1. Introduction to Air Circuit Breakers

Circuit breakers serve as the backbone of modern electrical protection systems. These critical components are designed to detect and interrupt abnormal electrical currents, such as those caused by overloads or short circuits, thereby preventing damage to equipment and reducing fire hazards.

By automatically disconnecting faulty circuits, circuit breakers enhance operational safety, ensuring the seamless functionality of electrical networks across residential, commercial, and industrial infrastructures.

1.1 Why Air Circuit Breakers Are Essential for Industrial and Commercial Applications

Air circuit breakers (ACBs) play a pivotal role in safeguarding large-scale electrical installations. Unlike miniature circuit breakers used in domestic settings, ACBs are engineered to handle high current ratings and withstand the severe electrical stresses associated with industrial environments.

Their robust design makes them suitable for protecting generators, transformers, and heavy machinery. Furthermore, ACBs facilitate selective tripping, allowing only the affected circuit to be isolated while the rest of the system remains operational, thereby minimizing downtime in critical industries.

1.2 Evolution and Development of Air Circuit Breakers

The inception of air circuit breakers dates back to the early 20th century when engineers sought alternatives to oil-based circuit breakers, which posed fire hazards.

Over the decades, advancements in arc quenching technology, materials, and automation have led to the development of sophisticated ACBs with enhanced reliability and efficiency.

Today, modern air circuit breakers incorporate digital monitoring systems and remote-control capabilities, enabling predictive maintenance and real-time fault diagnostics.

2. Fundamental Working Principle of Air Circuit Breakers

2.1 Understanding the Air as an Arc Quenching Medium

When a circuit breaker interrupts a fault current, an electric arc forms between the contacts due to the high energy involved. In air circuit breakers, atmospheric air serves as the medium for arc extinction.

