1. Introduction to Miniature Circuit Breakers (MCB)

Electricity is the lifeblood of modern civilization, powering homes, industries, and commercial enterprises. However, the same energy that fuels progress can also pose severe hazards if left unchecked. Circuit Breakers are very useful in overcurrent conditions, short circuits, and electrical surges threaten the safety of appliances, infrastructure, and human life itself. To mitigate these risks, engineers have developed various protective mechanisms, among which Miniature Circuit Breakers (MCBs) stand as a pivotal innovation.

1.1 Understanding Electrical Circuit Protection

Every electrical system operates within specific parameters—defined voltage levels, regulated current flow, and controlled resistance. When these parameters are breached due to unforeseen faults, the consequences can be catastrophic. Overloading, short circuits, and ground faults are common disruptions that compromise the integrity of an electrical network.

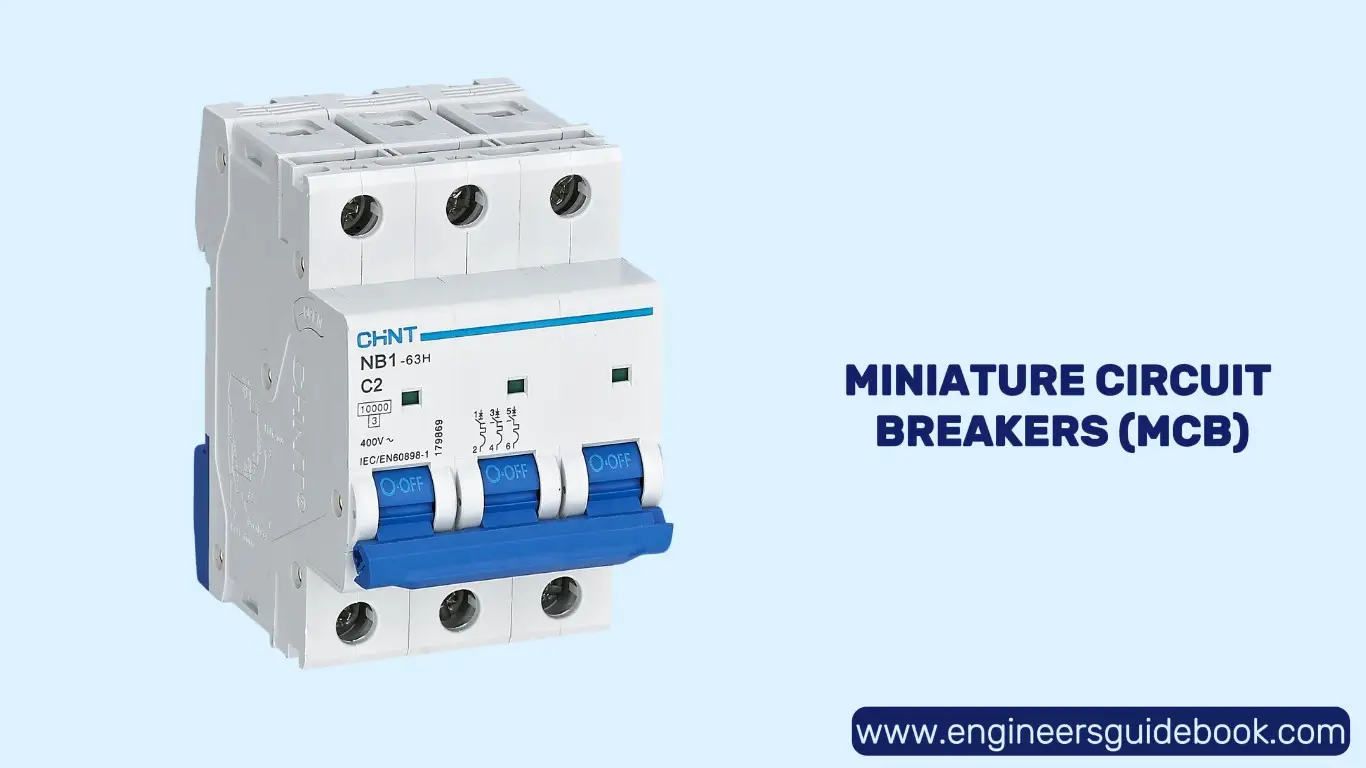

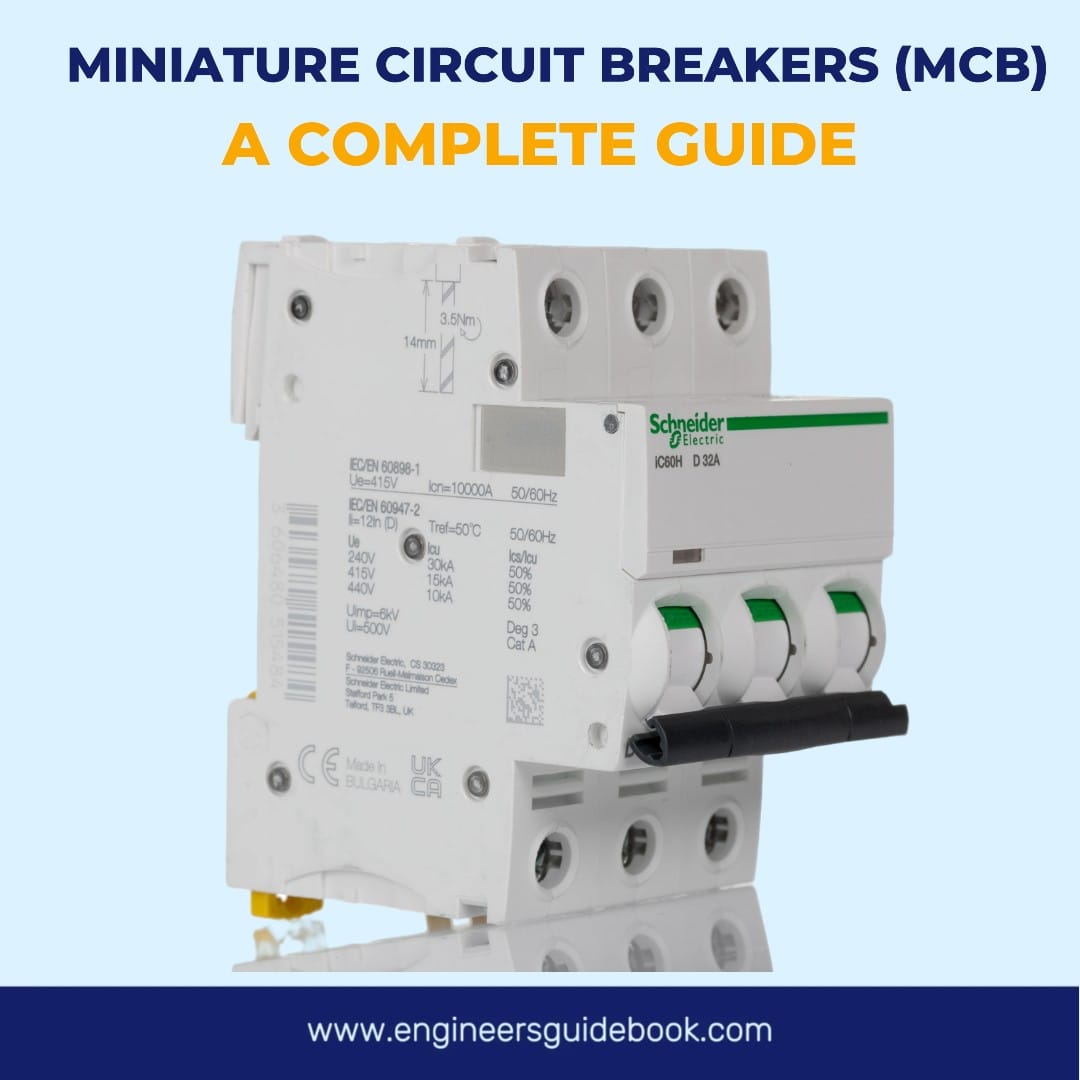

2. What is a Miniature Circuit Breaker (MCB)?

Miniature Circuit Breakers (MCBs) are integral components of modern electrical systems, offering protection against overcurrent, short circuits, and overloads. These devices are designed to automatically disconnect the electrical supply when an abnormal condition is detected, such as an excessive current flow, ensuring the safety of both electrical wiring and connected appliances.

Unlike fuses, which need to be replaced after each fault, MCBs can be reset and reused multiple times, providing a more cost-effective and convenient solution. They come in a range of sizes and specifications, making them versatile for various applications, from residential to industrial use.

MCBs are crucial in preventing fires, damage to electrical devices, and even electrical shock hazards. Understanding their basic construction and working principles is essential for appreciating their widespread use and reliability in electrical installations.

2.1 Definition and Basic Working Principle

A Miniature Circuit Breaker (MCB) is an automatic electrical switch that protects circuits from overcurrent, which could cause damage to the system or appliances. The primary function of an MCB is to interrupt the current flow in the event of an overload or short circuit. It is designed to detect excessive current and promptly break the circuit, preventing harm to electrical wiring or devices.

The working principle of an MCB relies on the combination of two mechanisms: thermal and magnetic tripping. The thermal component reacts to slow, sustained overcurrents (overload conditions), while the magnetic component responds instantly to high, sudden current spikes (short circuit conditions). This dual protection mechanism ensures that the MCB provides comprehensive circuit protection across a range of fault scenarios.

