1. Introduction

The manufacturing industry has long been reliant on reactive maintenance strategies, addressing equipment failures only when they occur. While this approach may seem cost-effective in the short term, it often results in unexpected downtime, increased repair costs, and reduced overall efficiency. A proactive maintenance strategy, such as Total Productive Maintenance (TPM), shifts the focus from mere equipment repair to comprehensive equipment care. By anticipating potential failures and systematically improving machine reliability, manufacturers can sustain operational excellence and avoid costly disruptions. In this guide will discuss in detail how you can implement TPM in your manufacturing unit.

1.1 Understanding the Core Principles of Total Productive Maintenance (TPM)

TPM is a holistic approach that integrates maintenance into the fabric of daily manufacturing operations. Unlike traditional maintenance programs that rely solely on maintenance personnel, TPM empowers all employees, from machine operators to top management, to take responsibility for equipment health. At its core, TPM is built on the principles of continuous improvement, preventive maintenance, and employee involvement, ensuring that equipment operates at peak efficiency with minimal unplanned downtime.

1.2 The Business Impact of Implementing TPM

Implementing TPM translates into tangible business benefits. Equipment reliability improves as proactive maintenance reduces breakdowns, leading to increased production uptime. TPM enhances overall equipment effectiveness (OEE), a crucial metric that evaluates availability, performance, and quality. Additionally, TPM fosters a culture of continuous improvement, where employees actively contribute to process optimization, ultimately driving cost savings and operational efficiency.

2. Understanding Total Productive Maintenance (TPM)

2.1 The Evolution of TPM

The origins of TPM can be traced back to Japan in the 1950s, with Nippon Denso, a subsidiary of Toyota, pioneering this methodology. Initially, maintenance was viewed as a separate function, detached from daily manufacturing processes. However, TPM revolutionized this perspective by integrating maintenance into production, emphasizing operator-driven maintenance activities and continuous improvements. This evolution has helped organizations achieve higher efficiency, reliability, and overall productivity.

2.2 The Core Philosophy of TPM

TPM is built on the philosophy that all employees, regardless of their role, share responsibility for equipment maintenance. This democratization of maintenance fosters a proactive mindset, where operators take ownership of machine performance and collaborate with maintenance teams to identify and eliminate inefficiencies. Continuous improvement, or kaizen, lies at the heart of TPM, ensuring that organizations consistently refine their processes to achieve peak operational performance.

2.3 Differentiating TPM from Other Maintenance Strategies: Preventive, Predictive, and Reactive Approaches

While TPM encompasses elements of preventive and predictive maintenance, it extends beyond these traditional methodologies. Preventive maintenance involves routine servicing to prevent equipment failures, while predictive maintenance leverages data analytics to forecast potential issues. Reactive maintenance, on the other hand, is purely corrective, addressing failures only after they occur. TPM integrates these approaches but uniquely emphasizes operator involvement and a structured framework for continuous improvement.

3. The Eight Pillars of TPM: A Structured Framework for Success

3.1 Autonomous Maintenance

Autonomous maintenance places the responsibility of routine equipment checks, lubrication, and minor repairs in the hands of machine operators. By equipping them with the necessary training and tools, organizations can reduce dependency on maintenance teams for minor issues, fostering a sense of ownership and proactive equipment management.

3.2 Planned Maintenance

Planned maintenance involves scheduled inspections and servicing to prevent sudden equipment failures. This structured approach ensures that maintenance activities are performed at optimal intervals, reducing the risk of breakdowns and extending the lifespan of machinery.

3.3 Quality Maintenance

Quality maintenance focuses on identifying and eliminating factors that contribute to defects and inconsistencies in manufacturing processes. By ensuring that machines operate within optimal parameters, organizations can maintain high product quality and minimize rework or waste.

3.4 Focused Improvement

Focused improvement, or kaizen, involves cross-functional teams collaborating to identify and resolve specific inefficiencies within manufacturing processes. By addressing bottlenecks and implementing incremental changes, companies can achieve significant long-term productivity gains.

3.5 Early Equipment Management

Integrating maintenance considerations during the design and procurement phase of equipment ensures that machines are inherently reliable and easy to maintain. This proactive approach minimizes future maintenance challenges and enhances overall equipment effectiveness.

3.6 Training and Education

A well-trained workforce is essential for the successful implementation of TPM. Training programs should focus on equipping employees with the technical skills required for maintenance tasks, as well as fostering a culture of continuous improvement.

