1. Introduction

Total Productive Maintenance (TPM) is a holistic maintenance approach that integrates preventive and predictive maintenance strategies with a focus on empowering employees at all levels. It aims to enhance overall equipment effectiveness (OEE) by reducing downtime, defects, and inefficiencies. Unlike traditional maintenance methodologies, TPM fosters a culture where maintenance is not solely the responsibility of specialized personnel but a shared effort among operators, engineers, and managers. In this article, we will discuss in detail the benefits of TPM and why you should implement this technique in your business.

1.1 The Origins and Evolution of TPM

TPM originated in Japan in the late 1960s as a response to the growing need for increased productivity and equipment reliability. Initially pioneered by Nippon Denso, a supplier of Toyota, TPM became an integral part of lean manufacturing. Over time, the methodology spread globally, adapting to various industries, including automotive, pharmaceuticals, and heavy machinery. Today, TPM is recognized as a vital component of Industry 4.0, integrating data analytics and automation to optimize maintenance strategies.

1.2 Why TPM is Essential for Modern Manufacturing

Modern manufacturing faces challenges such as fluctuating demand, stringent quality requirements, and high operational costs. TPM addresses these challenges by ensuring that machinery operates at peak efficiency, minimizing unexpected failures, and promoting a proactive approach to maintenance. By implementing TPM, organizations achieve higher production rates, improved product quality, and a safer working environment, positioning themselves competitively in the global market.

Also Read: PROCESS ENGINEERING

Total Productive Maintenance (TPM): An Overview

How To Implement TPM (Total Productive Maintenance)

2. Enhancing Equipment Efficiency and Reliability

2.1 Minimizing Unplanned Downtime

Unexpected equipment failures can lead to production delays, increased costs, and dissatisfied customers. TPM incorporates predictive maintenance techniques, such as vibration analysis and thermal imaging, to detect early signs of wear and tear. By addressing potential failures before they occur, TPM significantly reduces unplanned downtime, ensuring uninterrupted operations.

2.2 Extending the Lifespan of Machinery

Properly maintained equipment lasts longer, reducing the frequency of capital investments in new machinery. TPM promotes regular inspections, lubrication schedules, and operator-driven maintenance routines, which prevent premature deterioration. As a result, organizations maximize their return on investment (ROI) by extending the service life of critical assets.

Reactive maintenance often results in costly repairs due to undetected issues escalating into major failures. TPM employs condition monitoring techniques to identify abnormalities early, allowing minor corrections before significant damage occurs. This proactive approach minimizes expensive emergency repairs and reduces overall maintenance expenditures.

3. Boosting Overall Productivity

3.1 Eliminating Bottlenecks

Production bottlenecks often arise from machinery breakdowns, disrupting the workflow and causing inefficiencies. TPM systematically identifies weak points in production lines and ensures that all equipment functions at optimal capacity. By eliminating recurring failures, manufacturers achieve smoother operations and higher output rates.

3.2 Streamlining Workflows

Inefficiencies in production workflows result in wasted time and resources. TPM integrates lean manufacturing principles, such as Just-in-Time (JIT) and 5S, to create an organized and efficient production environment. By aligning maintenance schedules with production demands, TPM prevents unnecessary stoppages and enhances overall productivity.

4. Reducing Manufacturing Costs

4.1 Lowering Maintenance Expenses

Unscheduled maintenance often leads to inflated costs due to emergency repairs and production stoppages. TPM implements planned maintenance activities based on data analysis and historical trends, reducing unexpected expenses. Scheduled interventions ensure that equipment remains operational without costly last-minute fixes.

4.2 Decreasing Waste and Material Losses

Equipment failures not only halt production but also lead to defective products and material wastage. TPM ensures that machines operate under optimal conditions, reducing the likelihood of producing substandard goods. By minimizing material losses, organizations enhance cost efficiency and reduce environmental impact.

