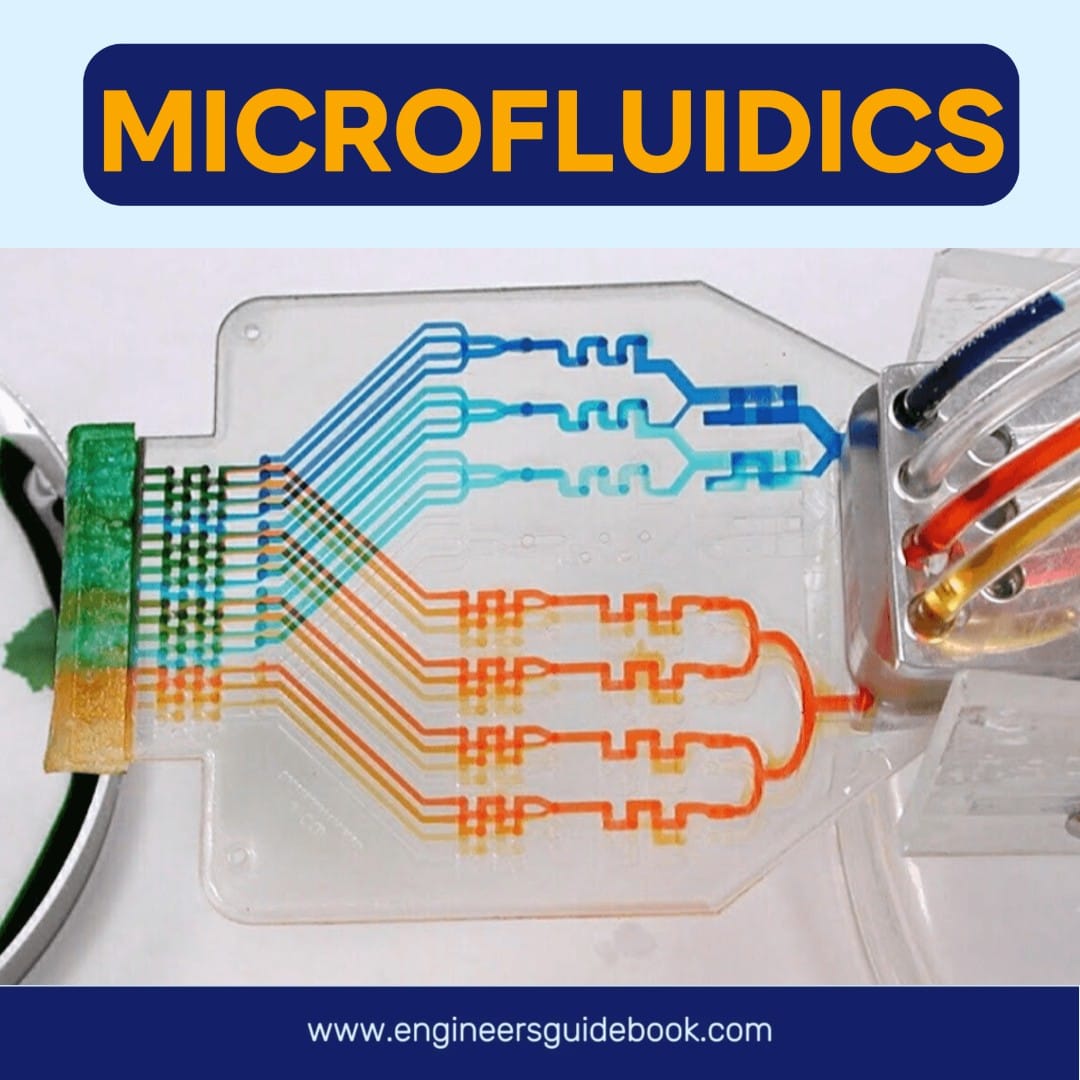

1. Introduction to Microfluidics

1.1 Defining Microfluidics: The Science of Miniaturized Fluid Control

Microfluidics is an interdisciplinary field that focuses on the precise manipulation and control of fluids at the microliter and nanoliter scales. By leveraging microscale fluid dynamics, microfluidics enables researchers and engineers to develop highly efficient and compact systems for various applications. This field is instrumental in biotechnology, chemical analysis, and diagnostic applications, as it allows for precise fluid handling with minimal reagent consumption. The defining characteristic of microfluidics is its reliance on microscale physics, which dictates fluid behavior differently than at the macroscopic level.

1.2 Historical Development

The origins of microfluidics trace back to early studies of capillary action and fluid mechanics in narrow channels. The concept gained momentum in the 20th century with the advent of microfabrication technologies originally developed for the semiconductor industry. The 1990s saw the emergence of the “lab-on-a-chip” concept, which revolutionized biomedical research and diagnostics by integrating multiple laboratory functions onto a single chip. These advancements allowed for faster, more efficient analysis of biological samples, reducing reliance on traditional bulky laboratory equipment.

1.3 Importance and Applications

Microfluidics has become indispensable in modern science and engineering due to its versatility and efficiency. Its applications span multiple disciplines, including medical diagnostics, environmental monitoring, pharmaceuticals, and energy research. In the biomedical sector, microfluidic devices facilitate point-of-care diagnostics, DNA sequencing, and personalized medicine. In industrial settings, they enable precise chemical reactions, drug development, and microreactor technology. The ability to miniaturize and automate processes with microfluidic systems has paved the way for groundbreaking innovations across numerous scientific fields.

