1. Introduction

1.1 Overview of Inductors in Electrical and Industrial Applications

Inductors are fundamental components in electrical circuits, crucial in various industrial applications. These passive devices, typically consisting of a coil of wire wound around a core, are designed to store energy in a magnetic field when electrical current passes through them. Their ability to oppose changes in current flow makes them indispensable in power electronics, telecommunications, and signal processing systems. In this guide, we will discuss in detail the types of inductors and their industrial uses.

1.2 Importance of Inductors in Modern Technology

Inductors are the backbone of modern electrical engineering, enabling advancements in automation, renewable energy systems, and high-frequency communications. Their usage spans industries, from automotive powertrains to medical imaging equipment, highlighting their adaptability. By mitigating electromagnetic interference (EMI) and stabilizing power supplies, inductors contribute to the reliability and efficiency of electronic circuits.

1.3 Key Principles Behind Inductor Functionality

At their core, inductors operate based on Faraday’s Law of Electromagnetic Induction. When current flows through the coil, a magnetic field is generated, which, upon fluctuation, induces a voltage opposing the change. This property, known as inductance, dictates an inductor’s effectiveness in storing energy, filtering signals, and regulating current flow in various electronic circuits.

2. Understanding Inductors

2.1 What is an Inductor? – The Basics of Electromagnetic Induction

An inductor is a fundamental passive electrical component designed to resist changes in current by inducing an opposing voltage. This property makes inductors essential in designing transformers, power supplies, and radio-frequency applications. Their behavior is dictated by their inductance value, measured in henries (H), which determines their ability to store magnetic energy.

2.2 Key Components of an Inductor – Core, Coil, and Magnetic Field

Inductors primarily consist of three components:

- Coil: A wire wound in a helical shape to facilitate magnetic field generation.

- Core: A material, often air, iron, or ferrite, which influences the inductance value and efficiency.

- Magnetic Field: An invisible force generated around the coil when current flows through it, crucial for energy storage and signal modulation.

2.3 How Inductors Store and Release Energy in Electrical Circuits

Inductors function by storing electrical energy in the form of a magnetic field when current flows through them. When the current is interrupted, the collapsing magnetic field induces a voltage that maintains the circuit’s current flow. This energy exchange mechanism makes inductors integral to filters, transformers, and oscillatory circuits.

