June 27, 2024 By Muhammad Ali 7 minutes read

Bearings are crucial components in many machines and mechanical systems. Their main job is to reduce friction between moving parts, which helps things run smoothly and efficiently.

Imagine trying to ride a bicycle without bearings on the wheels. it would be nearly impossible! Bearings make sure that machinery operates with minimal friction and wear, which is vital for maintaining performance and extending the lifespan of equipment.

Bearings are used in a wide range of engineering fields, including automotive, aerospace, and industrial machinery. In this article, we will discuss in detail the bearing and types of bearings used in the industry.

Bearings are mechanical components designed to reduce friction between moving parts and support the movement of rotating or sliding elements. Their primary function is to provide a smooth and controlled motion while carrying loads. By minimizing friction, bearings allow machines to operate more efficiently and with less wear and tear.

In simple terms, a bearing supports and guides a moving component, such as a shaft or axle, by providing a smooth surface for it to move against. This support is crucial in reducing the energy required for motion and preventing damage to the machinery.

Without bearings, the moving parts would directly contact each other, leading to increased friction, heat, and wear.

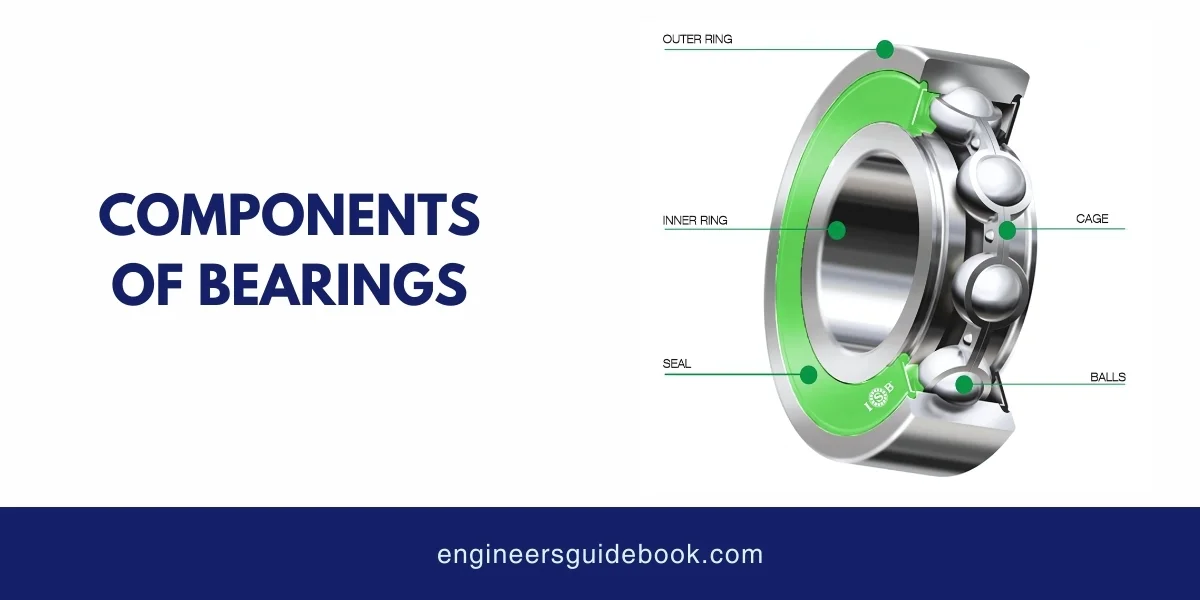

Bearings come in various shapes and sizes, but they typically consist of several key components:

Races (or Rings): Bearings generally have two rings, an inner race and an outer race. The inner race is attached to the rotating shaft, while the outer race is fixed to the housing of the machine. The races provide a surface for the rolling elements to move.

Rolling Elements: These are the parts of the bearing that carry the load and move within the races. They can be balls, rollers, or needles, depending on the type of bearing. Rolling elements minimize contact area, reducing friction and wear.

Cage (or Retainer): The cage is a structure that separates the rolling elements and holds them in place within the bearing. It ensures the even spacing of the rolling elements and prevents them from colliding with each other.

Lubricant: Although not a structural component, the lubricant plays a vital role in bearing functionality. It reduces friction and wear, dissipates heat, and prevents corrosion. Lubricants can be oils, greases, or solid films, depending on the application.

Seal or Shield: Some bearings have seals or shields to protect the rolling elements from contaminants like dust, dirt, and moisture. This protection enhances the bearing’s lifespan and performance.

