on optimizing production workflows has significantly impacted the manufacturing industry.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.