1. Introduction

Bolts are integral to modern engineering and construction, serving as essential fasteners that join materials with strength and precision. These mechanical components provide a secure, removable, and durable method of fastening, ensuring the structural integrity of everything from towering skyscrapers to intricate machinery.

Unlike adhesives or welding, bolts offer versatility by allowing disassembly and reassembly, making them indispensable in various industries, including aerospace, automotive, and infrastructure development. In this article, we will discuss in detail about types of Bolts and their uses.

Key Factors That Differentiate Bolts from Other Fasteners

Bolts stand apart from other fasteners such as screws, rivets, and nails due to their distinct design and functionality. Unlike screws, which are typically self-tapping, bolts require a nut or pre-threaded hole to secure materials. This design feature provides superior load distribution and clamping force.

Compared to rivets, bolts offer the advantage of removability without damaging the assembly. Their ability to withstand dynamic loads and repeated stress cycles makes them preferable in high-performance applications.

2. Anatomy of a Bolt: Structure and Components

2.1 Head

The head of a bolt serves as the gripping surface for tightening and loosening operations. Various head designs cater to specific applications: hexagonal heads are common in industrial settings due to their robust grip, whereas domed or countersunk heads are used in aesthetic or aerodynamic applications.

Additionally, flange heads provide built-in washers for enhanced load distribution, reducing the risk of loosening under vibration.

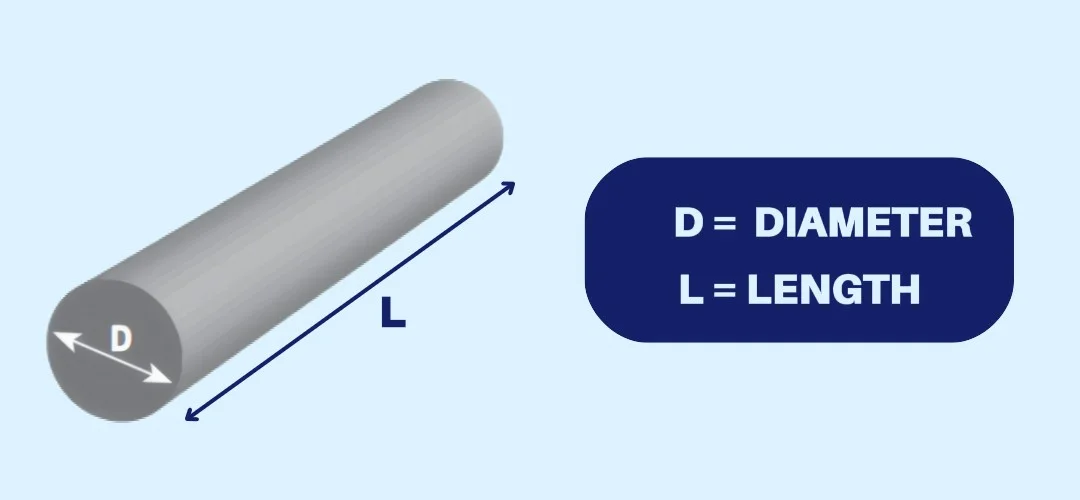

2.2 Shank

The shank is the unthreaded portion of a bolt, contributing to its shear strength and overall stability. A longer shank provides increased resistance to bending forces, making it ideal for structural applications. Bolts with a fully threaded design may lack a distinct shank but are used in scenarios requiring maximum grip over a specific length. The diameter and length of the shank directly impact the bolt’s load-bearing capacity and should be selected based on engineering calculations.

2.3 Threads: Types and Their Impact

Threads are helical ridges on the bolt that engage with nuts or tapped holes, ensuring a secure fit. Their design influences the distribution of loads across the fastener.

Fine threads provide greater tensile strength and resistance to loosening, making them suitable for precision applications.

Coarse threads, on the other hand, offer faster assembly and superior resistance to stripping in softer materials. Specialized thread designs, such as Acme and buttress threads, cater to high-load or axial movement applications.

2.4 Material Composition

Bolts are manufactured from a variety of materials, each offering distinct advantages based on environmental conditions and mechanical requirements. Steel bolts, including carbon and alloy steel variants, provide high tensile strength and affordability. Stainless steel resists corrosion, making it ideal for marine and outdoor applications. Brass and bronze bolts exhibit excellent conductivity and are widely used in electrical and decorative applications. For extreme conditions, titanium and Inconel bolts provide exceptional strength-to-weight ratios and high-temperature resistance.

2.5 Coatings and Platings

To improve durability and prevent corrosion, bolts are often coated or plated with protective materials. Zinc plating offers a cost-effective solution for general applications, while hot-dip galvanizing provides a thicker protective layer for outdoor and structural uses.

Phosphate coatings enhance lubrication and wear resistance, commonly used in automotive industries. Advanced coatings like PTFE (Teflon) provide additional resistance to chemical exposure and extreme temperatures.

3. Classification of Bolts Based on Design and Application

3.1 Machine Bolts vs. Structural Bolts

Machine bolts and structural bolts serve different functions based on their design and load-bearing capacities. Machine bolts are typically used in machinery and mechanical assemblies, featuring precise threading for controlled torque application.

Structural bolts, however, are engineered to withstand high shear and tensile loads in construction projects, such as bridges and steel frameworks. These bolts often adhere to strict industry standards, such as ASTM A325 and A490, to ensure performance and safety.

3.2 Threaded vs. Partially Threaded Bolts

The decision between fully threaded and partially threaded bolts depends on the application’s mechanical requirements. Fully threaded bolts provide uniform grip and are ideal for fastening components where shear strength is secondary to clamping force.

Partially threaded bolts, with a smooth shank section, offer superior resistance to bending and are preferred in load-bearing structures.

The transition between the shank and the threaded portion plays a crucial role in stress distribution and fatigue resistance.