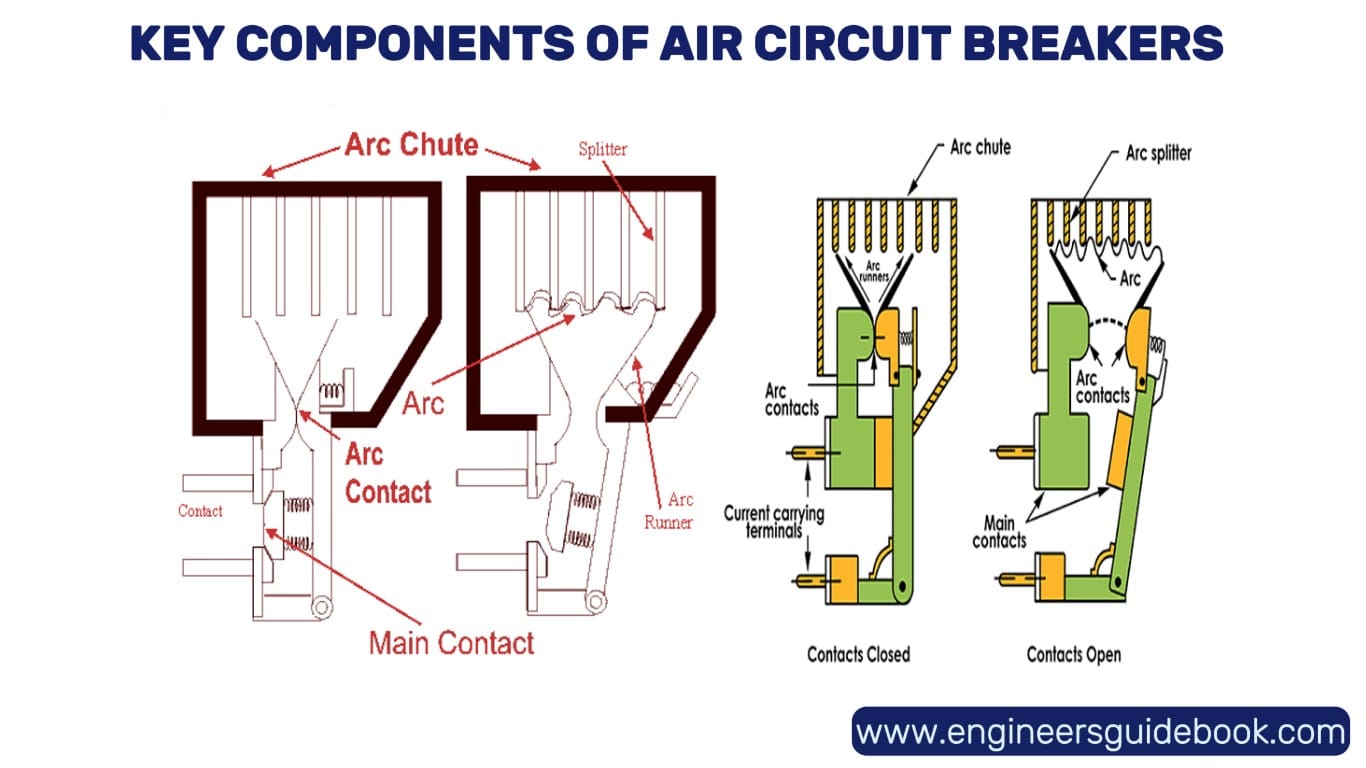

The natural cooling and deionization properties of air help dissipate the arc energy, preventing further conduction. The effectiveness of arc quenching in ACBs is enhanced by mechanisms such as arc chutes and blowout magnets, which control and elongate the arc for rapid extinction.

2.2 How Air Circuit Breakers Interrupt Fault Currents

The interruption process in ACBs involves several stages. Upon detecting an overcurrent or short circuit, the tripping mechanism activates, causing the breaker contacts to separate. As the contacts part, an arc forms due to the ionized air particles.

The breaker’s arc chute then forces the arc to elongate, increasing resistance and facilitating deionization. Once the arc is fully extinguished, the electrical flow is interrupted, ensuring system protection.

2.3 Key Components and Their Functions

- Main Contacts: Conduct normal operating current and separate during fault conditions.

- Arc Chute: Composed of multiple splitters that stretch and cool the arc.

- Blowout Coil: Generates a magnetic field to direct and control the arc movement.

- Operating Mechanism: Includes the spring and tripping assembly that enables automatic and manual operation.

- Trip Unit: Detects abnormal current conditions and initiates breaker operation.

3. Types of Air Circuit Breakers

3.1 Plain Break Type Air Circuit Breakers

Plain break ACBs are the most basic form, where the arc is allowed to expand freely in the air and dissipate naturally. This type is often used in low-voltage applications due to its simplicity. However, its arc extinction efficiency is relatively low compared to more advanced designs.

3.2 Magnetic Blowout Type Air Circuit Breakers

In this design, a magnetic field is used to force the arc away from the contacts and into an arc chute. The magnetic blowout mechanism enhances arc control, leading to faster extinction and reduced contact wear. These breakers are preferred for medium-voltage applications where improved arc management is required.

3.3 Air Chute Type Air Circuit Breakers

Air chute ACBs employ arc chutes with multiple plates to elongate and cool the arc effectively. The arc chute structure ensures controlled arc splitting, making this type highly efficient for high-current applications.

3.4 Cross-Blast Air Circuit Breakers

Cross-blast ACBs utilize a transverse air blast to drive the arc into an arc chute, where it is rapidly cooled and extinguished. This mechanism improves arc-quenching speed, making cross-blast ACBs suitable for heavy industrial loads.

4. Key Features and Design Specifications

4.1 Rated Voltage, Current, and Breaking Capacity

ACBs are classified based on their voltage rating, current carrying capacity, and breaking capacity, which determine their suitability for different applications. Higher-rated ACBs are designed to handle more significant fault currents without failure.

4.2 Arc Extinction and Cooling Mechanism

Efficient arc extinction is achieved through a combination of arc chutes, air blast technology, and magnetic blowout coils. These mechanisms work in tandem to dissipate heat and prevent re-ignition of the arc.

4.3 Insulation and Safety Features

Advanced insulation materials, such as epoxy resin and composite polymers, enhance dielectric strength, ensuring safe operation under high-voltage conditions. Modern ACBs also incorporate protective enclosures to prevent accidental contact with live components.

4.4 Contact Mechanism and Material Selection

High-performance materials, including silver alloys and tungsten composites, are used for breaker contacts to minimize wear and ensure prolonged service life. Specially designed contact structures reduce resistance and heat generation.

