1. Introduction

1.1 Defining Movable Pulleys

Movable pulleys are an integral part of mechanical systems, designed to reduce the amount of force required to lift heavy loads. Unlike fixed pulleys, which remain stationary, a movable pulley is attached to the load itself, allowing it to move along with it. This setup effectively reduces the effort needed by distributing the weight more efficiently.

1.2 The Role of Movable Pulleys

In various mechanical applications, movable pulleys play a crucial role in optimizing work efficiency. They are frequently used in lifting mechanisms, industrial machinery, and transportation systems. Their ability to minimize manual effort while maximizing output makes them indispensable in engineering and mechanical operations.

1.3 Why Understanding Their Pros and Cons is Essential

Understanding the advantages and disadvantages of movable pulleys is essential for engineers, designers, and industrial professionals. While they offer significant mechanical advantages, they also come with certain limitations. A comprehensive understanding helps in determining the appropriate use cases and ensures efficient implementation in mechanical systems.

2. Understanding Movable Pulleys

2.1 How Movable Pulleys Differ from Fixed Pulleys

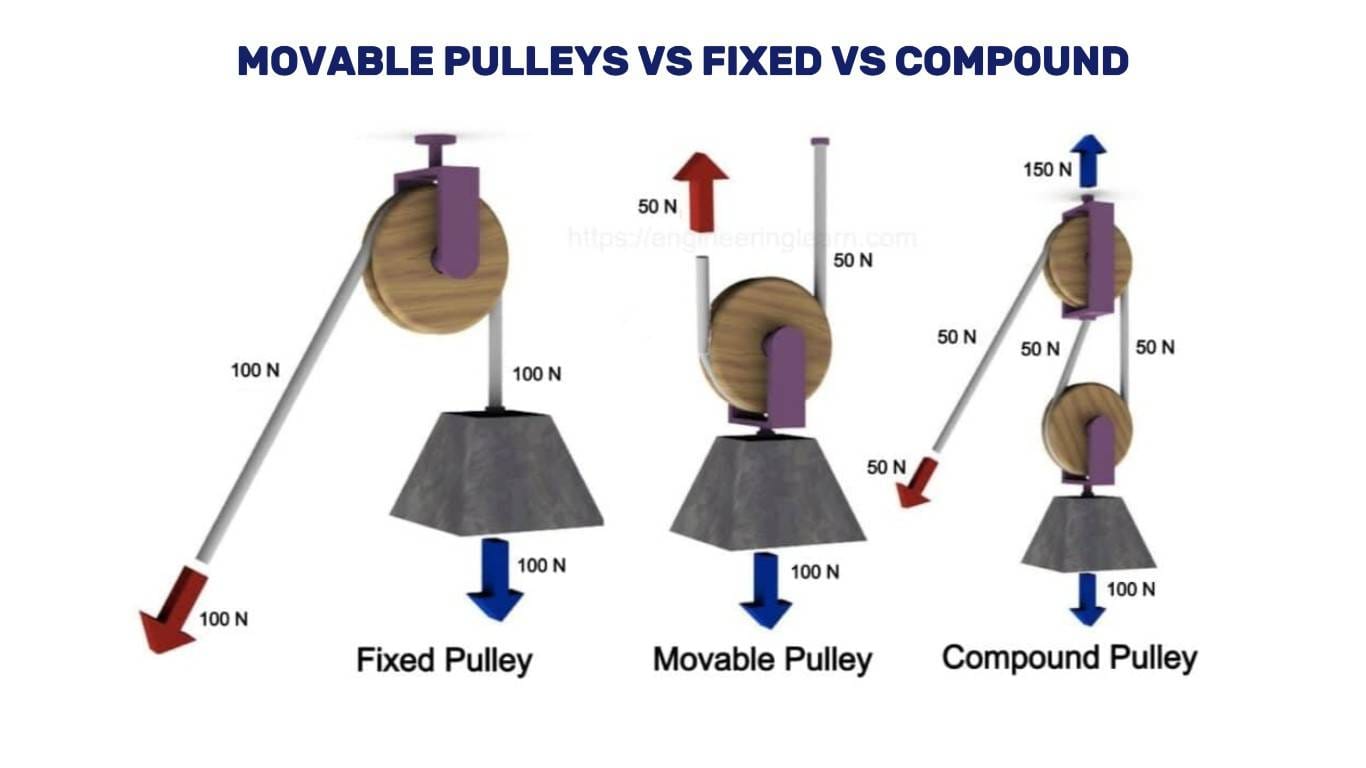

Fixed pulleys remain in one position and primarily change the direction of force, whereas movable pulleys move along with the load, reducing the effort needed to lift it. This fundamental difference results in varying applications, with movable pulleys being preferred for heavy-lifting tasks requiring force reduction.

2.2 The Physics Behind Movable Pulleys

Movable pulleys function based on the principles of mechanical advantage. When force is applied, the pulley system divides the load across multiple segments of rope, reducing the input effort needed. This principle allows for efficient weight distribution and optimized force application.