3.7 Safety, Health, and Environment

TPM emphasizes workplace safety by integrating health and environmental considerations into maintenance practices. Ensuring that equipment operates safely not only protects employees but also enhances operational sustainability.

3.8 TPM in Administrative Functions

While TPM is predominantly applied to manufacturing operations, its principles can also enhance administrative processes. Streamlining office workflows, reducing inefficiencies, and implementing continuous improvement initiatives in administrative functions contribute to overall organizational efficiency.

4. Building a Strong Foundation for TPM Implementation

4.1 Gaining Leadership Commitment

Leadership support is critical for TPM implementation. Senior management must actively endorse TPM initiatives, allocate resources, and promote a culture that values maintenance as a strategic function rather than a cost center.

4.2 Establishing a TPM Culture

Creating a TPM culture requires a paradigm shift from a reactive to a proactive maintenance mindset. Organizations must instill the belief that equipment care is a collective responsibility, with all employees contributing to operational excellence.

4.3 Setting Clear Goals and Metrics

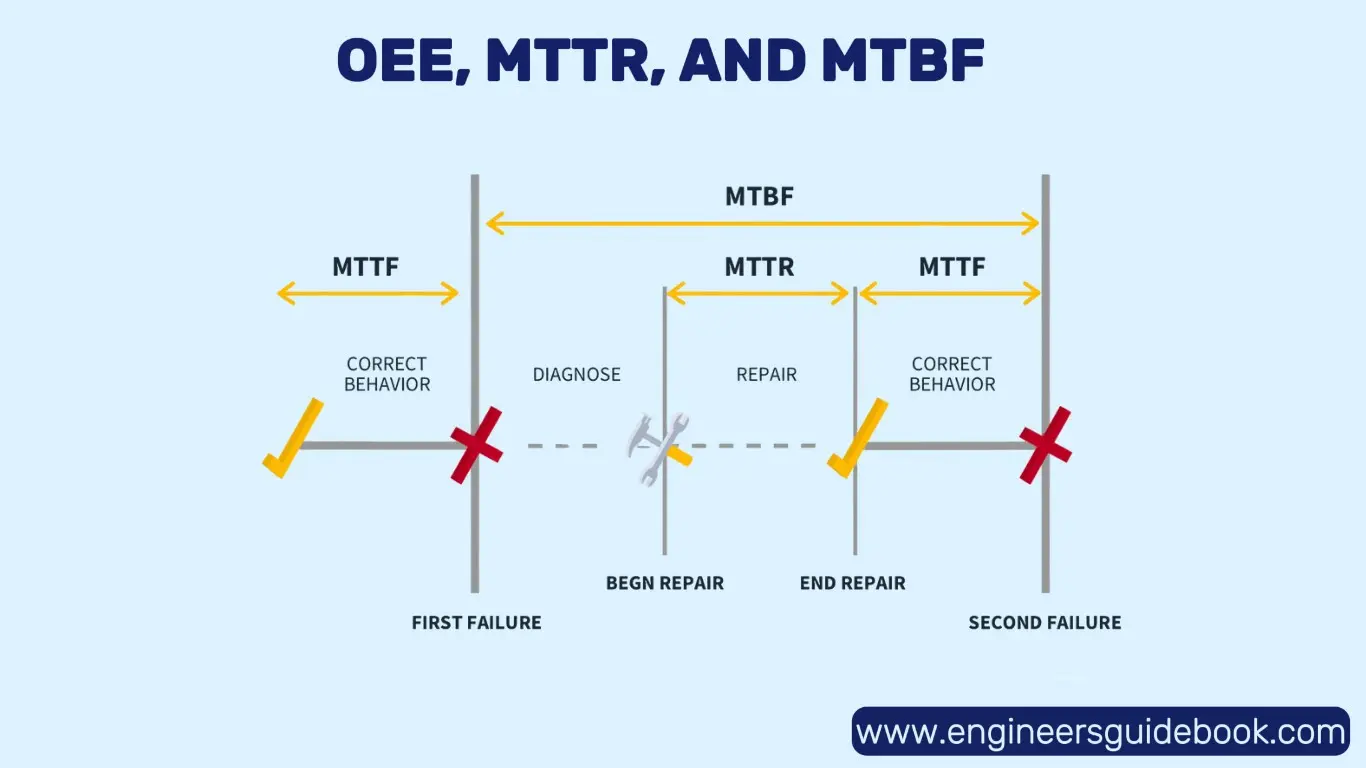

To gauge the effectiveness of TPM initiatives, organizations must establish clear performance metrics. Key Performance Indicators (KPIs) such as Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), and Mean Time to Repair (MTTR) provide valuable insights into maintenance efficiency and process improvements.