5. Applications of Air Circuit Breakers in Electrical Systems

5.1 Industrial Power Distribution

ACBs are indispensable in industrial settings where uninterrupted power supply is critical. They protect transformers, switchgear, and heavy machinery from electrical faults, ensuring operational continuity.

5.2 Utilization in Commercial

Large commercial complexes and skyscrapers rely on ACBs for distributing power safely across multiple floors. Their ability to handle high loads and provide selective tripping makes them essential for modern buildings.

5.3 Role in Power Plants

In power generation and transmission systems, ACBs safeguard substations and grid infrastructure from transient faults. Their reliability in high-voltage applications makes them a preferred choice for power utilities.

5.4 Integration in Renewable Energy Systems

With the rise of renewable energy sources such as solar and wind power, ACBs are increasingly used to manage electrical distribution in microgrids. Their ability to handle varying load conditions ensures the stability of renewable energy networks.

6. Installation, Maintenance, and Troubleshooting

6.1 Best Practices for Safe Installation

Proper installation is crucial to ensuring the optimal performance and longevity of air circuit breakers. Site selection should prioritize adequate ventilation and minimal exposure to dust and moisture. Mounting the breaker securely within a well-grounded switchgear panel enhances stability and safety.

Electrical connections must be torqued to manufacturer specifications to prevent overheating or loose contacts. A thorough insulation resistance test should be conducted before energization to identify potential faults. Commissioning should include a detailed functional test to verify tripping mechanisms and interlocks.

6.2 Routine Maintenance Procedures for Long-Term Reliability

Periodic maintenance is essential to sustain efficiency and prevent premature failure. Regular visual inspections help detect wear and contamination on contacts. Cleaning arc chutes and ensuring proper lubrication of mechanical components minimize friction-induced wear.

Contact resistance measurements should be performed to identify potential degradation in connectivity. Insulation integrity testing helps assess dielectric strength, ensuring the breaker remains operational under load conditions.

Adherence to the original equipment manufacturer (OEM) guidelines for periodic servicing ensures optimal breaker performance.

6.3 Common Issues and Troubleshooting Techniques

Air circuit breakers may exhibit various operational issues over time. Contact pitting or erosion can result in increased resistance and voltage drop, necessitating replacement.

Overheating at terminals often indicates loose connections, requiring immediate tightening. Failure to trip under fault conditions could be due to mechanical obstructions, defective trip coils, or auxiliary circuit malfunctions.

Inconsistent breaker operation may be linked to environmental factors such as humidity or dust accumulation. Employing infrared thermography can help identify hotspots and mitigate potential failures proactively.

6.4 Upgrading and Retrofitting Air Circuit Breakers

Older air circuit breakers can be upgraded with modern trip units, enhancing reliability and precision. Retrofitting with electronic trip units improves fault detection, allowing for advanced protective settings. Digital monitoring systems can be integrated to enable remote diagnostics and predictive maintenance.

Replacement of worn-out insulation materials ensures extended service life. When upgrading, compatibility with existing switchgear infrastructure must be assessed to avoid electrical mismatches or mechanical integration challenges.

7. Advantages and Limitations of Air Circuit Breakers

7.1 Benefits Over Other Types of Circuit Breakers

Air circuit breakers provide distinct advantages in medium-voltage applications. They offer high short-circuit interrupting capacity, ensuring reliable protection in industrial environments. Unlike oil circuit breakers, they eliminate fire hazards associated with flammable insulating materials.

Their open-air arc quenching mechanism simplifies maintenance and avoids gas handling complexities seen in SF6 breakers. Additionally, air circuit breakers exhibit excellent resistance to aging effects, maintaining performance consistency over extended periods.

7.2 Challenges and Constraints in Practical Applications

Despite their advantages, air circuit breakers present specific challenges. Their arc quenching mechanism generates significant heat and noise, necessitating robust cooling systems.

Frequent maintenance due to contact erosion increases operational costs. Additionally, their sensitivity to environmental contaminants such as dust and humidity can lead to performance degradation.

7.3 Comparisons with Vacuum and SF6 Circuit Breakers

Air circuit breakers differ significantly from vacuum and SF6 circuit breakers in terms of design and operation. Vacuum circuit breakers use a sealed vacuum chamber for arc extinction, offering near-zero maintenance requirements.