2. Fundamental Principles of Microfluidics

2.1 Fluid Dynamics at the Microscale

At the microscale, fluid behavior deviates significantly from macroscopic fluid dynamics due to the dominance of surface forces over inertial forces. Unlike traditional fluid systems that experience turbulence, microfluidic flows are typically laminar, meaning fluid streams do not mix through turbulence but rather through diffusion.

The study of microscale fluid behavior is crucial for designing effective microfluidic devices that leverage these unique properties for efficient fluid control.

2.2 The Role of Surface Tension, Viscosity, and Capillary Action

Surface tension plays a pivotal role in microfluidics, governing fluid movement in confined spaces. At this scale, the influence of gravity is negligible, and fluid motion is dictated by interfacial forces. Viscosity, which measures a fluid’s resistance to flow, becomes a dominant factor, impacting how liquids navigate microchannels.

Capillary action, the ability of a liquid to move through narrow spaces without external force, is harnessed in microfluidic systems to control fluid transport passively, reducing the need for complex pumping mechanisms.

2.3 Reynolds Number and Laminar Flow

The Reynolds number (Re) is a dimensionless parameter that characterizes fluid flow behavior. In microfluidics, the Reynolds number is typically low (Re < 1), indicating that flows are predominantly laminar rather than turbulent.

This predictability allows for precise control over fluid motion, enabling the design of intricate microfluidic networks where different fluids interact in controlled environments. The absence of turbulence ensures that fluid mixing occurs solely through molecular diffusion, a fundamental principle leveraged in microfluidic applications.

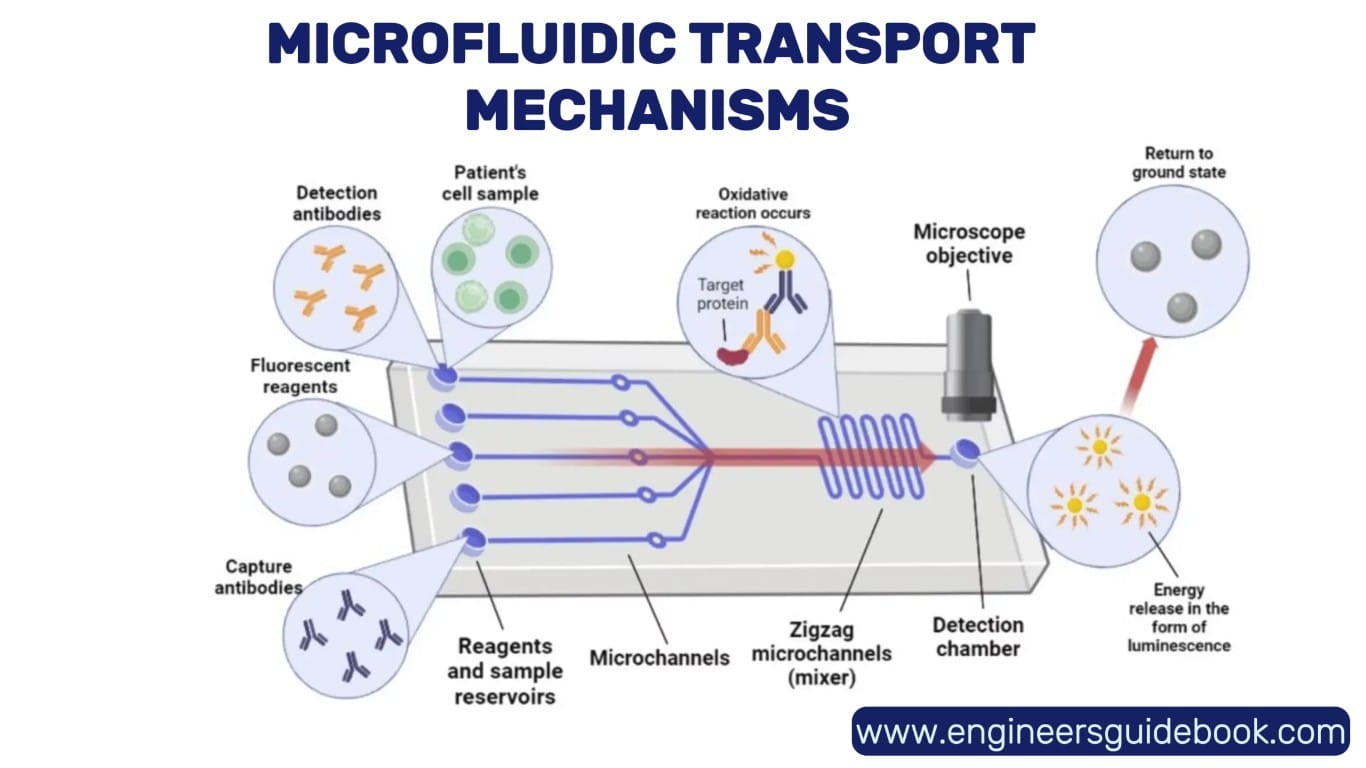

2.4 Microfluidic Transport Mechanisms

Microfluidic systems rely on various transport mechanisms to manipulate fluids efficiently. Diffusion, a passive process driven by concentration gradients, is crucial for molecular mixing and reactions.

