June 23, 2024 By Muhammad Ali 6 minutes read

Ball Bearings are essential components that are found in numerous applications in industry. From cars and airplanes to everyday household items. Ball bearings play a critical role in reducing friction and enabling smooth motion between moving parts, making them vital in various engineering fields.

In this article, we will cover the fundamental concepts and applications of ball bearings, offering valuable insights for both students and professionals.

Understanding ball bearings is important for anyone involved in engineering or technical fields. These small yet powerful components ensure the efficient operation of many machines and devices. By the end of this guide, you’ll have a solid grasp of the different types of ball bearings, their performance characteristics, and their wide-ranging applications.

The significant advancements in ball bearing technology began during the Renaissance. Leonardo da Vinci sketched one of the first designs for a ball bearing in the 15th century. However, it wasn’t until the late 19th and early 20th centuries that ball bearings saw widespread use in industrial applications.

The invention of the bicycle and the automobile drove the demand for more efficient and durable bearings. Innovators like Sven Wingquist and Henry Timken made substantial contributions to the development and commercialization of ball bearings, leading to the sophisticated and highly reliable bearings we use today.

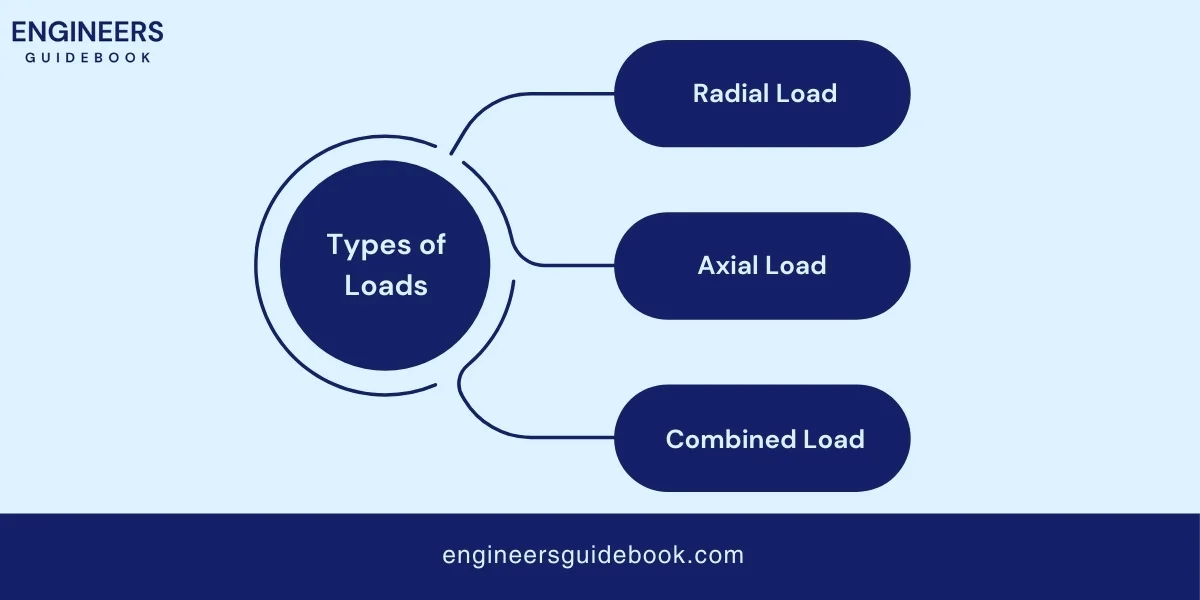

Ball bearings are designed to handle different types of loads:

These are perpendicular to the shaft and are the most common type of load that ball bearings encounter.

These loads are parallel to the shaft. Ball bearings can handle axial loads to varying degrees, depending on their design.

Many applications subject ball bearings to a combination of radial and axial loads. The bearing’s ability to handle these combined loads depends on its specific design and construction.