3. Classification of Inductors Based on Core Material

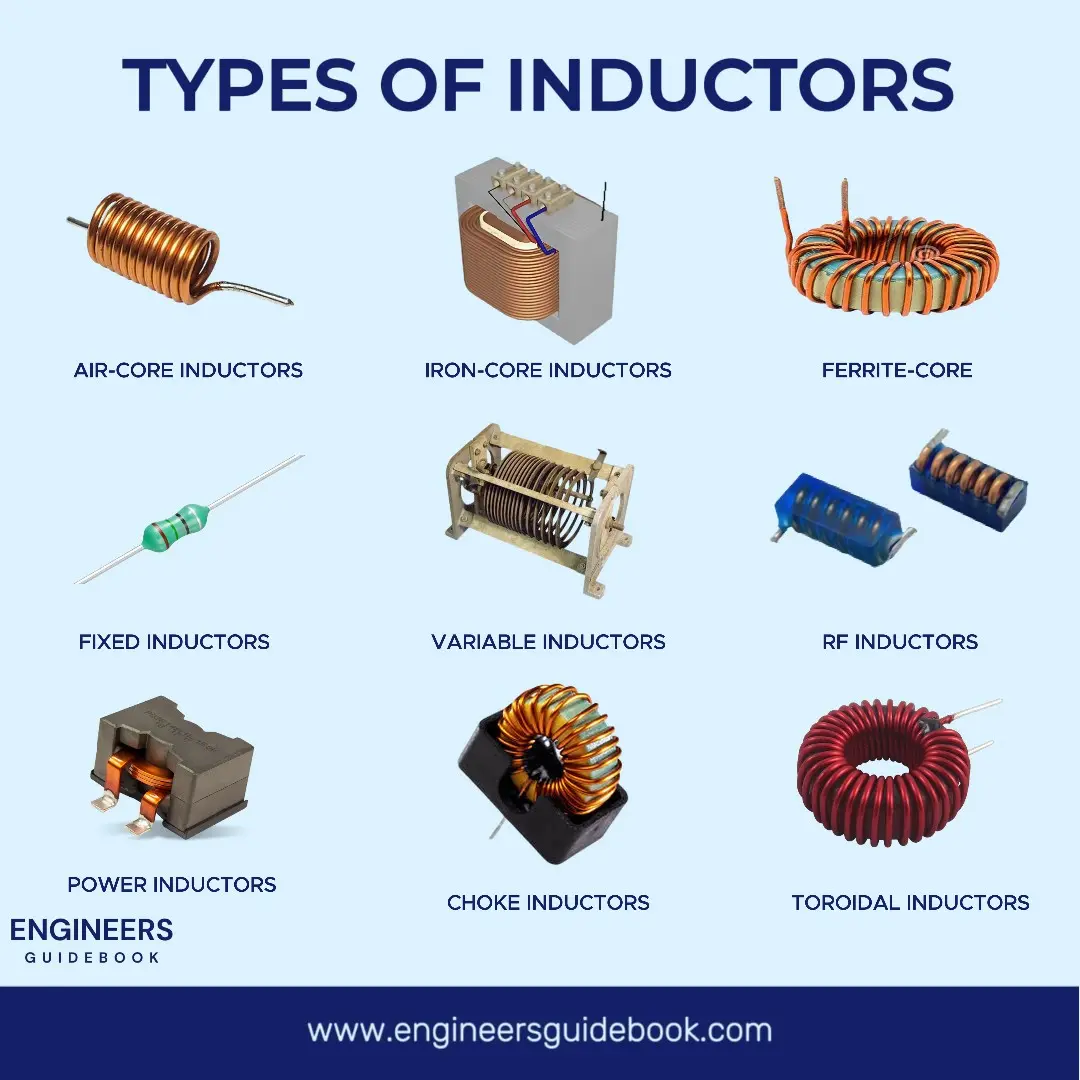

3.1 Air-Core Inductors

Air-core inductors, devoid of ferromagnetic material, offer minimal core losses and are ideal for high-frequency applications such as RF communication and signal processing. Their lightweight design and reduced magnetic saturation make them a preferred choice in circuits requiring minimal distortion.

3.2 Iron-Core Inductors

Iron-core inductors utilize iron or laminated iron as their core material, significantly enhancing magnetic permeability and inductance. These inductors are commonly found in transformers, industrial power supplies, and audio frequency applications, where high efficiency and reduced energy loss are paramount.

3.3 Ferrite-Core Inductors

Ferrite-core inductors employ a ceramic-like ferromagnetic material that efficiently suppresses high-frequency noise. Their ability to operate over a broad frequency range makes them essential in EMI filtering, radio transmission, and power conditioning applications.

3.4 Powdered-Iron Core Inductors

Powdered-iron core inductors, composed of compressed iron particles bound together, offer a balance between performance and cost. These inductors provide moderate permeability while minimizing eddy current losses, making them suitable for DC-DC converters and inverter circuits.

4. Types of Inductors and Their Specific Characteristics

4.1 Fixed Inductors

Fixed inductors possess a constant inductance value, ensuring stability in electrical circuits. They are widely used in filters, impedance-matching networks, and energy storage applications where predictable performance is required.

4.2 Variable Inductors

Variable inductors feature an adjustable core position, allowing fine-tuning of inductance values. These inductors are crucial in applications like tuning circuits and oscillators, where real-time frequency adjustments are necessary.

4.3 RF Inductors

RF inductors are optimized for radio-frequency applications, characterized by their minimal parasitic capacitance and resistance. They play a vital role in antennas, signal amplification, and impedance matching circuits in wireless communication systems.

4.4 Power Inductors

Power inductors are designed to withstand high current loads while minimizing energy loss. Their robust construction and thermal stability make them indispensable in power electronics, including DC-DC converters and battery charging systems.

4.5 Choke Inductors

Choke inductors, or simply chokes, are specialized inductors designed to filter out high-frequency noise while allowing DC or low-frequency signals to pass. They are essential in power supply circuits, motor controllers, and audio equipment to enhance signal purity.

4.6 Toroidal Inductors

Toroidal inductors, characterized by their doughnut-shaped core, offer high inductance with minimal electromagnetic interference. Their compact design and efficient energy transfer make them a preferred choice for power transformers and energy storage applications.

4.7 Multi-Layer Inductors

Multi-layer inductors are constructed by stacking multiple conductive layers within a compact structure, optimizing space usage in densely populated circuit boards. These inductors are prevalent in smartphones, wearable devices, and medical implants, where miniaturization is critical.