Bearings operate by providing a rolling or sliding surface that reduces friction between moving parts. Here’s a simplified explanation of how they work:

Load Transmission: The load from the moving part (such as a rotating shaft) is transferred to the rolling elements, which distribute it evenly across the bearing.

Reduced Friction: As the rolling elements move between the inner and outer races, they reduce friction by rolling instead of sliding. This rolling motion significantly lowers the energy required for movement.

Support and Alignment: Bearings support the moving part, keeping it aligned and preventing unwanted motion. This alignment is crucial for maintaining the efficiency and precision of the machine.

Heat Dissipation: Bearings help dissipate heat generated by friction, ensuring that the machinery operates within safe temperature limits.

Vibration and Noise Reduction: By providing a smooth motion, bearings reduce vibrations and noise, contributing to a quieter and more stable operation.

Bearings are classified based on various factors, including load direction and motion allowed. Understanding these classifications helps engineers select the most suitable bearing for a given application.

Radial bearings are designed to support loads that are perpendicular to the axis of rotation. They are the most common type of bearing and are used in applications where the primary load is in a radial direction.

Radial bearings are widely used in various applications, such as electric motors, pumps, and gearboxes.

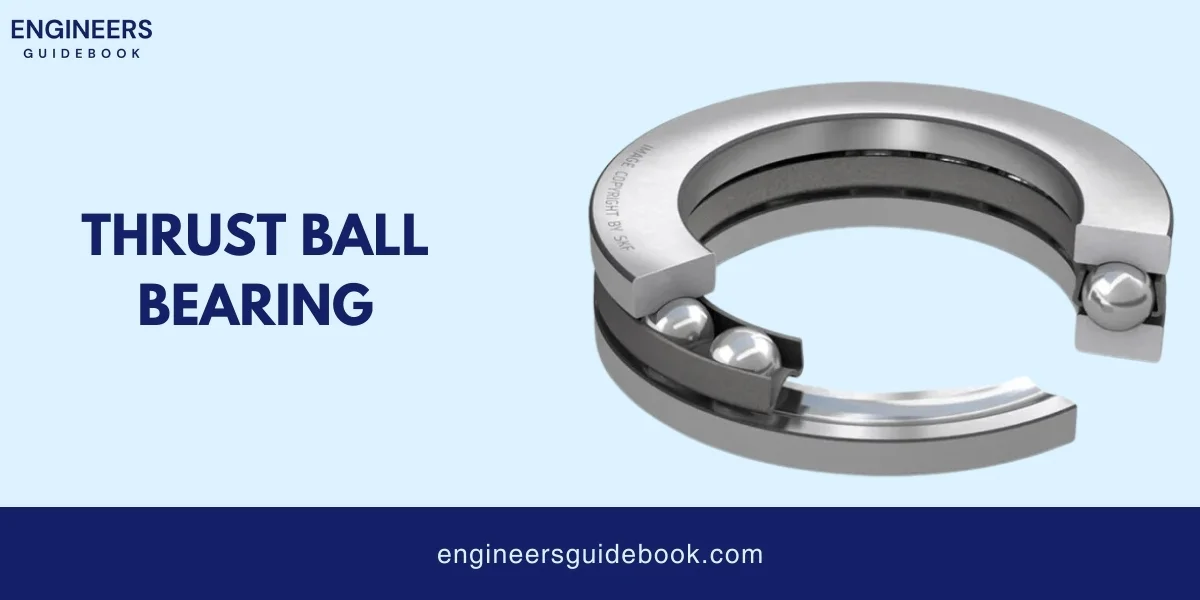

Axial bearings, also known as thrust bearings, are designed to support loads that are parallel to the axis of rotation. They are used in applications where the primary load is in an axial direction.

Axial bearings are commonly found in automotive and aerospace applications, where they support thrust loads from rotating parts like propellers and gears.

Plain bearings, also known as sliding bearings, rely on sliding motion between two surfaces. They have no rolling elements and are generally simple in design.

Plain bearings are used in applications where space is limited, and moderate speeds are required.

Rolling-element bearings utilize rolling elements, such as balls or rollers, to reduce friction between moving parts. They are designed to handle both radial and axial loads, depending on their configuration.

Rolling-element bearings are versatile and used in various applications, including automotive, aerospace, and industrial machinery.

Bearings come in various types, each designed to meet specific requirements and applications. Here, we’ll explore the main categories of bearings, highlighting their structures, features, advantages, and typical uses.

Read More: Ball Bearings: Fundamental Concepts and Applications

In Angular Contact Ball Bearings Raceways are positioned at an angle to the bearing axis, allowing them to handle combined radial and axial loads.