2.3 Common Applications of Movable Pulleys in Everyday Life

Movable pulleys are widely used in construction cranes, gym equipment, elevators, and maritime rigging. Their ability to facilitate heavy lifting with minimal effort makes them a fundamental component in numerous industries.

3. Working of Movable Pulleys

3.1 Basic Principle

A movable pulley consists of a wheel that rotates around an axle and is attached to the load. When force is applied, the pulley moves along with the load, effectively reducing the effort required by distributing force across multiple points.

3.2 Force Distribution in a Movable Pulley System

The force applied to a movable pulley is divided between the sections of the supporting rope. This division allows for a significant reduction in the force required to lift the load, as the pulley system provides a mechanical advantage.

3.3 Role of Tension in Reducing the Required Effort

Tension plays a critical role in pulley systems. In a movable pulley, the distribution of tension across multiple rope sections ensures that the lifting effort is minimized. The increased tension efficiency allows for smoother operation and less strain on the user.

3.4 Step-by-Step Explanation of a Movable Pulley in Action

- The load is attached to the pulley system.

- A rope or cable runs over the pulley, with one end secured while force is applied to the other.

- As force is exerted, the pulley moves along with the load, reducing the effort needed to lift it.

- The mechanical advantage increases as more pulleys are incorporated into the system.

3.5 Examples of Movable Pulleys in Real-World Applications

- Construction Cranes: Used to lift and position heavy materials efficiently.

- Elevators: Integrated into pulley systems to enhance vertical motion.

- Gym Equipment: Provides resistance in weight-training machines

- Rescue Operations: Used in hoisting mechanisms for safe and efficient lifting.

4. The Advantages of Movable Pulleys

4.1 Increased Mechanical Advantage

The primary advantage of a movable pulley is its ability to reduce the force needed to lift heavy objects. By distributing weight across multiple support points, it enhances efficiency and reduces strain.

4.2 Improved Load Distribution

Movable pulleys evenly distribute weight, preventing excessive strain on any single point. This results in improved system stability and extended operational longevity.

4.3 Industrial Applications

These pulleys are adaptable to numerous mechanical setups, from industrial cranes to gym machinery. Their flexibility in integration makes them invaluable in engineering applications.

4.4 Ease of Lifting Heavy Loads with Minimal Effort

By leveraging mechanical advantage, movable pulleys enable users to lift substantial loads with significantly less force. This makes them indispensable in industries requiring heavy material handling.

4.5 Integration with Other Pulley Systems for Maximum Efficiency

Movable pulleys are often combined with fixed pulleys to form compound systems, further amplifying mechanical advantage. This hybrid approach optimizes force distribution and enhances overall functionality.

5. The Disadvantages of Movable Pulleys

5.1 Increased Complexity Compared to Fixed Pulleys

Unlike fixed pulleys, movable pulleys require additional components and a more intricate setup. This complexity can make their installation and maintenance more challenging.

5.2 More Components, Higher Maintenance Needs

With additional moving parts, movable pulleys demand regular maintenance to prevent wear and ensure smooth operation. Bearings, axles, and rope integrity must be routinely checked for optimal performance.

5.3 The Challenge of Managing Friction

Friction between the rope and pulley wheel can lead to gradual wear, reducing efficiency. Proper lubrication and high-quality materials help mitigate this issue.

5.4 Space Considerations

Movable pulleys require additional space for movement and proper functionality. In confined areas, alternative lifting mechanisms might be more practical.

5.5 Higher Initial Costs and Installation Efforts

Compared to simple fixed pulley systems, movable pulleys often involve higher initial costs due to additional components and installation complexity. However, their long-term benefits often outweigh these initial expenses.

6. Comparing Movable Pulleys to Other Pulley Types

6.1 Movable vs. Fixed Pulleys

Movable pulleys and fixed pulleys serve distinct mechanical functions. A fixed pulley remains stationary, primarily redirecting force but not reducing the effort required to lift a load. In contrast, a movable pulley moves with the load, providing mechanical advantage by reducing the necessary input force.

Fixed pulleys are simpler and more durable, whereas movable pulleys enhance efficiency but require additional components and maintenance.

6.2 How Movable Pulleys Fit into Compound Pulley Systems

Compound pulley systems integrate both fixed and movable pulleys, combining their strengths to achieve greater mechanical advantage. This setup allows for more efficient load distribution and minimizes the effort needed to lift heavy objects. The synergy between fixed and movable pulleys makes compound systems ideal for cranes, elevators, and large-scale lifting operations.

6.3 When to Use Movable Pulleys Over Other Mechanical Alternatives

Movable pulleys are best suited for scenarios where reducing effort is crucial. They are preferred in industrial lifting, construction, and maritime applications where loads are heavy, and mechanical advantage is necessary. When space constraints or low-maintenance requirements are a priority, alternative systems such as gears or hydraulic lifts may be more suitable.

7. Real-world applications of Movable Pulleys

7.1 Construction and Heavy Lifting

Movable pulleys are indispensable in the construction industry, aiding in the efficient lifting of materials such as steel beams, concrete blocks, and other heavy loads. Their ability to reduce manual effort increases productivity while minimizing worker fatigue and injury.