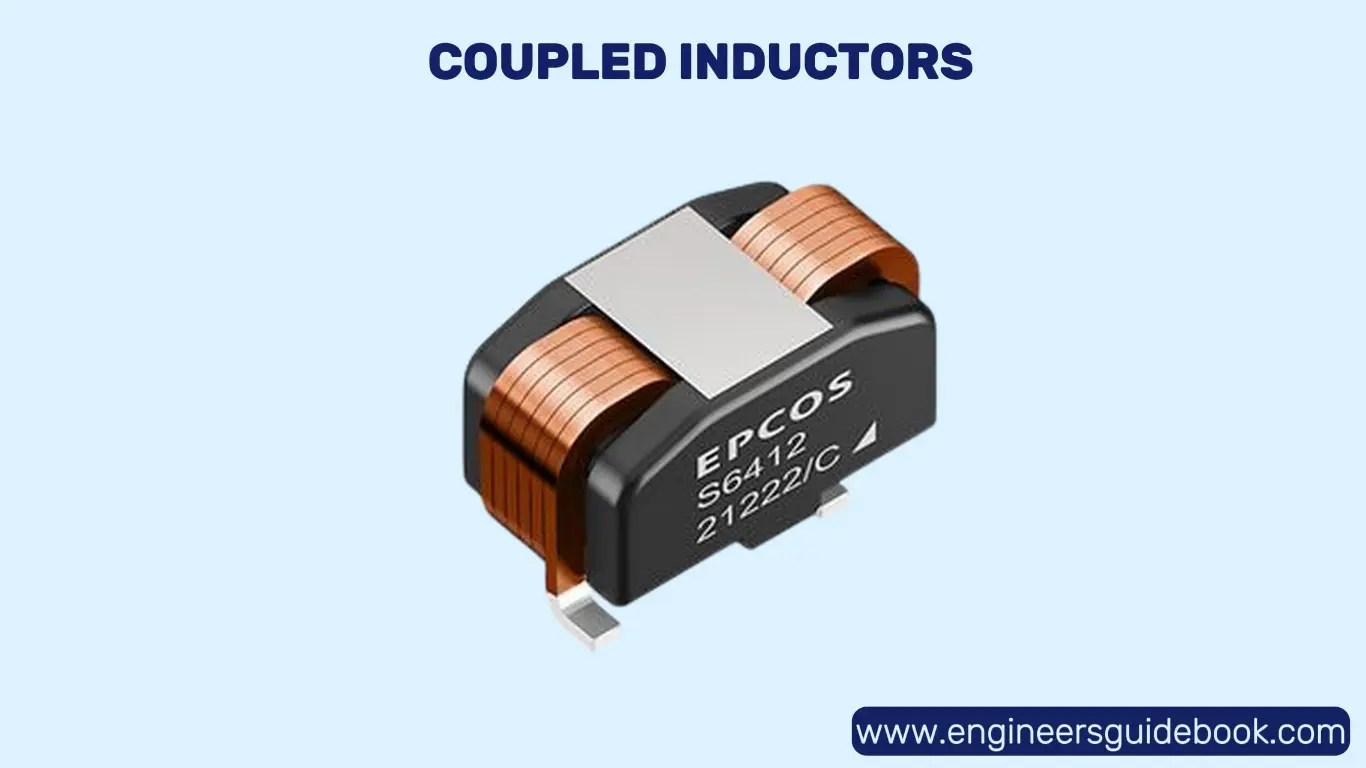

4.8 Coupled Inductors

Coupled inductors consist of multiple windings that share a magnetic path, enabling efficient energy transfer between circuits. They are commonly found in transformers, switched-mode power supplies, and voltage regulation modules.

4.9 Surface Mount Inductors

Surface mount inductors are designed for automated PCB assembly, offering high reliability and performance in compact electronic devices. Their applications include voltage regulation, EMI suppression, and power management in consumer electronics and industrial automation.

5. Industrial Applications of Inductors

5.1 Inductors in Power Supplies

Inductors play a pivotal role in power supply circuits, primarily in voltage regulation and noise filtering. They smooth out fluctuations by resisting sudden changes in current, thereby ensuring a stable voltage output. In switched-mode power supplies (SMPS), inductors store and release energy efficiently, contributing to energy conversion with minimal losses. Their filtering capabilities suppress unwanted electrical noise, enhancing the reliability of electronic devices.