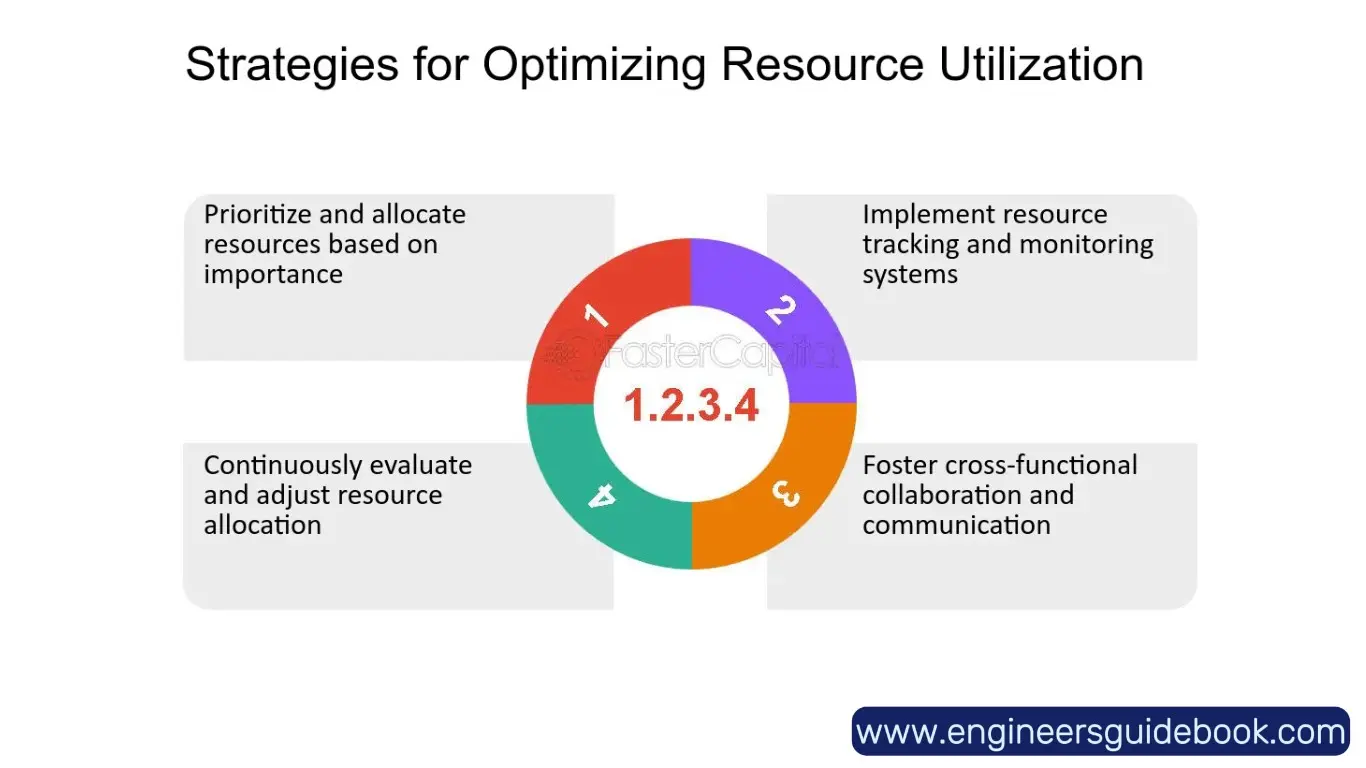

4.3 Optimizing Resource Utilization

Effective resource utilization is critical for maintaining profitability. TPM aligns maintenance activities with production goals, ensuring that energy, manpower, and raw materials are used efficiently. This synchronization reduces unnecessary expenses and contributes to a more cost-effective manufacturing process.

5. Improving Product Quality and Consistency

Faulty machinery often leads to defects, resulting in rework or product recalls. TPM ensures that all equipment functions at peak performance, preventing variations in product quality. By maintaining consistent operational conditions, manufacturers achieve higher-quality standards and reduce customer complaints.