Electrokinetic transport, including electrophoresis and electroosmosis, exploits electrical fields to control fluid and particle movement within microchannels.

Pressure-driven flow, facilitated by external pumps or capillary forces, provides another means of fluid transport, ensuring precise flow rates and minimizing mechanical complexity in microfluidic devices.

3. Microfabrication Techniques for Microfluidic Devices

3.1 Soft Lithography

Soft lithography is a widely used technique in microfluidic fabrication, involving the molding of elastomeric materials such as polydimethylsiloxane (PDMS). This method enables the rapid prototyping of microfluidic devices with intricate channel designs.

PDMS is particularly favored due to its biocompatibility, transparency, and flexibility, making it an ideal material for biomedical applications. Soft lithography techniques allow for cost-effective and high-resolution fabrication of microfluidic networks, supporting a range of experimental and commercial applications.

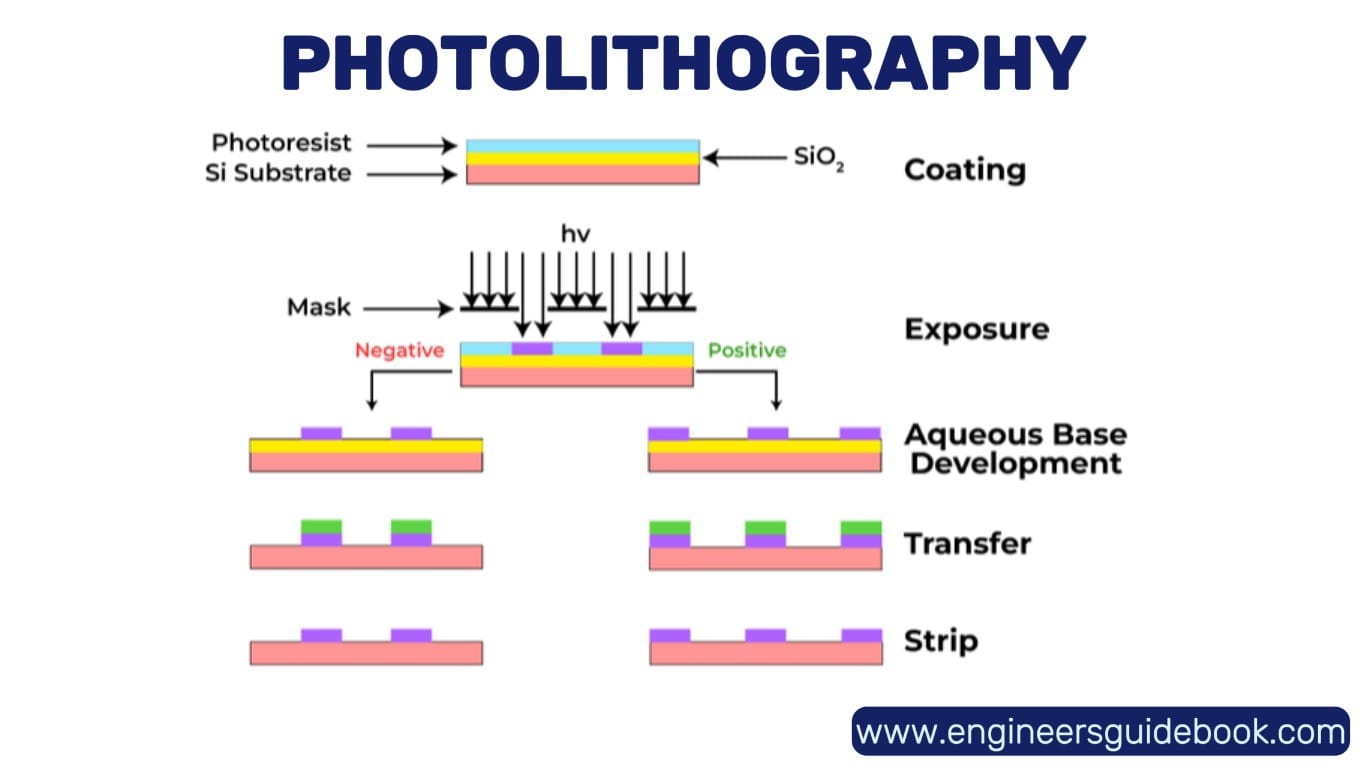

3.2 Photolithography and Etching

Photolithography, a process borrowed from the semiconductor industry, involves the use of UV light to pattern microstructures onto a substrate coated with a photoresist.

Following exposure and development, etching techniques such as wet or dry etching are used to remove material and define microfluidic features.

These methods enable the production of highly precise and durable microfluidic chips, commonly fabricated from silicon or glass. Despite the high-resolution capabilities, the cost and complexity of photolithography limit its accessibility compared to soft lithography.

3.3 3D Printing and Emerging Rapid Prototyping Methods

Advancements in 3D printing have introduced new possibilities for microfluidic device fabrication. Additive manufacturing techniques allow for the rapid prototyping of intricate microchannel designs, reducing fabrication time and costs.