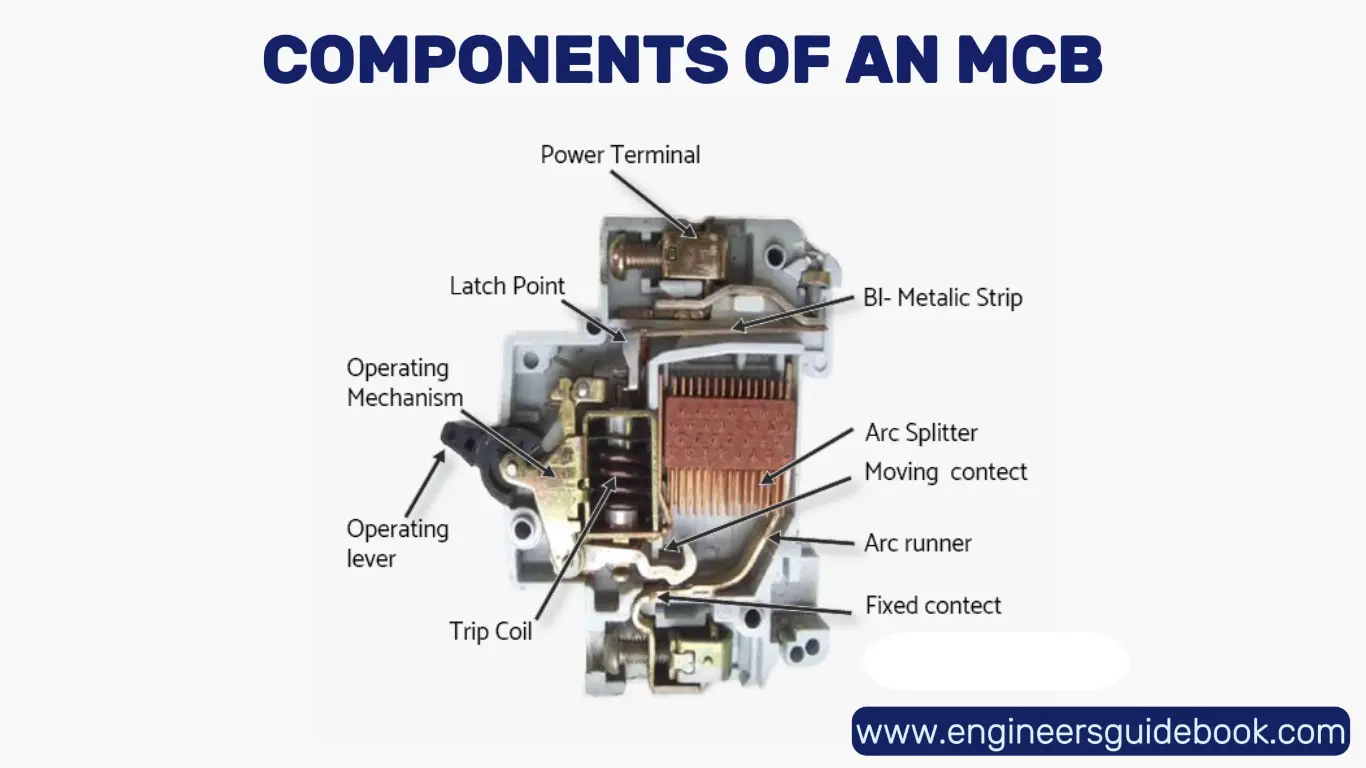

2.2 Components of an MCB and Their Functions

An MCB consists of several key components that work together to detect faults and break the circuit:

- Thermal Bimetallic Strip: This component is responsible for detecting overloads. It consists of two strips of metal with different expansion rates. When the current exceeds the rated value for an extended period, the strip heats up and bends, triggering the trip mechanism.

- Magnetic Coil: The magnetic coil is crucial for detecting short circuits. It operates instantly when the current exceeds a predefined threshold, activating the mechanism to trip the breaker in a fraction of a second.

- Trip Mechanism: This is the heart of the MCB. When either the thermal or magnetic component detects an abnormality, the trip mechanism activates, causing the contacts inside the breaker to open and interrupt the current flow.

- Contacts: These conductive components close the circuit under normal conditions. When the MCB trips, the contacts open, thereby breaking the circuit and preventing further damage.

- Reset Button: After an MCB has tripped, the user can manually reset the device, restoring the circuit to its operational state. This is a significant advantage over fuses, which need to be replaced after every fault.

2.3 How MCBs Differ from Traditional Fuses

While both MCBs and fuses serve the same basic purpose—protecting electrical circuits from overloads and short circuits—there are significant differences between the two. The primary distinction lies in their mechanism and reusability.

- Reusability: One of the most prominent differences is that MCBs can be reset after tripping, making them reusable. Fuses, on the other hand, need to be replaced each time they blow. This makes MCBs more convenient and cost-effective in the long run, especially in high-maintenance environments.

- Speed of Response: MCBs are faster in response times, particularly when dealing with short circuits. Their magnetic tripping mechanism acts almost instantaneously, whereas fuses have a delayed response, potentially causing more damage before they blow.

- Precision: MCBs offer more precise protection. The thermal and magnetic mechanisms can be calibrated to specific settings, providing greater flexibility in handling various types of faults. Fuses, however, operate on a simple mechanism without such customization.

- Safety: MCBs often provide more consistent and reliable protection due to their design and modern advancements. Fuses, while effective, may present safety risks during installation and replacement, particularly when the fuse is incorrectly rated for the application.

3. Types of Miniature Circuit Breakers

MCBs come in various types, each designed to meet specific needs depending on the application. The differences in these types are primarily based on the tripping characteristics and the number of poles, which determine the MCB’s suitability for different circuits and environments.

