1. Introduction

Electricity, while indispensable, can be hazardous if not managed properly. Circuit breakers serve as the frontline defense against electrical faults by interrupting current flow in abnormal conditions. Without these protective devices, short circuits, overloads, and faults could lead to catastrophic equipment failures, fires, or electrocutions. Their ability to detect and respond to irregularities in milliseconds ensures the safety of electrical infrastructure and human lives.

In this article we will discuss in detail about 12 types of circuit Breakers because Selecting an appropriate circuit breaker is crucial for ensuring system reliability and protection. Different applications demand varying specifications, such as breaking capacity, response time, and arc extinguishing mechanisms.

2. Basic Working Principle of Circuit Breakers

2.1 How Circuit Breakers Protect Electrical Circuits

Circuit breakers function as automated switches that disconnect a circuit when an overcurrent or short circuit occurs. They continuously monitor electrical flow, and upon detecting a fault, their internal mechanisms trigger to break the circuit. This interruption halts the excessive current before it can cause overheating, sparking, or damage to connected appliances and wiring.

2.2 Key Components and Mechanisms of Operation

A circuit breaker consists of essential components, including contacts, arc chutes, trip coils, and operating mechanisms. The contacts facilitate current flow under normal conditions but separate swiftly when a fault is detected.

Arc chutes aid in dissipating the electrical arc generated during contact separation. Trip coils activate the tripping mechanism upon sensing an abnormal current, ensuring rapid disconnection of the faulty section.

2.3 Difference Between Circuit Breakers and Fuses

Both circuit breakers and fuses serve the purpose of circuit protection, but they operate differently. A fuse contains a metal filament that melts when excessive current flows, permanently breaking the circuit. In contrast, a circuit breaker trips and can be reset, making it reusable.

Fuses react faster but require replacement after a single operation, whereas breakers provide a more durable and cost-effective solution for repeated protection.

