August 24, 2024 By Bilal 6 minutes read

Eye bolts are versatile hardware components that play a crucial role in various industries, providing secure anchor points for lifting, rigging, and securing loads. These simple devices, consisting of a threaded shank with a looped head or “eye,” are invaluable for tasks where objects need to be lifted, pulled, or secured. In this comprehensive guide, we will delve into the different types of eye bolts, their specific uses, best practices, and key considerations for selecting the right type for different applications.

Eye bolts are fasteners that feature a looped end (the eye) and a threaded shaft. The eye acts as an anchor point through which cables, ropes, or hooks can pass. They are commonly used in lifting applications, but they can also be employed to secure heavy machinery, hoist loads, or even serve as attachment points for rigging.

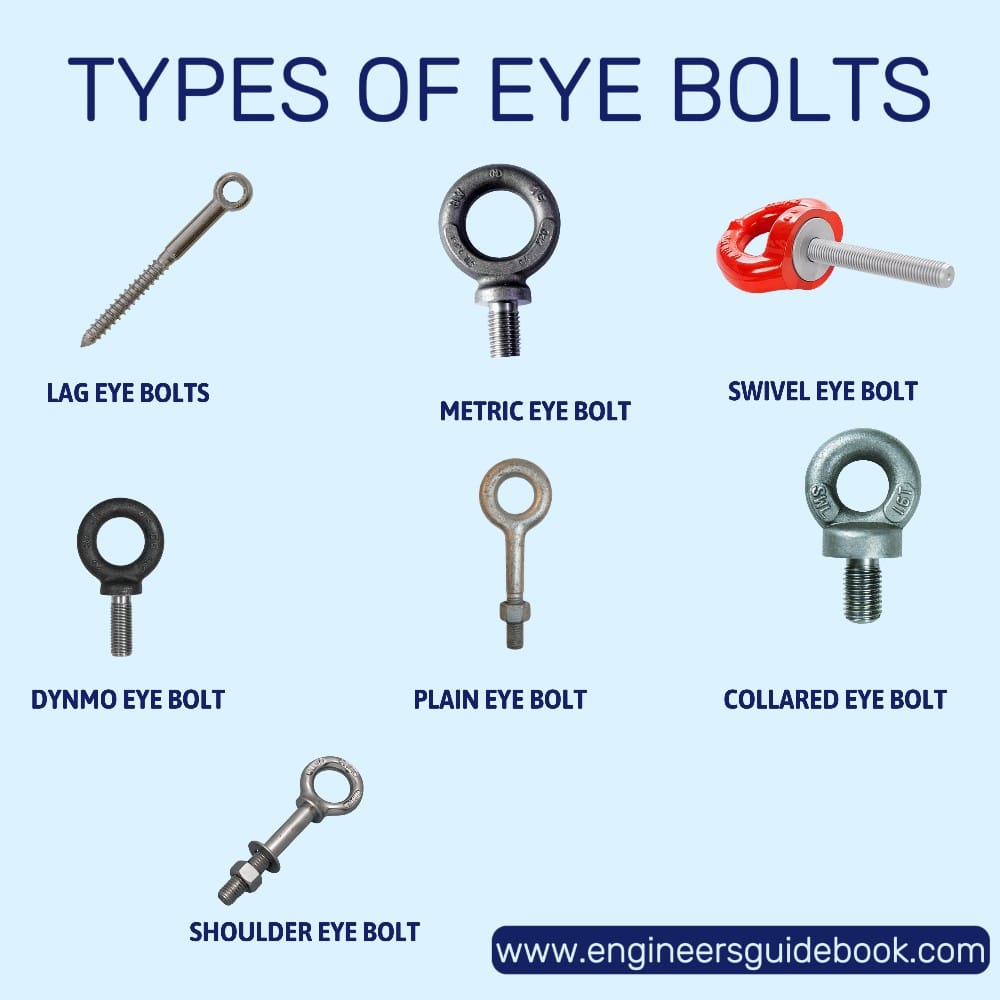

Eye bolts come in various types, each suited for specific tasks. It is essential to understand the differences to choose the correct type for your application.