3.1 Classification Based on Tripping Characteristics

MCBs can be classified based on their tripping characteristics, which determine how quickly the breaker will trip under different conditions. The tripping characteristics are crucial in ensuring that the breaker responds appropriately to the types of electrical faults most likely to occur in specific applications.

3.1.1 Type B MCB: Ideal for Residential Use

Type B MCBs are designed to trip when the current exceeds 3 to 5 times the rated current. They are typically used in residential applications where the risk of high inrush currents (such as motor startup currents) is low. These MCBs provide excellent protection for lighting circuits, household appliances, and other low-power devices that are common in residential settings.

3.1.2 Type C MCB: Suitable for Commercial and Industrial Applications

Type C MCBs trip when the current exceeds 5 to 10 times the rated current. These are ideal for commercial and industrial applications where there is a higher likelihood of inrush currents, such as motors, transformers, and other equipment with higher startup demands. Type C MCBs strike a balance between sensitivity and tolerance for temporary high currents, ensuring adequate protection without unnecessary trips.

3.1.3 Type D MCB: Designed for High-Inrush Current Loads

Type D MCBs are designed to trip when the current exceeds 10 to 20 times the rated current. These are typically used for applications with very high inrush currents, such as large motors, fluorescent lighting, and welding equipment. Type D MCBs can withstand these large surges without tripping, making them suitable for environments where brief high current spikes are expected.

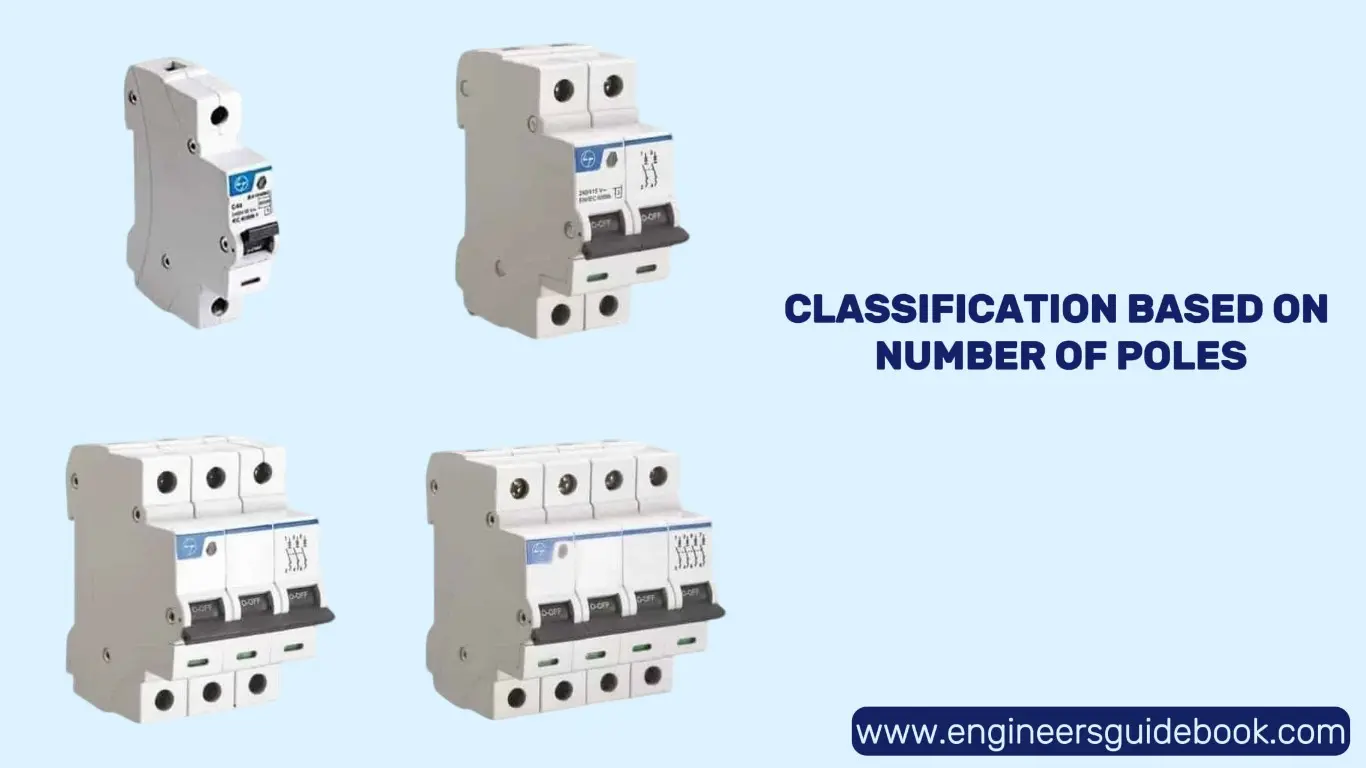

3.2 Classification Based on Number of Poles

The number of poles in an MCB determines how many electrical circuits the device can protect simultaneously. The choice of poles depends on the configuration of the electrical system and the number of phases it employs.

3.2.1 Single-Pole MCB

A Single-Pole MCB is designed to protect a single-phase circuit. It is commonly used in residential applications where the electrical system operates on a single phase, such as lighting circuits and small household appliances.