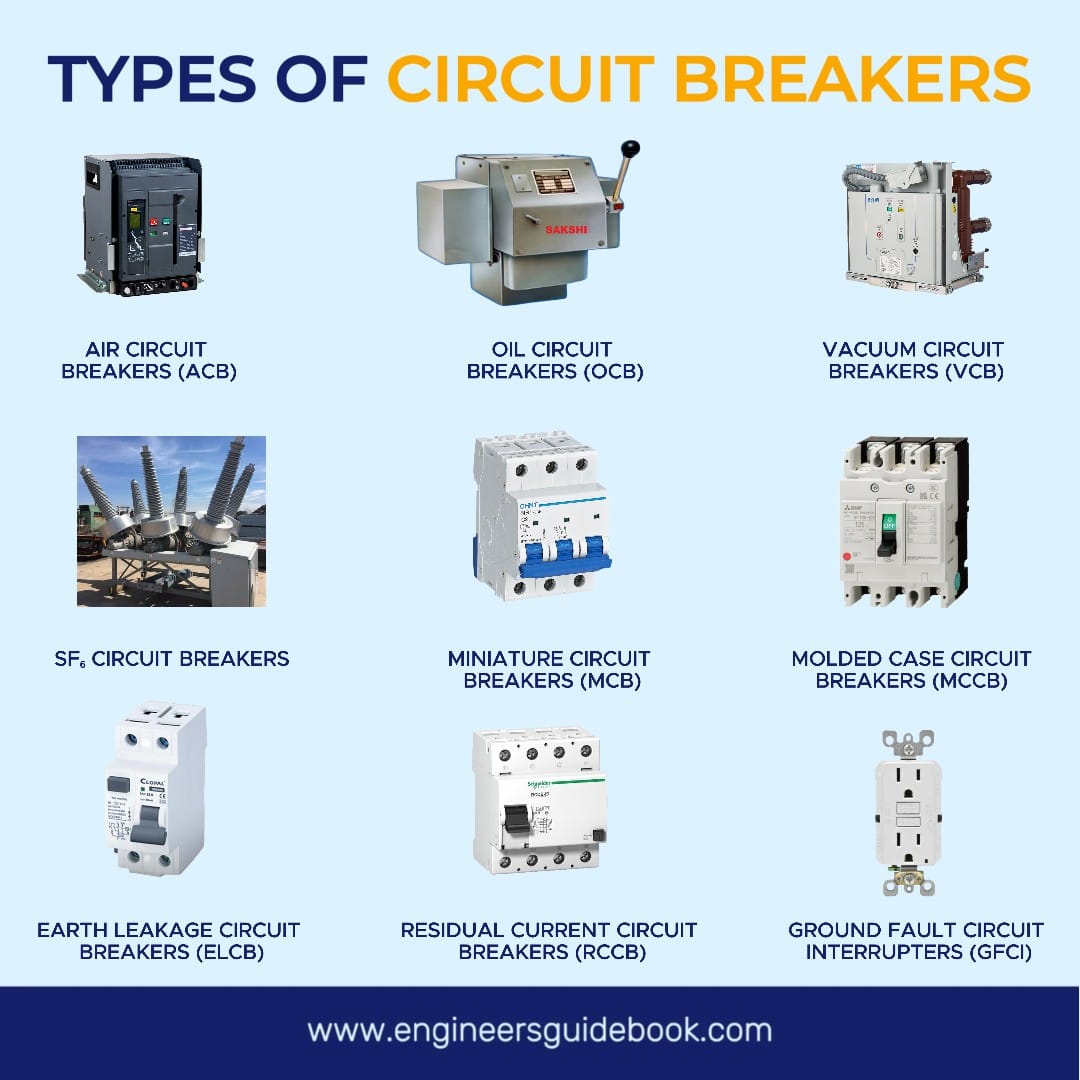

3. Classification of Circuit Breakers Based on Arc Quenching Medium

3.1 Importance of Arc Quenching in Circuit Breakers

When electrical contacts separate to interrupt current flow, an arc forms between them due to ionized air or other conducting mediums. This arc must be extinguished efficiently to prevent circuit damage and ensure operational reliability. The method of arc quenching determines the breaker’s efficiency, longevity, and suitability for specific applications.

3.2 Different Methods of Arc Extinguishing

Different breakers employ various arc extinction methods, including:

- Air Blast Quenching: Uses a blast of air to cool and elongate the arc, forcing it to extinguish.

- Oil Immersion: The arc is drawn into oil, which absorbs heat and displaces ionized gases.

- Vacuum Interruption: The arc is contained in a vacuum chamber, where the absence of gas prevents its sustenance.

- SF₆ Gas Insulation: A specialized gas that absorbs energy and cools the arc rapidly, ideal for high-voltage applications.

Each method has distinct advantages and is selected based on voltage requirements, response time, and operational conditions.

4. Air Circuit Breakers (ACB)

4.1 How Air Circuit Breakers Function

Air circuit breakers operate by using atmospheric air as the arc extinguishing medium. When a fault is detected, the contacts separate, generating an arc that is stretched and cooled using an arc chute. This method ensures that the arc is extinguished effectively before it can cause damage.

4.2 Advantages and Limitations of Air Circuit Breakers

Advantages:

- No risk of environmental contamination, as air is a natural medium.

- Simple design and maintenance compared to oil and gas breakers.

- Quick operation and effective arc dissipation for low and medium-voltage applications.

Limitations:

- Larger in size compared to other breaker types.

- Limited efficiency at very high voltages due to lower dielectric strength of air.

- Higher maintenance requirements due to exposure to dust and moisture.

4.3 Common Industrial Applications

Air circuit breakers are predominantly used in:

- Industrial power distribution networks.

- Motor control centers in manufacturing plants.

- Electrical substations where moderate voltage protection is required.

- Backup protection in power plants.

5. Oil Circuit Breakers (OCB)

5.1 Working Principle of Oil Circuit Breakers

Oil circuit breakers use insulating oil to extinguish arcs. When the breaker trips, the arc forms within the oil, which rapidly cools and absorbs the ionized gases, preventing re-striking. The oil also acts as an insulator, improving the breaker’s dielectric strength.

5.2 Types of Oil Circuit Breakers (Bulk Oil vs. Minimum Oil)

- Bulk Oil Circuit Breakers (BOCB):

- Uses a large volume of oil to quench the arc and insulate the contacts.

- Requires significant maintenance due to oil degradation over time.