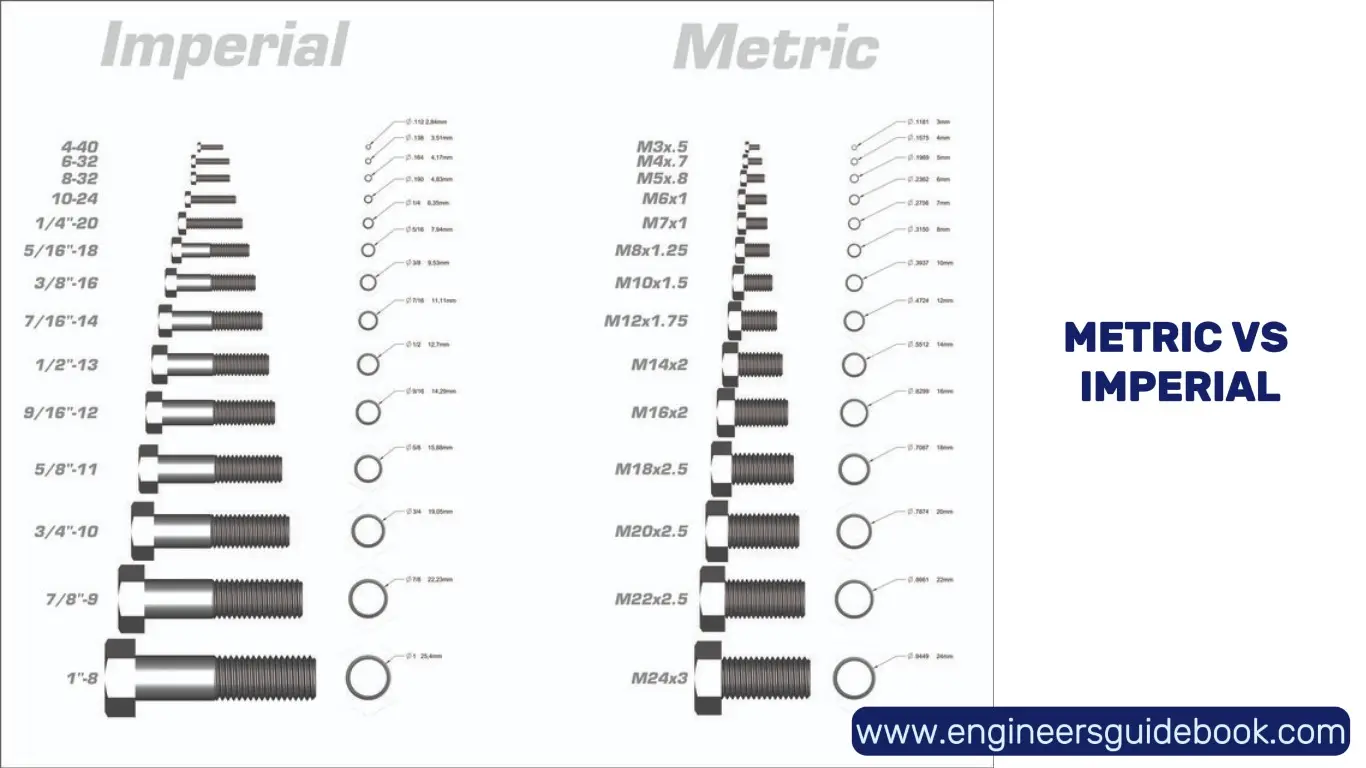

3.3 Metric vs. Imperial Bolts

Bolts are classified based on metric and imperial measurement systems, each following different sizing conventions. Metric bolts, commonly used worldwide, adhere to ISO and DIN standards, with sizes denoted in millimetres.

Imperial bolts, following SAE and ASTM standards, are measured in inches and fractions. Understanding these standards is essential when sourcing or replacing bolts in international engineering projects to ensure compatibility and proper fitment.

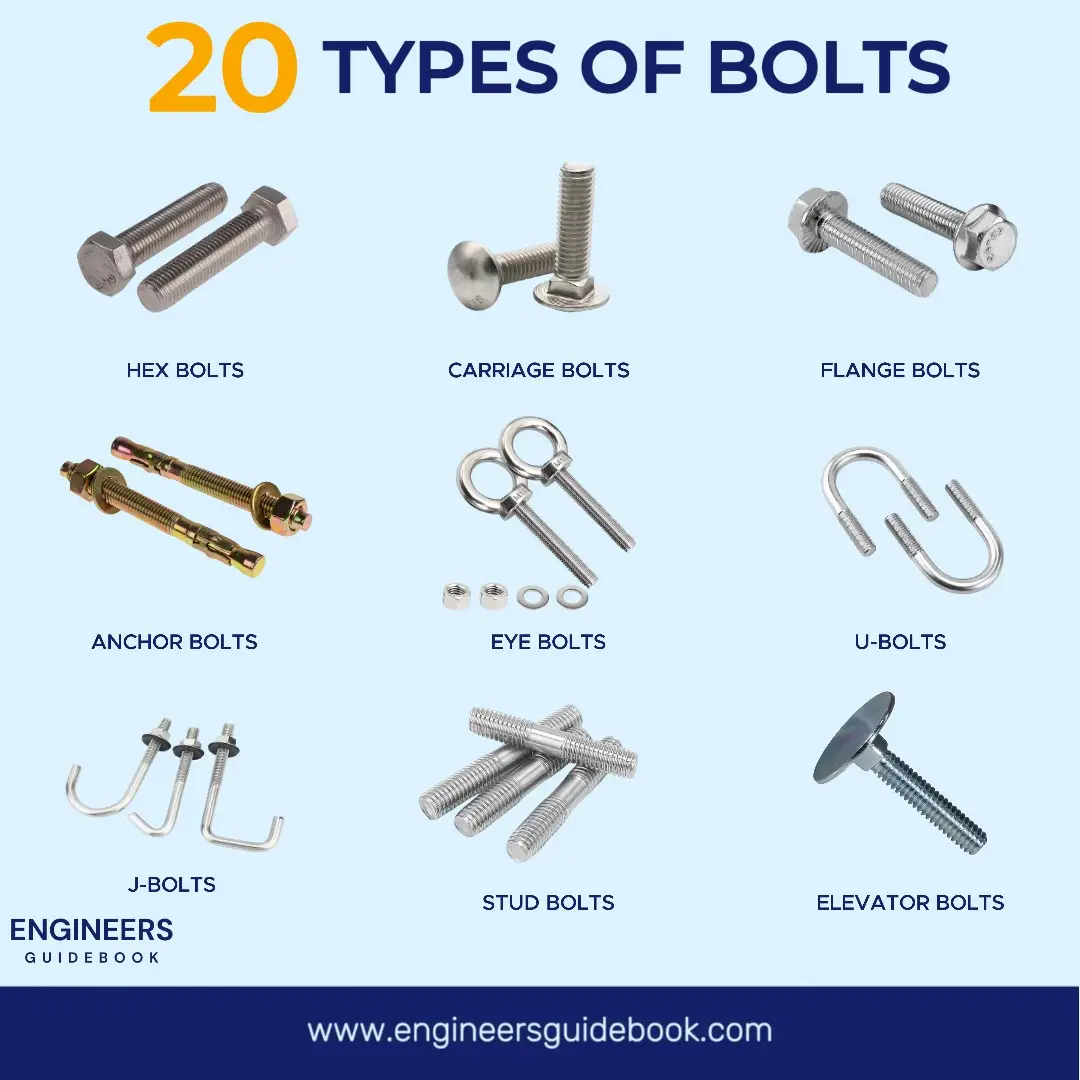

4. Common Types of Bolts

4.1 Hex Bolts

Hex bolts, recognized by their six-sided head, are among the most commonly used fasteners in industrial and structural applications. Their robust design allows them to endure high tensile and shear forces, making them ideal for load-bearing structures.

Engineered for resilience, these bolts are frequently crafted from high-grade steel alloys and are available in various strength grades, such as Grade 5, Grade 8, and ASTM A325.

Their superior durability ensures long-term structural integrity, even in harsh environments.

Standard vs. Heavy Hex Bolts

The primary distinction between standard and heavy hex bolts lies in the dimensions of the head. Heavy hex bolts feature a larger head size, providing a greater bearing surface and improved clamping force.

This distinction is particularly advantageous in structural applications where increased load distribution is necessary. Standard hex bolts, while smaller, offer versatility and are widely used in general-purpose fastening.

Applications

Hex bolts play a vital role in assembling machinery, constructing buildings, and securing bridge components. Their ease of installation, combined with high load-bearing capabilities, makes them indispensable in automotive manufacturing, heavy equipment assembly, and steel construction.

4.2 Carriage Bolts

Carriage bolts are uniquely characterized by their domed head and square neck beneath the head. This design prevents the bolt from spinning during installation, providing a secure fastening solution without requiring a secondary tool to hold the head.

