1. Introduction

In the realm of mechanical design, it’s often the smallest components that exert the greatest influence. Lock washers, seemingly trivial in size and cost, serve a function that is both foundational and indispensable. They inhabit a space between bolt and base, quiet yet critical.

Much like the keystone in an arch, they ensure the structural integrity of the whole assembly. Their presence mitigates failure, reinforces connections, and enhances the longevity of mechanical systems.

1.1 Why Lock Washers Matter

Bolted joints, though ubiquitous, are prone to failure under the duress of time, vibration, and cyclic stress. Lock washers provide a defensive mechanism against this decay. They are the unsung heroes in high-stakes environments—aviation, automotive, industrial machinery—

where a single loose bolt can precipitate catastrophic consequences. By enhancing the grip of fasteners and distributing loads, lock washers become the quiet custodians of operational stability.

2. What Is a Lock Washer?

2.1 Definition and Basic Function

A lock washer is a specially engineered component designed to prevent threaded fasteners from loosening unintentionally. Its form varies—split, toothed, conical—but its mission remains the same: maintain joint security under dynamic conditions.

By applying tension or biting into the material surface, lock washers introduce resistance to motion and ensure fasteners remain immobile once torqued into position.

These washers act as mechanical insurance policies. They’re not passive spacers but active agents in preserving tension and inhibiting slippage. Where simple flat washers fail, lock washers persist—providing a tactical advantage in applications where movement, vibration, or thermal cycling are concerns.

2.2 How Lock Washers Differ from Standard Washers

Standard washers are fundamentally passive components. Their purpose is primarily to distribute load, protect surfaces, and reduce wear beneath the bolt head or nut. They serve as cushions, preventing gouging or material deformation.

Lock washers, on the other hand, are dynamic. Their design often incorporates spring tension, serrations, or split ends—each feature crafted to resist loosening.

While a standard washer may slide under rotational force, a lock washer resists. This distinction, though subtle in form, is profound in function. Lock washers are not merely protective; they are preventative.

3. The Science Behind Lock Washers

3.1 How Lock Washers Prevent Loosening

Fasteners loosen for many reasons—vibration, temperature fluctuation, differential expansion, or cyclical loading. Lock washers intervene by increasing resistance at the joint interface. They either deform elastically to maintain tension or embed their sharp features into the adjoining surfaces, thereby anchoring the fastener.

Split lock washers, for instance, operate through torsional resistance. When compressed, the split ends create a spring force that fights against rotational loosening.

Toothed variants work via surface interference—biting into the metal and generating frictional hold. These mechanisms work in tandem with torque to form a resilient, vibration-resistant seal.

3.2 Mechanical Principles

Lock washers function at the intersection of several mechanical principles. Friction—induced by surface roughness or interlocking teeth—acts as the first line of defense. Tension, particularly in spring-style washers, provides axial force that keeps the fastener compressed and secure.

When the bolt begins to rotate or the assembly vibrates, this residual tension works like a preloaded spring, restoring equilibrium and preventing unthreading.