Precision is essential in modern manufacturing, particularly in industries such as aerospace and healthcare. TPM supports calibration and standardization of equipment to ensure accuracy in production. Regular maintenance checks eliminate performance deviations, resulting in products that meet stringent quality requirements.

Consistently delivering high-quality products builds brand reputation and customer trust. TPM enhances quality control measures, ensuring that products meet specifications without defects. Satisfied customers lead to repeat business, strengthening market position and long-term profitability.

6. Empowering Employees Through Autonomous Maintenance

6.1 Encouraging Operator Involvement in Routine Maintenance

Autonomous maintenance is a fundamental pillar of Total Productive Maintenance (TPM), emphasizing direct operator engagement in the upkeep of machinery. Traditionally, maintenance responsibilities were confined to specialized technicians, but TPM shifts this paradigm by equipping operators with the knowledge and authority to perform routine checks, lubrication, and minor adjustments.

This not only reduces reliance on dedicated maintenance personnel but also ensures quicker identification of irregularities, fostering a more responsive approach to equipment management.

6.2 Developing Technical Skills

Empowering operators with maintenance responsibilities cultivates a sense of ownership over the machinery they handle daily. Training programs focused on diagnostic skills, troubleshooting techniques, and fundamental repair procedures enhance workforce competency, bridging the gap between operations and maintenance.

This technical empowerment boosts morale and job satisfaction, as employees become proactive stakeholders in maintaining production efficiency rather than passive participants in the manufacturing process.

6.3 Fostering a Proactive Maintenance Culture on the Shop Floor

A proactive maintenance culture emerges when employees take initiative in preventing potential equipment failures rather than reacting to breakdowns. Through continuous education and engagement, workers develop an acute awareness of machinery behavior, allowing them to anticipate and rectify issues before they escalate.

This cultural shift minimizes downtime, strengthens teamwork, and enhances the overall effectiveness of TPM implementation.

7. Enhancing Workplace Safety and Compliance

7.1 Reducing Accidents Through Well-Maintained Equipment

Poorly maintained machinery poses significant safety hazards, leading to workplace injuries and costly disruptions. TPM mitigates these risks by ensuring that equipment operates within optimal conditions, free from mechanical faults that could result in unexpected failures. Routine inspections and adherence to safety checklists prevent hazardous incidents, safeguarding both personnel and production integrity.