The smooth, rounded top also enhances aesthetics and safety by minimizing exposed sharp edges.

Applications

Carriage bolts are commonly used in wooden structures, fencing, and metal frameworks where a flush finish is desired. Their square neck fits snugly into pre-drilled holes in wooden or metal materials, ensuring a firm grip that prevents loosening under vibration.

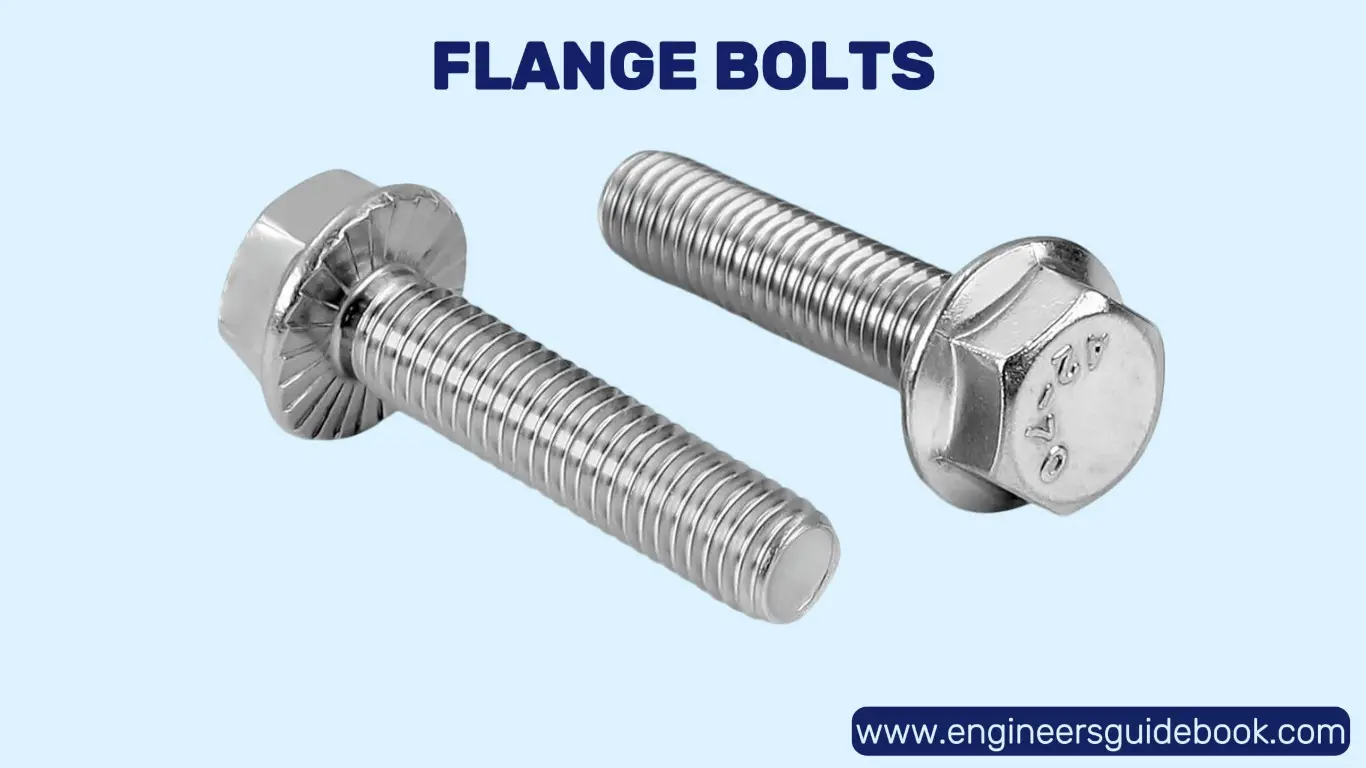

4.3 Flange Bolts

Flange bolts are distinct in their design, featuring an integrated washer-like flange beneath the head. This built-in washer distributes clamping force more evenly, reducing stress concentrations and enhancing the bolt’s overall grip. This feature eliminates the need for a separate washer, streamlining assembly and improving efficiency.

Applications

Due to their high resistance to loosening caused by vibration, flange bolts are widely utilized in automotive manufacturing, engine assembly, and mechanical frameworks. Their ability to provide a secure hold without additional components makes them an excellent choice for high-stress environments.

4.4 Anchor Bolts

Anchor bolts are essential for affixing structures to concrete surfaces, providing stability in construction and heavy machinery installations. These bolts are embedded in concrete before it sets, creating a firm bond that withstands shear and tensile forces.

4.4.2 L-Shaped, U-Shaped, and Straight Anchor Bolts

Anchor bolts come in various shapes, each serving a distinct purpose. L-shaped bolts offer excellent resistance against pull-out forces and are used in securing steel columns. U-shaped bolts provide additional support in applications requiring dual anchoring points. Straight anchor bolts are typically used in deep embedment applications where high tensile strength is necessary.

4.5 Eye Bolts

Eye bolts feature a looped head, allowing them to serve as anchor points for cables, ropes, and chains. These bolts are integral in lifting operations, providing secure attachment points for hoisting heavy loads in industrial and marine applications.

Applications

Forged eye bolts are created from a single piece of material, enhancing their strength and durability. They are ideal for high-load applications where safety is paramount. Bent eye bolts, while more economical, are best suited for lighter loads and non-critical applications.

4.6 U-Bolts

U-bolts are shaped like the letter “U” and are primarily used to secure pipes, tubes, and round objects to support structures. Their symmetrical design allows for uniform clamping force, ensuring stability and alignment in piping systems.

Applications

U-bolts are manufactured in various diameters and lengths to accommodate different pipe sizes and load requirements. They are widely used in construction, automotive exhaust systems, and marine applications where vibration resistance is essential.

4.7 J-Bolts

J-bolts feature a distinctive J-shaped hook, making them effective for anchoring structures, securing fences, and supporting industrial frameworks. Their curved design enhances grip and stability, particularly in foundation installations.

Applications

J-bolts are embedded into concrete to provide secure attachment points for columns, light poles, and heavy equipment foundations. Their ability to resist pull-out forces ensures long-term reliability in structural applications.

4.8 Lag Bolts (Lag Screws)

Lag bolts, also known as lag screws, are designed with coarse threads and a hex head, allowing them to embed deeply into wood and other soft materials. Their large size and deep threading provide exceptional holding power, making them ideal for securing heavy timber structures.

Applications

Lag bolts are used in applications requiring extreme fastening strength, such as deck construction, framing, and heavy-duty furniture assembly. Pre-drilling pilot holes is recommended to prevent wood splitting and ensure optimal grip. These bolts offer a durable and reliable fastening solution for high-load wooden structures.