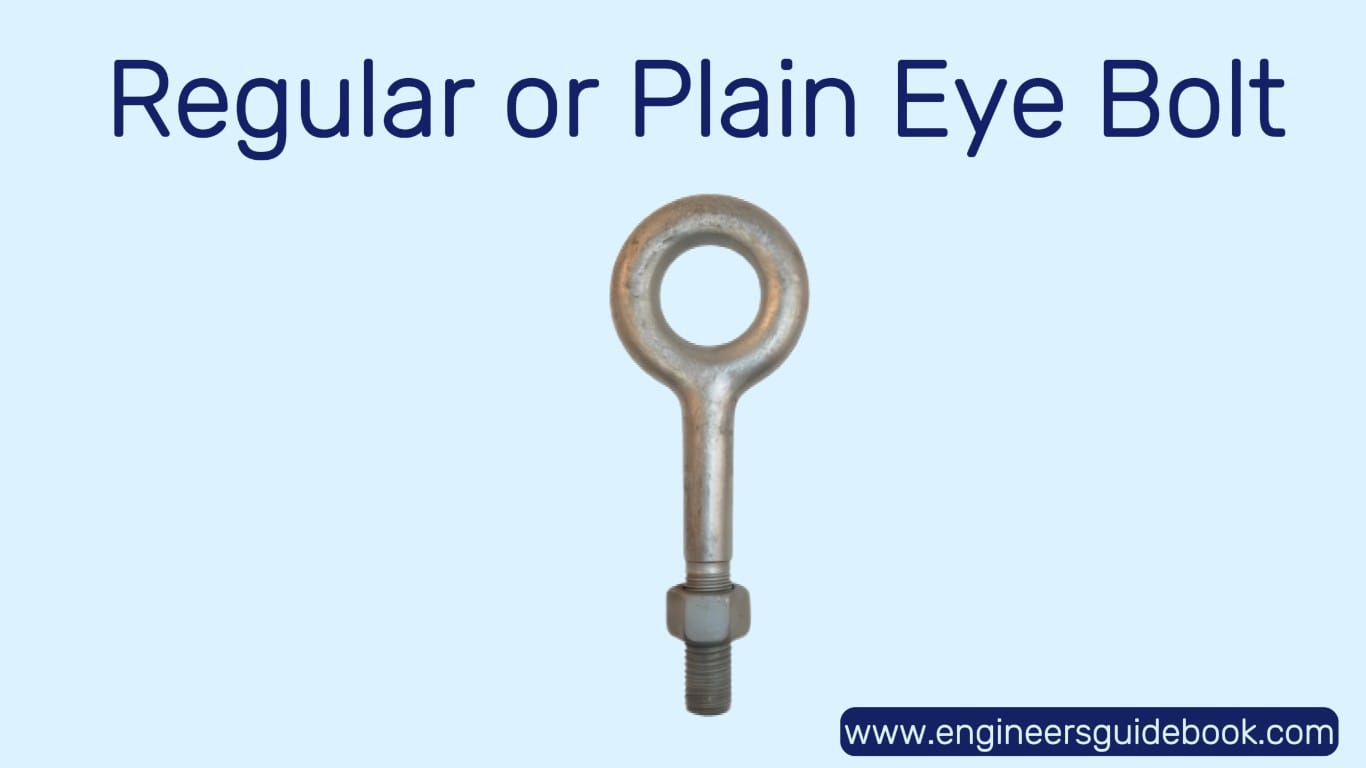

Regular or plain eye bolts have a threaded shank with a circular eye at the top. These bolts are typically designed for straight, in-line loading applications, meaning the load is applied directly along the axis of the shank. They are ideal for vertical lifts or securing objects in a linear fashion.

