1. Introduction

Electrical safety is a fundamental aspect of circuit design and maintenance, ensuring the protection of both equipment and human life. The risk of electrical faults, including short circuits, overloads, and power surges, can lead to catastrophic failures, fires, and electrocution hazards. Implementing protective devices is essential to mitigate these risks, making electrical safety a crucial consideration in residential, commercial, and industrial applications.

Fuses serve as frontline protectors in electrical circuits by preventing excessive current from flowing through sensitive components. By design, they act as sacrificial devices that break the circuit when an overcurrent situation arises, effectively halting electrical damage. This simple yet vital component ensures the longevity of electrical systems while maintaining safe operating conditions.

This guide provides an in-depth exploration of electrical fuses, detailing their working principles, classifications, and applications. By understanding fuses comprehensively, electrical engineers, technicians, and enthusiasts can make informed decisions when selecting and implementing them in various circuits.

2. What Is an Electrical Fuse?

2.1 Definition and Basic Concept

An electrical fuse is a protective device designed to safeguard circuits by breaking the electrical connection when excessive current flows through it. This prevents overheating, damage to components, and potential fire hazards. Typically, a fuse consists of a metal wire or strip that melts when subjected to high current levels beyond its rated capacity.

2.2 Historical Background and Evolution of Fuses

The concept of fuses dates back to the early days of electrical engineering when Thomas Edison introduced them in the late 19th century as part of his DC power distribution system. Over time, fuse technology has evolved to accommodate increasing power demands, leading to advancements such as high-rupturing capacity (HRC) fuses, resettable fuses, and miniaturized fuse designs for electronic circuits.