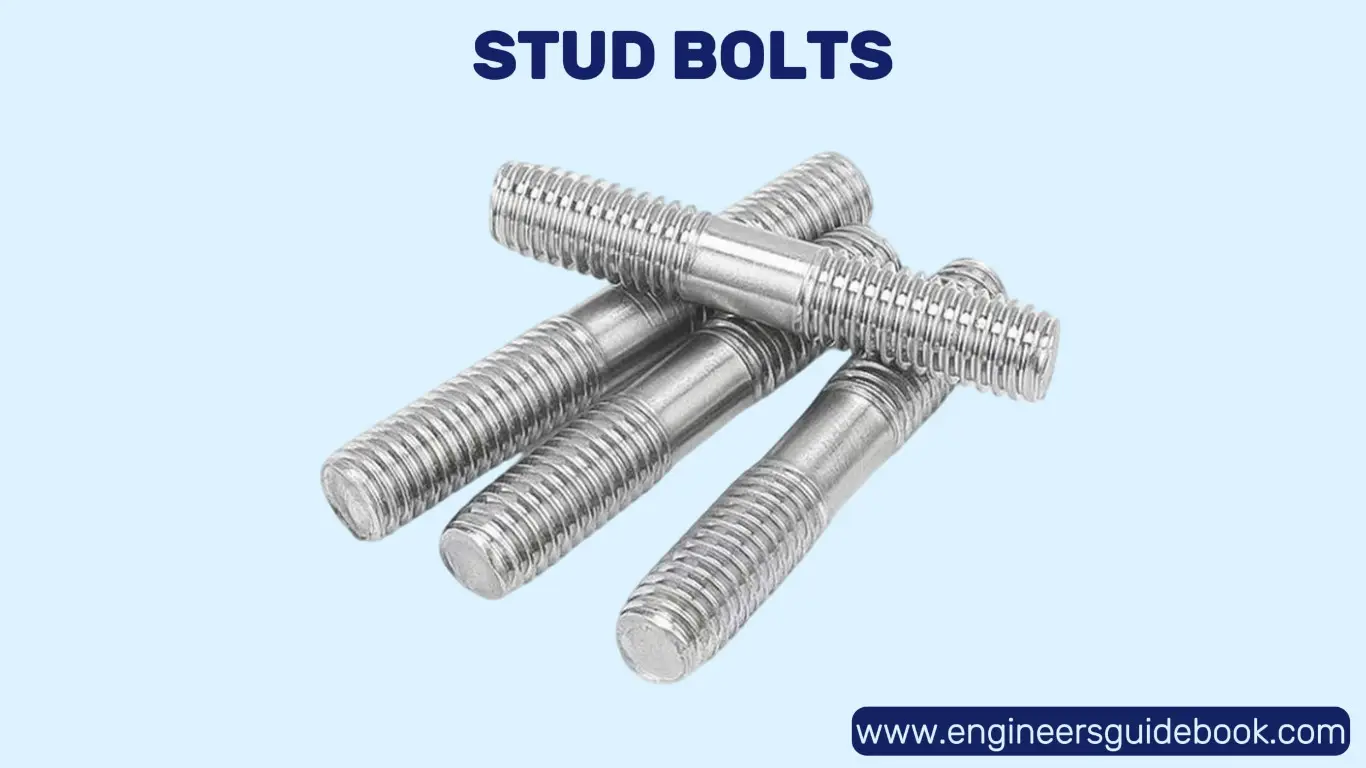

4.9 Stud Bolts

Stud bolts feature continuous threading along their entire length, making them indispensable for flange connections in industrial applications. Unlike conventional bolts, which have a defined head, stud bolts are designed to be used with nuts on both ends, providing a balanced and uniform clamping force. This characteristic ensures a secure and stable joint, which is critical in high-pressure environments.

Applications

Stud bolts are widely used in the oil and gas industry, particularly in pressure vessel assembly, heat exchangers, and pipeline installations. Their ability to maintain high tensile strength and resistance to extreme conditions makes them the preferred choice for industries dealing with fluctuating pressures and temperatures.