Materials such as resins, thermoplastics, and hydrogels can be used to create customized microfluidic platforms with enhanced functionality.

Emerging rapid prototyping methods, including stereolithography (SLA) and digital light processing (DLP), are transforming the landscape of microfluidics by enabling scalable and accessible production.

3.4 Material Selection

The choice of material for microfluidic devices depends on the intended application and required properties.

Polymers such as PDMS, polymethyl methacrylate (PMMA), and cyclic olefin copolymer (COC) are widely used due to their cost-effectiveness and ease of fabrication.

Glass microfluidic devices offer excellent chemical resistance and optical transparency, making them ideal for analytical applications. Silicon-based microfluidic chips provide high precision and durability but are often more expensive to manufacture.

The selection of materials plays a crucial role in optimizing device performance, ensuring compatibility with fluids, and enhancing long-term reliability.

4. Microfluidic Device Components and Their Functions

4.1 Microchannels and Network Design

Microchannels form the fundamental structural framework of microfluidic devices. These conduits, typically fabricated from materials such as polydimethylsiloxane (PDMS), glass, or silicon, enable the controlled transport of minute fluid volumes.

Their geometrical configuration influences fluid dynamics, with parameters such as channel width, depth, and surface chemistry dictating flow behavior. Complex network designs incorporating bifurcations, T-junctions, and serpentine pathways facilitate precise fluid manipulation, optimizing mixing, separation, and reaction kinetics within microfluidic systems.