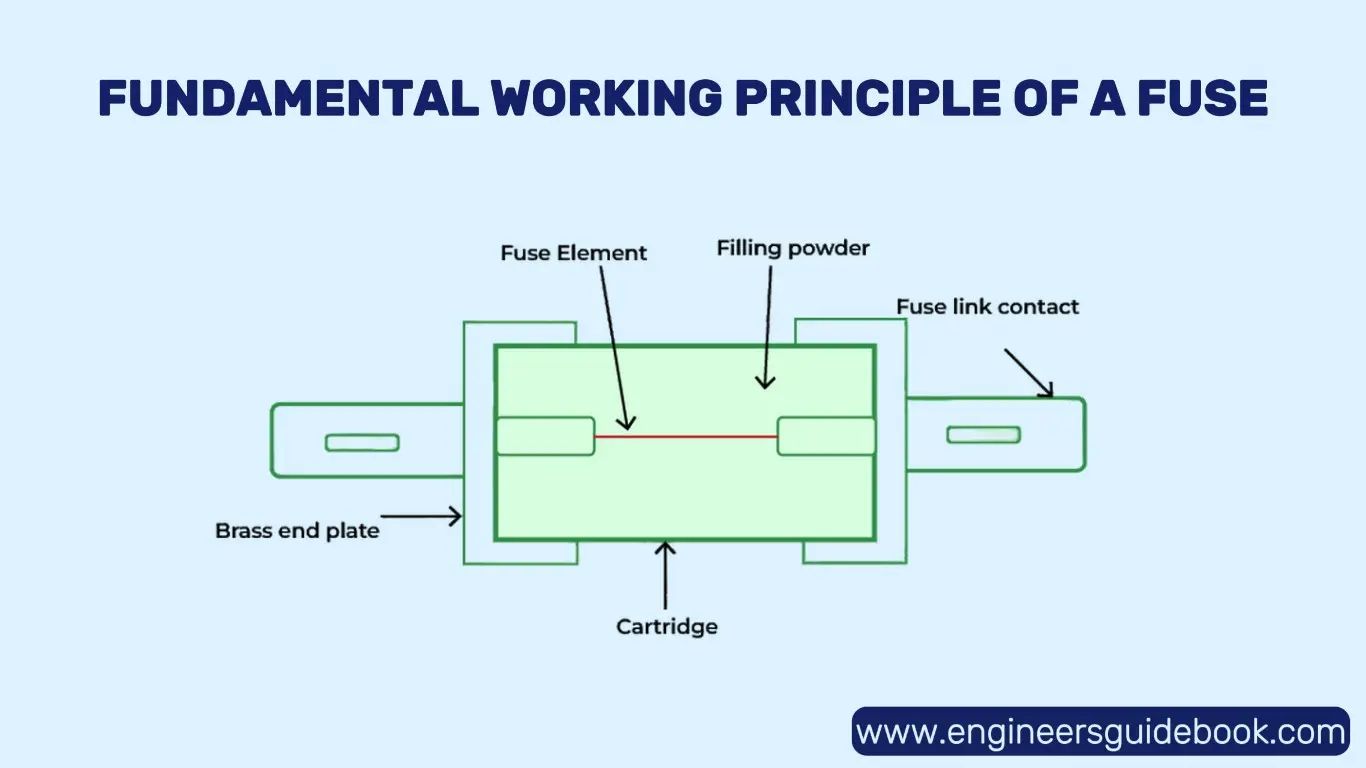

3. The Fundamental Working Principle of a Fuse

3.1 How a Fuse Interrupts Excessive Current Flow

When current exceeds a fuse’s rated capacity, the increased resistance generates heat, causing the fuse element to melt. This action creates an open circuit, preventing further current flow and protecting downstream components from damage.

3.2 The Melting Mechanism and Role of Fuse Elements

The fuse element, usually made of materials like tin, silver, or copper, is engineered to melt at a predetermined temperature. Factors such as element thickness, material properties, and ambient temperature influence the response time and effectiveness of a fuse in an electrical system.

3.3 Differences Between Fuses and Circuit Breakers

While both fuses and circuit breakers serve the same protective function, fuses are single-use devices that require replacement after operation, whereas circuit breakers can be reset. Fuses respond rapidly to overcurrent conditions, making them preferable in applications where precise and instantaneous protection is needed.