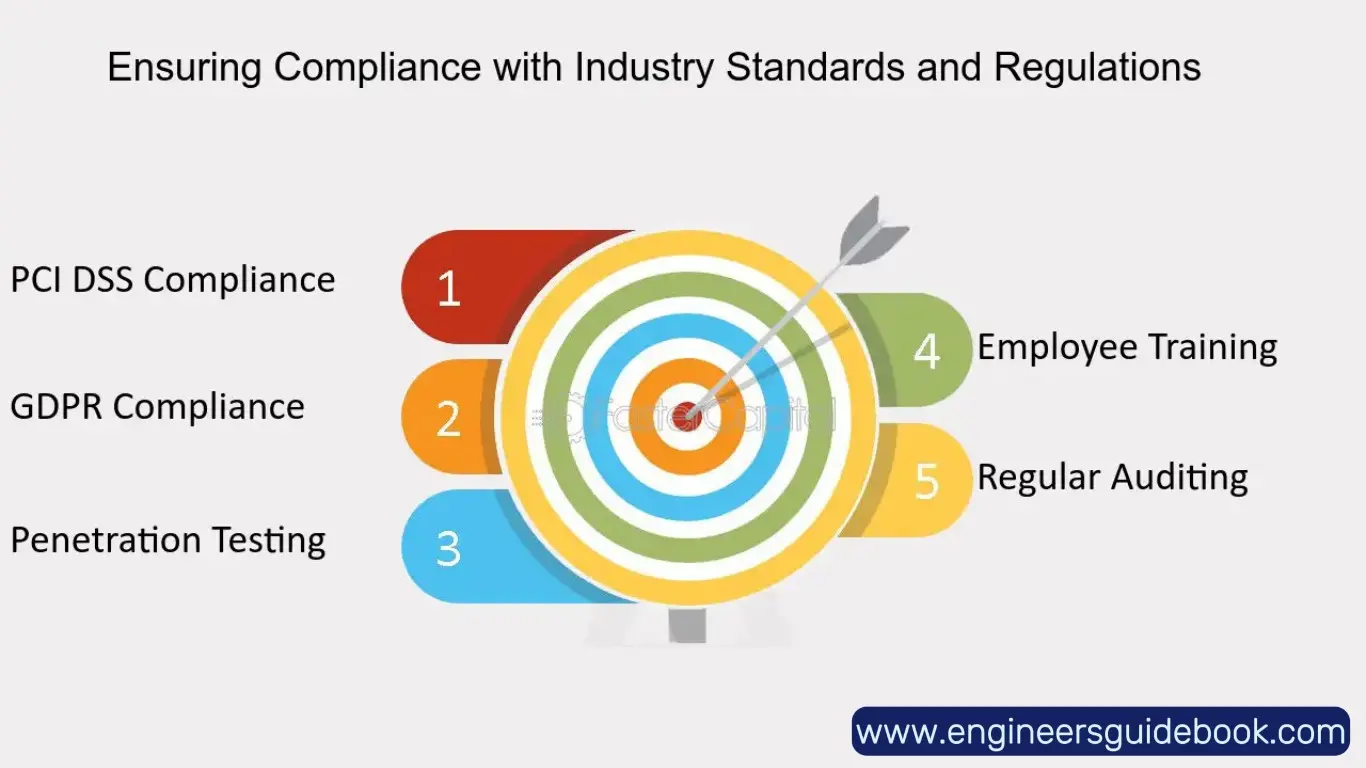

7.2 Ensuring Compliance with Industry Safety Regulations

Regulatory bodies impose stringent safety standards to protect workers and maintain operational excellence. TPM facilitates compliance by integrating safety protocols into daily maintenance routines. Regular audits, documentation of maintenance activities, and adherence to preventive measures ensure that equipment meets legal requirements, reducing the likelihood of penalties and legal complications.

7.3 Creating a Safer Work Environment for Employees

A structured maintenance approach contributes to a safer and more organized workspace. By eliminating leaks, malfunctions, and mechanical inefficiencies, TPM reduces the risk of fire hazards, chemical spills, and ergonomic injuries. A clean, well-maintained environment enhances employee confidence, reinforcing a culture of safety that prioritizes well-being alongside productivity.

8. Strengthening Equipment Availability and Utilization

8.1 Increasing Machine Uptime

Predictive maintenance, a core component of TPM, leverages data analytics and sensor technology to foresee potential failures before they occur. By monitoring critical parameters such as vibration, temperature, and lubrication levels, organizations can schedule maintenance activities with precision, preventing unexpected shutdowns and ensuring continuous production flow.

8.2 Optimizing Production

Unreliable machinery disrupts production timelines, causing delays that impact supply chain efficiency. TPM enhances scheduling accuracy by maintaining equipment in peak condition, reducing uncertainties associated with breakdowns. Reliable machinery allows for streamlined production planning, meeting delivery commitments and optimizing resource allocation.

8.3 Maximizing Asset Utilization

Efficient asset utilization translates to improved financial performance. TPM ensures that machines operate at maximum efficiency throughout their lifecycle, reducing idle time and underperformance. By extending equipment longevity and minimizing costly repairs, organizations realize a higher return on investment, strengthening their competitive edge in the market.

9. Reducing Production Losses and Waste

9.1 Addressing Minor Stoppages

Frequent minor stoppages, often overlooked in traditional maintenance approaches, collectively contribute to substantial production losses. TPM addresses these inefficiencies by encouraging operators to identify and rectify small-scale disruptions before they compound into significant downtime. This proactive approach maintains operational continuity and preserves productivity levels.