Cylindrical Roller Bearings Rollers are longer than their diameter, allowing for high radial load capacity.

Cylindrical Roller Bearings are Used in gearboxes, electric motors, and heavy machinery where high radial loads are present.

Spherical Roller Bearings feature two rows of spherical rollers that can handle both radial and axial loads.

Tapered Roller Bearings consist of tapered rollers and raceways, designed to handle both radial and axial loads.

Needle Roller Bearings Long, thin rollers provide high load capacity with minimal radial space.

Jewel bearings have low friction and excellent wear resistance, making them ideal for applications where precision and longevity are essential.

The use of synthetic jewels provides a hard, smooth surface that minimizes friction and wear.

They are ideal for applications where traditional bearings may not perform well, providing unique solutions to complex challenges.

Choosing the right bearing is crucial for the performance, efficiency, and longevity of mechanical systems.

The load capacity of a bearing refers to its ability to support the forces exerted on it during operation.

Radial Load: This is the load acting perpendicular to the axis of rotation. Bearings designed to support radial loads include ball bearings and cylindrical roller bearings. Engineers should consider the magnitude and direction of the radial load when selecting these types of bearings.

Axial Load: Axial or thrust load is the load acting parallel to the axis of rotation. Bearings like thrust ball bearings and roller thrust bearings are specifically designed to handle axial loads. Understanding the nature of the axial load is crucial for selecting the appropriate bearing.

Combined Load: Some applications involve both radial and axial loads. In such cases, bearings like angular contact ball bearings and tapered roller bearings, which can handle combined loads, should be considered.

Bearings are rated based on their ability to support dynamic (moving) and static (stationary) loads.

The dynamic load rating indicates the bearing’s capacity to support a load over a specified lifespan, while the static load rating refers to the maximum load the bearing can withstand without permanent deformation.

High-Speed Applications: For applications involving high speeds, such as turbines and electric motors, bearings with low friction and excellent heat dissipation properties are required. Ball bearings and certain roller bearings are well-suited for high-speed applications due to their low friction and precise operation.

Low-Speed Applications: In low-speed applications, such as conveyors and heavy machinery, bearings with high load-carrying capacity and durability are more important than speed. Bearings like plain bearings and spherical roller bearings are often used in these scenarios.

Lubrication: Proper lubrication reduces friction, wear, and heat generation in bearings. Engineers should consider the type of lubrication required, whether it’s oil, grease, or solid film, and the maintenance intervals needed to ensure optimal performance.

Durability: The durability of a bearing is determined by its material properties, design, and manufacturing quality. Bearings made from high-quality materials and designed for specific applications tend to have higher durability and longer service life.

Engine Components: Ball bearings and needle roller bearings are used in engine components like camshafts and crankshafts. They reduce friction and support the high-speed operation of these critical parts.

Steering Systems: Thrust ball bearings are commonly used in steering systems to handle axial loads and ensure precise steering control.

Pumps and Compressors: Bearings are used in pumps and compressors to reduce friction and support high-speed rotation. Ball bearings and roller bearings are commonly used in these applications.

Printing Presses: Roller bearings and ball bearings are used in printing presses to support high-speed operation and ensure precise alignment of printing components.

Robotics: Bearings play a crucial role in robotics, providing smooth and precise motion control for robotic arms and joints. Angular contact ball bearings and flexure bearings are often used in robotic applications.

The bearing industry is continually evolving with new materials, technologies, and designs that enhance performance, efficiency, and sustainability.

Ceramic Bearings: Ceramic bearings are made from materials like silicon nitride or zirconia, offering several advantages over traditional steel bearings. They are lightweight, corrosion-resistant, and can withstand high temperatures and speeds.