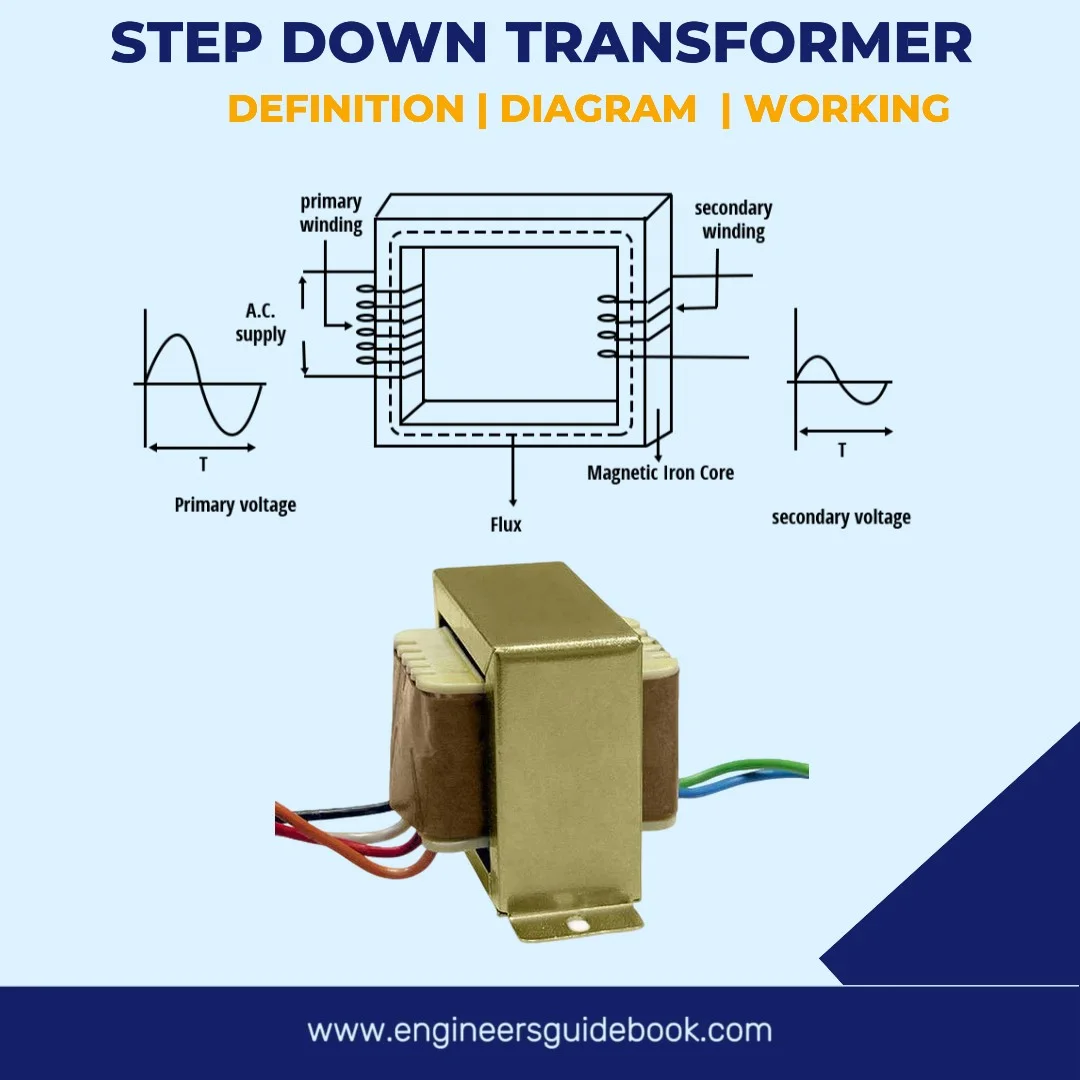

5.2 Transformers and Inductors in Power Transmission

Transformers rely on inductors to efficiently transfer electrical energy across varying voltage levels. By utilizing electromagnetic induction, inductors in transformers help step up or step down voltages in power transmission networks. This function is essential for minimizing energy losses over long distances, improving grid efficiency, and ensuring stable electricity distribution in industrial and commercial applications.