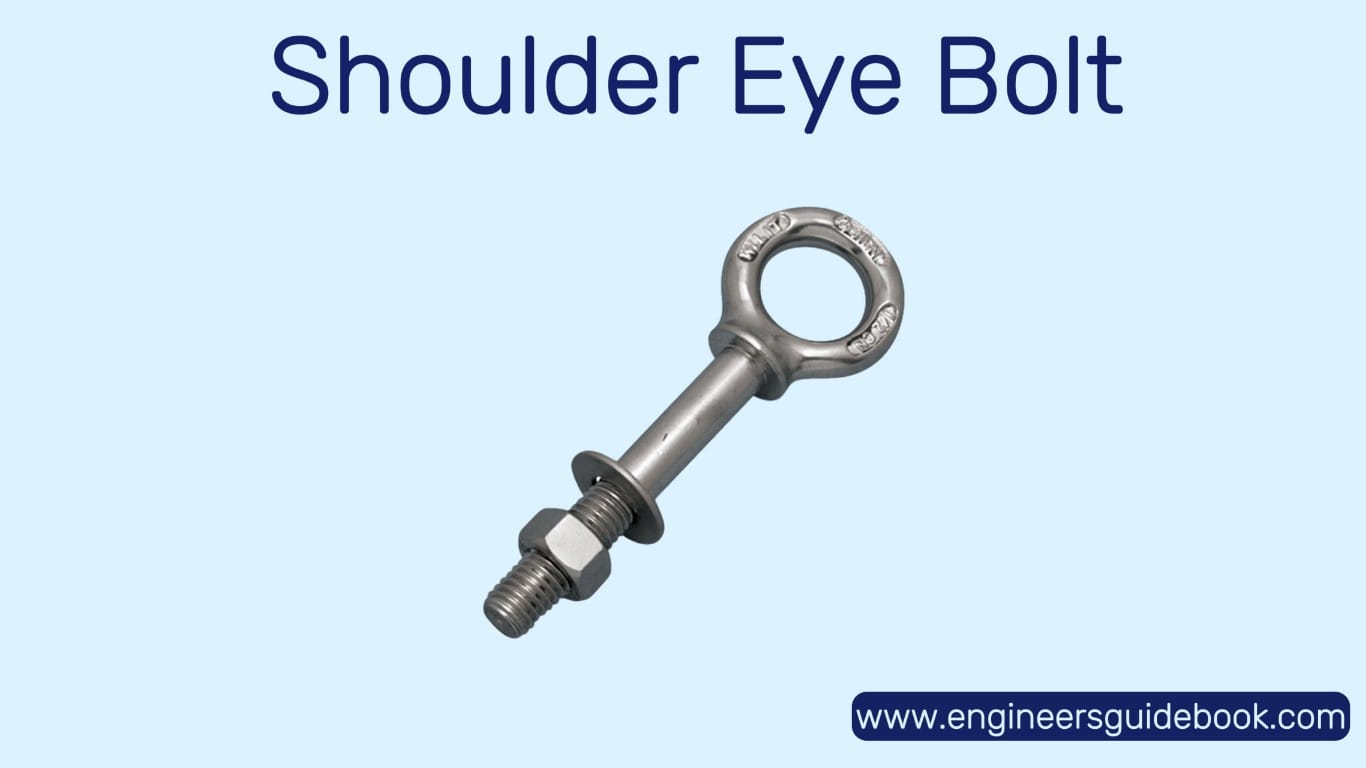

Shoulder eye bolts are designed for both straight and angular loads. The “shoulder” or flange between the eye and the shank provides added strength, making these bolts suitable for use in applications where the load is applied at an angle.