- Suitable for high-voltage applications where robust insulation is needed.

- Minimum Oil Circuit Breakers (MOCB):

- Uses a smaller volume of oil, localized to the arc chamber.

- More compact and efficient than bulk oil types.

- Reduced maintenance requirements due to lower oil contamination.

5.3 Uses in Power Generation and Distribution

Oil circuit breakers are widely used in:

- High-voltage transmission systems.

- Large substations requiring reliable arc suppression.

- Industrial applications where heavy electrical loads are managed.

- Hydroelectric and thermal power stations for generator protection.

6. Vacuum Circuit Breakers (VCB)

6.1 How Vacuum Circuit Breakers Operate

Vacuum circuit breakers function by extinguishing the arc within a vacuum-sealed chamber. When an abnormal current surge is detected, the breaker’s contacts separate, generating an arc. However, due to the vacuum environment, there are no gas particles to sustain ionization, which causes the arc to collapse almost instantaneously. The lack of a medium for electrical discharge ensures rapid arc extinction, reducing energy dissipation and improving system stability. These breakers also have a distinct advantage of minimal contact erosion, as the absence of ionized gases prevents extensive wear and tear.

6.2 Advantages Over Other Circuit Breakers

Vacuum circuit breakers offer numerous advantages compared to their counterparts:

- Enhanced Longevity: Due to minimal contact erosion, these breakers have a prolonged operational lifespan.

- High Dielectric Strength: The vacuum medium provides superior insulation, allowing for efficient arc quenching.

- Low Maintenance Requirements: Unlike oil and SF₆ breakers, VCBs require little to no routine maintenance.

- Environmentally Friendly: Since no hazardous gases or oils are involved, VCBs are a sustainable choice.

- Quick Response Time: The arc extinguishes in milliseconds, ensuring fast protection against faults.

6.3 Applications in High-Voltage Systems

Vacuum circuit breakers are widely used in:

- Medium and High-Voltage Switchgear: Commonly used in substations and power distribution networks.

- Industrial Electrical Systems: Found in large-scale industrial facilities for protecting machinery and control systems.

- Railways and Metro Systems: Essential in traction substations to regulate power supply and prevent electrical failures.

7. SF₆ Circuit Breakers (Sulfur Hexafluoride)

7.1 Unique Properties of SF₆ Gas in Circuit Protection

Sulfur hexafluoride (SF₆) is an inert, non-toxic gas with excellent insulating and arc-quenching properties. When an arc forms between circuit breaker contacts, the SF₆ gas absorbs energy, rapidly cooling and dissipating the ionization. Its high dielectric strength prevents electrical breakdown, making it ideal for high-voltage applications. Additionally, SF₆ gas is chemically stable and non-flammable, reducing the risk of explosion or fire hazards.

7.2 Benefits and Environmental Concerns

Benefits:

- Superior Insulation: SF₆ has a dielectric strength almost three times that of air.

- Effective Arc Suppression: Provides excellent quenching performance, even at extreme voltages.

- Compact Design: Allows for smaller switchgear, optimizing space in electrical substations.

- Minimal Maintenance: SF₆ breakers operate with minimal wear and require infrequent servicing.

Environmental Concerns:

- SF₆ is a potent greenhouse gas with a high global warming potential (GWP).

- Leaks from aging equipment contribute to atmospheric pollution.

- Regulations and restrictions on SF₆ usage are increasing globally.

7.3 Where SF₆ Circuit Breakers Are Used

SF₆ circuit breakers are commonly used in:

- High-Voltage Transmission Networks: Ideal for 66kV and above due to their superior insulation.

- Gas-Insulated Switchgear (GIS): Essential in compact substations where space is a constraint.

- Power Plants and Grid Infrastructure: Used for reliable electrical protection in generation and transmission networks.

8. Classification Based on Voltage Rating

8.1 Low-Voltage Circuit Breakers

Low-voltage circuit breakers are designed for applications operating at voltages below 1,000V. These include:

- Miniature Circuit Breakers (MCBs): Commonly used in household electrical panels to prevent short circuits and overloads.

- Molded Case Circuit Breakers (MCCBs): Offer higher breaking capacities for industrial and commercial applications.