5.3 Inductors in Renewable Energy Systems

In renewable energy systems, inductors contribute to energy efficiency and stability. In solar inverters and wind turbine generators, inductors help smooth DC-AC conversions, reducing harmonic distortions. They also aid in maximum power point tracking (MPPT) systems by regulating voltage and current levels, ensuring optimal energy extraction from renewable sources.

5.4 Automotive Applications

Inductors are integral to electric vehicles (EVs), where they support battery management systems, power conversion, and regenerative braking mechanisms. In EV powertrains, high-frequency inductors improve energy efficiency by mitigating losses in inverters and converters. Additionally, they play a crucial role in EMI suppression, ensuring seamless operation of sensitive automotive electronics.

5.5 Inductors in Telecommunications

Telecommunication systems rely on inductors for signal conditioning and radio-frequency (RF) filtering. RF inductors ensure signal clarity by filtering out interference, enhancing data transmission quality. In base stations, satellite communication, and fiber-optic networks, inductors optimize impedance matching and minimize signal degradation.

5.6 Inductors in Medical Equipment

Medical equipment, such as MRI machines, CT scanners, and patient monitoring systems, incorporates inductors for precise signal processing. Their ability to filter noise and stabilize power supplies ensures accurate diagnostic imaging and uninterrupted operation of life-saving devices. Additionally, inductors play a role in electromagnetic shielding, protecting sensitive medical instruments from external interference.

5.7 Inductors in Aerospace and Defense

Aerospace and defense applications demand high-reliability components, and inductors are no exception. In avionics, radar systems, and communication satellites, inductors contribute to stable power distribution and interference suppression. Their ability to withstand extreme temperatures, vibrations, and radiation makes them indispensable in mission-critical environments.

5.8 Role of Inductors in Industrial Automation and Robotics

Industrial automation and robotics rely on inductors for precise motion control, power regulation, and signal conditioning. In servo motors, PLC systems, and robotic controllers, inductors mitigate voltage fluctuations and enhance operational stability. Their contribution to energy efficiency ensures smooth and reliable functioning of automated processes in manufacturing and logistics.

6. Specialized Inductors for High-Performance Applications

6.1 High-Frequency Inductors

High-frequency inductors are optimized for applications requiring minimal energy losses and rapid signal processing. In wireless communication devices, including smartphones, Wi-Fi routers, and satellite systems, these inductors ensure efficient signal transmission and reception with minimal interference.

6.2 Miniature Inductors

Miniature inductors are designed for compact electronic systems, including wearable devices and Internet of Things (IoT) applications. Their small form factor allows seamless integration into space-constrained devices without compromising performance. These inductors facilitate power regulation and RF signal filtering in next-generation smart technologies.

6.3 High-Current Inductors

Heavy industrial machinery demands inductors capable of handling high currents while maintaining efficiency. High-current inductors, with robust cores and heat-resistant materials, ensure reliable power distribution in motor drives, heavy-duty power supplies, and industrial-grade inverters.

6.4 EMI Suppression Inductors

EMI suppression inductors are engineered to minimize electromagnetic disturbances in sensitive electronic circuits. Widely used in consumer electronics, automotive systems, and industrial control panels, these inductors prevent signal distortion and enhance device performance in electromagnetically noisy environments.

7. Factors to Consider When Selecting an Inductor for Industrial Use

7.1 Inductance Value

Selecting the right inductance value ensures optimal circuit performance. The inductance, measured in henries (H), must align with the circuit’s frequency, impedance, and energy storage needs to avoid inefficiencies.

7.2 Core Material and Its Impact on Performance

The core material significantly affects the inductance value, energy efficiency, and operational stability. Common materials include air, iron, ferrite, and powdered iron, each offering distinct advantages in specific applications.

7.3 Current and Voltage Ratings

Inductors must support the circuit’s current and voltage requirements to prevent overheating and performance degradation. Exceeding rated limits can lead to saturation, power loss, or even failure of the component.