9.2 Minimizing Rework and Scrap

Defective machinery produces substandard goods, leading to increased rework and material wastage. TPM ensures that equipment functions with precision, reducing variability in manufacturing processes. By maintaining calibration accuracy and eliminating inconsistencies, TPM upholds product quality, minimizes defects, and reduces unnecessary expenditures on rework and waste disposal.

9.3 Supporting Lean Manufacturing Principles

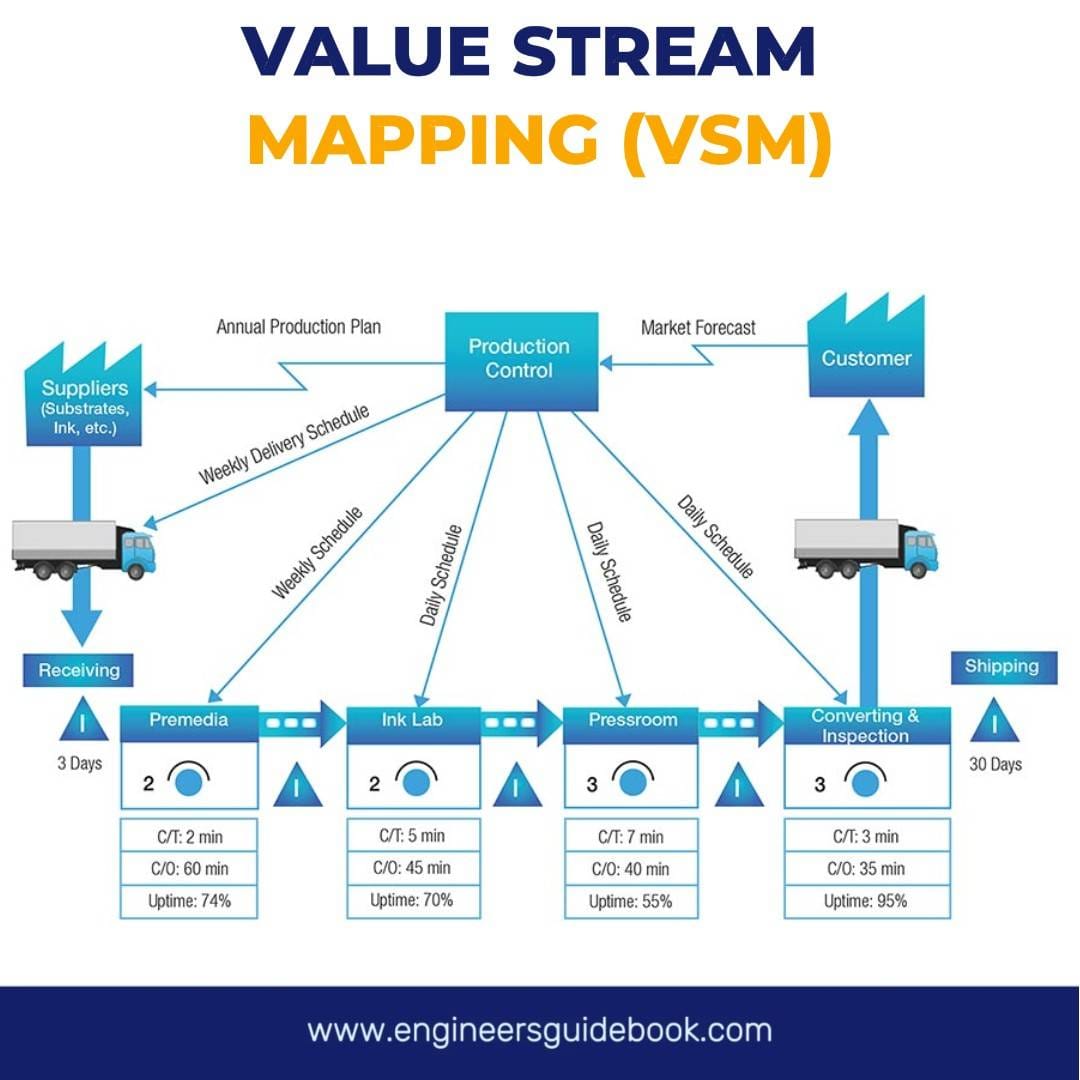

Lean manufacturing aims to eliminate inefficiencies, and TPM aligns seamlessly with this philosophy. By reducing equipment-related waste, optimizing workflow, and improving machine reliability, TPM supports lean initiatives such as Just-in-Time (JIT) production and value stream mapping. This integration fosters a streamlined manufacturing process with minimal resource wastage.

10. Integrating TPM with Lean Manufacturing and Six Sigma

10.1 Synergizing TPM with Waste-Reduction Strategies

Waste reduction is a fundamental objective of both TPM and lean manufacturing. Through systematic maintenance and continuous improvement, TPM eliminates waste associated with machine breakdowns, inefficient processes, and unnecessary downtime. This synergy enhances productivity while reducing environmental impact, aligning operations with sustainability goals.

10.2 Enhancing Continuous Improvement Initiatives

Six Sigma and TPM share a common goal: process optimization through data-driven decision-making. TPM complements Six Sigma methodologies by identifying maintenance-related inefficiencies that impact production quality. By integrating statistical analysis with maintenance strategies, organizations achieve consistent process refinement and enhanced operational performance.

10.3 Achieving Operational Excellence

The fusion of TPM, Lean, and Six Sigma creates a holistic approach to operational excellence. Advanced analytics, machine learning, and condition-based monitoring transform maintenance from a reactive task into a strategic function. Organizations that adopt this integrated approach benefit from reduced operational costs, enhanced efficiency, and sustained competitive advantage.

11. Enhancing Energy Efficiency and Sustainability

11.1 Reducing Energy Consumption