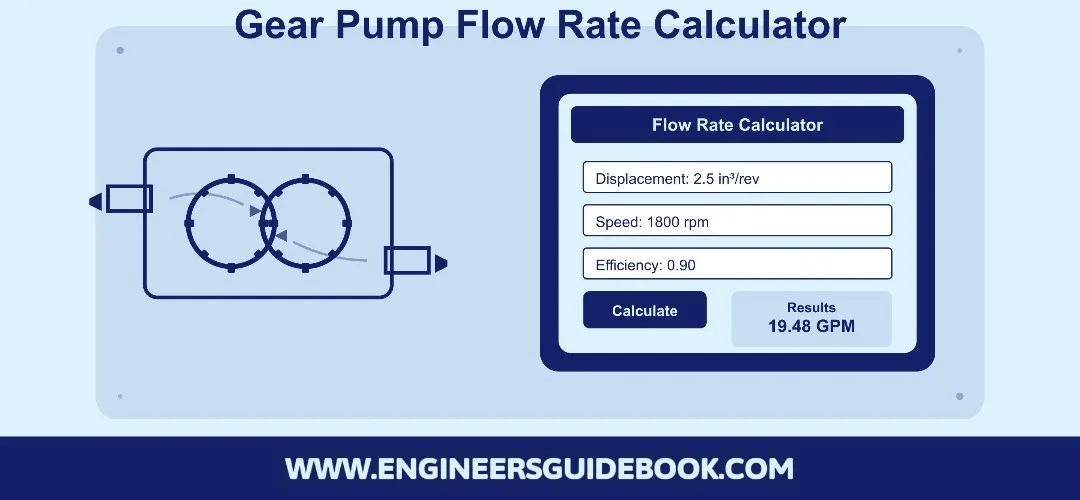

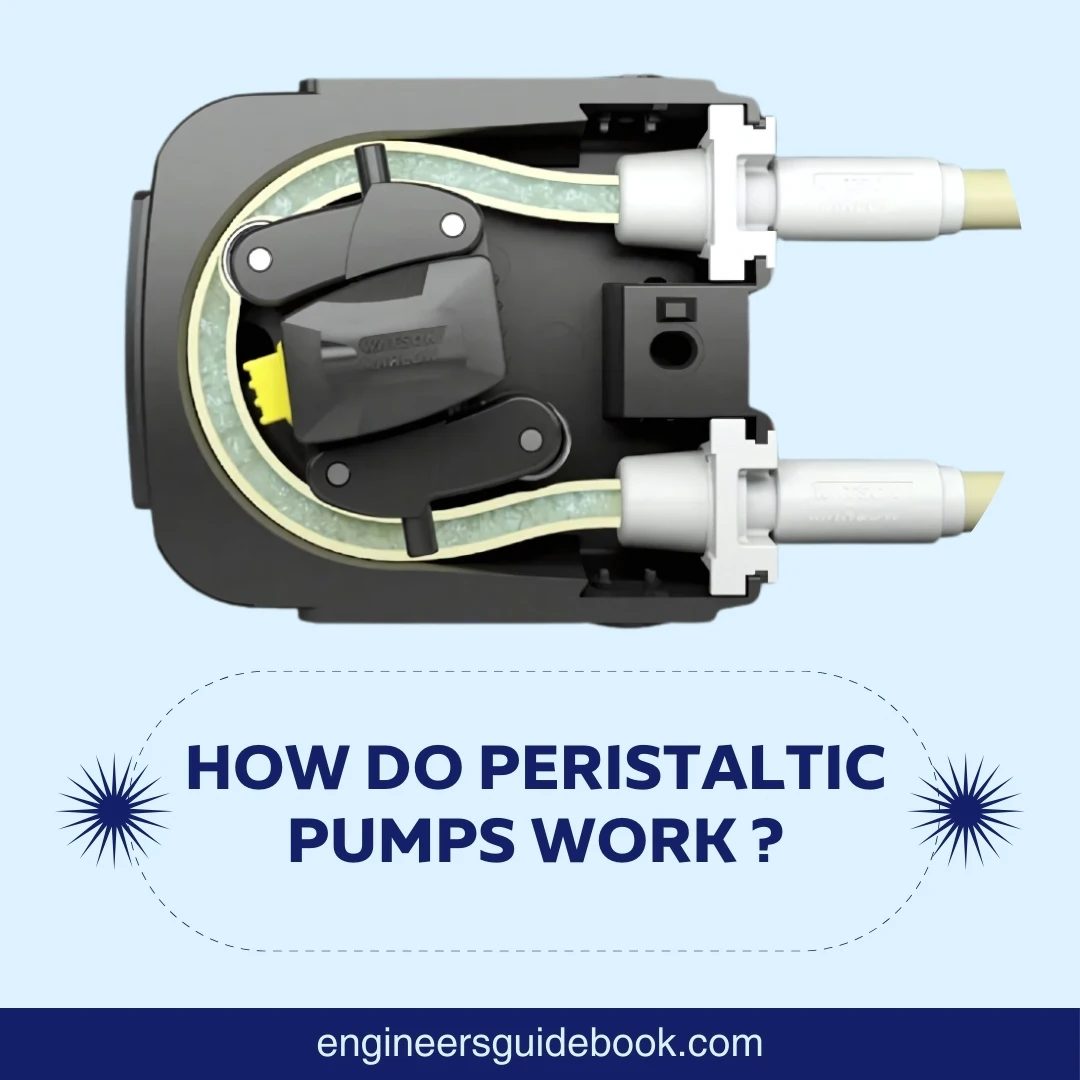

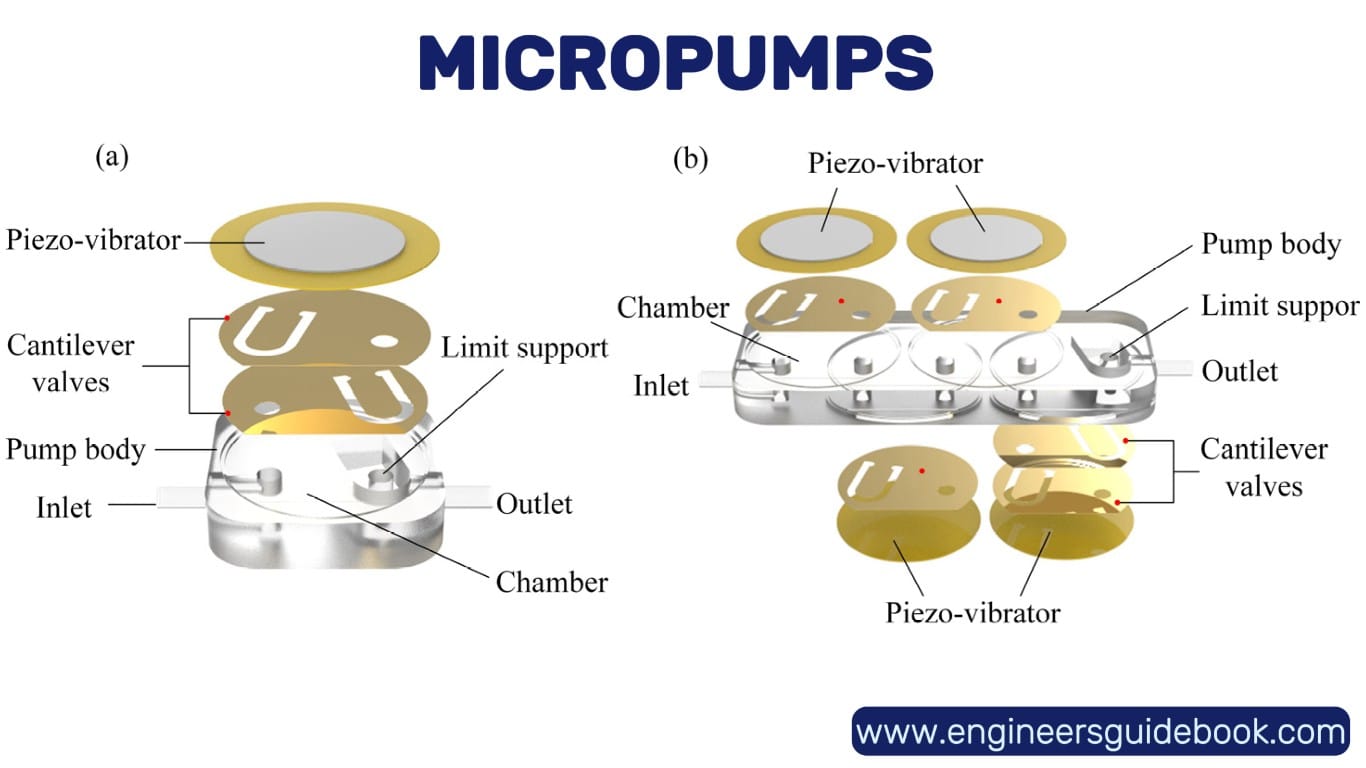

4.2 Micropumps and Valves

Micropumps and valves are indispensable for actuating and regulating fluid flow within microfluidic architectures. Micropumps, classified into mechanical (e.g., diaphragm, peristaltic) and non-mechanical (e.g., electroosmotic, thermocapillary), drive fluid movement through varied actuation mechanisms.