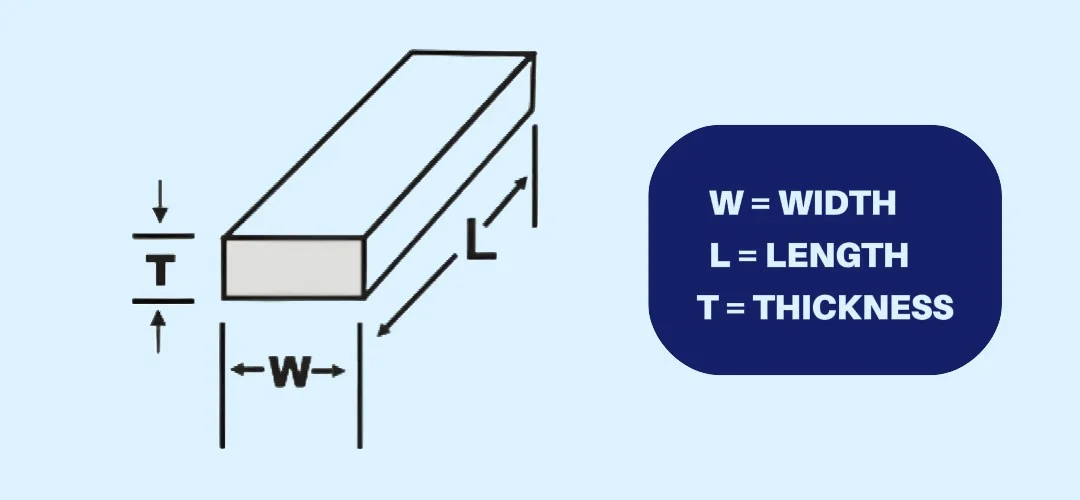

7.4 Physical Size and Mounting Type

Space constraints and mounting preferences dictate inductor selection. Surface mount inductors (SMD) are ideal for compact PCB layouts, while through-hole inductors offer mechanical robustness for high-power applications.

7.5 Temperature Stability and Environmental Considerations

Industrial environments often expose inductors to extreme temperatures, humidity, and vibrations. Choosing inductors with high thermal stability and protective coatings ensures long-term reliability in harsh conditions.

8. Advancements in Inductor Technology

8.1 Nanotechnology and the Future of High-Efficiency Inductors

Nanotechnology has revolutionized inductor design, enabling ultra-efficient and miniaturized components. Advanced nanomaterials enhance inductance while reducing energy losses, paving the way for next-generation electronic circuits.

8.2 Smart Inductors with Embedded Sensors for IoT Applications

The integration of smart inductors with embedded sensors enhances real-time monitoring and adaptability in IoT-based systems. These inductors dynamically adjust their properties based on environmental conditions, optimizing power management.

8.3 3D-Printed Inductors – Customization and Rapid Prototyping

3D printing technology enables rapid prototyping and customization of inductors for specialized applications. Engineers can tailor inductors to specific performance needs, reducing development time and manufacturing costs.

9. Conclusion

9.1 Summary of Key Types of Inductors and Their Uses

Inductors serve diverse roles in industrial, automotive, telecommunications, and renewable energy sectors. Their varied designs and core materials cater to specific circuit demands, ensuring efficiency and reliability.

Ongoing advancements in materials science, nanotechnology, and smart electronics continue to enhance inductor performance. The integration of inductors in emerging technologies, such as AI-driven automation and quantum computing, is poised to redefine their industrial significance.

Inductors remain indispensable components in modern electrical engineering. As industries progress toward more energy-efficient and intelligent systems, inductors will continue to adapt, ensuring seamless functionality in ever-evolving technological landscapes.

10. FAQ’S

1. What is the primary function of an inductor?

An inductor stores energy in a magnetic field when electrical current flows through it and resists sudden changes in current.

2. How do inductors help in power supplies?

Inductors regulate voltage and filter out unwanted noise, ensuring stable power delivery in electrical circuits.

3. What are the main types of inductors used in industrial applications?

Common types include air-core, iron-core, ferrite-core, toroidal, RF, power, and surface-mount inductors.

4. Why are inductors important in renewable energy systems?

Inductors enhance energy conversion efficiency in solar inverters, wind turbines, and battery management systems.

5. How do inductors reduce electromagnetic interference (EMI)?

EMI suppression inductors block high-frequency noise, ensuring signal integrity in electronic circuits.

6. What role do inductors play in electric vehicles (EVs)?

They help manage power flow, optimize battery charging, and improve motor drive efficiency in EV systems.

7. How do I choose the right inductor for an industrial application?

Consider factors like inductance value, core material, current rating, physical size, and environmental conditions.

8. What are the latest advancements in inductor technology?

Innovations include nanotechnology-based inductors, 3D-printed designs, and smart inductors with embedded sensors.

One Response

your writing is just like the wikipedia and information is like you got it from internet. but good lookinga article on this complex topic