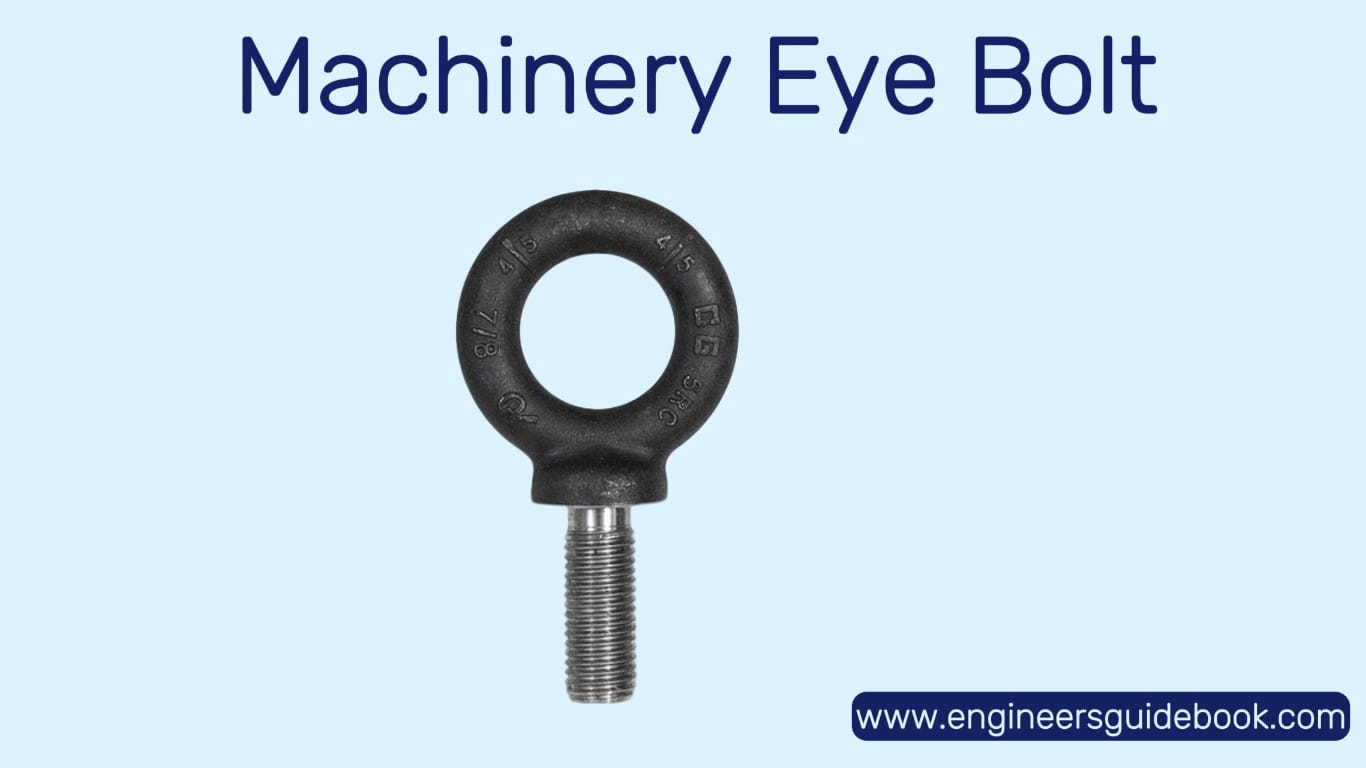

Machinery eye bolts are specifically designed for use in machinery and equipment lifting. These bolts have a thicker shank and a smaller, forged eye, making them more robust and capable of handling heavy loads. The shank is typically fully threaded, allowing for secure attachment to heavy equipment or machinery.