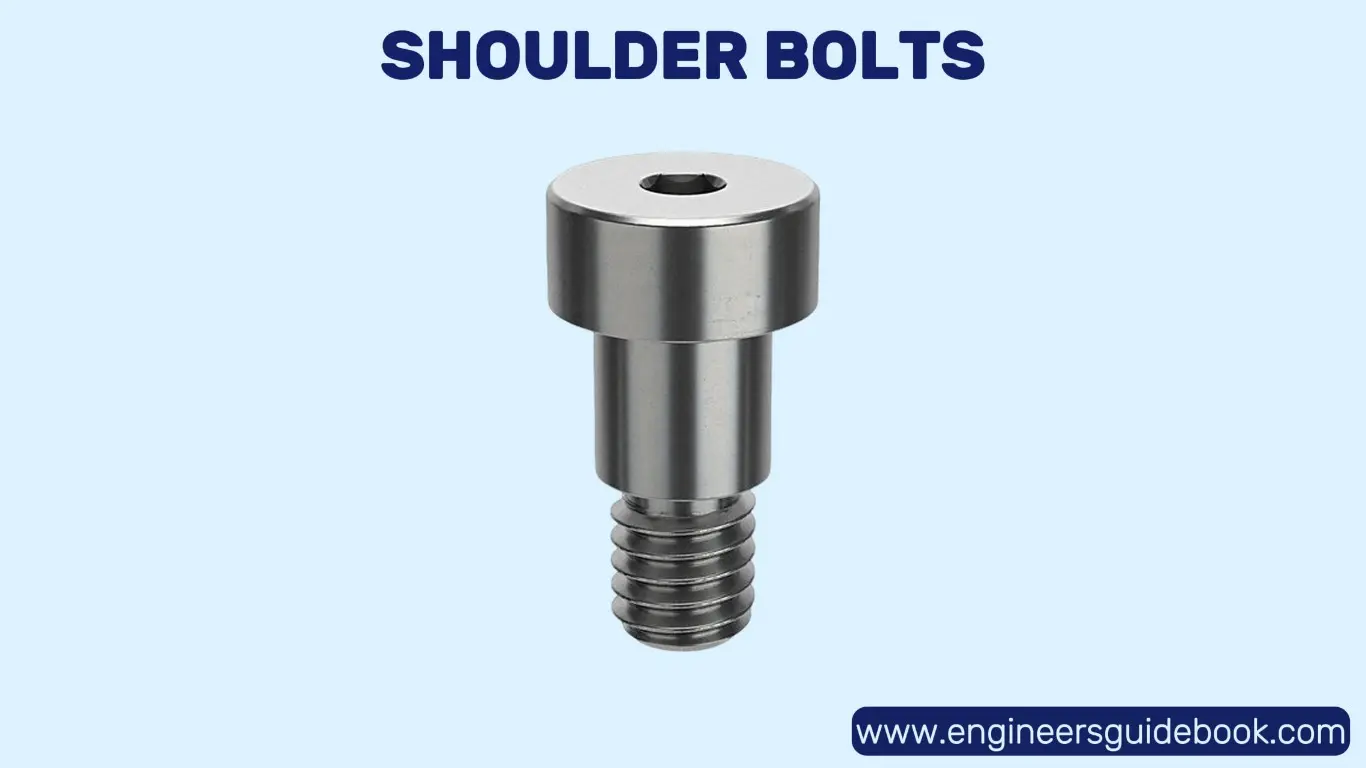

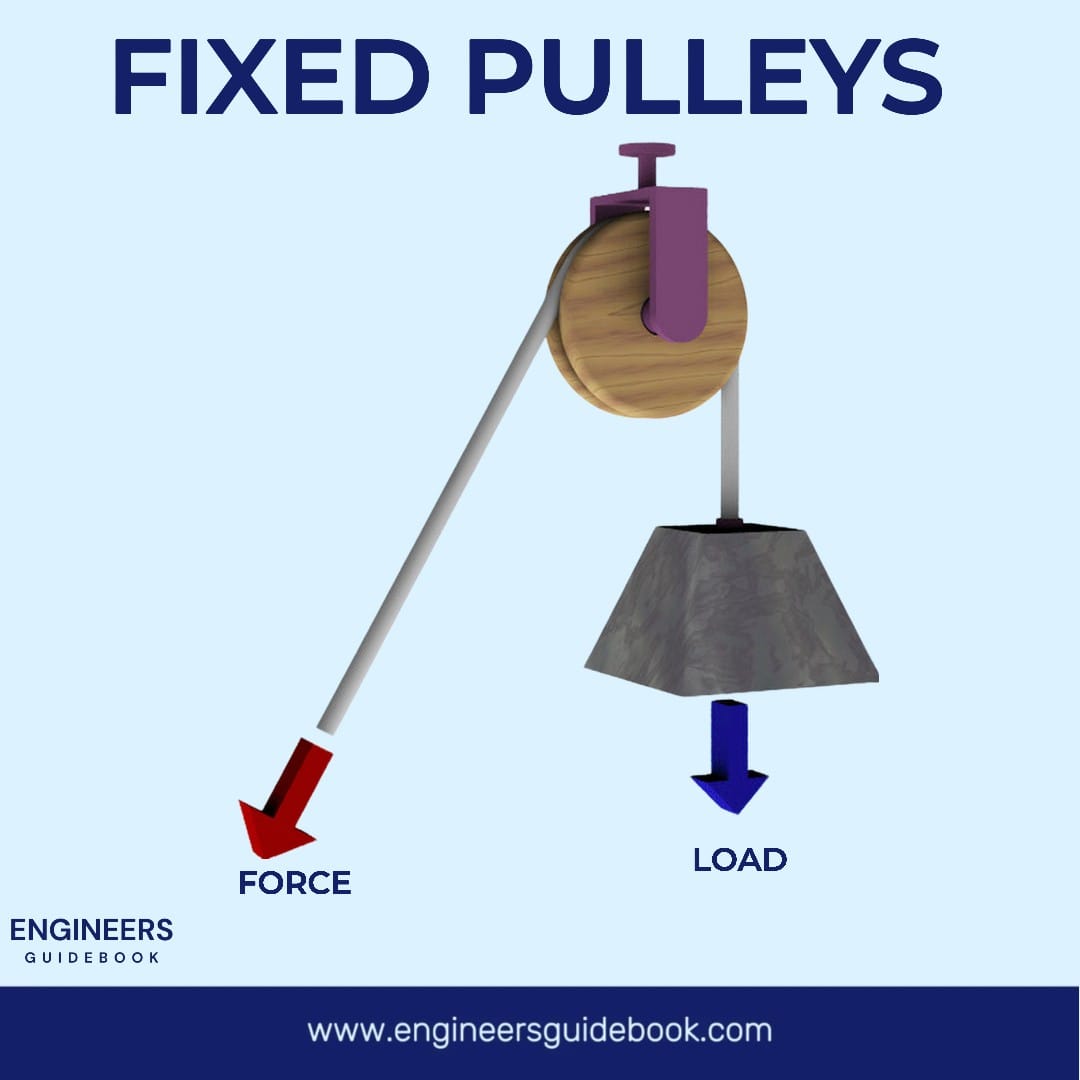

4.10 Shoulder Bolts

Shoulder bolts, also known as stripper bolts, have a distinct unthreaded shoulder between the head and the threaded portion. This design allows for rotational movement, making them ideal for applications requiring precise mechanical motion, such as pulleys, gears, and linkages.

Applications

Due to their precise tolerances, shoulder bolts are extensively used in machinery that requires controlled movement. Industries such as automation, robotics, and aerospace leverage their unique structure to ensure the smooth and reliable operation of mechanical assemblies.

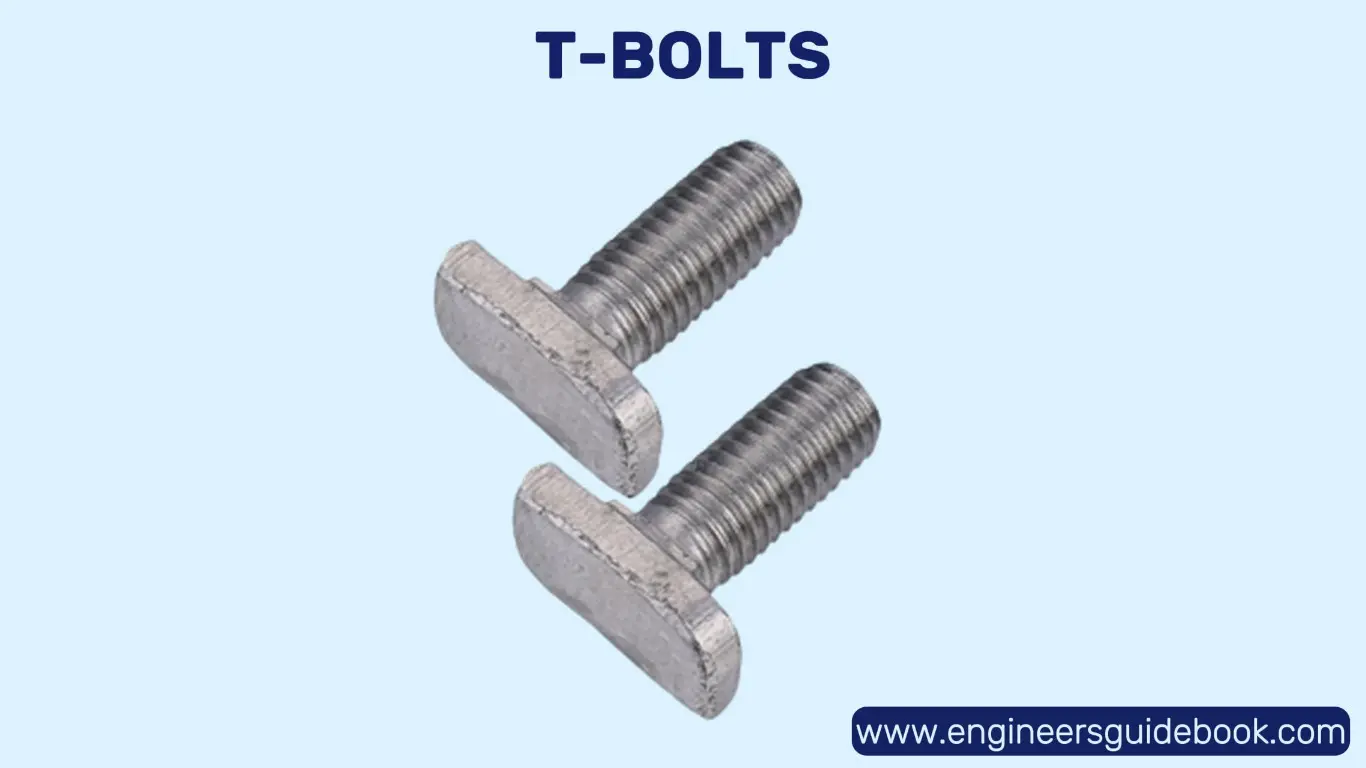

4.11 T-Bolts

T-bolts are designed to slide into T-slot tracks, allowing for fast and secure positioning. Their unique shape enables quick assembly and reconfiguration in modular frameworks, which is crucial for industries requiring adjustable fastening solutions.