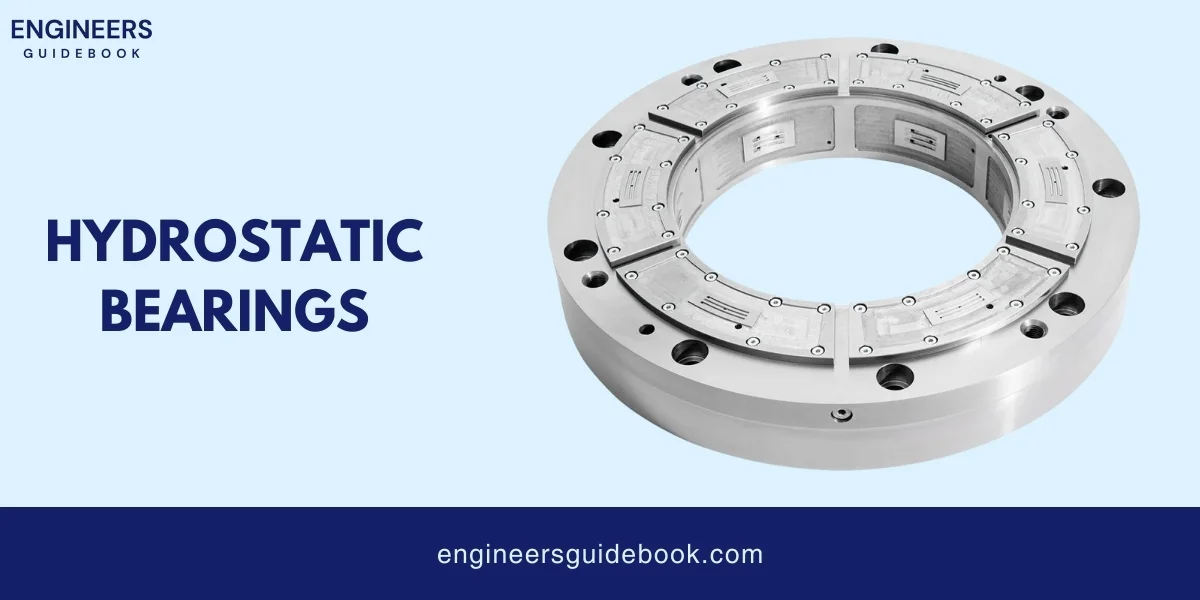

Composite Bearings: Composite bearings are made from a combination of materials, such as reinforced plastics, polymers, and metal alloys. These materials are engineered to provide specific properties, such as reduced friction and enhanced wear resistance.

Self-Lubricating Bearings: Self-lubricating bearings are designed to operate without external lubrication. They use advanced materials, such as PTFE (polytetrafluoroethylene) or other engineered plastics, to provide a low-friction surface.

Smart bearings can monitor parameters like temperature, vibration, and load in real time, allowing for early detection of potential issues and reducing the risk of unexpected failures.

Common coatings include diamond-like carbon (DLC), chromium, and ceramic-based coatings. Each coating offers specific advantages, such as reduced friction or increased hardness.

Engineers can use 3D printing to create customized bearings that meet specific application requirements, optimizing performance and reducing waste.

Throughout this guide, we have explored the essential aspects of bearings, their classifications, types, applications, and emerging industry trends. Bearings, as mechanical components, are vital for reducing friction between moving parts and supporting loads, significantly enhancing machinery’s performance and longevity.

They can be classified by load direction and motion allowed, helping engineers select the right bearing for specific applications. With 15 types of bearings discussed, including plain, rolling-element, and magnetic bearings, each offers unique features for various applications.

Proper selection, maintenance, and understanding of future trends, such as smart bearings and sustainability, are key to optimizing performance and reliability.

The main types include:

Consider load type, speed, environmental conditions, maintenance needs, and space constraints. Choose a bearing that meets these specific requirements.

Bearing failure is caused by inadequate lubrication, contamination, overloading, misalignment, and wear. Prevent it by ensuring proper lubrication, protection from contaminants, correct load application, proper alignment, and regular maintenance.

Lubrication frequency depends on operating conditions, load, and speed. Follow manufacturer recommendations, but typically, regular checks every few months are advisable.

Common materials include steel, ceramic, plastic, and composites. The choice depends on the application requirements, such as load, speed, and environmental conditions.

The lifespan varies based on load, speed, maintenance, and operating conditions. Properly maintained bearings can last from several years to decades.

Yes, if they are not damaged and within tolerances. Thoroughly clean and inspect them before reuse.

Seals and shields protect bearings from contaminants like dust and moisture, reducing wear and extending their lifespan.

Look for unusual noises, increased vibration, overheating, and visible wear or damage.

Smart bearings have sensors that monitor conditions like temperature and vibration, enabling predictive maintenance and real-time performance data.

Ceramic bearings are lightweight, corrosion-resistant, and can withstand high temperatures and speeds, making them ideal for specialized applications like aerospace and racing.

Muhammad Ali holds a PhD in Mechanical Engineering from MIT and is currently conducting groundbreaking research on sustainable energy systems. His innovative work in renewable energy integration has earned him numerous accolades in the engineering community.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.

2 Responses

Amazing piece of information..very educative.

This is a good tip particularly to those new to the blogosphere.

Short but very accurate info… Thank you for sharing this one.

A must read article!