Microvalves, which can be passive (check valves) or active (solenoid, pneumatic), dictate directional flow and compartmentalization, enabling sequential operations in lab-on-a-chip applications.

4.3 Microreservoirs and Chambers

Microreservoirs serve as localized storage units, accommodating reagents, buffers, or biological samples before integration into microfluidic workflows.

Reaction chambers, often integrated with micro-mixers, enhance mass transfer and reaction efficiency. These components play a pivotal role in droplet-based microfluidics, where emulsified microdroplets serve as individual reaction vessels, enabling high-throughput screening and single-cell studies.

4.4 Sensors and Detection Mechanisms

Embedded sensors within microfluidic devices provide real-time monitoring of fluidic properties such as pressure, flow rate, temperature, and chemical composition. Optical (fluorescence, absorbance), electrochemical (amperometric, potentiometric), and mechanical (cantilever-based) detection mechanisms facilitate precise analysis of biochemical interactions.

Integration with microelectronic components enhances automation, enabling applications in medical diagnostics and environmental monitoring.

5. Key Applications of Microfluidics

5.1 Lab-on-a-Chip Technology

Lab-on-a-chip (LOC) systems revolutionize conventional laboratory methodologies by miniaturizing and integrating complex biochemical assays onto a single microfluidic platform. These devices streamline workflows involving sample preparation, reaction processing, and detection, reducing reagent consumption and assay time while enhancing portability and automation.

5.2 Biomedical Diagnostics

Microfluidic diagnostic platforms facilitate point-of-care testing (POCT) by enabling rapid and accurate detection of biomarkers, pathogens, and nucleic acids.

Techniques such as lateral flow assays, droplet-based digital PCR, and microfluidic ELISA significantly enhance sensitivity and specificity, making them invaluable for infectious disease surveillance, cancer diagnostics, and personalized medicine.

5.3 Drug Delivery Systems

Microfluidic drug delivery systems leverage controlled fluidic environments to administer therapeutics with high precision.

By harnessing stimuli-responsive carriers, microfluidic-based drug delivery enables targeted release in response to physiological conditions such as pH, temperature, or enzymatic activity, thereby minimizing systemic toxicity and enhancing treatment efficacy.

5.4 Organ-on-a-Chip

Organ-on-a-chip (OoC) technology replicates the microarchitecture and functional characteristics of human tissues on microfluidic platforms.

These biomimetic systems incorporate microvascular networks, cell co-cultures, and dynamic fluid perfusion to model physiological and pathological conditions, offering advanced tools for drug screening, toxicology studies, and disease modeling.

5.5 Environmental and Chemical Sensing

Microfluidic sensors enable real-time monitoring of environmental contaminants, including heavy metals, organic pollutants, and microbial pathogens.

Portable and highly sensitive, these devices employ fluorescence spectroscopy, electrochemical detection, and surface-enhanced Raman spectroscopy (SERS) for field-deployable environmental analysis and food safety testing.

6. Microfluidics in Biotechnology and Medicine

6.1 DNA Sequencing and Genomics

Microfluidic technologies enhance genomic studies by enabling high-throughput DNA sequencing, polymerase chain reaction (PCR), and nucleic acid hybridization assays.

Droplet microfluidics, in particular, facilitates single-molecule sequencing and genomic library preparation, drastically reducing costs and increasing sequencing speed.

6.2 Point-of-Care Testing

Microfluidic POCT devices democratize healthcare by providing immediate diagnostic results in decentralized settings.

Utilizing paper-based and chip-based microfluidics, these platforms facilitate early disease detection, epidemiological surveillance, and resource-limited healthcare interventions.

6.3 Single-Cell Analysis

Microfluidic platforms empower researchers to investigate cellular heterogeneity by isolating and analyzing individual cells. Applications range from cancer cell profiling to immunophenotyping, where single-cell RNA sequencing and high-throughput flow cytometry yield unprecedented biological insights.

6.4 Tissue Engineering and Regenerative Medicine Applications

Microfluidics plays a critical role in tissue engineering by enabling controlled cell culture environments, scaffold fabrication, and bioprinting.

Perfusable microfluidic scaffolds enhance vascularization and cellular differentiation, advancing regenerative therapies for organ transplantation and wound healing.

7. Industrial and Engineering Applications of Microfluidics

7.1 Microfluidics in Chemical Processing and Synthesis

Microfluidic reactors revolutionize chemical synthesis by offering precise reaction control, enhanced mixing efficiency, and rapid heat/mass transfer.

These microscale chemical systems are instrumental in nanoparticle synthesis, combinatorial chemistry, and process intensification.

7.2 Fuel Cells and Energy Generation

Microfluidic fuel cells improve energy conversion efficiency by optimizing reactant flow distribution, minimizing crossover losses, and enhancing electrode-electrolyte interactions.

Innovations in microfluidic flow cells facilitate compact, high-performance energy storage solutions for portable electronics and wearable devices.

7.3 Aerospace and Automotive Applications

Microfluidic heat exchangers and liquid cooling systems enhance thermal management in aerospace and automotive applications.