Applications

CNC machining, workbenches, and fixture setups rely heavily on T-bolts for their ability to provide stable yet adjustable fastening. These bolts ensure that components can be securely held in place while allowing for easy adjustments when necessary.

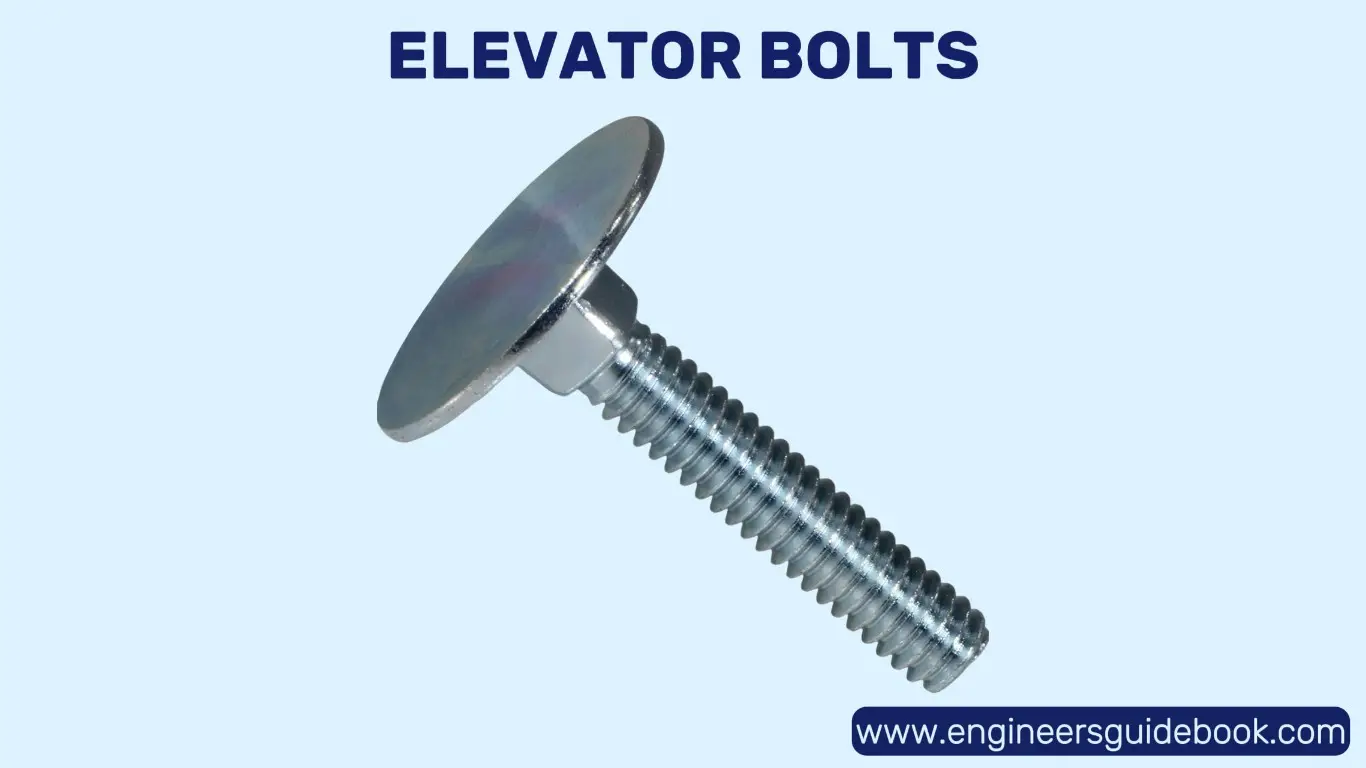

4.12 Elevator Bolts

Elevator bolts are characterized by their broad, flat heads, which help distribute loads evenly across surfaces. This feature makes them particularly suitable for applications where surface integrity is crucial, preventing material damage.

Applications

Industries such as agriculture and material handling depend on elevator bolts for securing conveyor belts. Their flush-mount design prevents snagging and ensures smooth operation in moving systems, reducing the risk of breakdowns.

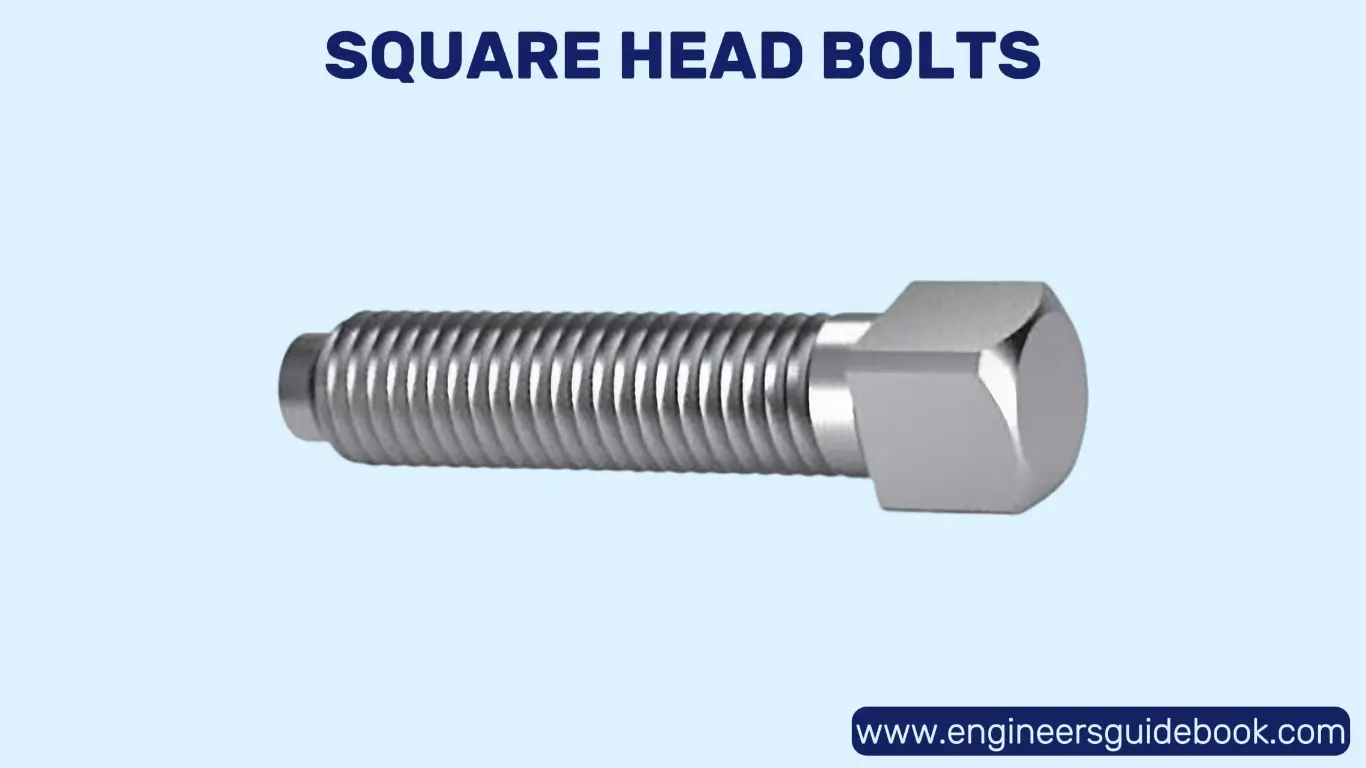

4.13 Square Head Bolts

Once common in the 19th century, square head bolts continue to be used in traditional and restoration projects. Their four-sided heads offer an aesthetic and functional appeal, making them desirable for structural fastening.