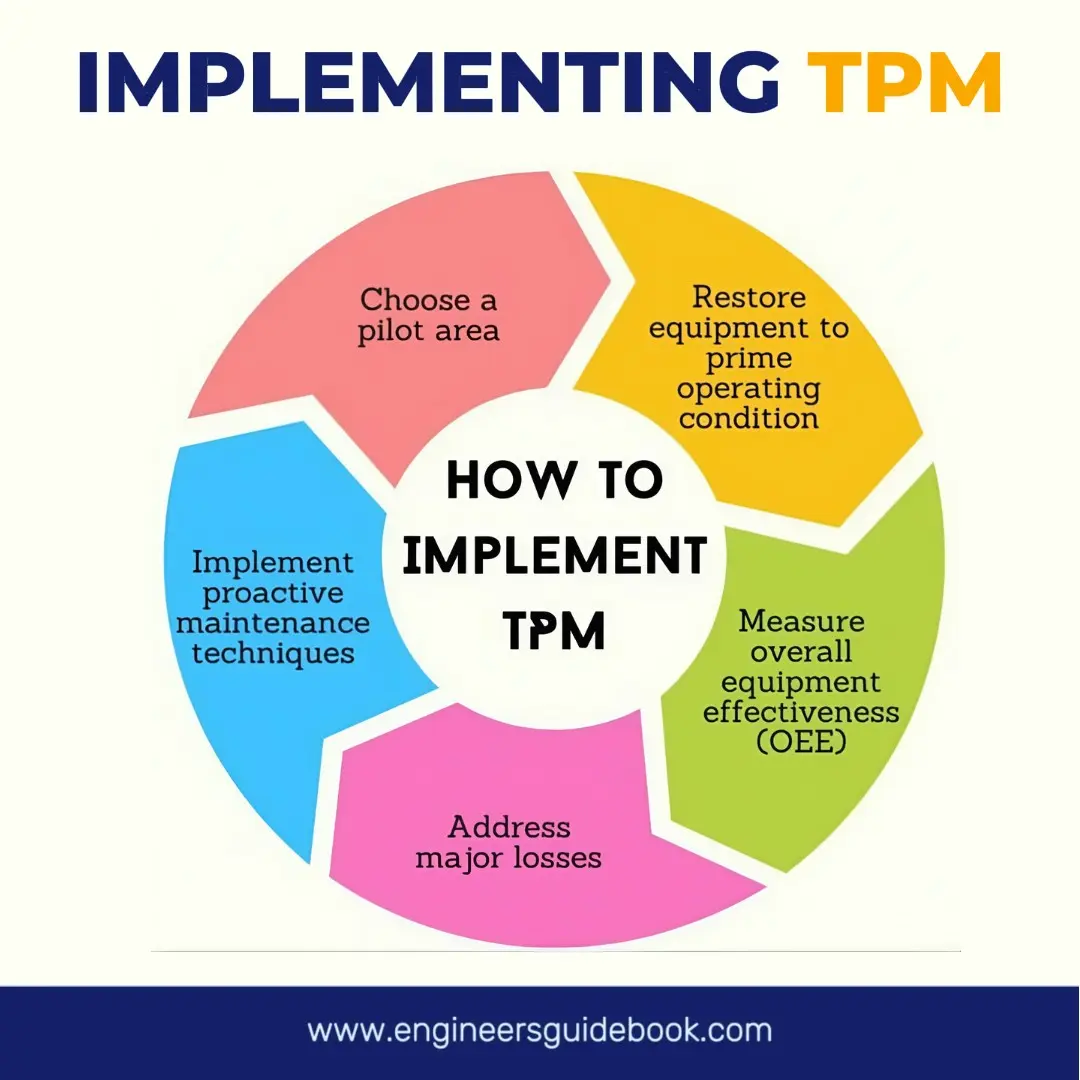

5. Step-by-Step Guide to Implementing TPM in Manufacturing

5.1 Conducting an Initial Equipment Assessment

Before implementing TPM, manufacturers must conduct a thorough assessment of their equipment to identify inefficiencies, recurring failures, and production bottlenecks. This involves gathering historical maintenance data, analyzing breakdown trends, and inspecting machinery for signs of wear and tear. By understanding the current state of equipment reliability, organizations can prioritize maintenance efforts and allocate resources effectively.