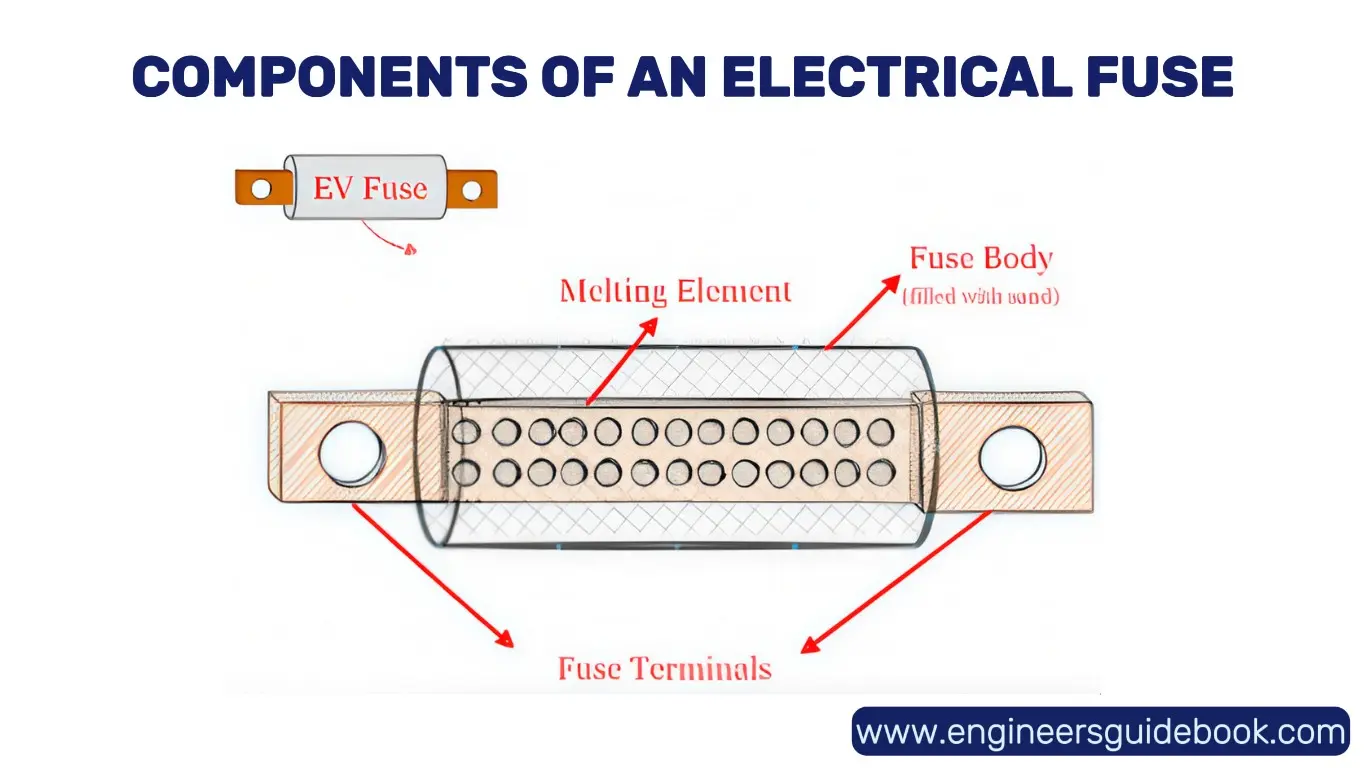

4. Key Components of an Electrical Fuse

4.1 Fuse Element

The fuse element is the primary component responsible for breaking the circuit in case of excessive current. It is engineered with precise melting characteristics to ensure reliability.

4.2 Casing and Housing Materials

Fuse casings are typically made from non-conductive materials such as ceramic, glass, or plastic. These materials offer insulation and heat resistance, preventing external damage and ensuring operational safety.

4.3 Contacts and Terminals for Electrical Connection

The fuse’s contacts establish electrical continuity within the circuit. High-quality metallic contacts ensure minimal resistance and effective current transfer while facilitating secure installation.

4.4 Indicator Mechanism in Modern Fuses

Many contemporary fuses incorporate visual or electronic indicators to signal when they have blown, simplifying troubleshooting and maintenance processes.

5. Classification of Electrical Fuses

5.1 Based on Application: Industrial, Residential, and Automotive

Fuses vary based on their intended application, with industrial fuses designed for high-power machinery, residential fuses used in home electrical systems, and automotive fuses protecting vehicle circuits.

5.2 Based on Operating Characteristics: Fast-Acting vs. Slow-Blow

Fast-acting fuses respond immediately to overcurrent conditions, whereas slow-blow fuses tolerate short-duration surges before tripping, making them ideal for motor-driven devices.

5.3 Based on Voltage Ratings: Low Voltage vs. High Voltage Fuses

Low-voltage fuses are suitable for household applications, while high-voltage fuses are utilized in power transmission and heavy industrial settings.

5.4 Based on Fuse Design: Cartridge, Resettable, and Plug Fuses

Different fuse designs cater to specific needs, such as cartridge fuses for industrial use, resettable fuses for electronics, and plug fuses for domestic installations.

6. Types of Electrical Fuses and Their Uses

6.1 Rewirable Fuses:

Rewirable fuses feature a replaceable wire element, commonly found in older domestic electrical installations.

6.2 Cartridge Fuses:

Cartridge fuses, housed in cylindrical casings, are widely used in industrial circuits for their reliability and ease of replacement.

6.3 Blade Fuses:

Blade fuses, characterized by flat metal terminals, are commonly used in automobiles to protect electrical systems efficiently.

6.4 HRC (High Rupturing Capacity) Fuses:

HRC fuses are designed to handle high fault currents, ensuring safe operation in industrial and power distribution systems.

