June 27, 2024 By Muhammad Ali 7 minutes read

Lobe pumps play a crucial role in various industrial processes, including food and beverage production, pharmaceuticals, and manufacturing. Just like gear pumps, lobe pumps are rotating positive displacement pumps. They are designed to transfer liquids and semi-solid materials with high viscosity, such as slurries, pastes, and gels. Lobe pumps are commonly known as rotary lobe pumps or simply lobes.

Lobe pumps consist of two or more lobes that rotate inside a cavity. The rotation of the lobes creates a vacuum at the inlet side, allowing fluid to enter the pump. As the lobes continue to rotate, they displace the fluid towards the discharge side.

in this article, we have provided a comprehensive understanding of lobe pumps, including their history, structure, operation, and application advantages and disadvantages. It also includes information on maintenance and troubleshooting to ensure optimal performance and longevity of the pump.

A lobe pump is a type of positive displacement pump that uses rotating lobes to move fluid from one place to another. It consists of at least two cylindrical or oval-shaped rotary lobes that rotate inside a chamber, creating a continuous vacuum and pressure cycle.

The history of lobe pumps can be traced back to the 19th century when French engineer Henri Pitot invented the first piston pump. However, it was not until the late 20th century that lobe pumps gained widespread popularity.

In the early 1970s, advancements in materials and manufacturing techniques led to the development of lobe pumps with improved efficiency and durability. This made them suitable for a wide range of applications in various industries.

Today, lobe pumps are widely used in different sectors due to their versatility, reliability, and cost-effectiveness.

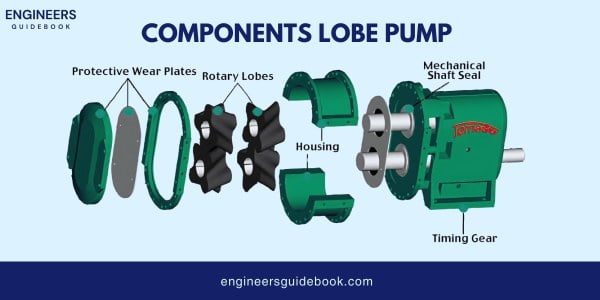

Some main components of centrifugal pump.

The basic function of the lobe is to create a chamber for fluid movement, ensuring efficient transfer. Lobes are generally made of stainless steel or other durable materials for longevity.

Casing surrounds the lobes and fluid chamber, providing a sealed environment. Casings are built to withstand pressure and resist corrosion, ensuring durability.

The shaft connects lobes with the main drive mechanism. Ensure synchronized movement of the rotors for smooth operation.

Seals are used to prevent fluid leakage and maintain efficiency. Mostly include mechanical seals and O-rings, chosen based on application needs.

Bearings hold the shafts in place and maintain rotor alignment. One of the major functions of bearings is reducing friction and wear, prolonging the pump’s life.

Timing gears ensure precise timing of the lobes, preventing them from touching. Maintain smooth operation and avoid damage to the rotors.

Lobe Rotation: Two or more lobes inside the pump casing rotate in opposite directions. These lobes are carefully designed so they don’t touch each other.

Liquid Entry: As the lobes rotate, spaces between them and the pump casing increase. This creates a vacuum that draws the liquid into the pump through the inlet.

Trapping the Liquid: The lobes continue to rotate, trapping the liquid in the cavities between the lobes and the casing.

Movement of Liquid: The trapped liquid moves along the inner walls of the pump casing. The lobes ensure a continuous flow, maintaining the pressure needed to move the liquid.

Discharge: As the lobes continue to rotate, the trapped liquid reaches the outlet. The decrease in space pushes the liquid out of the pump through the outlet.

Repeat Cycle: The cycle repeats as the lobes continue to turn, providing a steady, pulsing flow of liquid.

Single-lobe pumps have one lobe per rotor. They are best for low-pressure tasks where gentle fluid handling is not critical.

These pumps are used in applications that require simple fluid transfer, making them ideal for basic industrial processes.

Double-lobe pumps feature two lobes on each rotor, which enhances their efficiency. The additional lobe provides better fluid movement, making these pumps suitable for industries like food and beverages.

They handle liquids carefully, ensuring products like yogurt or sauces are transported without damage.

Triple-lobe pumps include three lobes per rotor, offering a higher capacity and smoother fluid flow. This design is perfect for thick or abrasive fluids, making them useful in the chemical and pharmaceutical industries.

They provide precise handling, which is essential for maintaining the quality of sensitive products.

Gentle Handling of Fluids: Lobe pumps ensure that delicate fluids are moved without damage, preserving product integrity.