3.2.2 Double-Pole MCB

Double-Pole MCBs protect both the live and neutral wires in a single-phase system. These are used when the protection of both wires is necessary, such as in certain domestic circuits or for specific appliances that require both poles to be disconnected simultaneously for safety reasons.

3.2.3 Triple-Pole MCB

Triple-Pole MCBs are used in three-phase systems, where they protect three live wires. These are commonly found in industrial applications and large commercial buildings where three-phase electrical systems are used to power heavy machinery and equipment.

3.2.4 Four-Pole MCB

Four-Pole MCBs are used for the protection of three-phase circuits that also require a neutral wire. These are employed in high-power systems, such as large commercial installations, to ensure that all four conductors (three phases and the neutral) are disconnected in the event of a fault.

4. Working Mechanism of an MCB

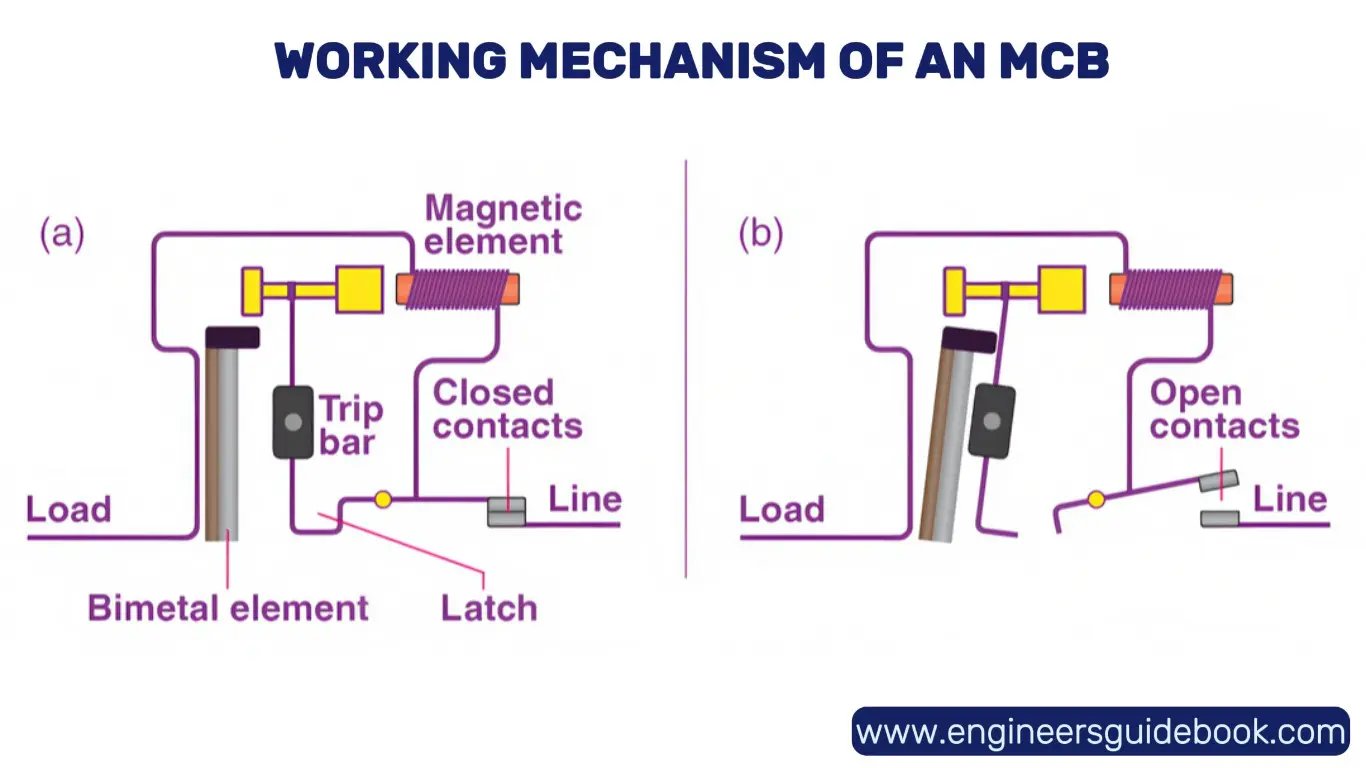

The working mechanism of an MCB involves a combination of thermal and magnetic principles, each designed to protect against different types of electrical faults.

4.1 Thermal Mechanism: Protection Against Overload

The thermal mechanism of an MCB is activated in response to sustained overload conditions. When the current exceeds the rated value over a period of time, the bimetallic strip inside the MCB heats up and bends. This action triggers the trip mechanism, disconnecting the circuit to prevent overheating and potential fire hazards.

4.2 Magnetic Mechanism: Protection Against Short Circuit

The magnetic mechanism responds instantaneously to short circuits. A sudden surge in current creates a magnetic field that activates a spring-loaded trip mechanism. This rapid response ensures that the circuit is disconnected before significant damage can occur due to the short circuit.

4.3 Tripping Process: How an MCB Responds to Electrical Faults

When either the thermal or magnetic mechanism detects an electrical fault, the MCB’s contacts open, interrupting the current flow. This quick action prevents damage to electrical wiring, appliances, or devices. Once tripped, the MCB must be manually reset to restore power to the circuit.