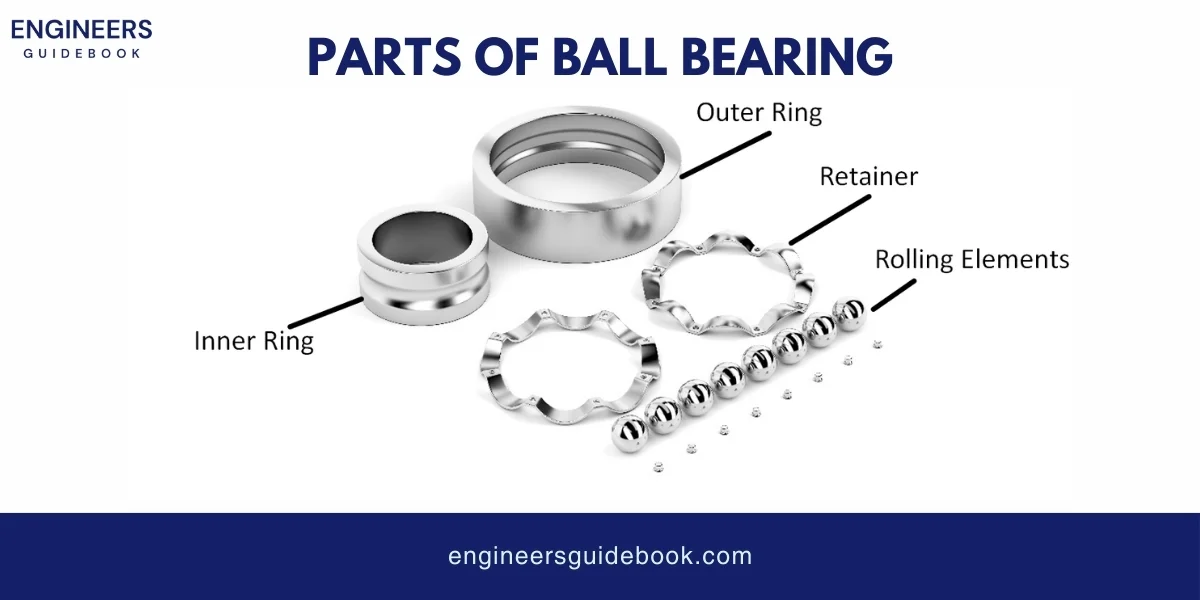

1. Inner and Outer Races: These are the two rings where the balls roll. The inner race is attached to the rotating shaft, while the outer race is fixed to the housing.

2. Balls: These spherical rolling elements are positioned between the inner and outer races. The balls carry the load and allow the inner race to rotate smoothly.

3. Cage: Also known as the retainer, the cage holds the balls in place, evenly spaced, and prevents them from colliding.

4. Seals and Shields: These protect the bearing from contaminants like dust and moisture, extending its life and maintaining its performance.

Ball bearings work by using smooth balls that roll between the inner and outer races. When the inner race rotates, the balls roll in their paths, reducing the friction between the moving parts.

This rolling motion significantly reduces the resistance compared to sliding motion, which is why ball bearings are so effective in improving efficiency and performance.

Ball bearings come in various types, each designed to handle specific loads and conditions. Understanding the different types of ball bearings is essential for selecting the right one for your application.