By leveraging microchannel-based cooling architectures, these systems improve heat dissipation in high-power electronic components, batteries, and combustion engines.

7.4 Microfluidics in Consumer Electronics and Inkjet Printing

Microfluidic principles underpin modern inkjet printing technologies, enabling precise droplet formation and deposition for high-resolution printing. Additionally, microfluidic actuators and sensors are integrated into consumer electronic devices, facilitating touch-sensitive interfaces, liquid lens systems, and miniaturized optical devices.

8. Computational Modeling and Simulation in Microfluidics

8.1 Computational Fluid Dynamics (CFD) for Microfluidic Systems

Computational Fluid Dynamics (CFD) plays a pivotal role in understanding and optimizing microfluidic systems. Given the unique behaviors of fluids at the microscale, where laminar flow dominates and surface tension significantly impacts movement, CFD simulations provide detailed insights into fluid interactions within microchannels.

These simulations enable researchers to predict velocity fields, pressure gradients, and shear stresses, facilitating the refinement of device performance before fabrication.

8.2 Modeling Particle and Cell Behavior in Microchannels

Microfluidics is widely used for biomedical applications, necessitating precise modeling of particle and cell behavior in constrained fluidic environments. Simulations help predict how biological cells, nanoparticles, or chemical reagents behave under various flow conditions.

Factors such as hydrodynamic focusing, electrophoresis, and dielectrophoresis can be explored computationally, reducing experimental trial-and-error and expediting the development of diagnostic and therapeutic applications.

8.3 Optimizing Device Design through Simulation-Based Prototyping

Traditional prototyping methods can be time-consuming and expensive. Simulation-based prototyping enables rapid iteration and optimization of microfluidic device designs.

Engineers and researchers can assess multiple design configurations, evaluate mixing efficiency, and minimize potential failures before moving to physical fabrication.

This computational approach enhances efficiency and significantly reduces material waste.

9. Challenges and Limitations in Microfluidics

9.1 Fabrication Constraints

Fabrication of microfluidic devices requires high precision, often necessitating specialized techniques such as photolithography, soft lithography, and micro-milling.

However, achieving sub-micron accuracy while maintaining cost-effectiveness remains a challenge. Material selection, resolution limitations, and batch-to-batch variability contribute to fabrication complexity.

9.2 Fluid Control and Stability Issues at the Microscale

At the microscale, surface forces dominate over inertial forces, leading to challenges in fluid control. Issues such as bubble formation, unintended flow resistance, and unpredictable meniscus behavior can disrupt fluid stability.

Maintaining uniform flow rates and ensuring consistent reagent delivery in lab-on-a-chip systems require advanced engineering strategies, including precise actuation mechanisms and surface treatments.

9.3 Material Compatibility and Biocompatibility Considerations

Material selection for microfluidic devices is crucial, particularly for biomedical applications. Many polymers, such as PDMS (polydimethylsiloxane), are commonly used but exhibit absorption of small molecules, potentially interfering with assays.

Additionally, ensuring biocompatibility for cell cultures and drug screening necessitates non-toxic, chemically inert materials that do not leach contaminants.

9.4 Scalability and Mass Production Challenges

While microfluidic devices offer immense potential, their large-scale manufacturing remains a bottleneck. Many fabrication methods are suited for prototyping but are not easily scalable for commercial production.

Standardizing microfabrication techniques, developing cost-effective manufacturing pipelines, and ensuring reproducibility across batches are ongoing challenges in the field.

10. Advances and Innovations in Microfluidic Technology

10.1 Smart and Adaptive Microfluidic Systems

Modern microfluidic devices incorporate intelligent functionalities, such as real-time feedback control and dynamic response to external stimuli.

Adaptive microfluidics, leveraging stimuli-responsive polymers and embedded electronics, enable automated adjustments to fluid flow, temperature, and reagent mixing, enhancing system versatility for biomedical and analytical applications.

10.2 Integration with Artificial Intelligence and Machine Learning

The convergence of microfluidics with artificial intelligence (AI) and machine learning (ML) has revolutionized experimental workflows.

AI-driven algorithms analyze fluid dynamics, predict optimal flow parameters, and automate image recognition in droplet-based assays. This integration accelerates drug discovery, personalized medicine, and biosensing applications by enabling high-throughput data analysis and decision-making.

10.3 Emerging Nanofluidic Systems

Nanofluidics, an extension of microfluidics, deals with fluid manipulation in channels with dimensions below 100 nanometers.

At this scale, molecular interactions, electrostatic forces, and quantum effects play a significant role. Nanofluidic devices have transformative potential in fields such as single-molecule detection, desalination technologies, and targeted drug delivery.

10.4 Hybrid and Multi-Material Microfluidic Devices

The integration of multiple materials within a single microfluidic device enhances functionality and expands application possibilities. Hybrid approaches combining silicon, glass, and flexible polymers enable customized mechanical and chemical properties.

Multi-material microfluidics support advanced functionalities such as embedded microelectrodes, multiplexed sensing, and 3D bioprinting of tissue models.

11. Future Trends and Research Directions in Microfluidics

11.1 The Role of Microfluidics in Next-Generation Healthcare

Microfluidic technology is poised to revolutionize healthcare by enabling rapid, portable, and cost-effective diagnostic solutions.