4.4 Resetting and Reusability of MCBs

Unlike fuses, MCBs are reusable. After tripping, the user can manually reset the device by flipping a switch. This feature reduces maintenance costs and provides a more sustainable solution for protecting electrical circuits, especially in environments with frequent low-level faults.

5. Applications of Miniature Circuit Breakers

MCBs are used in a wide array of applications across various sectors, offering protection for electrical systems ranging from household wiring to industrial machinery.

5.1 Residential Applications: Safeguarding Home Wiring

In residential settings, MCBs protect wiring and devices from overcurrent and short circuits. They are commonly used in homes to safeguard lighting circuits, appliance outlets, and HVAC systems. Their reusability and quick response times ensure that households remain safe from electrical hazards.

5.2 Industrial Applications: Ensuring Machinery Protection

In industrial environments, MCBs are crucial for protecting heavy machinery, production lines, and electrical panels. They prevent costly damage to sensitive equipment by interrupting the power supply during fault conditions, ensuring operational continuity and reducing downtime.

5.3 Commercial Applications: Securing Office and Retail Spaces

In commercial establishments, MCBs are used to protect office buildings, retail outlets, and data centers from power surges and overloads. They ensure that electrical systems function efficiently without risking damage to essential devices, such as computers, security systems, and lighting.

5.4 Specialized Applications: Solar Power Systems and Smart Grids

MCBs are also increasingly used in specialized applications like solar power systems and smart grids. In solar setups, MCBs protect the inverter and other critical components from overcurrent and short circuit

6. Selection Criteria for Choosing the Right MCB

Selecting the appropriate Miniature Circuit Breaker (MCB) for a given electrical system is a critical decision. The correct MCB ensures optimal protection, minimizes risk, and guarantees that the electrical system functions efficiently without interruptions. Several factors should be considered when choosing the right MCB, ranging from current ratings to compliance with safety standards. Understanding these factors ensures that the right MCB is chosen for each unique application, whether for residential, commercial, or industrial purposes.

6.1 Factors to Consider Before Purchasing an MCB

Before purchasing an MCB, there are several critical factors to keep in mind. These considerations help ensure that the selected MCB aligns with the electrical system’s specific requirements.

6.1.1 Rated Current and Breaking Capacity

The rated current of an MCB represents the maximum current the breaker can handle continuously without tripping. It is essential to choose an MCB with a rated current that matches the load demand of the circuit it will protect.

6.1.2 Tripping Curve Selection

MCBs are classified into different types based on their tripping curves, which determine how the MCB responds to overloads and short circuits. The tripping curve defines the time it takes for the MCB to trip at various current levels.

Depending on the nature of the load, a specific tripping curve type should be selected. For example, Type B MCBs are suitable for residential applications, whereas Type C and Type D MCBs are more suited to commercial and industrial uses, where inrush currents are higher.

6.1.3 Voltage Rating and Frequency Compatibility

The voltage rating indicates the maximum voltage that the MCB can handle without compromising its performance. It is essential to select an MCB whose voltage rating matches or exceeds the system’s operating voltage.

Additionally, the frequency compatibility ensures that the MCB functions correctly in systems with specific frequency requirements, such as 50 Hz or 60 Hz, commonly seen in residential and industrial applications.

6.1.4 Compliance with Safety Standards

For an MCB to be reliable, it must comply with relevant safety standards and certifications. This includes meeting international standards such as IEC (International Electrotechnical Commission) or UL (Underwriters Laboratories) certifications.

These standards ensure that the MCB has been tested and proven to meet the required performance, safety, and durability specifications, providing peace of mind to users.

6.2 Common Mistakes to Avoid When Selecting an MCB

Selecting an MCB involves more than just looking at the price tag or basic features. Several common mistakes can lead to selecting the wrong device, compromising the safety of the electrical system. These include:

- Underestimating the Load Demand: Choosing an MCB with too low a rated current or inadequate breaking capacity for the load can lead to frequent trips or even equipment damage.

- Ignoring Tripping Characteristics: Failing to consider the tripping curve of the MCB for the type of equipment or load being used can cause unnecessary tripping or failure to protect against faults effectively.

- Overlooking Safety Compliance: Always verify that the MCB meets all relevant safety standards. Using non-compliant MCBs can result in inefficient protection, voided warranties, and legal implications.

- Neglecting Voltage and Frequency Compatibility: Ensure that the voltage and frequency ratings of the MCB match the system’s requirements. Choosing an incompatible MCB can cause malfunction or failure during operation.

7. Installation and Maintenance of MCBs

Proper installation and maintenance of MCBs are vital for ensuring their longevity and functionality. An improperly installed or poorly maintained MCB can lead to ineffective protection, resulting in damage to the electrical system and its components.

7.1 Step-by-Step Guide to Installing an MCB

- Switch Off the Main Power Supply: Before starting any installation work, ensure that the main power supply is switched off to prevent the risk of electric shock.