Energy efficiency is a cornerstone of modern manufacturing, and TPM plays a pivotal role in achieving it. By maintaining equipment in peak condition, unnecessary energy wastage due to friction, overheating, or inefficiencies is significantly reduced. Regular lubrication, alignment checks, and performance monitoring ensure that machines operate within their optimal parameters, thereby lowering overall energy consumption.

11.2 Minimizing Environmental

Environmental sustainability is closely tied to effective maintenance strategies. Equipment failures often result in leaks of hazardous substances, excessive emissions, and increased material waste. TPM mitigates these risks by implementing preventive measures that address potential inefficiencies before they become critical. Sealing air leaks, preventing fluid spills, and ensuring combustion efficiency are some key aspects that contribute to a greener production environment.

11.3 Aligning TPM With Sustainability Goals

As industries worldwide strive to reduce their carbon footprint, TPM serves as a strategic enabler. By integrating TPM with sustainability initiatives, manufacturers can achieve energy conservation, waste reduction, and enhanced regulatory compliance. The proactive nature of TPM aligns with corporate social responsibility (CSR) goals, helping companies foster an environmentally responsible image while also improving operational efficiency.

12. Boosting Employee Morale and Engagement

12.1 Creating a Culture of Responsibility and Accountability

TPM is not just about machine maintenance; it also fosters a culture where employees take ownership of their workspaces. By involving operators in maintenance activities, TPM instills a sense of responsibility, ensuring that employees actively participate in keeping equipment in optimal condition. This heightened sense of accountability contributes to overall workplace discipline and morale.

12.2 Encouraging Teamwork in Maintenance and Problem-Solving

A well-implemented TPM framework promotes collaboration between maintenance personnel, operators, and management. Cross-functional teamwork is encouraged through structured problem-solving exercises, daily maintenance routines, and shared responsibility for equipment performance. This collaborative approach strengthens workplace cohesion and enhances overall productivity.