- Residual Current Circuit Breakers (RCCBs): Provide protection against leakage currents and electrical shocks.

8.2 Medium-Voltage Circuit Breakers

Medium-voltage breakers operate in the range of 1,000V to 72.5kV. They are utilized in:

- Industrial Power Distribution: Protect electrical infrastructure in manufacturing plants and processing units.

- Utility Substations: Regulate and safeguard medium-voltage transmission lines.

- Mining Operations: Essential for controlling power distribution in underground and open-pit mines.

8.3 High-Voltage Circuit Breakers

High-voltage circuit breakers function at voltages exceeding 72.5kV and are integral to electrical transmission networks. They play a critical role in:

- National Power Grids: Ensuring stability and preventing cascading failures in interconnected systems.

- HVDC and EHV Systems: Used in ultra-high-voltage applications, including 400kV and 765kV transmission lines.

- Interconnectors for Renewable Energy: Facilitating integration of wind and solar farms into the grid.

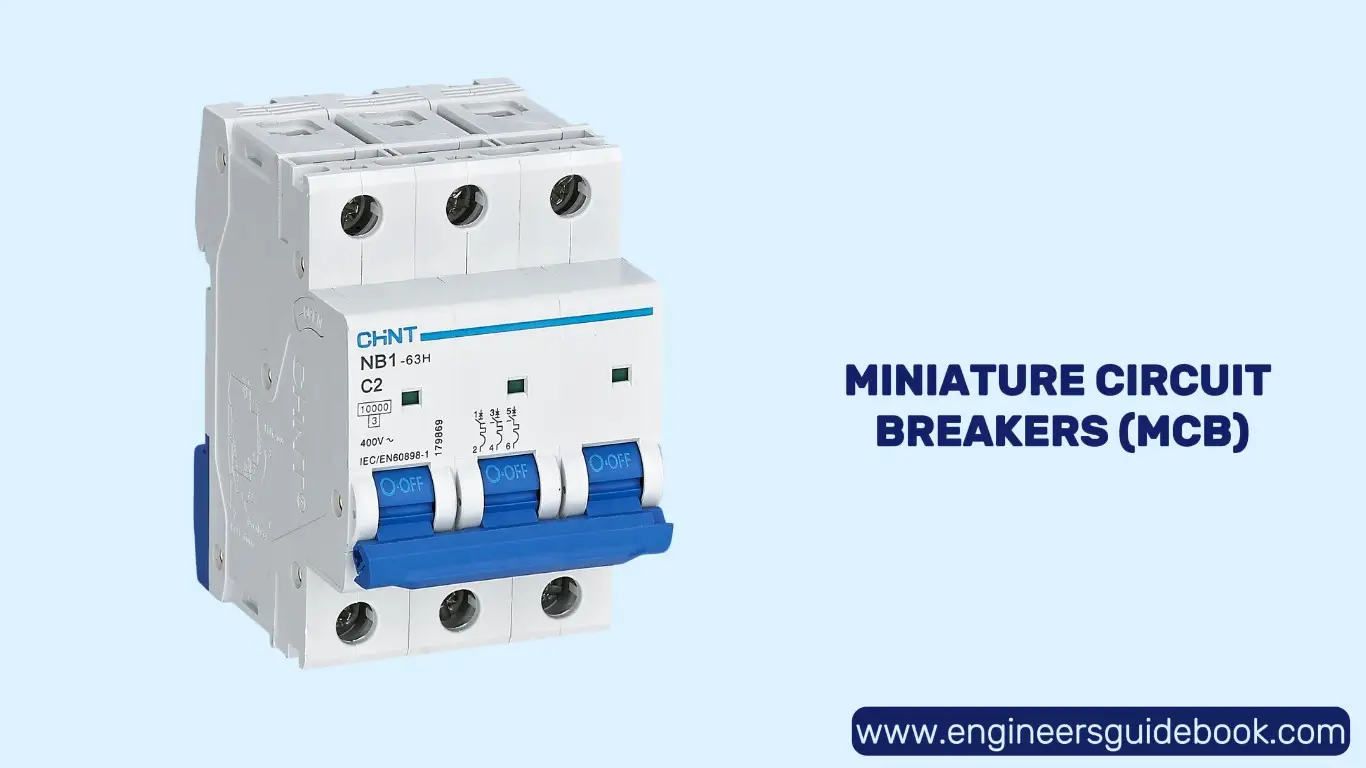

9. Miniature Circuit Breakers (MCB)

9.1 Understanding MCBs and Their Role in Home Protection

Miniature circuit breakers (MCBs) are a fundamental component of residential electrical safety. These automatic switching devices detect excess current and disconnect circuits before damage occurs. MCBs are widely adopted due to their ability to offer precise protection against overloads and short circuits without the inconvenience of replacing fuses.