High Efficiency and Low Shear: They operate with high efficiency, using low shear rates to maintain fluid quality, which is essential in many sensitive applications.

Self-Priming Capabilities: These pumps can create a vacuum to draw in fluids, making them effective in applications where priming is necessary.

Bi-Directional Flow and Reversible Operations: Lobe pumps allow for easy changes in the flow direction, offering flexibility in various operational settings.

Ability to Handle Solids: They are capable of moving thick and solid-containing fluids, making them versatile for many industrial processes.

In a yogurt production facility, lobe pumps were used to transport delicate yogurt mixtures without damaging the product.

The gentle handling and low shear provided by the lobe pumps maintained the yogurt’s texture and consistency, leading to improved product quality and customer satisfaction.

A pharmaceutical company needed a reliable pump for handling sensitive biologics. Lobe pumps were chosen due to their ability to operate with minimal shear and their hygienic design. This ensured the biologics remained effective, while the easy cleaning process met strict industry hygiene standards.

In a chemical plant, lobe pumps were used to transfer abrasive and corrosive chemicals. The robust design and ability to handle solids allowed for efficient processing of harsh fluids, reducing maintenance downtime and increasing overall productivity.

A cosmetics manufacturer utilized lobe pumps to transport creams and lotions. The pumps provided smooth, consistent flow, ensuring that the products maintained their desired texture. This contributed to higher product quality and reduced waste during production.

Recent advancements in lobe pump design have focused on improving efficiency and durability. Innovations include enhanced rotor profiles that reduce pulsation and increase flow rates.

Materials like advanced stainless-steel alloys and coatings have been introduced to improve corrosion resistance and longevity, making pumps more reliable in harsh environments.

Automation and smart technology have significantly impacted lobe pump operations. Many modern pumps now feature smart sensors that monitor performance in real time, providing data on flow rates, pressure, and temperature.

This allows for predictive maintenance, reducing downtime and extending the lifespan of the pumps. Automated control systems also enable precise adjustments, enhancing overall process efficiency and reducing manual intervention.

Lobe pumps are indispensable in many industries, offering gentle fluid handling, versatility, and high efficiency. Their ability to manage a wide range of viscosities and delicate products makes them ideal for applications in food, pharmaceuticals, and chemicals.

Recent technological advancements, including improved materials and smart automation, have enhanced their performance and reliability. As industries continue to evolve, lobe pumps will remain a vital tool, adapting to meet the growing demands of modern processing while ensuring product quality and operational efficiency.

A lobe pump is a type of positive displacement pump that uses rotating lobes to move fluids through the pump chamber.

Lobe pumps operate by the rotation of two or more lobes that do not touch each other. As they rotate, they create expanding cavities on the intake side and decreasing cavities on the discharge side, moving the fluid from the inlet to the outlet.

Lobe pumps are used in various industries including food and beverage, pharmaceuticals, biotechnology, and chemical processing due to their ability to handle viscous fluids and solids gently.

Lobe pumps are typically made from stainless steel for durability and sanitary purposes, but other materials like cast iron or plastic can be used depending on the application.

Regular maintenance involves inspecting and replacing worn parts, lubricating bearings, ensuring proper alignment, and cleaning to prevent contamination and buildup.

While both are positive displacement pumps, lobe pumps have lobes that do not touch and are better for handling solids and sensitive fluids, whereas gear pumps have meshing gears and are typically used for lower viscosity fluids.

Yes, lobe pumps are ideal for handling viscous fluids due to their robust design and ability to generate consistent flow rates regardless of fluid viscosity.

Common issues include cavitation, overheating, and leaks. Troubleshooting tips involve checking for blockages, ensuring proper alignment, and verifying fluid levels.

Troubleshooting involves checking for common issues such as blockages, leaks, worn lobes, improper alignment, and inadequate lubrication. Regular inspections and maintenance can help identify and resolve these issues.

Main components include the lobes, pump casing, shaft, bearings, seals, and the drive mechanism.

Yes, lobe pumps can handle solids or particulates without damage due to the non-contacting lobes and gentle pumping action.

Selection is based on factors such as fluid viscosity, flow rate, pressure requirements, temperature, and the presence of solids or abrasives in the fluid.

Common issues include wear and tear on lobes, leaks, blockages, and improper alignment. Regular maintenance and prompt replacement of worn parts can prevent these issues.

Muhammad Ali holds a PhD in Mechanical Engineering from MIT and is currently conducting groundbreaking research on sustainable energy systems. His innovative work in renewable energy integration has earned him numerous accolades in the engineering community.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.