5.2 Forming Cross-Functional TPM Teams

Successful TPM implementation requires cross-functional collaboration. Forming dedicated TPM teams consisting of operators, maintenance technicians, engineers, and management ensures that diverse perspectives contribute to maintenance improvements. These teams should be responsible for analyzing performance data, proposing preventive measures, and driving continuous improvement initiatives.

5.3 Developing Standard Operating Procedures (SOPs) for Maintenance Activities

Establishing clear and standardized maintenance procedures is essential for consistency and efficiency. SOPs should outline step-by-step guidelines for routine inspections, lubrication, cleaning, minor repairs, and troubleshooting. Providing employees with structured protocols enhances equipment longevity, reduces variability in maintenance practices, and ensures adherence to best practices.

5.4 Implementing 5S as a Prerequisite for TPM

5S (Sort, Set in Order, Shine, Standardize, Sustain) lays the foundation for TPM by creating a well-organized and clutter-free workspace. A structured 5S approach ensures that tools, spare parts, and workstations are arranged for easy access, reducing delays in maintenance activities. Moreover, a clean and structured environment minimizes the risk of equipment failure caused by dust, debris, or misplacement of critical components.

5.5 Training Operators and Technicians

Empowering employees with the knowledge and skills required for proactive maintenance is a key pillar of TPM. Training programs should cover equipment operation, basic troubleshooting, and preventive maintenance techniques. Investing in hands-on training sessions ensures that operators can detect early warning signs of equipment deterioration, enabling timely interventions.

5.6 Launching Pilot Projects

Before rolling out TPM across the entire manufacturing facility, launching pilot projects in select areas allows organizations to evaluate effectiveness and address potential challenges. A pilot approach enables teams to refine maintenance strategies, fine-tune workflows, and gather feedback from operators. Once successful, the TPM methodology can be expanded systematically to other departments.

6. Overcoming Common Challenges in TPM Implementation

6.1 Resistance to Change

Introducing TPM often encounters resistance from employees who are accustomed to reactive maintenance approaches. To overcome this challenge, organizations must foster a culture of change management. Engaging employees through workshops, clear communication of TPM benefits, and incentivizing participation can enhance acceptance and commitment to the new maintenance paradigm.

6.2 Lack of Resources and Budget Constraints

One of the primary barriers to TPM adoption is the perceived cost of implementation. However, organizations can justify investments by demonstrating the long-term cost savings associated with reduced downtime, lower maintenance expenses, and improved productivity. Conducting a cost-benefit analysis and presenting data-driven ROI projections can help secure management buy-in for TPM initiatives.

6.3 Managing Data and Documentation

Effective TPM relies on accurate data collection, tracking, and analysis. Digital maintenance management systems (CMMS) can streamline data recording, track machine performance, and generate predictive maintenance insights. Transitioning from manual record-keeping to automated systems enhances efficiency, reduces errors, and enables data-driven decision-making.

7. Measuring TPM Effectiveness and Continuous Improvement

7.1 Key Performance Indicators (KPIs) for TPM Success: OEE, MTTR, and MTBF

Measuring the success of TPM requires tracking key performance indicators (KPIs) such as Overall Equipment Effectiveness (OEE), Mean Time to Repair (MTTR), and Mean Time Between Failures (MTBF). OEE provides insights into equipment availability, performance, and quality, while MTTR and MTBF assess maintenance efficiency and failure frequency. Regular monitoring of these metrics helps organizations gauge progress and identify areas for improvement.

7.2 Root Cause Analysis for Recurring Issues

When equipment failures persist despite TPM implementation, root cause analysis (RCA) techniques such as Fishbone Diagrams and the “5 Whys” method can help identify underlying problems. RCA enables organizations to address systemic issues rather than applying temporary fixes, ensuring long-term reliability and performance improvements.