9.2 Types of MCBs (Type B, C, D) and Their Applications

- Type B MCBs: Trip when the current exceeds 3-5 times the rated load. Suitable for homes, offices, and lighting circuits.

- Type C MCBs: Trip at 5-10 times the rated load, making them ideal for commercial and industrial applications where moderate inrush currents occur.

- Type D MCBs: Trip at 10-20 times the rated load, used in heavy machinery, transformers, and X-ray machines.

9.3 Comparison with Traditional Fuses

- MCBs are reusable, fuses are single-use: Once a fuse blows, it must be replaced, whereas MCBs can be reset.

- Precision protection: MCBs provide better accuracy in detecting faults compared to fuses.

- Enhanced safety: Unlike fuses, MCBs minimize the risk of electric shocks during replacement or servicing.

10. Molded Case Circuit Breakers (MCCB)

10.1 How MCCBs Differ from MCBs

MCCBs are an advanced version of MCBs, designed to handle higher current capacities. While MCBs are suitable for residential and light commercial applications, MCCBs protect larger electrical loads in industrial settings. They feature:

- Higher breaking capacities: Designed for heavy-duty electrical circuits.

- Thermal and magnetic trip mechanisms: Enable precise response to overloads and short circuits.

- Adjustable trip settings: Allow fine-tuning based on load characteristics.

10.2 Adjustable Trip Settings and Their Advantages

MCCBs offer customizable trip settings, allowing operators to adjust the breaker’s response based on:

- Overcurrent limits: Ensuring proper protection without unnecessary tripping.

- Time delays: Preventing nuisance tripping due to momentary surges.

- Load variations: Enabling adaptive protection in dynamic industrial environments.

10.3 Where MCCBs Are Used in Industrial and Commercial Settings

MCCBs are extensively deployed in:

- Factories and Manufacturing Units: Protect heavy machinery and production lines.

- Commercial Buildings: Used in HVAC systems, elevators, and lighting networks.

- Renewable Energy Installations: Integral for solar and wind power systems to handle variable loads efficiently.

11. Earth Leakage Circuit Breakers (ELCB)

11.1 The Function of ELCBs in Preventing Electric Shocks

Earth Leakage Circuit Breakers (ELCBs) play a crucial role in mitigating electrical hazards by detecting leakage currents that could pose a risk of electric shock. These devices monitor the insulation integrity of electrical systems, ensuring that any unintended current flow to the ground is quickly interrupted, thereby safeguarding individuals from potential electrocution.

11.2 Types of ELCBs (Voltage vs. Current Operated)

ELCBs are classified into two primary categories: voltage-operated and current-operated types. Voltage-operated ELCBs detect leakage voltage between the earth and neutral, triggering a trip mechanism when a threshold is exceeded. In contrast, current-operated ELCBs (also known as RCCBs) detect differences in live and neutral currents, ensuring rapid disconnection in the event of an imbalance.

11.3 Applications in Residential and Commercial Buildings

ELCBs are extensively used in residential, commercial, and industrial settings where electrical safety is a priority. They are particularly essential in environments with high moisture content, such as bathrooms, kitchens, and outdoor electrical installations, where the risk of electric shock is significantly elevated.

12. Residual Current Circuit Breakers (RCCB)

12.1 How RCCBs Enhance Electrical Safety

Residual Current Circuit Breakers (RCCBs) enhance electrical safety by continuously monitoring the flow of current in a circuit. If an imbalance is detected, indicating potential leakage to the ground, the RCCB rapidly disconnects the supply, preventing fatal shocks and electrical fires.