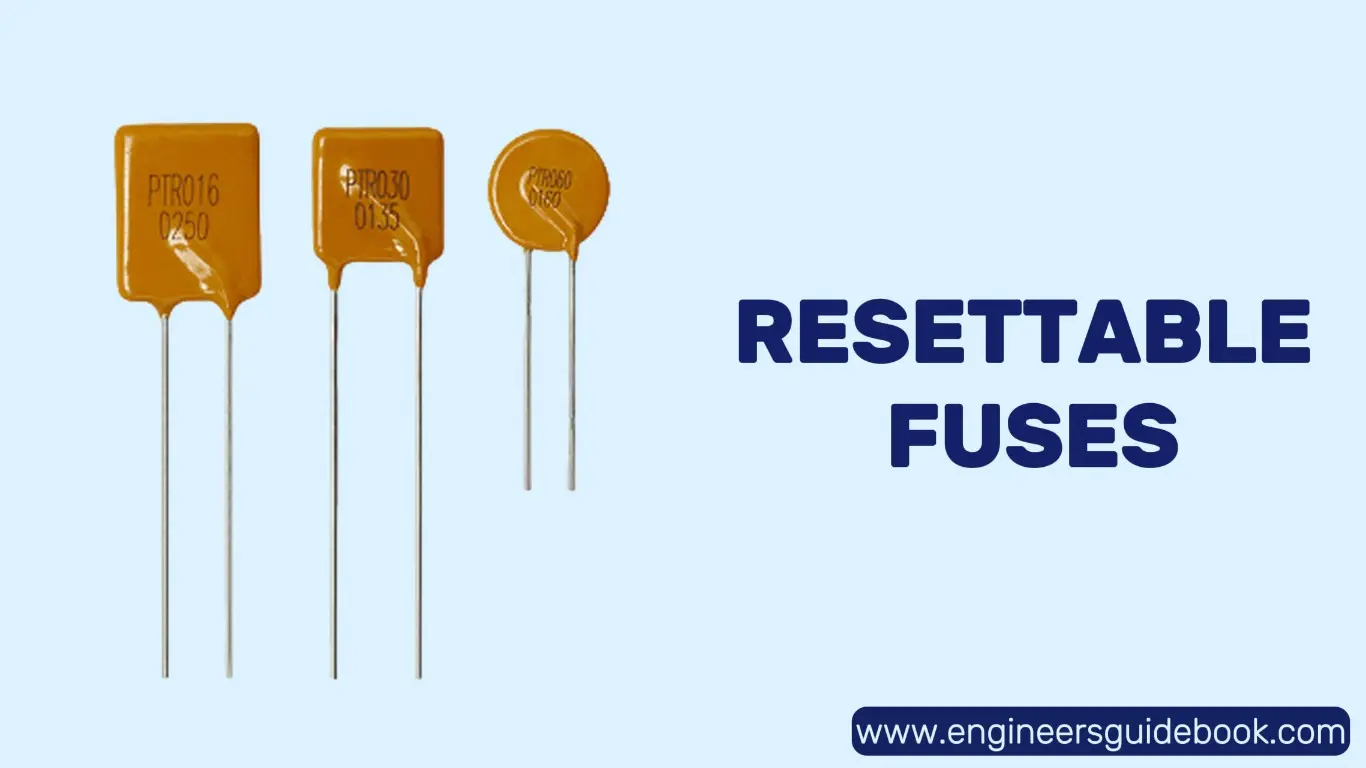

6.5 Resettable Fuses (PTC Fuses):

Polymeric Positive Temperature Coefficient (PTC) fuses automatically reset after cooling down, making them ideal for modern electronic applications.

6.6 Thermal Fuses:

Thermal fuses disconnect circuits in response to excessive temperature buildup, preventing overheating-related failures.

7. How Do Electrical Fuses Work in a Circuit?

7.1 Normal Operation vs. Overcurrent Situations

Under normal operating conditions, an electrical fuse allows current to flow through its conductive element without interruption. However, when an overcurrent situation arises due to a short circuit or excessive load, the fuse’s internal resistance generates heat, leading to the melting of the fuse element. This intentional failure disconnects the circuit, preventing further damage to electrical components.

7.2 Heat Generation and Fuse Melting Process

Fuses operate on the principle of thermal energy conversion. As electrical current passes through the fuse, it encounters slight resistance, causing minimal heat generation. When the current surpasses the rated threshold, heat accumulates rapidly, reaching the fuse element’s melting point. The material composition of the fuse, typically a low-melting-point alloy, ensures a precise and predictable melting response to overcurrent conditions.

7.3 Breaking the Circuit and Preventing Electrical Damage

Once the fuse element melts, the electrical circuit is physically broken, halting the flow of current instantaneously. This interruption prevents overheating, fire hazards, and potential equipment failure. Unlike circuit breakers, which can be reset, fuses require replacement after activation, ensuring that electrical faults are not bypassed inadvertently.