12.3 Recognizing Employee Contributions to TPM Success

Acknowledging employee contributions is crucial to sustaining TPM efforts. Recognition programs, performance incentives, and appreciation initiatives reinforce a positive feedback loop where employees remain motivated to uphold TPM principles. When workers see the tangible impact of their efforts on equipment performance and overall efficiency, their engagement levels increase significantly.

13. Facilitating Predictive and Condition-Based Maintenance

13.1 Leveraging IoT and Sensors

The advent of the Industrial Internet of Things (IIoT) has revolutionized maintenance strategies. TPM now incorporates smart sensors and IoT-enabled devices that continuously monitor equipment health. These technologies allow for real-time data collection, enabling early detection of anomalies and timely interventions before failures occur.

13.2 Implementing Data-Driven Maintenance

Data analytics plays a crucial role in modern TPM strategies. By leveraging historical performance data and machine learning algorithms, manufacturers can make informed decisions about maintenance schedules, resource allocation, and process optimization. Predictive maintenance powered by data insights minimizes unexpected breakdowns and enhances overall asset reliability.

13.3 Reducing Unexpected Failures

Predictive maintenance is a game-changer in TPM, allowing manufacturers to anticipate failures before they happen. By analyzing vibration patterns, thermal imaging data, and other condition-based indicators, maintenance teams can proactively address issues, thereby reducing unplanned downtime and increasing equipment lifespan.

14. Improving Equipment Standardization and Documentation

14.1 Establishing Clear Maintenance Procedures

Standardized maintenance procedures are essential for consistency and efficiency. TPM encourages the development of detailed guidelines for equipment servicing, troubleshooting, and calibration. These documented best practices ensure that maintenance tasks are performed systematically, reducing variability and enhancing reliability.

14.2 Ensuring Consistency in Machine Handling

Variation in maintenance practices can lead to inconsistent performance across equipment. TPM enforces uniformity by training employees on standardized troubleshooting techniques, ensuring that machines are handled and serviced in a consistent manner. This minimizes errors, enhances equipment longevity, and improves overall operational stability.

14.3 Enhancing Knowledge Retention

Documentation is a critical component of TPM, serving as a repository of technical knowledge and historical data. Well-maintained records allow for easy reference, facilitating knowledge transfer between shifts and across generations of workers. By systematically logging maintenance activities, root cause analyses, and equipment performance trends, manufacturers can build a robust knowledge base that supports long-term operational efficiency.

15. Increasing Competitive Advantage in the Industry

15.1 Positioning TPM as a Differentiator for Operational Excellence

Companies that implement TPM effectively can position themselves as industry leaders in reliability and efficiency. A well-maintained production system minimizes waste, reduces costs, and ensures consistent quality—giving manufacturers a distinct competitive edge. TPM fosters a reputation for operational excellence, making businesses more attractive to investors, partners, and customers.

15.2 Gaining a Market Edge Through Higher Productivity and Quality

Organizations that adopt TPM can achieve superior productivity and product quality. Fewer machine failures mean increased throughput, allowing businesses to fulfill higher order volumes with the same resources. Additionally, well-maintained equipment ensures precision in manufacturing, leading to fewer defects and a stronger reputation in the market.

15.3 Adapting to Industry Trends with TPM-Driven Agility

TPM enables companies to quickly adapt to evolving industry demands. By ensuring that equipment remains reliable and efficient, organizations can integrate new technologies, scale operations, and respond to market fluctuations with agility. This flexibility is crucial in a competitive landscape where rapid innovation drives success.

16. Case Studies: Real-World Examples of Benefits of TPM

16.1 How Leading Manufacturers Have Benefited from TPM Implementation

Many global manufacturers have successfully leveraged TPM to drive operational improvements. Companies in industries such as automotive, aerospace, and consumer goods have reported significant reductions in downtime, enhanced equipment longevity, and improved product quality through structured TPM programs.