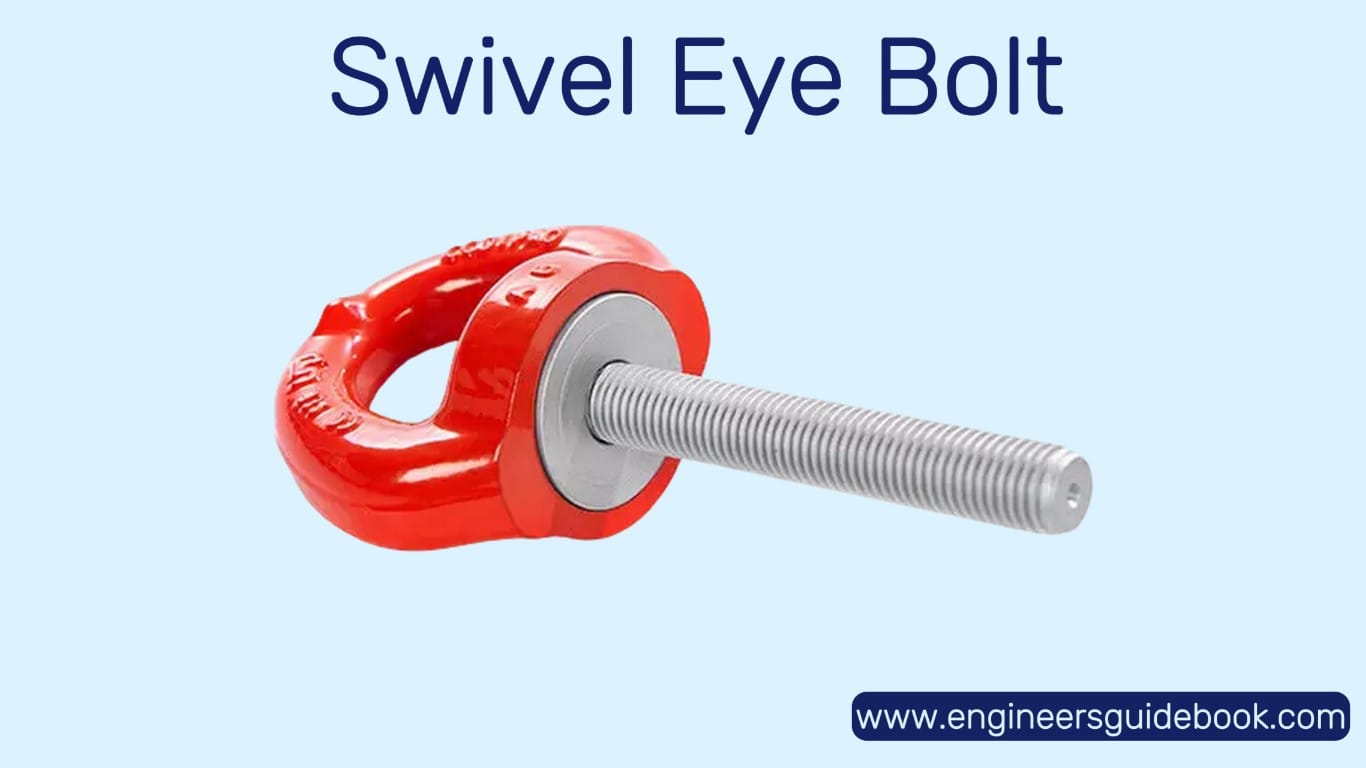

Swivel eye bolts are equipped with a rotating eye that allows for 360-degree movement. This feature makes them ideal for lifting loads that might need to rotate during the lifting process. The eye remains free to align with the load, reducing stress on the bolt itself.

Lag eye bolts have a pointed, screw-like shank designed for use in wood or other soft materials. Instead of threading into a nut, the shank is screwed directly into the wood, creating a secure anchor point.

Dynamo eye bolts are specifically designed for electric dynamos, turbines, and other heavy machinery in the power generation industry. They feature a heavy-duty construction and are typically forged from high-strength steel alloys to ensure they can handle the dynamic stresses involved in such environments.