7.4 How Different Fuse Types Respond to Overloads

Different fuse types exhibit varying responses to overload conditions. Fast-acting fuses respond almost instantly to overcurrent events, making them ideal for protecting sensitive electronics. In contrast, time-delay fuses, also known as slow-blow fuses, tolerate temporary current surges, such as those caused by motor startups, without unnecessary activation. Selecting the appropriate fuse type is crucial for achieving optimal circuit protection.

8. Fuse Ratings and Their Significance

8.1 Current Rating:

The current rating of a fuse determines the maximum continuous current it can carry without melting. Selecting a fuse with an appropriate current rating ensures that normal operating conditions do not lead to premature failure while providing reliable protection against sustained overcurrent scenarios.

8.2 Voltage Rating:

A fuse’s voltage rating specifies the maximum circuit voltage it can safely interrupt. Using a fuse with an insufficient voltage rating may result in arcing and incomplete circuit disconnection. High-voltage fuses are engineered with advanced insulation and arc-extinguishing mechanisms to handle elevated voltage levels safely.

8.3 Breaking Capacity:

The breaking capacity, or interrupting rating, defines the maximum fault current a fuse can safely interrupt without sustaining damage. Fuses with low breaking capacities may rupture violently under high fault currents, posing a safety risk. Industrial and power system fuses typically feature high breaking capacities to withstand extreme fault conditions.

8.4 Response Time:

The response time of a fuse determines how quickly it reacts to overcurrent situations. Fast-acting fuses provide immediate protection for sensitive components such as semiconductors and precision electronics. Time-delay fuses accommodate transient surges, such as motor inrush currents, without unnecessary operation. Understanding response characteristics is essential for selecting a fuse that balances protection with circuit functionality.

9. Factors Affecting Fuse Performance

9.1 Ambient Temperature and Environmental Conditions

The performance of an electrical fuse is significantly influenced by its surrounding environment. Elevated ambient temperatures can cause a fuse to operate closer to its melting point, reducing its lifespan and increasing the likelihood of premature failure. Conversely, extremely low temperatures may cause the fuse material to become brittle, affecting its response time. Environmental factors such as humidity, vibration, and exposure to corrosive elements can degrade fuse contacts and housing, leading to unreliable performance over time.

9.2 Load Characteristics and Electrical Demand Variations

Fluctuations in electrical load directly impact fuse operation. Continuous overloading beyond the rated capacity accelerates wear, while sudden surges, such as those caused by inductive loads, can create transient currents that stress the fuse element. Non-linear loads, including those from switching power supplies and variable frequency drives, introduce harmonics that may lead to localized heating and unpredictable fuse behavior.

9.3 Material Composition and Fuse Quality Standards

The composition of a fuse element determines its melting characteristics and reliability. High-quality fuses utilize precisely formulated alloys that ensure consistent performance. Compliance with industry standards such as IEC, UL, and ANSI guarantees that fuses meet stringent safety and durability criteria. Substandard materials or manufacturing defects can result in inconsistent blow times and potential safety hazards.

9.4 Installation Position and Contact Resistance

The positioning of a fuse within a circuit influences its thermal dissipation and electrical conductivity. Poorly secured fuse connections introduce contact resistance, generating localized heating that can degrade performance. Properly mounted fuses with minimal resistance ensure efficient current flow and reliable protection against overcurrent conditions.

10. Installation and Replacement of Electrical Fuses

10.1 How to Properly Select a Fuse for Your Circuit

Choosing the correct fuse involves evaluating parameters such as current rating, voltage rating, and breaking capacity. The fuse must be appropriately rated to handle normal operating conditions while providing adequate protection against faults. Additionally, factors such as response time (fast-acting vs. time-delay) should be considered based on the application requirements.

10.2 Step-by-Step Guide to Installing a New Fuse

- Disconnect the power supply to prevent electrical shock.

- Identify the faulty fuse and verify its specifications.

- Ensure the replacement fuse matches the required ratings.

- Securely place the fuse into its holder, ensuring firm contact.