16.2 Key Lessons from Successful TPM Adoption Across Industries

Organizations that have successfully implemented TPM share common best practices, including strong leadership commitment, employee training, and cross-functional collaboration. These case studies highlight how businesses can overcome challenges and maximize the benefits of TPM for sustained success.

16.3 Measurable Improvements in Efficiency, Cost Savings, and Quality

Quantifiable benefits from TPM implementation include reduced maintenance costs, increased overall equipment effectiveness (OEE), and higher yield rates. Companies have also reported improved workplace safety and lower environmental impact, reinforcing TPM’s role as a holistic improvement strategy.

17. Challenges and Best Practices for TPM Implementation

17.1 Overcoming Resistance to Cultural Change in Maintenance Practices

One of the biggest challenges in TPM implementation is overcoming employee resistance to change. Many workers are accustomed to reactive maintenance approaches and may be reluctant to embrace proactive strategies. Effective change management, employee engagement, and continuous training are key to fostering a TPM culture.

17.2 Ensuring Cross-Departmental Collaboration for TPM Success

TPM is not limited to the maintenance department—it requires collaboration across production, quality assurance, and supply chain management. Encouraging open communication and teamwork ensures that TPM initiatives align with broader organizational goals, enhancing overall efficiency.

17.3 Tracking and Measuring TPM Effectiveness

To ensure TPM success, organizations must track key performance indicators (KPIs) such as overall equipment effectiveness (OEE), mean time between failures (MTBF), and mean time to repair (MTTR). Regular performance reviews and data-driven decision-making help refine TPM strategies and sustain long-term improvements.

18. Conclusion

TPM is a strategic approach that enhances equipment reliability, reduces costs, and improves overall productivity. By fostering a proactive maintenance culture, organizations can achieve long-term operational excellence and sustainability.

Implementing TPM requires an initial investment of time and resources, but the long-term benefits far outweigh the costs. Improved efficiency, reduced downtime, and enhanced quality make TPM a crucial pillar of modern manufacturing success.

In an era of increasing competition and technological advancement, TPM provides a roadmap for sustainable growth. Organizations that prioritize proactive maintenance and continuous improvement will position themselves as industry leaders, ensuring long-term profitability and resilience.

19. FAQ’S

1. What is Total Productive Maintenance (TPM)?

TPM is a comprehensive maintenance approach that focuses on proactive and preventive strategies to maximize equipment efficiency, reduce downtime, and improve overall production reliability.

2. How does TPM improve equipment reliability?

TPM enhances equipment reliability by implementing autonomous maintenance, predictive analytics, and regular inspections, ensuring machines operate at peak efficiency with minimal unplanned failures.

3. What are the key pillars of TPM?

TPM is based on eight pillars, including autonomous maintenance, focused improvement, planned maintenance, quality maintenance, early equipment management, education and training, safety and environment, and administrative TPM.

4. How does TPM reduce manufacturing costs?

By preventing breakdowns, minimizing waste, and optimizing maintenance schedules, TPM lowers repair costs, reduces material losses, and enhances energy efficiency, leading to significant cost savings.

5. What role do employees play in TPM?

Employees are actively involved in TPM through autonomous maintenance, continuous improvement initiatives, and cross-functional collaboration, fostering a sense of ownership and accountability.

6. How does TPM support lean manufacturing?

TPM aligns with lean principles by reducing waste, improving equipment effectiveness, and streamlining processes, ensuring a smooth and uninterrupted production flow.

7. What industries benefit the most from TPM?

TPM is widely used in manufacturing, automotive, pharmaceuticals, food processing, and other industries where equipment reliability and operational efficiency are critical.

8. What are the biggest challenges in TPM implementation?

Common challenges include resistance to cultural change, lack of employee engagement, inadequate training, and difficulty in sustaining long-term improvements without strong leadership commitment..

One Response

Hey there! I’ve been following your weblog for a while now and finally got the bravery to go ahead and give you a shout out from Kingwood Tx! Just wanted to tell you keep up the excellent job!