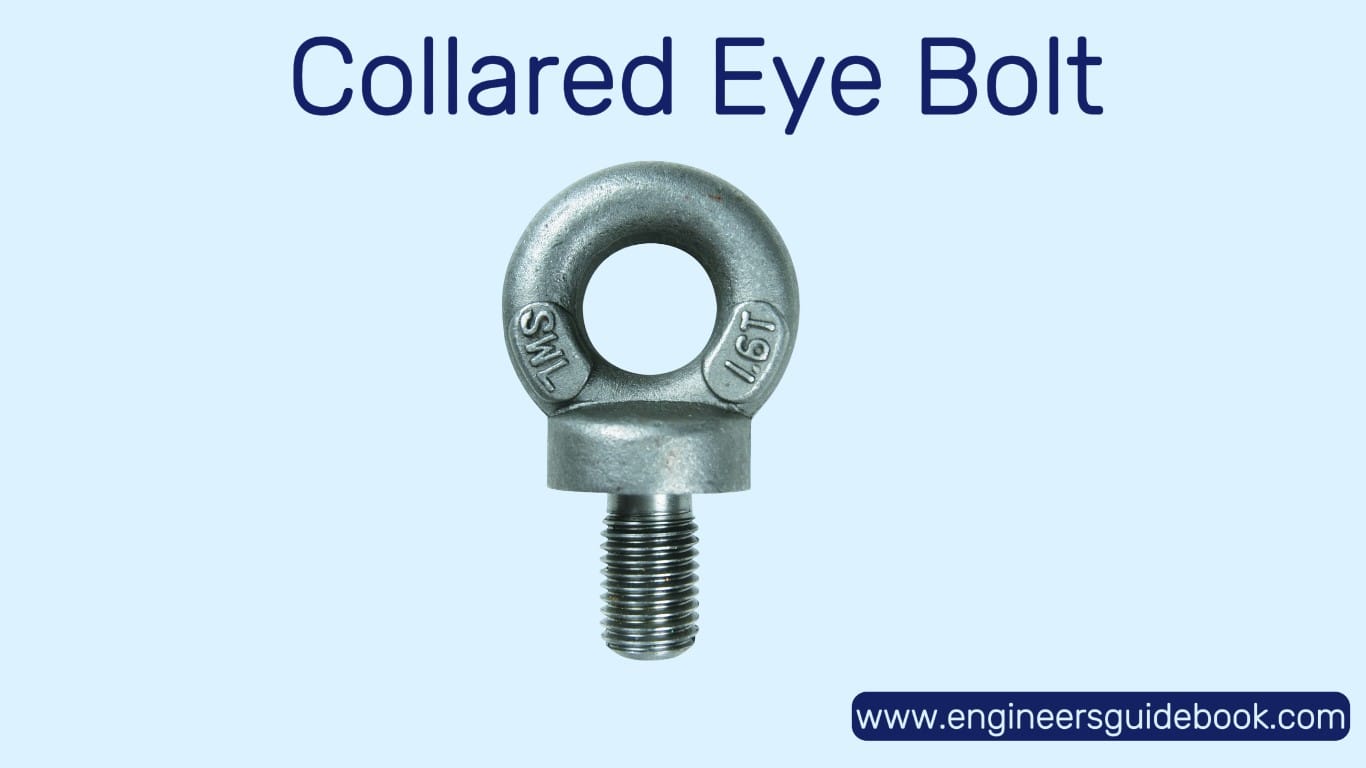

Collared eye bolts have a collar or flange under the eye, which increases their load-bearing capacity when the load is applied at an angle. This design helps reduce bending stress on the bolt, making it more robust in angled loading scenarios.

Metric eye bolts, as the name suggests, are designed to meet metric standards rather than imperial standards. They are commonly used in countries that follow the metric system. They come in various sizes and strengths, offering a standardized approach to lifting applications in these regions.

Eye bolts are available in a wide range of materials, each suited for specific environmental and load conditions. Some of the most commonly used materials include:

Eye bolts are frequently used in lifting applications to hoist heavy objects securely. They serve as anchor points for hooks, chains, or slings. For lifting, shoulder eye bolts or machinery eye bolts are recommended to ensure that the load is evenly distributed and secure.

Examples:

In rigging applications, eye bolts serve as anchor points to secure cables or chains that are used to stabilize or move heavy loads. Swivel eye bolts are especially useful in these cases, as they can rotate, preventing cables from twisting or tangling.

Examples:

Eye bolts are used to anchor objects securely to a surface. This is particularly useful in scenarios where objects need to be secured but not necessarily lifted. Lag eye bolts are commonly used for anchoring in wood or other soft materials.