- Restore power and test circuit functionality.

10.3 Safety Precautions When Replacing a Blown Fuse

Always use insulated tools and wear appropriate personal protective equipment (PPE). Ensure that the circuit is completely de-energized before replacement. Verify the cause of fuse failure to prevent recurring issues. Avoid touching metallic contacts directly to reduce the risk of electric shock.

10.4 Common Mistakes to Avoid During Fuse Installation

Installing a fuse with an incorrect rating can lead to circuit instability. Loose connections increase resistance, causing excessive heating. Replacing a fuse without identifying the root cause of failure may result in repeated blowouts, potentially damaging connected equipment.

11. How to Identify a Blown Fuse

11.1 Visual Signs of a Blown Fuse

A blown fuse often exhibits visible signs such as a broken filament, discoloration, or burn marks on the fuse body. In cartridge-type fuses, the presence of soot or melted glass indicates an overcurrent event.

11.2 Using a Multimeter to Test Fuse Continuity

Set the multimeter to the continuity mode and place the probes on both fuse terminals. A functional fuse will show near-zero resistance, while a blown fuse will display infinite resistance or no continuity.

11.3 Differences Between a Faulty Fuse and a Wiring Issue

A non-functional circuit does not always indicate a blown fuse. Damaged wiring, loose connections, or faulty components can mimic fuse failure. Systematically testing the circuit elements can help differentiate between fuse failure and other electrical faults.

12. Consequences of Using the Wrong Fuse

12.1 Risks of Underrated Fuses:

Using a fuse with a lower current rating than required results in frequent failures, disrupting operations and increasing maintenance costs.

12.2 Dangers of Overrated Fuses:

An overrated fuse allows excessive current to flow, defeating its protective function. This can lead to overheating of conductors and components, posing fire risks.

13. Advantages of Using Fuses in Electrical Circuits

- Fuses offer an economical means of safeguarding electrical systems against excessive current.

- Fuses operate passively, providing fail-safe protection without requiring external intervention.

- Their rapid response to overcurrent conditions helps prevent catastrophic failures and minimizes fire hazards.

- Fuses are available in diverse sizes and ratings, making them suitable for applications ranging from microelectronics to industrial power systems.

14. Limitations of Electrical Fuses

- Unlike circuit breakers, fuses require replacement after operation, increasing maintenance efforts.

- Certain advanced circuit breakers react faster to transient faults than conventional fuses.

- Fuses may not be suitable for large-scale industrial applications requiring instantaneous fault isolation.

- The disposal of used fuses contributes to electronic waste, raising sustainability concerns.

15. Electrical Fuse vs. Circuit Breaker: Key Differences

15.1 Functional Distinctions Between Fuses and Circuit Breakers

Fuses rely on thermal melting, while circuit breakers use mechanical tripping mechanisms.

15.2 Speed and Efficiency of Protection Mechanisms

Circuit breakers can be reset, whereas fuses must be replaced after a fault.

15.3 Cost Comparison and Maintenance Requirements

Fuses are cost-effective upfront but require replacement, whereas circuit breakers have a higher initial cost but lower recurring expenses.

15.4 When to Use a Fuse and When to Use a Circuit Breaker

Fuses are ideal for low-cost applications with predictable faults, while circuit breakers are preferred for dynamic electrical systems requiring resettable protection.

16. Applications of Electrical Fuses in Various Industries

Residential Electrical Systems:

Electrical fuses play a crucial role in residential applications, safeguarding household wiring and appliances from overcurrent conditions. In home distribution panels, fuses prevent electrical fires by interrupting excessive current flow. Appliances such as air conditioners, refrigerators, and microwave ovens incorporate fuses to protect their internal circuitry from power surges and short circuits. The simplicity and reliability of fuses make them an integral component of residential electrical safety.

Automotive Industry:

Automobiles rely on fuses to shield intricate electrical components from damage. Modern vehicles are equipped with multiple fuse boxes containing blade-type and cartridge fuses that protect circuits associated with lighting, infotainment systems, ignition, and power windows. Automotive fuses are specifically designed to handle vibration, temperature variations, and transient voltage spikes, ensuring uninterrupted operation of essential vehicle functions.