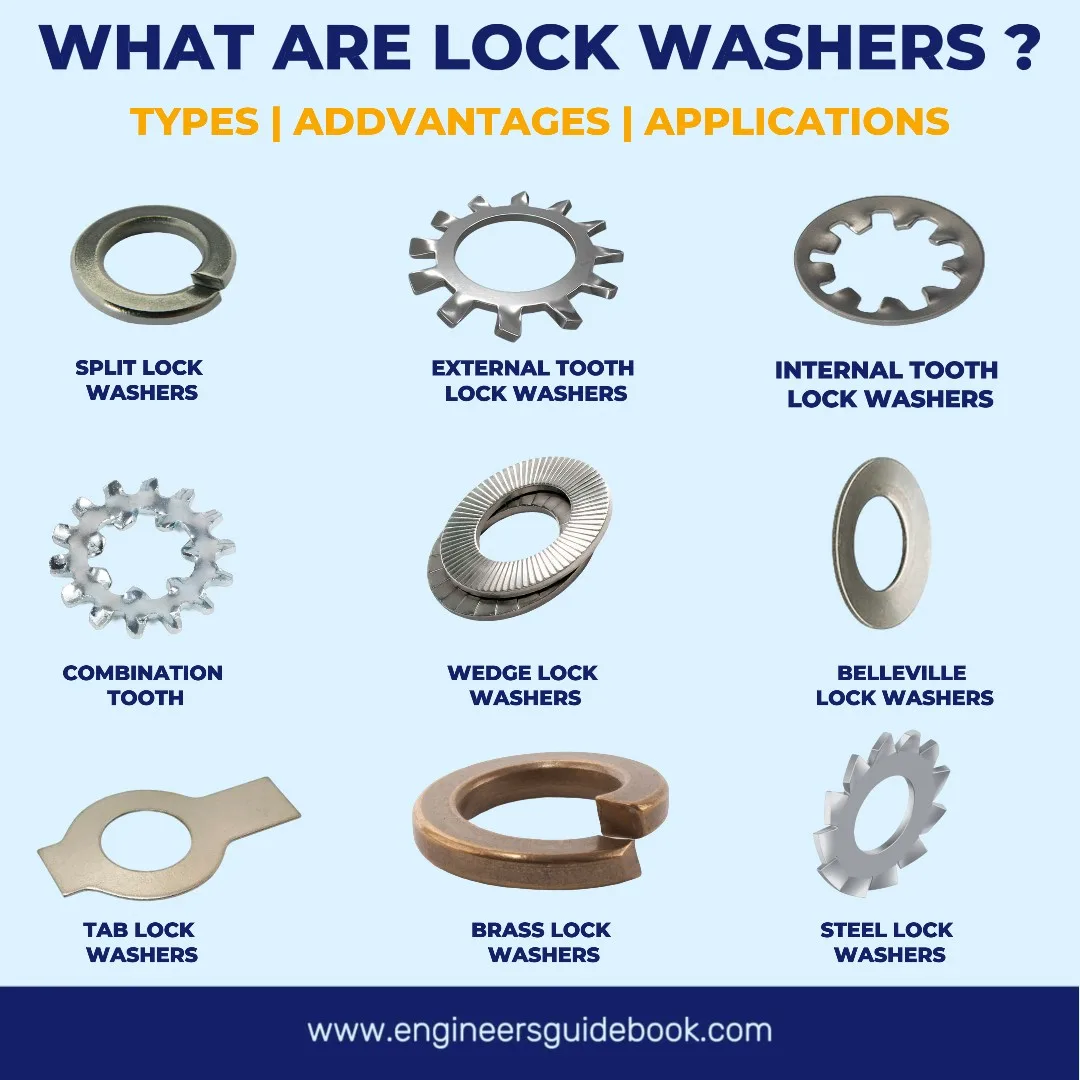

4. Types of Lock Washers

4.1 Split Lock Washers

Split lock washers, also known as helical spring washers, are among the most common and recognizable forms of lock washers. Their signature feature—a single cut that spirals into a helical shape—imbues them with a spring-like quality.

When compressed, this spring tension pushes back against the nut or bolt, creating continuous pressure. This pressure increases friction and inhibits loosening, especially in environments with minor vibration or shifting loads.

4.2 External Tooth Lock Washers

Designed with a ring of outward-facing serrations, external tooth lock washers maximize surface contact. The teeth dig into the bearing surface of the joint, acting as miniature anchors that resist rotation.

They are particularly effective when used with larger fastener heads or softer materials, such as aluminum. The aggressive grip provided by external teeth makes them ideal for electrical and automotive assemblies where vibration is prevalent and where a firm mechanical bond is essential.

4.3 Internal Tooth Lock Washers

Internal tooth lock washers possess teeth that radiate inward toward the center, offering a more aesthetically discreet locking mechanism.

These washers are especially advantageous when space is limited or where external protrusions are undesirable.