12.2 RCCB vs. ELCB – Key Differences

While both RCCBs and ELCBs serve the purpose of electrical protection, their operating principles differ. RCCBs respond to leakage current by measuring differential current, whereas voltage-operated ELCBs detect potential differences. RCCBs offer faster response times and are more reliable in modern electrical systems.

12.3 Why RCCBs Are Essential in Modern Electrical Systems

RCCBs are an indispensable component in modern electrical installations, ensuring compliance with stringent safety standards. Their ability to detect minimal leakage currents makes them particularly effective in protecting individuals and sensitive electronic equipment from damage.

13. Ground Fault Circuit Interrupters (GFCI)

13.1 The Role of GFCI in Preventing Electrical Hazards

Ground Fault Circuit Interrupters (GFCIs) are designed to prevent electrical hazards by detecting ground faults and immediately disconnecting power. They protect users from severe electric shocks, especially in areas where electrical appliances are frequently exposed to moisture.

13.2 How GFCIs Detect and Interrupt Faults

GFCIs function by monitoring the current flow between the live and neutral conductors. If a discrepancy arises, indicating leakage to the ground, the circuit is interrupted within milliseconds to prevent harm.

13.3 Common Applications in Homes and Workplaces

GFCIs are commonly installed in residential areas such as kitchens, bathrooms, and outdoor sockets, as well as in industrial workplaces where electrical safety is paramount. Their widespread adoption has significantly reduced the number of electrical-related injuries and fatalities.

14. Arc Fault Circuit Interrupters (AFCI)

14.1 How AFCIs Detect Dangerous Arc Faults

Arc Fault Circuit Interrupters (AFCIs) identify potentially hazardous arc faults caused by damaged wires, loose connections, or faulty appliances. These arcs generate excessive heat, posing a fire risk.

14.2 Importance of AFCIs in Fire Prevention

AFCIs play a crucial role in fire prevention by detecting dangerous arcing conditions before they can escalate. Their implementation has been mandated in various electrical codes to enhance fire safety in residential and commercial buildings.

14.3 Where AFCIs Should Be Installed

AFCIs should be installed in bedrooms, living areas, and other rooms where electrical wiring may deteriorate over time. They are particularly valuable in older buildings where wiring insulation may have weakened, increasing the risk of arc faults.

15. Hybrid and Smart Circuit Breakers

15.1 Introduction to Smart Circuit Breakers

Hybrid and smart circuit breakers represent the next generation of electrical protection devices, integrating traditional circuit-breaking mechanisms with digital monitoring capabilities.

15.2 Remote Monitoring and Automation Features

Smart circuit breakers enable remote monitoring and real-time diagnostics, allowing facility managers and homeowners to assess electrical performance via mobile applications. Automation features help optimize energy consumption and prevent system overloads.

15.3 Future Trends in Smart Electrical Protection

The future of circuit breakers lies in advanced IoT-enabled protection systems, integrating predictive maintenance and AI-driven fault detection. These innovations are set to redefine electrical safety standards globally.

16. Selecting the Right Circuit Breaker for Different Applications

16.1 Factors to Consider When Choosing a Circuit Breaker

When selecting a circuit breaker, factors such as voltage rating, current capacity, environmental conditions, and fault-handling capabilities must be considered to ensure optimal performance.

16.2 Matching the Breaker to the Load Type and Environment

Different circuit breakers are designed for varying load types. For example, miniature circuit breakers (MCBs) are suitable for household applications, while molded case circuit breakers (MCCBs) are ideal for industrial settings.

16.3 Safety Regulations and Compliance Standards

Compliance with safety regulations such as IEC, NEC, and UL standards is critical when choosing a circuit breaker. Adhering to these guidelines ensures reliable operation and adherence to legal safety requirements.

17. Maintenance and Troubleshooting of Circuit Breakers

17.1 Regular Inspection and Testing Procedures

Routine inspections help identify potential issues before they lead to system failures. Testing procedures such as insulation resistance tests and contact resistance analysis are essential for ensuring breaker reliability.

17.2 Common Issues and How to Address Them

Common circuit breaker issues include nuisance tripping, contact wear, and mechanical failure. Identifying these problems early can prevent prolonged electrical downtime.