Industrial Machinery and Power Plants:

Heavy-duty fuses are employed in industrial settings to safeguard machinery, motor drives, and high-power electrical equipment. Factories, processing plants, and power generation facilities utilize high-capacity fuses to protect transformers, switchgear, and control panels from overcurrent faults. The rapid response of industrial-grade fuses prevents catastrophic failures, minimizing downtime and reducing the risk of fire hazards in high-energy environments.

Renewable Energy Systems:

Renewable energy systems, such as solar photovoltaic (PV) installations and wind turbines, require specialized fuses to handle fluctuating power levels. DC-rated fuses are commonly used in solar arrays to protect battery storage units and inverters from electrical overloads. Wind energy systems integrate fuses within control circuits and power transmission lines to ensure system reliability and longevity. The evolving landscape of renewable energy demands advanced fuse technologies to enhance efficiency and safety.

17. National and International Standards for Fuses

17.1 IEC and ANSI Standards for Electrical Fuses

The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) establish global benchmarks for fuse performance and safety. These standards define parameters such as breaking capacity, response time, and thermal characteristics, ensuring uniformity in fuse applications across different regions and industries.

17.2 UL Certification and Safety Compliance

Underwriters Laboratories (UL) certification guarantees that fuses comply with stringent safety and quality requirements. UL-listed fuses undergo rigorous testing to verify their ability to interrupt fault currents effectively. Compliance with UL standards is crucial for electrical products sold in North America, assuring users of their reliability and fire resistance.

17.3 Industry-Specific Regulations for Fuse Applications

Various industries impose sector-specific regulations on fuse implementation. The automotive sector follows ISO standards for vehicular fuses, while the telecommunications industry adheres to NEBS (Network Equipment-Building System) standards. Aviation and defense applications require compliance with MIL-SPEC fuse specifications to ensure high-reliability performance under extreme conditions.

18. Conclusion

Electrical fuses serve as fundamental protective devices, preventing overcurrent conditions from damaging electrical circuits. Their diverse applications span residential, industrial, automotive, and renewable energy sectors, demonstrating their universal significance in electrical safety.

Routine inspection and maintenance of fuses ensure their continued effectiveness. Checking for signs of wear, corrosion, or improper installation can prevent potential failures and enhance the longevity of electrical systems.

Adopting best practices in fuse selection, installation, and replacement is crucial for maintaining electrical safety. Awareness of fuse ratings, compliance with regulatory standards, and proactive maintenance contribute to a secure and efficient electrical infrastructure.

19. FAQS

How Do I Choose the Right Fuse for My Circuit?

Selecting the appropriate fuse requires consideration of voltage rating, current rating, and breaking capacity. The fuse must match the operational characteristics of the circuit while providing adequate protection against transient and sustained overcurrent events.

Can I Replace a Blown Fuse with a Wire or Coin?

Substituting a blown fuse with a wire or coin is extremely hazardous and should never be attempted. Doing so eliminates the circuit’s protective mechanism, increasing the risk of electrical fires, equipment damage, and severe injury.

Why Does My Fuse Keep Blowing Repeatedly?

Frequent fuse blowouts indicate underlying electrical faults such as short circuits, overloaded circuits, or defective components. Diagnosing the root cause and addressing the issue is essential before replacing the fuse to prevent recurring failures.

Are There Fuses That Can Be Reset Instead of Replaced?

Yes, resettable fuses, such as polymeric positive temperature coefficient (PPTC) fuses, automatically restore their functionality after a fault is cleared. These self-resetting fuses are commonly used in electronic circuits, automotive applications, and battery protection systems.

6 Responses

Great knowledge on the electrical fuses. Shared your article with others

Very nice article. Good knowledge for professionals

Much appriciated that you have pick that topic and explain it well. looking forword to reading your other articles too

excellent article on this topic. good knowlege for all engineers. i have share this article on my social media.

Remcomended

very good explaintion I have read other articles as well. your knowledge is good

You actually make it seem so easy with your presentation but I find this matter to be really something which I think I would never understand. It seems too complex and very broad for me. I’m looking forward for your next post, I’ll try to get the hang of it!