4.4 Combination Tooth Lock Washers

Merging the benefits of both internal and external tooth designs, combination tooth lock washers provide an all-encompassing grip. Their serrations attack the surface from both sides—internal for the bolt or screw, and external for the mating surface.

4.5 Wedge Lock Washers

Wedge lock washers are engineered for precision and performance in high-vibration environments. Consisting of two interlocking washers with cam faces on one side and radial teeth on the other, they operate on a principle of tension amplification.

4.6 Belleville (Conical) Lock Washers

Belleville washers, also known as conical spring washers, are characterized by their cone shape, which compresses under load to create high spring tension. Unlike traditional flat washers, Belleville washers exert a consistent axial force that counters bolt relaxation and thermal cycling.

Their ability to maintain tension over time makes them indispensable in scenarios where joint integrity must be preserved under fluctuating loads or temperature conditions—such as flange joints, pressure vessels, and valve assemblies.

4.7 Tab Washers

Tab washers represent the epitome of mechanical locking. Equipped with one or more protruding tabs, these washers physically engage with the bolt or a keyed slot in the assembly. Once bent into position, the tabs act as a permanent lock against rotational movement.

They are commonly used in critical automotive and aerospace components, where positive mechanical locking is paramount. Unlike spring-based options, tab washers rely on physical obstruction, offering unyielding reliability in high-stakes environments.

5. Materials Used in Lock Washers

5.1 Steel Lock Washers

Carbon steel is the go-to material for general-purpose lock washers due to its high strength and cost-efficiency. Suitable for indoor and controlled environments, steel lock washers provide robust tension and mechanical strength without breaking the bank.

5.2 Stainless Steel Lock Washers

When exposed to moisture, chemicals, or extreme temperatures, stainless steel lock washers shine. Resistant to rust, oxidation, and wear, stainless steel varieties are favored in marine, food processing, and medical applications.

5.3 Brass, Copper, and Other Specialty Materials

For more niche applications, materials such as brass and copper offer unique advantages. Brass lock washers are non-magnetic, electrically conductive, and corrosion-resistant—ideal for electronics and telecommunications.

Copper, with its high thermal conductivity and malleability, serves well in applications involving heat transfer or electrical grounding.

5.4 Coated and Plated Lock Washers

In scenarios where bare metal may degrade, coated and plated lock washers offer an additional layer of resilience.

Zinc plating, black oxide, phosphate coating, and other surface treatments enhance corrosion resistance, improve wear characteristics, and sometimes even add aesthetic value.

6. When Should Lock Washers Be Used?

6.1 Applications with High Vibration and Movement

Fasteners in motion-heavy settings—think engines, turbines, industrial mixers—are prone to back off over time. Lock washers provide a counterforce, absorbing vibration and anchoring bolts into place.

6.2 When Thermal Expansion Could Loosen Fasteners

Materials expand and contract with temperature shifts, and so do the fasteners within them. This thermal cycling can cause bolts to relax, particularly in engines, exhaust systems, and HVAC units.

Lock washers mitigate these effects by maintaining pressure as the surrounding environment expands or contracts.

6.3 Assemblies Subjected to Frequent Stress Changes

In assemblies that undergo changing loads—such as rotating machinery, cranes, or heavy transport vehicles—the internal stresses fluctuate constantly. These variations can compromise fastening torque.

Lock washers absorb the mechanical flexing and ensure that the fastener remains properly seated, preserving the structural integrity of the assembly.

6.4 Lightweight or Soft Materials That Require Added Grip

Fastening into soft substrates like aluminum, plastic, or wood requires special consideration. These materials are prone to deformation and lack the rigidity to hold threads under torque.

Lock washers enhance surface friction and prevent slip, ensuring a secure connection without over-tightening or damaging the material.

6.5 Preventing Rotation in Critical Equipment Installations

In safety-sensitive applications—such as medical devices, aerospace systems, and structural supports—any degree of rotational loosening is unacceptable. Lock washers serve as a vital insurance mechanism, ensuring bolts remain fixed under all operating conditions.