Examples:

Due to their corrosion resistance, stainless steel and galvanized eye bolts are commonly used in marine environments for various tasks. These bolts provide secure anchor points for rigging, towing, and securing boats, yachts, and other watercraft.

Examples:

Eye bolts are essential in industrial settings for moving and securing large, heavy equipment. Machinery eye bolts are designed to handle the stress of lifting large industrial machines, making them indispensable in factories, warehouses, and power plants.

Examples:

Choosing the correct eye bolt for your application is critical to ensuring safety and performance. Here are the key considerations:

The load capacity of an eye bolt is one of the most important factors to consider. Ensure the bolt is rated to handle the weight of the object being lifted or secured. Always refer to manufacturer specifications to determine the bolt’s load rating.

The environment in which the eye bolt will be used should dictate the material. For corrosive environments, stainless steel or galvanized bolts are preferable. For general indoor use, carbon steel may suffice.

If the load will be applied at an angle, choose a shoulder eye bolt or a collared eye bolt, which can handle angular loads without bending or breaking. For straight vertical loads, regular or machinery eye bolts can be used.

Consider the material in which the eye bolt will be installed. Lag eye bolts are suitable for wood, while regular or shoulder eye bolts are ideal for metal or other solid materials.

Ensure the thread type of the eye bolt matches the application. Some eye bolts have coarse threads, while others have fine threads. The right thread type can affect the strength and security of the bolt in its application.

Proper installation is crucial to the performance and safety of eye bolts. Follow these best practices for optimal results:

Eye bolts are indispensable tools in numerous industries, offering secure, reliable anchor points for lifting, rigging, and securing heavy loads.

By understanding the different types of eye bolts and their specific uses, you can select the right one for your needs and ensure safe and efficient operations. Whether you’re lifting heavy machinery, securing a boat, or anchoring outdoor structures, choosing the right eye bolt is key to success. Always follow best practices for installation and maintenance to maximize the performance and longevity of your eye bolts.

Eye bolts are used as anchor points for lifting, rigging, and securing loads. They provide a secure loop through which ropes, cables, or chains can pass, making them suitable for various industrial, construction, and marine applications.

There are several types of eye bolts, including:

Each type serves a specific function, with some designed for vertical loads and others for angular or dynamic loads.

A plain eye bolt is designed for straight, in-line loads, while a shoulder eye bolt can handle angular loads due to its reinforced shoulder. Shoulder eye bolts provide added strength for loads applied at an angle.

Yes, shoulder and collared eye bolts are designed to handle angular loads. However, the load angle should be minimized to avoid over-stressing the bolt. Plain eye bolts should not be used for angular loading as they may bend or break.

Eye bolts are made from various materials, including:

The choice of material depends on the environment and load conditions. For example, stainless steel is used in corrosive environments, while carbon steel is suitable for general-purpose applications.

To install an eye bolt:

The load capacity of an eye bolt depends on its size, type, and material. Always consult the manufacturer’s specifications for load ratings. Factors like load direction (vertical vs. angular) also impact the bolt’s capacity.

When selecting an eye bolt, consider:

Yes, eye bolts are commonly used for lifting heavy loads. Shoulder eye bolts, machinery eye bolts, and swivel eye bolts are often used in these applications. Always ensure the eye bolt is rated for the weight and type of load being lifted.

Improper use of eye bolts can result in:

No, regular or plain eye bolts are not designed for dynamic or rotating loads. For such applications, a swivel eye bolt is recommended, as it can rotate 360 degrees and reduce stress on the bolt and cables.

Regularly inspect eye bolts for signs of wear, including:

Yes, eye bolts can be used in outdoor or marine environments, but the material selection is crucial. Stainless steel and galvanized steel eye bolts are recommended for outdoor or marine applications because of their corrosion resistance.

Bilal Arshad, with a PhD in Mechanical Engineering from Caltech, specializes in robotics and automation. His cutting-edge research in autonomous systems is revolutionizing industrial manufacturing processes.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.

One Response

This is a fantastic and well-organized guide to eye bolts. The detailed information is very useful for engineers.