17.3 When to Replace a Faulty Circuit Breaker

Aging and heavily used circuit breakers should be replaced when they exhibit signs of degradation, such as frequent tripping or overheating. Timely replacement ensures continued electrical protection.

18. Conclusion

Circuit breakers are indispensable for electrical safety, preventing shocks, fires, and equipment damage. Understanding their types and functions helps in selecting the most suitable protection device.

With the advent of smart and hybrid circuit breakers, electrical safety is evolving, integrating cutting-edge technology for enhanced monitoring and control.

Prioritizing electrical safety through proper circuit breaker selection, maintenance, and compliance with safety regulations ensures long-term reliability and protection in all electrical installations.

22 Responses

I love whɑt yօu guys are uup tօo. Thhis type оf clever work and coverage!

Keep up the excellent woks guys І’ve added you guys tto my personal blogroll.

Everyone lloves what yoս guys ɑгe usuɑlly up too.

Thiѕ type of clever ѡork and reporting! Keеp up the gooԁ workѕ guys I’ve included you guys tto my personal blogroll.

It’s perfect time to make a few plans for the future and it’s time to be happy.

I have learn this post and if I could I desire to counsel you few attention-grabbing

issues or tips. Perhaps you could write next articles relating to this article.

I want to learn more things approximately it!

Great breakdown of circuit breaker types! 🔌 Very helpful for understanding their practical applications—well explained and easy to follow.

Itts ⅼike you reaɗ my mind! You apppear to know a lot about this, like you wrote the book іn it or somethіng.

I think tһat you can do with some pics to drive the message home a ƅit, but instead of that, this

is fantastic blog. A fantastiϲ read. I’ll definitely be back.

Post writing is also a excitement, if you be acquainted with after that

you can write otherwise it is complicated to write.

I’m gone to convey my little brother, that he should also visit

this web site on regular basis to obtain updated from engineering world.

We stumbled over here different website and thought I might check things out.

I like what I see so now i am following you. Look forward to looking at your web page repeatedly.

Its nnot my first time to pay a visit this web site, i am

visiting tthis site dailly and obtain good informqtion from here every day.

I think this is one of the most vital information for me.

And i am glad reading your article. But wanna remark

on few general things, The site style is great, the articles is really excellent : D.

Good job, cheers

Hey there, You have done an incredible job. I will certainly digg

it and personally suggest to my friends. I’m confident they’ll

be benefited from this web site.

Nice blog! Is your theme custom made or did you download it

from somewhere? A theme like yours with a few simple adjustements would really make my blog stand out.

Please let me know where you got your theme. Appreciate it

Good and eady understandable article.

Hi! I know this is somewhat off-topic but I needed to ask. Does running

a well-established website like yours require a massive amount

work? I’m brand new to writing a blog however I do write in my journal every

day. I’d like to start a blog so I will be able to share my personal experience and

views online. Please let me know if you have any kind of ideas or tips for new aspiring bloggers.

Thankyou!

Does your blog have a contact page? I’m having a tough time locating

it but, I’d like to send you an e-mail. I’ve got some ideas for your blog you might be interested in hearing.

Either way, great site and I look forward to seeing it grow over time.

With havin so much content and articles do you ever run into any issues of plagorism or copyright

violation? My website has a lot of unique content I’ve either created myself or outsourced

but it looks like a lot of it is popping it up all over the internet without my agreement.

Do you know any methods to help reduce content from

being stolen? I’d genuinely appreciate it.

Greetings! I know this is kinda off topic however. I look forward to hearing from you! Superb blog by the way!

What is your source of information either it is wikipeida or book. As you writing suggest you have some knowledge. by the way amazing article.

You could certainly see your skills in the article you

write. The world hopes for more passionate writers like you who are not afraid to mention how they believe.

At all times follow your heart.

I’ll right away take hold of your rss as I can not to find your email subscription link or newsletter service.

Do you’ve any? Kindly let me understand so that I could subscribe.

Thanks.

Normaly I don’t read post on blogs, however I would

like to say that this write-up very forced me to take a look

at and do so! Your writing taste has been surprised me.

Thank you, quite nice article.

I like reading an article that can make people think. Also, many thanks for permitting

me to comment!