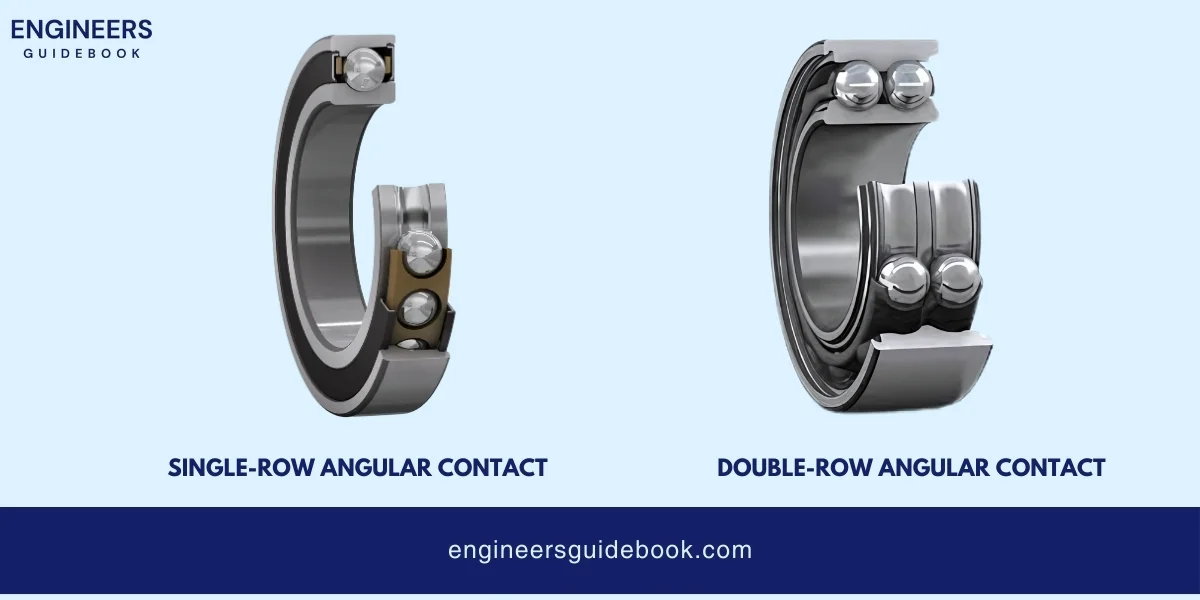

1. Single Row Angular Contact Bearings:

2. Double Row Angular Contact Bearings:

Ball bearings are crafted from a wide range of materials but the most commonly used materials are

Thermoplastic: Used in applications requiring lightweight and corrosion-resistant bearings. Suitable for low-load and low-speed applications, such as food processing equipment.

1. Forging:

The raw material, usually steel, is heated and shaped into rough bearing rings through a forging process. This step ensures the material has the desired strength and structure.

2. Turning:

The forged rings are machined to precise dimensions using lathes, forming the bearing’s inner and outer races.

3. Heat Treatment:

The machined rings undergo heat treatment to achieve the necessary hardness and durability.

4. Grinding:

The races are ground to their final dimensions and surface finish. This step ensures the races are smooth and accurately sized for the balls to roll smoothly.

5. Honing:

A fine machining process that further refines the surface finish of the races. It ensures the bearing runs quietly and efficiently.

6. Assembly:

The balls, races, and cages are assembled together. The components are carefully fitted to ensure proper alignment and smooth operation.

7. Quality Control:

Bearings undergo rigorous quality control checks at each stage of manufacturing. These checks include dimensional inspections, hardness tests, and noise and vibration assessments to ensure the bearings meet the required standards.

Applications of Ball Bearings

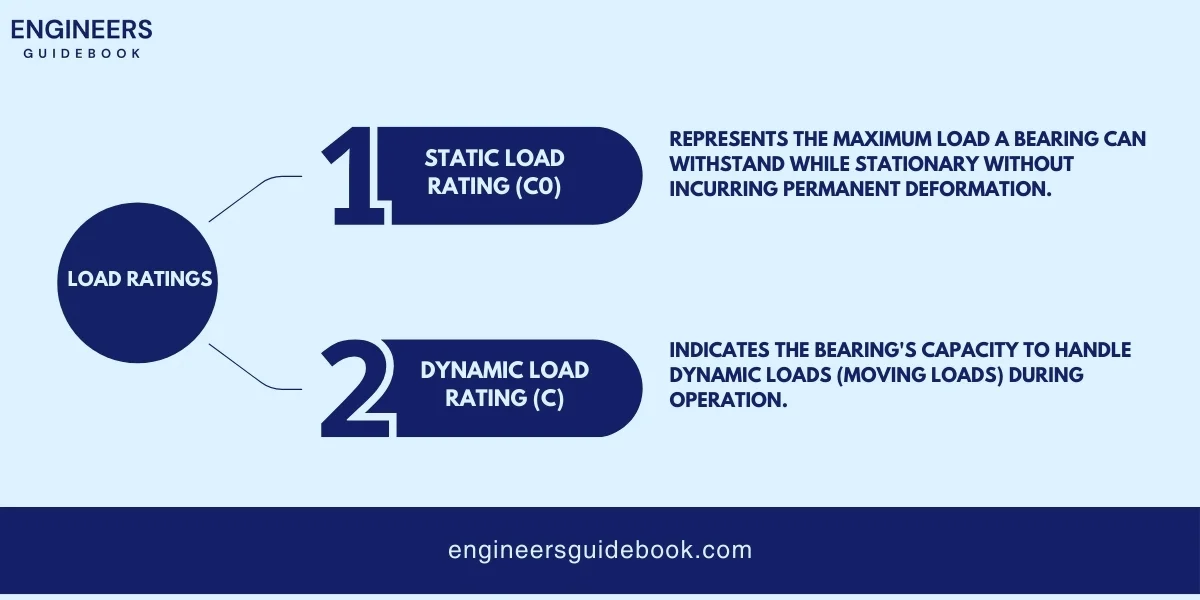

Ball bearings are renowned for enhancing the performance and efficiency of mechanical systems. To ensure optimal operation, it’s important to understand their key performance characteristics, including load ratings, speed ratings, friction, lubrication, and noise considerations.