Applications

The squared-off design provides a firm grip for wrenches, reducing slippage during tightening and loosening. This feature is particularly beneficial in construction and woodworking applications where torque control is crucial.

4.14 Toggle Bolts

Toggle bolts are designed for securing objects to hollow walls where conventional fasteners fail. Their expanding wing mechanism allows for a strong hold behind wall surfaces, ensuring stability.

Applications

When inserted into a drilled hole, the wings of a toggle bolt expand, distributing weight over a broader area. This mechanism is essential for mounting heavy objects like cabinets, shelves, and television brackets.

4.15 Hanger Bolts

Hanger bolts feature wood screw threads on one end and machine screw threads on the other, allowing them to secure objects to both wood and metal. This versatility makes them an indispensable choice in mixed-material applications.

Applications

Hanger bolts are widely used in furniture assembly, cabinetry, and ceiling suspensions. Their ability to create strong, invisible joints makes them ideal for aesthetic and structural applications.

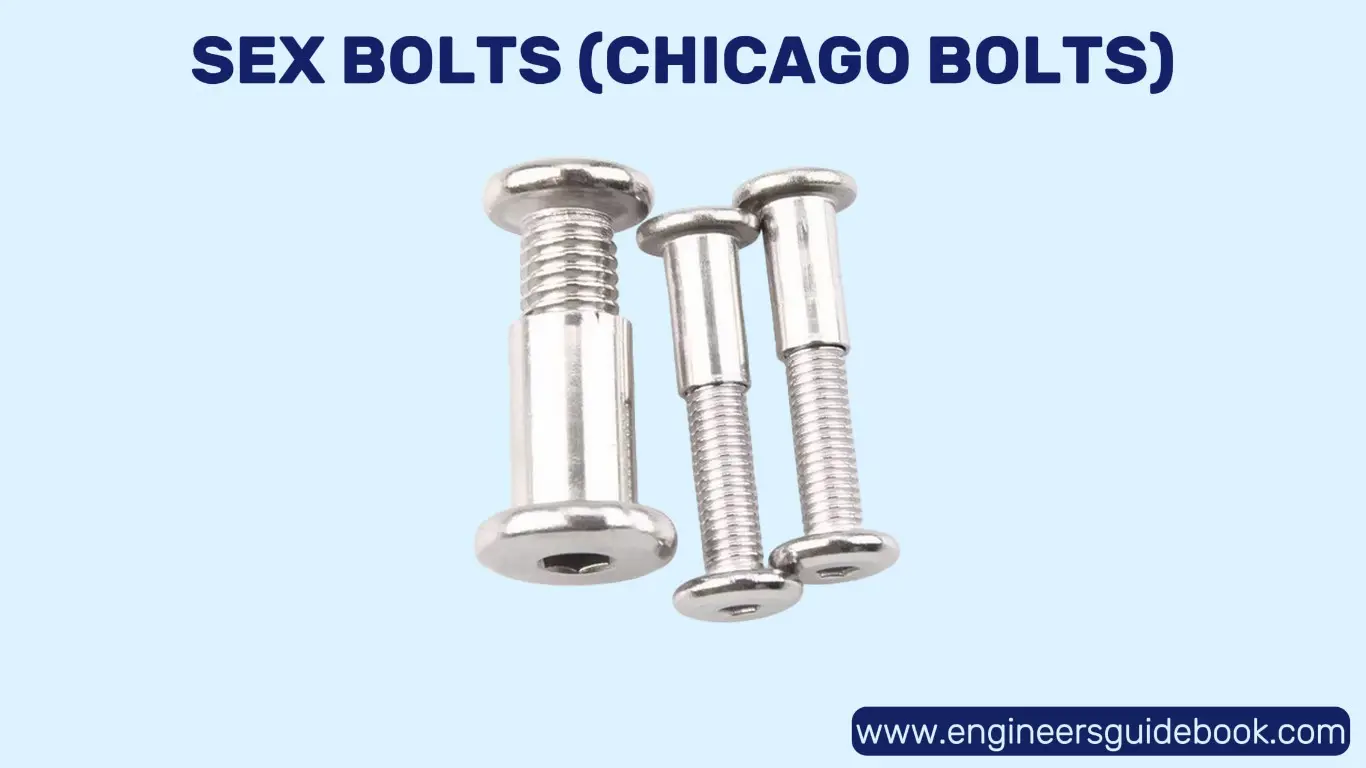

4.16 Sex Bolts (Chicago Bolts)

Sex bolts, also known as Chicago bolts, are two-piece fasteners that provide a seamless finish. Their aesthetic appeal and sturdy construction make them ideal for architectural applications where appearance matters.

Applications

Unlike standard bolts, sex bolts eliminate the need for exposed nuts, creating a sleek and polished look. They are widely used in furniture manufacturing, bookbinding, and signage installations.

4.17 Plow Bolts

Plow bolts feature a countersunk head, allowing them to sit flush with the surface when installed. This design prevents obstruction in moving machinery and ensures a smooth operational flow.

Applications

These bolts are extensively used in earth-moving equipment, such as bulldozers and plows, where durable and flush fasteners are required to withstand extreme forces.

4.18 Hex Tap Bolts

Hex tap bolts are entirely threaded, providing superior holding power. This feature makes them suitable for applications requiring extensive grip strength, such as automotive and industrial machinery.

Applications

Unlike standard hex bolts, which have a partially threaded shank, hex tap bolts feature full threading, offering enhanced flexibility in fastening applications.