7. Industries Applications

7.1 Aerospace and Aviation

In the unforgiving altitudes of the aerospace and aviation sector, mechanical reliability is paramount. Every component, no matter how minor, must endure extreme vibrations, rapid pressure fluctuations, and intense thermal gradients.

Lock washers play a pivotal role in this high-stakes environment by securing fasteners within engine assemblies, fuselage panels, landing gear, avionics, and turbine enclosures.

7.2 Automotive and Heavy Machinery

From high-speed vehicles to earth-shaking excavators, the automotive and heavy machinery industries operate within a landscape of continuous motion and relentless mechanical strain.

Lock washers serve as the unsung guardians of torque integrity across numerous systems—suspension assemblies, transmission housings, engine mounts, and chassis joints.

7.3 Electronics and Electrical Engineering

In the realm of microcurrents and fragile circuits, the function of a lock washer goes beyond mechanical fastening it becomes a linchpin of conductivity and circuit stability.

Whether stabilizing sensitive instrumentation or securing heat sinks to CPUs, lock washers are essential to maintaining uninterrupted performance in high-density electronic environments.

8. Common Applications in Everyday Use

8.1 Household Appliances

Lock washers play a silent yet significant role within the inner workings of everyday household appliances. From washing machines to dishwashers, and even blenders, these components must endure continuous vibration and repetitive motion.

8.2 Furniture and DIY Projects

Flat-pack furniture and home improvement projects are often prone to joint loosening over time, especially when fasteners are driven into MDF, plywood, or softwoods. Lock washers are frequently included—or should be—within the hardware kits of ready-to-assemble products.

8.3 Bicycles and Recreational Equipment

Recreational equipment, particularly bicycles, skateboards, and scooters, experience substantial vibration, impact, and motion during operation. Lock washers are strategically positioned in areas subject to repetitive torque, such as wheel hubs, brake systems, seat mounts, and handlebar stems.

9. Proper Installation of Lock Washers

9.1 Choosing the Right Lock Washer for the Job

Selecting the appropriate lock washer requires a balance of function, material compatibility, and mechanical demand. Start by evaluating the nature of the application: Is the environment prone to vibration?

Will the assembly face exposure to moisture, chemicals, or temperature extremes? Each question narrows the field.

For general applications, a carbon steel split lock washer may suffice. For corrosive environments, stainless steel is the superior option.

9.2 Step-by-Step Installation Guide

- Prepare the Surface: Clean the mating surfaces of any debris, grease, or corrosion. A clean surface ensures proper seating and maximum friction.

- Select the Washer: Choose the correct size and type of lock washer to match your bolt and application.

- Positioning: Place the lock washer between the fastener (bolt or nut) and the substrate. For tooth washers, ensure the teeth face the surface that requires gripping.

- Tighten the Fastener: Use the recommended torque for the fastener. Over-tightening can deform the washer and reduce its locking effectiveness, while under-tightening compromises the joint.

- Inspect the Assembly: Visually inspect the washer to confirm it has deformed or seated properly, depending on type. In some designs, a slight flattening is expected.

Proper alignment and seating are crucial. The washer must compress uniformly under the fastener to maintain pressure across the joint.

9.3 Common Mistakes to Avoid During Installation

One of the most common errors is using the wrong type of washer for the material. For instance, placing a split washer on a soft aluminum surface can cause scarring or embedding, leading to premature loosening.

Another pitfall is reusing lock washers. Once compressed or bitten into a surface, their integrity is compromised. Always replace them when reassembling joints.

10. Conclusion

Lock washers may be diminutive in size, but their contribution to mechanical stability is nothing short of substantial. Across industries—from aerospace to electronics, construction to marine engineering—they serve as a quiet but critical line of defense against fastener loosening, structural fatigue, and operational failure.

Their diverse designs and materials allow them to adapt to unique environmental demands, ensuring that bolts remain secure even under extreme conditions of vibration, temperature shifts, and mechanical stress.