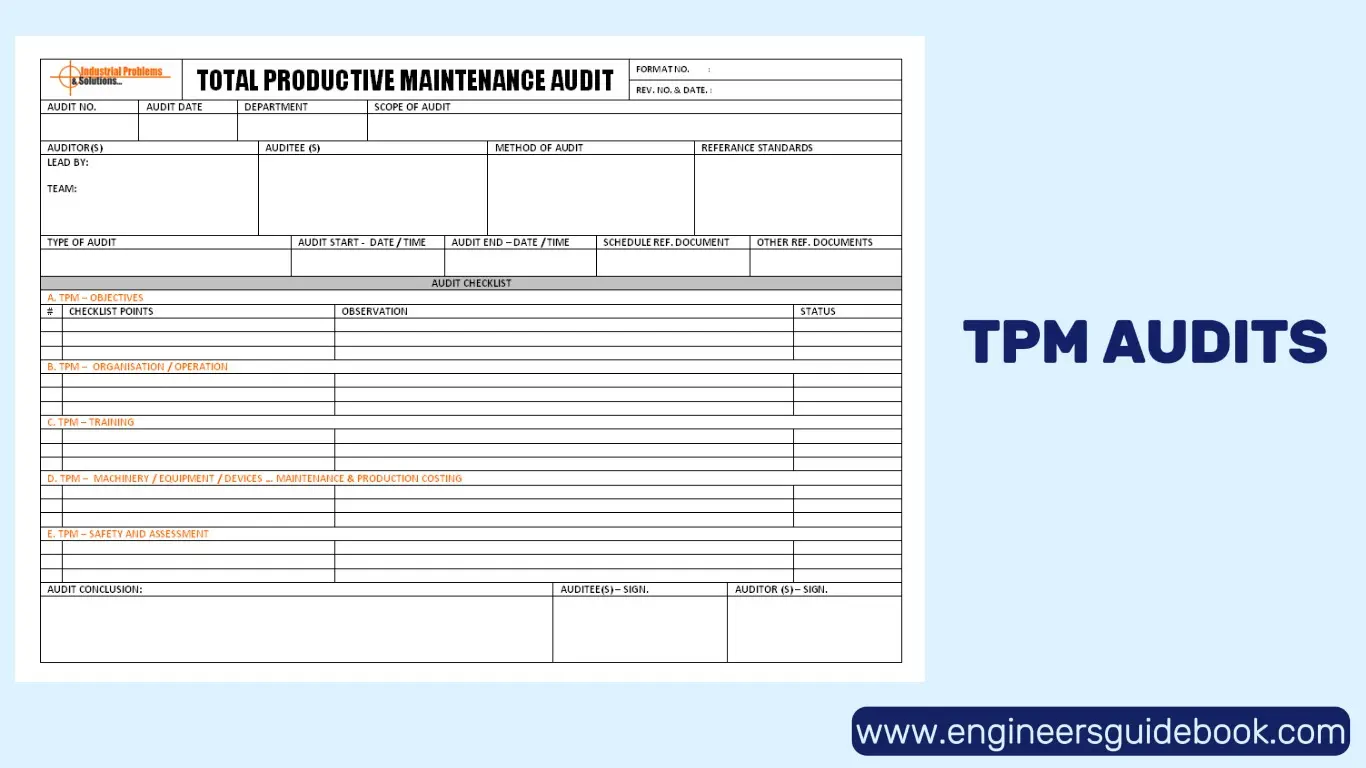

7.3 Periodic TPM Audits

Regular TPM audits assess adherence to maintenance protocols, identify deviations from best practices, and reinforce a culture of continuous improvement. Audits should be conducted periodically to evaluate the effectiveness of TPM programs, ensure compliance with SOPs, and refine maintenance strategies based on evolving operational needs.

8. Case Studies of Successful TPM Implementation

8.1 How Leading Manufacturers Achieved Higher Productivity Through TPM

Numerous global manufacturers have leveraged TPM to drive productivity improvements. For instance, Toyota’s commitment to TPM has enabled the company to achieve world-class manufacturing efficiency, reducing breakdowns and maximizing asset utilization. Similarly, Unilever implemented TPM across its production facilities, resulting in enhanced OEE and significant cost reductions.

8.2 Lessons Learned from Real-World TPM Success Stories

Organizations that have successfully adopted TPM emphasize the importance of leadership commitment, employee engagement, and a structured implementation approach. Case studies reveal that gradual implementation, continuous training, and data-driven decision-making are key to overcoming implementation challenges. Learning from industry success stories provides valuable insights for organizations embarking on their TPM journey.

9. The Future of TPM: Trends and Innovations

9.1 The Role of Industry 4.0 and IoT in TPM

The integration of Industry 4.0 technologies into Total Productive Maintenance (TPM) is revolutionizing the way manufacturers manage equipment reliability and performance. The Industrial Internet of Things (IIoT) enables real-time data collection from machines, providing deep insights into their operational health. Sensors and connected devices continuously monitor key parameters such as vibration, temperature, and pressure, helping maintenance teams detect early signs of wear and inefficiency.