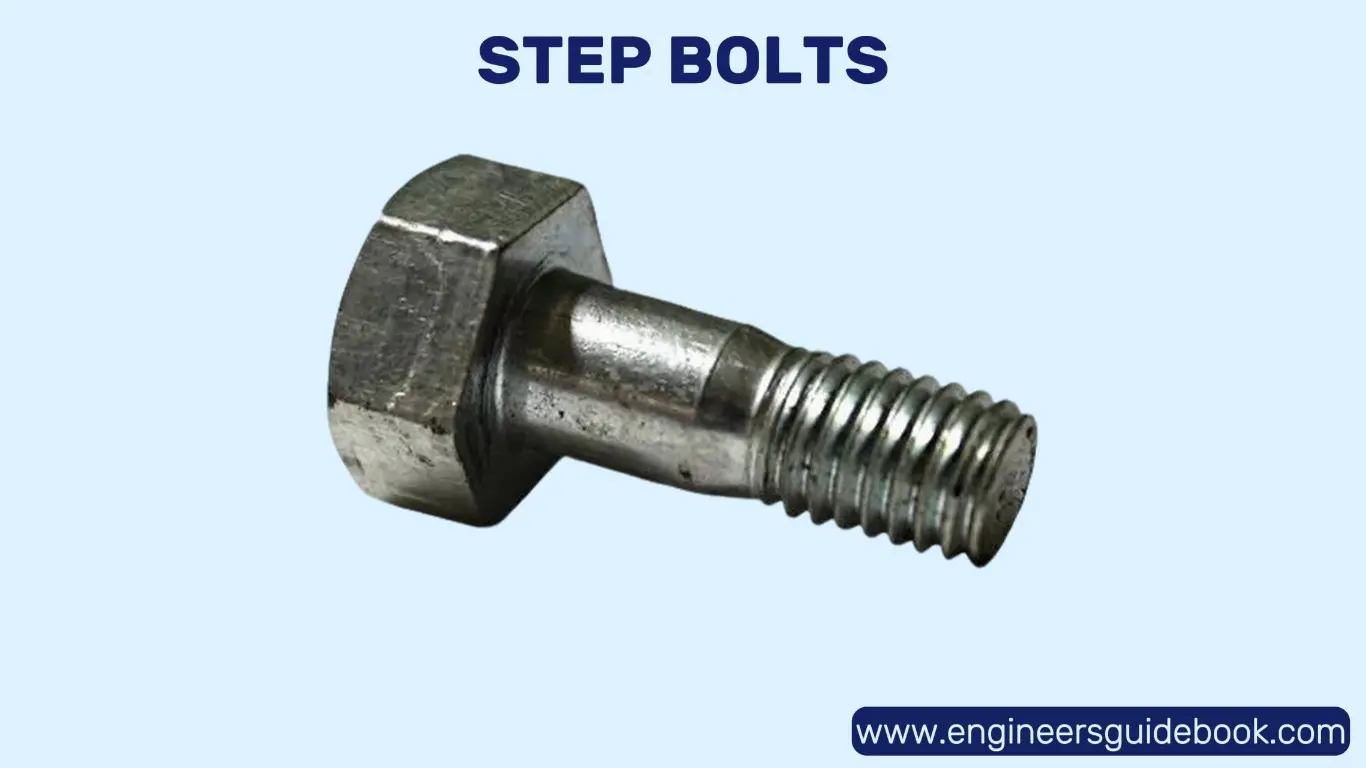

4.19 Step Bolts

Step bolts have a broad, domed head that reduces the risk of foot injuries while providing secure fastening. This feature makes them ideal for walkways and ladder rungs in industrial settings.

Applications

Step bolts are a staple in utility infrastructure, particularly in transmission towers. Their anti-slip design and high strength make them essential for climbing and maintenance operations.

4.20 Rib Neck Bolts

Rib neck bolts feature ribbed sections below the head, preventing them from rotating during installation. This design is particularly beneficial in environments with high vibrations.

Applications

These bolts are commonly used in railway tracks, heavy machinery, and structural frameworks where maintaining a firm grip is critical for operational safety.

5. Advantages of Using Bolts

5.1 Strength and Load-Bearing Capabilities

Bolts provide superior tensile and shear strength compared to other fastening methods such as screws and rivets. Their ability to withstand high loads without deformation makes them indispensable in critical structural applications. Unlike nails or adhesives, bolts offer mechanical interlocking that enhances load distribution and prevents sudden failure under stress.

5.2 Reusability and Ease of Maintenance

Unlike welding or adhesive bonding, bolts allow for easy disassembly and reassembly, making them ideal for structures that require regular maintenance. Their reusability not only reduces material costs but also minimizes downtime in industries where equipment maintenance is frequent. This makes bolts a preferred choice in machinery, automotive, and aerospace applications.

5.3 Corrosion Resistance and Longevity

The lifespan of a bolt largely depends on the material used. Stainless steel, titanium, and galvanized bolts are resistant to oxidation and corrosion, ensuring longevity even in harsh environments. Proper coatings, such as zinc plating or anodization, further enhance their resistance to moisture, chemicals, and extreme temperatures.

5.4 Enhanced Structural Stability

Bolts provide excellent resistance to both dynamic (moving) and static (stationary) forces. Their ability to absorb vibrations and distribute loads evenly makes them essential in heavy machinery, bridges, and high-rise buildings. The use of locking mechanisms, such as lock washers and nylon inserts, prevents loosening under repetitive stress.

6. Applications of Bolts in Various Industries

6.1 Aerospace

The aerospace industry demands bolts that can endure high pressure, temperature fluctuations, and vibrations. High-strength alloy bolts, such as those made from titanium and Inconel, ensure structural integrity in aircraft engines, fuselage assemblies, and landing gear mechanisms.

6.2 Automotive

From chassis assembly to engine components, bolts play a crucial role in automotive manufacturing. High-torque bolts are used in wheel hubs, suspension systems, and transmission assemblies to ensure reliability and safety on the road. Anti-corrosion coatings help extend the lifespan of automotive bolts, especially in regions with harsh weather conditions.

6.3 Construction

Bolts are fundamental to the construction industry, providing essential connections in steel frameworks, bridges, and high-rise buildings. Anchor bolts secure structures to concrete foundations, while high-strength structural bolts reinforce joints in large-scale infrastructure projects.

6.4 Machinery and Equipment

Industrial machinery relies on bolts for assembling rotating and stationary components. Precision-engineered bolts prevent misalignment and enhance operational efficiency in heavy-duty equipment such as turbines, conveyor systems, and hydraulic presses.

6.5 Marine and Offshore

The maritime and offshore industries require bolts that resist saltwater corrosion and extreme environmental conditions. Stainless steel, bronze, and polymer-coated bolts are commonly used in shipbuilding, oil rigs, and underwater pipelines to ensure long-term reliability.

6.6 DIY and Home Improvement

Bolts are widely used in home improvement projects, including furniture assembly, deck construction, and plumbing installations. Their versatility and ease of use make them a staple in hardware stores and workshops for both professionals and DIY enthusiasts.

7. Factors to Consider When Selecting the Right Bolt

7.1 Load Requirements

Choosing the right bolt requires an understanding of its tensile and shear strength. High-load applications, such as structural engineering and industrial machinery, require bolts with high tensile ratings to prevent failure under stress. Shear strength is crucial in applications where lateral forces are significant.

7.2 Environmental Factors

Bolts used in outdoor or high-moisture environments must be resistant to rust and corrosion. Stainless steel, galvanized coatings, and polymer finishes enhance durability in extreme temperatures, humidity, and chemically reactive settings.

7.3 Thread Type and Pitch

Thread design impacts the efficiency of bolt fastening. Coarse threads provide better grip in soft materials like wood, while fine threads offer higher strength in metal applications. Understanding thread pitch and compatibility with nuts ensures optimal performance.

7.4 Bolt Grades and Strength Ratings

Standardized grading systems, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), classify bolts based on their material strength and intended use. High-strength bolts (e.g., Grade 8, 12.9) are used in heavy machinery, while lower-grade bolts (e.g., Grade 2) are suitable for general applications.

8. Conclusion

Selecting the correct bolt requires careful consideration of load requirements, environmental factors, and material properties. By understanding these variables, engineers and builders can ensure structural integrity and safety in their projects.

Proper installation techniques, including torque control, pre-load tensioning, and the use of locking mechanisms, enhance bolt performance. Routine inspection and maintenance prevent premature failure and extend the lifespan of bolted connections.

Advancements in bolt technology, such as smart fasteners with embedded sensors, self-locking designs, and eco-friendly materials, are revolutionizing the industry. These innovations promise increased efficiency, sustainability, and reliability in engineering and construction applications.

3 Responses

Nut and bolts are important parts of machine in industrya nd this article gives all the information for the selsection of the these parts. i would say i am impressfrom your writing. keep it up

can you explain in depth and also share your email i have some questions

Some genuinely good articles on this website , thanks for contribution.