- Mount the MCB on the Distribution Board: The MCB should be mounted securely on the electrical panel or distribution board. Ensure that it is properly aligned and that the rail is compatible with the MCB’s design.

- Connect the Incoming and Outgoing Wires: The incoming (line) and outgoing (load) wires should be connected to the MCB terminals. Ensure that the wire gauge matches the MCB’s rated current.

- Tighten the Connections: After connecting the wires, ensure that they are securely tightened using the appropriate tool. Loose connections can cause overheating or failure.

- Test the Installation: Once the MCB is installed, switch the power back on and test the MCB by manually tripping it to verify that it responds correctly to faults.

7.2 Safety Precautions During Installation

Safety during installation is paramount. Always wear insulated gloves, use insulated tools, and ensure that the installation area is dry and free from conductive materials. Moreover, it is crucial to follow local electrical codes and regulations to prevent electrical hazards.

7.3 Regular Maintenance and Inspection Checklist

Regular maintenance is essential to ensure the continued efficiency of MCBs. The following tasks should be performed at regular intervals:

- Check for Physical Damage: Inspect the MCB for signs of physical damage, such as cracks or scorch marks, which could indicate overheating or electrical faults.

- Verify Tightness of Connections: Over time, connections may loosen. Ensure that all terminals are tightly secured to prevent arcing or overheating.

- Test the MCB Functionality: Test the MCB by simulating overload or short circuit conditions to ensure that it trips as expected.

- Clean the MCB: Dust and debris can accumulate over time, affecting the MCB’s performance. Regularly clean the MCB to prevent these issues.

7.4 Troubleshooting Common Issues with MCBs

MCBs are generally reliable devices, but like all electrical components, they may encounter issues. Common problems include:

- Frequent Tripping: This could be due to an overloaded circuit, a short circuit, or a faulty MCB. Check the load and inspect the MCB for damage.

- MCB Fails to Trip: If the MCB does not trip during an overload or short circuit, it may be faulty and require replacement.

- Loose Connections: If the MCB is overheating or malfunctioning, check for loose connections and tighten them if necessary.

8. Advantages and Limitations of Miniature Circuit Breakers

MCBs are indispensable for modern electrical systems, but like any technology, they come with both advantages and limitations. Understanding these factors helps users make informed decisions about their application.

8.1 Key Benefits of Using MCBs Over Fuses

- Reusability: Unlike fuses, MCBs can be reset after tripping, eliminating the need for costly replacements.

- Faster Response Time: MCBs react faster than fuses, particularly in the case of short circuits, providing superior protection.

- Precision: MCBs offer more accurate and customizable protection settings, allowing users to select the right tripping curve based on the application.

- Reduced Downtime: The ability to reset an MCB quickly minimizes downtime, especially in commercial and industrial environments.

8.2 Limitations and Considerations for Specific Applications

- Cost: MCBs are generally more expensive than fuses, especially for larger, more complex systems.

- Size Limitations: MCBs may not be suitable for very high current systems without being oversized, leading to inefficiency in some cases.

- Complexity: For certain low-load applications, a fuse might be more cost-effective and simpler.