Next-generation lab-on-a-chip devices will facilitate point-of-care testing, early disease detection, and precision medicine. Continuous advancements in miniaturization, automation, and integration with biosensors will drive widespread adoption in clinical settings.

11.2 Advances in Wearable and Implantable Microfluidic Devices

Wearable and implantable microfluidic systems represent a significant leap in personalized healthcare. Devices capable of real-time monitoring of biomarkers, sweat analysis, and minimally invasive drug delivery are under active development.

These innovations will enhance chronic disease management, optimize athletic performance monitoring, and improve patient adherence to treatment regimens.

11.3 Expanding Applications in Space Exploration and Remote Sensing

Microfluidic technology is increasingly being explored for space-based applications, where compact, efficient, and autonomous systems are essential.

Microfluidic platforms enable on-site chemical analysis, astronaut health monitoring, and resource utilization in extraterrestrial environments. Similarly, in remote and inaccessible regions on Earth, microfluidics can facilitate environmental monitoring and disease surveillance.

11.4 The Convergence of Microfluidics with Synthetic Biology

Synthetic biology and microfluidics are converging to create programmable biological systems. Microfluidic bioreactors allow precise control over cellular environments, enabling the synthesis of engineered biomolecules, cell-free protein production, and high-throughput genetic screening.

This synergy will drive innovations in bioengineering, sustainable biomanufacturing, and artificial cell development.

12. Regulatory and Ethical Considerations in Microfluidics

12.1 Standardization and Quality Control in Microfluidic Manufacturing

The field of microfluidics has witnessed significant advancements, yet the absence of universal manufacturing standards poses challenges for widespread adoption and commercialization.

Standardization ensures device reproducibility, reliability, and compatibility across different applications, particularly in biomedical diagnostics and pharmaceutical research.

12.2 Ethical Implications of Microfluidics in Human and Environmental Applications

As microfluidic technologies become integral to biomedical research and environmental monitoring, ethical considerations emerge regarding their deployment and societal impact.

One primary concern revolves around the potential for unequal access to microfluidic-based healthcare solutions.

While these devices promise affordable and rapid diagnostics, disparities in global healthcare infrastructure could lead to unequal distribution, exacerbating health inequalities.

12.3 Data Privacy and Security Concerns in Digital Microfluidic Devices

The integration of microfluidics with digital technologies has led to the emergence of digital microfluidic devices (DMFs), which rely on electronic control and automation.

These systems are widely used in healthcare diagnostics, wearable biosensors, and remote patient monitoring. However, the collection and transmission of sensitive biological data introduce privacy and security risks.

13. Case Studies and Real-World Applications

13.1 COVID-19 Rapid Testing

The emergence of COVID-19 necessitated rapid, accurate, and scalable testing methodologies. Microfluidic platforms enabled the development of lab-on-a-chip devices that significantly reduced diagnostic turnaround times.

These devices utilized nucleic acid amplification techniques such as RT-PCR within microfluidic channels, minimizing reagent consumption while maintaining high sensitivity and specificity. As a result, mass screening became more accessible, aiding in pandemic management efforts worldwide.

13.2 Microfluidic Approaches to Personalized Medicine

Personalized medicine relies on precise and patient-specific treatment regimens. Microfluidic systems facilitate single-cell analysis, biomarker detection, and individualized drug testing, ensuring optimized therapeutic strategies.

By integrating microfluidics with genomics and proteomics, researchers can develop tailored treatments for conditions like cancer, neurodegenerative disorders, and autoimmune diseases, thus improving patient outcomes while minimizing adverse effects.

13.3 Breakthroughs in Microfluidic-Based Drug Discovery

The pharmaceutical industry has embraced microfluidics to accelerate drug discovery and development. Microfluidic screening platforms enable high-throughput testing of compounds on miniaturized biological models.

Organs-on-a-chip, a revolutionary application, mimic human physiological conditions, allowing researchers to evaluate drug efficacy and toxicity with unprecedented accuracy. This innovation reduces reliance on animal testing and enhances the predictive power of preclinical studies.

13.4 Sustainable Microfluidic Solutions for Water Purification

Water purification remains a pressing global challenge. Microfluidic systems provide novel approaches for detecting and removing contaminants at the microscale.

These systems utilize electrokinetic and membrane-based separation techniques to filter pollutants, heavy metals, and pathogens with high precision.

Furthermore, microfluidic biosensors can monitor water quality in real time, offering cost-effective and scalable solutions for clean water access in resource-limited regions.

14. Conclusion

Microfluidics has emerged as a transformative field with applications spanning healthcare, environmental science, and industrial processes. By leveraging microscale fluid dynamics, researchers and engineers can develop cost-effective, rapid, and precise solutions for complex challenges.

Innovations such as lab-on-a-chip technology, organ-on-a-chip models, and microfluidic drug screening continue to redefine scientific methodologies.

The integration of microfluidics into scientific and medical research has led to groundbreaking advancements. In medicine, it has revolutionized diagnostics, drug delivery, and personalized treatments.

In industrial applications, it has enhanced chemical processing, energy generation, and material synthesis. The interdisciplinary nature of microfluidics ensures its continued expansion across diverse fields.