SF6 circuit breakers employ sulfur hexafluoride gas as an insulating medium, providing superior dielectric properties and compact designs. While air circuit breakers excel in cost-effectiveness and ease of maintenance, they lag behind in arc extinction efficiency compared to SF6 and vacuum technologies.

8. Safety Standards and Regulatory Compliance

8.1 International Standards for Air Circuit Breakers

Air circuit breakers mustcomply with global standards to ensure safety and reliability. The International Electrotechnical Commission (IEC) 60947-2 standard specifies requirements for low-voltage circuit breakers. IEEE C37 standards outline performance benchmarks for medium-voltage applications. Compliance with these standards guarantees operational integrity and alignment with industry best practices.

8.2 National Electrical Code (NEC) and IEC Guidelines

The NEC provides region-specific regulations governing the installation and operation of air circuit breakers. Adherence to NEC 240 ensures proper overcurrent protection in electrical systems.

IEC 62271 outlines testing and performance criteria for medium-voltage circuit breakers. Following these guidelines minimizes risks associated with improper breaker selection and deployment.

8.3 Environmental Considerations and Sustainability Factors

Air circuit breakers offer eco-friendly alternatives to SF6-based circuit breakers, eliminating concerns related to greenhouse gas emissions.

9. Future Trends and Innovations in Air Circuit Breaker Technology

9.1 Advances in Smart Circuit Breaker Technology

Smart air circuit breakers integrate advanced sensors and microcontrollers to enable real-time monitoring and predictive analytics.

These systems enhance fault detection accuracy and optimize load distribution. Wireless connectivity allows remote diagnostics and proactive maintenance scheduling.

9.2 Digital Monitoring and Remote Control Capabilities

Modern air circuit breakers incorporate IoT-enabled interfaces for remote operation. Cloud-based analytics process real-time breaker data, improving operational transparency.

Predictive algorithms help prevent unexpected failures by identifying early signs of degradation.

9.3 The Future of Air Insulation in High-Voltage Protection

Innovations in air-insulated technology focus on reducing footprint while enhancing dielectric strength. Research into hybrid insulation systems aims to improve arc quenching efficiency. As industries prioritize sustainability, air-insulated circuit breakers are expected to gain wider adoption in high-voltage networks.

10. Conclusion

Air circuit breakers play a critical role in electrical protection, offering a reliable and environmentally friendly alternative to other breaker types. Their distinct advantages, including ease of maintenance and cost-effectiveness, make them indispensable in industrial applications.

Selecting the appropriate air circuit breaker requires careful consideration of voltage ratings, interrupting capacity, and environmental conditions. Proper evaluation ensures optimal system performance and longevity.

The evolution of air circuit breaker technology continues to enhance reliability and efficiency. With advancements in smart monitoring and sustainable insulation techniques, these breakers will remain a crucial component of electrical infrastructure for years to come.

11. FAQs

11.1 What is the primary function of an air circuit breaker?

An air circuit breaker protects electrical circuits by interrupting fault currents and preventing damage to connected equipment.

11.2 How does an air circuit breaker differ from a vacuum circuit breaker?

An air circuit breaker uses atmospheric air for arc extinction, while a vacuum circuit breaker relies on a sealed vacuum chamber, offering lower maintenance requirements.

11.3 What are the common causes of failure in air circuit breakers?

Frequent causes include contact wear, insulation degradation, and mechanical failures in the tripping mechanism.

11.4 How often should an air circuit breaker be serviced?

Routine maintenance is typically performed annually, but high-demand environments may require more frequent inspections.

11.5 Can air circuit breakers be used in outdoor environments?

While they are generally designed for indoor use, specialized enclosures can facilitate outdoor applications.

11.6 What factors influence the selection of an air circuit breaker?

Key factors include voltage rating, breaking capacity, installation environment, and compliance with regulatory standards.

11.7 Are air circuit breakers environmentally friendly?

Yes, they do not rely on harmful gases like SF6, making them a sustainable choice for electrical protection.

11.8 What advancements are shaping the future of air circuit breakers?

Digital monitoring, predictive maintenance algorithms, and hybrid insulation technologies are driving the next generation of air circuit breakers.

2 Responses

what is your source of information and what is your qulifications

Hello, i believe that i noticed you visited my site so i came to “return the choose”.I’m attempting to to find things to improve my site!I assume its ok to make use of a few of your ideas!!