Predictive maintenance, a core aspect of smart TPM, leverages IoT-driven analytics to anticipate failures before they occur. By analyzing historical performance data and identifying patterns, manufacturers can schedule maintenance proactively, reducing unplanned downtime and optimizing resource allocation. The ability to predict failures with a high degree of accuracy not only enhances productivity but also extends equipment lifespan, ultimately improving return on investment (ROI).

9.2 Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are redefining how manufacturing plants approach maintenance and equipment reliability. These technologies process vast datasets at an unprecedented speed, identifying anomalies that may not be evident through traditional inspection methods. AI-driven condition monitoring systems can detect subtle deviations from normal operating conditions, triggering alerts for preventive action.

Machine learning algorithms improve over time, learning from past maintenance interventions and continuously refining their predictive accuracy. AI-powered chatbots and virtual assistants can also provide on-the-spot troubleshooting guidance to operators, minimizing the need for extensive human intervention. By integrating AI into TPM strategies, manufacturers can reduce maintenance costs, improve operational efficiency, and ensure consistent product quality with minimal disruptions.

9.3 Sustainable TPM Practices

Sustainability is becoming an integral component of modern TPM initiatives. As industries strive to reduce their carbon footprint and improve energy efficiency, TPM methodologies are evolving to incorporate eco-friendly practices. Sustainable TPM focuses on optimizing machine performance while minimizing energy consumption, emissions, and waste.

One approach is energy-efficient maintenance, where equipment is monitored to ensure it operates at peak efficiency. Regular lubrication, proper alignment, and proactive component replacement help reduce excessive energy use. Additionally, TPM-driven process optimizations can enhance material utilization, reducing scrap rates and improving overall resource efficiency.

Manufacturers are also exploring alternative energy sources, such as solar and wind power, to sustain their operations while aligning with global sustainability goals. By integrating environmentally conscious practices into TPM, organizations can achieve compliance with regulatory standards, lower operational costs, and contribute to a greener industrial ecosystem.

10. Conclusion

10.1 The Long-Term Benefits of a Well-Executed TPM Program

A successfully implemented TPM program yields significant long-term advantages for manufacturers. Enhanced equipment reliability, reduced downtime, and improved product quality are just a few of the tangible benefits. Over time, TPM fosters a culture of ownership and responsibility among employees, leading to higher engagement and collaboration across departments. The systematic approach to maintenance ensures that machines operate efficiently, reducing unexpected failures and costly emergency repairs.

Furthermore, TPM contributes to financial stability by optimizing asset utilization and minimizing waste. The cost savings associated with reduced breakdowns, lower defect rates, and streamlined operations can be reinvested into further technological advancements and workforce development, reinforcing a cycle of continuous improvement.

11. FAQS

What is Total Productive Maintenance (TPM)?

TPM is a maintenance strategy that aims to maximize equipment efficiency by involving all employees in proactive maintenance activities.

What are the key benefits of implementing TPM in manufacturing?

TPM improves equipment reliability, reduces downtime, enhances product quality, increases efficiency, and lowers maintenance costs.

What are the eight pillars of TPM?

The eight pillars of TPM include Autonomous Maintenance, Planned Maintenance, Quality Maintenance, Focused Improvement, Early Equipment Management, Training & Education, Safety & Environment, and TPM in Administration.

How is TPM different from preventive and predictive maintenance?

TPM is a holistic approach involving the entire workforce, while preventive maintenance follows scheduled servicing and predictive maintenance uses data analytics to forecast failures.

What are the biggest challenges in implementing TPM?

Common challenges include resistance to change, lack of management support, inadequate training, budget constraints, and difficulty in sustaining TPM practices.

How does Industry 4.0 and IoT enhance TPM?

Industry 4.0 and IoT enable real-time equipment monitoring, predictive maintenance, and data-driven decision-making, improving TPM efficiency.

How can companies measure the success of TPM implementation?

Key performance indicators (KPIs) such as Overall Equipment Effectiveness (OEE), Mean Time to Repair (MTTR), and Mean Time Between Failures (MTBF) help measure TPM effectiveness.

What are the first steps to implementing TPM in a factory?

Companies should start with leadership commitment, initial equipment assessments, training programs, forming TPM teams, and launching pilot projects before full-scale implementation