Dynamic Load Rating (C)

Static Load Rating (C0)

Choosing the right ball bearing is crucial for ensuring the optimal performance and longevity of your application. Here are the key factors to consider when selecting ball bearings.

Proper installation and maintenance of ball bearings are essential to ensure their optimal performance and longevity. Here’s a guide to help you get it right.

Always install bearings in a clean environment to prevent contaminants from entering the bearing, which can cause premature failure.

Use the right tools for installation. Avoid using hammers or other improper tools that can damage the bearing.

When installing bearings, apply even pressure to both the inner and outer rings. To avoid misalignment and damage, use a press-fit method rather than striking the bearing.

Ensure the bearing is correctly aligned with the shaft and housing. Misalignment can lead to uneven load distribution and early failure.

If you hear unusual noise coming from the bearing, it could indicate misalignment, lack of lubrication, or contamination. Inspect and address the root cause promptly.

Excessive wear may be due to improper installation, insufficient lubrication, or overload. Ensure correct installation procedures and adequate lubrication.

Misaligned bearings can cause uneven load distribution and increased wear. Check alignment during installation and adjust as necessary.

Ball bearings are vital components in a wide range of applications, from automotive and aerospace to industrial machinery and consumer electronics. Understanding the fundamental concepts, types, performance characteristics, and applications of ball bearings is essential for anyone involved in engineering and technical fields.

By exploring the materials and manufacturing processes, we can appreciate the precision and care that go into producing these essential components. Proper installation and maintenance practices ensure that ball bearings operate efficiently and have a long lifespan. Staying informed about the latest innovations and trends in ball bearing technology can help professionals select the best solutions for their needs, enhancing performance and sustainability.

This comprehensive guide aims to provide valuable insights and practical knowledge for students and professionals alike, ensuring a thorough understanding of ball bearings and their critical role in modern technology.

Ball bearings are typically made of hardened steel, stainless steel, or ceramic materials.

Ball bearings reduce friction by using smooth balls that roll between inner and outer surfaces, minimizing contact and friction.

Common types include deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, and thrust ball bearings.

Ball bearings are used in various applications such as automotive, aerospace, industrial machinery, medical devices, and consumer electronics.

Consider load capacity, speed, environmental conditions, space constraints, and maintenance requirements.

Yes, certain types of ball bearings like angular contact bearings can handle both radial and axial loads.

The lifespan depends on the operating conditions, but properly maintained ball bearings can last for many years.

Lubrication reduces friction, wear, and prevents corrosion, significantly extending the bearing’s life.

Yes, many ball bearings are designed to operate at high speeds, though this often comes at the expense of load capacity.

The bore diameter is usually measured with precision tools such as calipers or micrometers.

Signs include unusual noise, increased vibration, excessive heat, and visible wear or damage.

Sealed bearings provide better protection against contaminants but add friction, while shielded bearings offer moderate protection with less friction.

Use proper tools and techniques to ensure alignment and avoid applying excessive force, which can damage the bearing.

Muhammad Ali holds a PhD in Mechanical Engineering from MIT and is currently conducting groundbreaking research on sustainable energy systems. His innovative work in renewable energy integration has earned him numerous accolades in the engineering community.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.

7 Responses

There’s something almost meditative about your writing. The way you unfold ideas with such precision and care feels like watching a sculptor work — each word chipped away, each sentence shaped into something beautiful. It’s a slow, deliberate process that results in something truly remarkable.

Happy to dive into discussions, share thoughts, and gain fresh perspectives along the way.

I’m interested in understanding different opinions and sharing my input when it’s helpful. Interested in hearing new ideas and building connections.

enjoyed the article as it is very comprehensive and detailed. good knowledge for engineers

this is a common type article not much you ahve provided.

kindly also write an article on bearing number defination. good article on this topic.

from where you get this information. suggest me some source also

But a smiling visitant here to share the love (:, btw great design. “Competition is a painful thing, but it produces great results.” by Jerry Flint.