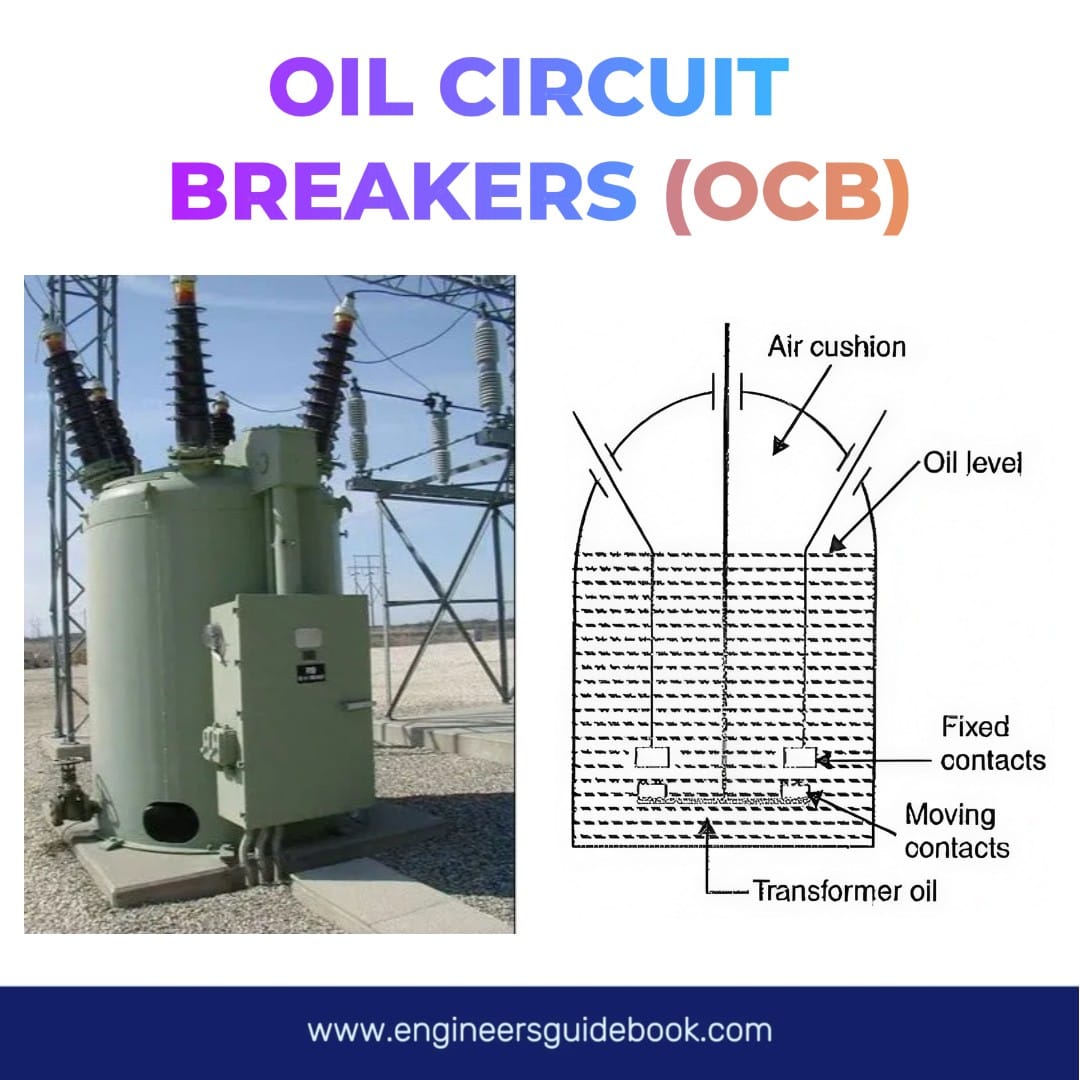

8.3 Comparing MCBs with Other Circuit Protection Devices

MCBs, fuses, and Residual Current Devices (RCDs) all serve the purpose of protecting electrical circuits. While MCBs are excellent for overcurrent and short circuit protection, fuses offer simpler, more economical solutions for low-power circuits.

RCDs, on the other hand, provide essential protection against electric shocks, complementing MCBs in safety-critical environments.

9. Future Trends and Innovations in MCB Technology

As electrical systems evolve, so too does the technology behind MCBs. Emerging innovations focus on enhancing performance, integration with modern systems, and reducing environmental impact.

9.1 Smart MCBs and IoT Integration

The integration of Internet of Things (IoT) technology with MCBs is on the rise. Smart MCBs can communicate with control systems, providing real-time data on circuit status, fault conditions, and load performance. This allows for predictive maintenance, reducing downtime and improving system reliability.

9.2 Enhancements in Tripping Sensitivity and Efficiency

Advancements in materials and design are leading to MCBs that offer finer sensitivity and faster response times. These innovations enhance the efficiency of protection in sensitive circuits, ensuring that electrical systems can handle complex loads and high-performance demands without compromising safety.

9.3 Environmental Impact and Eco-Friendly MCB Solutions

As sustainability becomes a key focus in electrical design, manufacturers are working on creating MCBs that have minimal environmental impact. This includes the use of recyclable materials, energy-efficient manufacturing processes, and designs that reduce energy consumption during operation.

10. Conclusion

Miniature Circuit Breakers (MCBs) are vital components of electrical protection systems. Their ability to interrupt the circuit during overloads or short circuits ensures the safety and longevity of electrical systems. With various types of MCBs tailored for different applications, selecting the correct model is crucial for achieving optimal performance and protection.

To ensure the effective operation of MCBs, it is essential to select the right type based on load demands, regularly maintain and inspect the devices, and adhere to safety precautions during installation.

The future of circuit protection will see the rise of smarter, more efficient MCBs that integrate with modern IoT systems, enhancing safety and reliability. As technology continues to evolve, MCBs will become even more integral to safe and efficient electrical systems.

7 Responses

An outstanding share! I’ve just forwarded this onto a co-worker who has been conducting a little research on this.

And he actually bought me breakfast because I discovered it for him…

lol. So let me reword this…. Thanks for the meal!!

But yeah, thanks for spending the time to discuss

this issue here on your internet site.

hi!,I love your writing very much! percentage we keep up a correspondence extra about your post on AOL?

I need an expert in this area to unravel my problem. May be that’s you!

Looking forward to look you.

Informative article, totally what I was looking for.

It’s a shame you don’t have a donate button! I’d definitely donate to this fantastic blog!

I guess for now i’ll settle for bookmarking and adding your

RSS feed to my Google account. I look forward to fresh

updates and will talk about this site with my Facebook

group. Chat soon!

Do you mind if I quote a couple of your posts as long as I provide credit

and sources back to your blog? My website is in the exact same niche as yours and my visitors would certainly benefit from some

of the information you present here. Please let me

know if this ok with you. Appreciate it!

I do agree with all the ideas you’ve offered on your post.

They are very convincing and will certainly work.

Still, the posts aree too brief for starters.

Could you please lengthen them a bit from next time? Thank yoou for the post.

Hey there, You’ve done an excellent job. I will definitely digg it and personally recommend to my friends. I’m confident they will be benefited from this web site.