7.2 Cranes and Hoists

Industrial cranes and hoists rely on movable pulleys to manage extreme loads with precision. By incorporating multiple pulleys, these systems distribute weight effectively, reducing strain on individual components and allowing for safer, more controlled lifting.

7.3 Elevators and Lift Systems

Elevators incorporate movable pulley mechanisms to facilitate smooth vertical motion. The mechanical advantage provided by these pulleys ensures efficient energy usage and enhances safety in high-rise buildings, cargo lifts, and warehouse storage systems.

7.4 Sailing and Rigging

Sailing vessels utilize movable pulleys in their rigging systems, allowing sailors to adjust sails effortlessly. These pulleys enable smooth control over ropes and sails, optimizing wind usage and enhancing maneuverability at sea.

7.5 Gym Equipment

Many exercise machines use movable pulleys to create variable resistance in strength training. These systems allow for a smoother, more controlled workout by evenly distributing resistance throughout the motion.

8. The Science of Efficiency in Movable Pulleys

8.1 How Mechanical Advantage Translates to Energy Savings

Movable pulleys reduce the effort needed to lift a load, leading to significant energy savings in mechanical operations. By decreasing input force, they minimize strain on motors, engines, and manual labor.

8.2 The Relationship Between Load, Effort, and Pulley Placement

The efficiency of a movable pulley system depends on its configuration. Proper placement ensures optimal force distribution, minimizing resistance and maximizing mechanical advantage.

8.3 Addressing Energy Loss Due to Friction and Pulley Material

Friction can lead to energy loss in pulley systems. Using high-quality materials, such as low-friction bearings and durable cables, can enhance efficiency and prolong the lifespan of pulley components.

9. Innovations and Advancements in Movable Pulley Technology

9.1 Modern Materials and Their Impact on Durability and Performance

Advancements in materials, including composite polymers and high-strength alloys, have improved the durability and load-bearing capacity of movable pulleys. These innovations enhance longevity and reduce maintenance requirements.

9.2 Smart Pulley Systems

The integration of smart sensors and automation has revolutionized pulley systems. Load-sensing technologies optimize weight distribution, improving safety and efficiency in industrial applications.

9.3 The Future of Movable Pulleys in Engineering and Robotics

As engineering and robotics continue to evolve, movable pulleys are being integrated into automated lifting systems, robotic arms, and self-adjusting mechanical structures, enhancing their functionality and adaptability.

10. Choosing the Right Pulley System for Your Needs

10.1 Key Factors to Consider

Selecting the appropriate pulley system involves assessing load capacity, available space, and budget constraints. A balance between efficiency and practicality ensures optimal performance.

10.2 When to Opt for a Movable Pulley Over Other Lifting Mechanisms

Movable pulleys are ideal for scenarios requiring reduced effort and enhanced lifting capabilities. When consistent force distribution and mechanical advantage are necessary, they outperform simple fixed pulley systems.

10.3 Evaluating Long-Term Benefits and Trade-offs

Understanding the long-term advantages of movable pulleys, such as reduced labor costs and increased efficiency, can justify initial investment costs and maintenance requirements.

11. Troubleshooting Common Issues with Movable Pulleys

11.1 Diagnosing Excessive Friction and Wear

Friction and wear can impede pulley efficiency. Regular lubrication, proper alignment, and high-quality components help mitigate these issues.

11.2 Addressing Alignment and Tension Problems

Misalignment and improper tensioning can cause uneven force distribution, leading to operational inefficiencies. Regular inspections ensure smooth functionality.

11.3 Preventative Maintenance Tips to Extend Pulley Lifespan

Routine maintenance, including inspections, cleaning, and timely replacement of worn components, extends the lifespan and reliability of movable pulley systems.

12. Environmental and Economic Impact of Movable Pulleys

12.1 Sustainable Design Choices for Efficient Energy Use

Eco-friendly materials and energy-efficient pulley systems contribute to sustainability efforts, reducing environmental impact in industrial applications.

12.2 Cost-Effectiveness of Movable Pulleys in Industrial Settings

Movable pulleys enhance cost efficiency by lowering energy consumption, reducing labor costs, and minimizing wear on machinery.

Types of Gears | Advantages, Disadvantages And Uses |

Heat Transfer: Conduction Convection and Radiation Explained

Differences Between AC and DC Motors

12.3 Reducing Waste Through Proper Pulley Maintenance and Recycling

Proper maintenance and recycling of pulley components prevent unnecessary waste, promoting a circular economy and reducing industrial environmental footprints.

13. Conclusion

Assessing the advantages and limitations of movable pulleys helps determine their suitability for specific applications, balancing efficiency, cost, and practicality.

Despite advancements in technology, movable pulleys remain essential in various industries, proving their enduring significance in engineering and mechanical systems.

Innovations in materials, automation, and robotics will continue to shape the future of pulley systems, enhancing their efficiency and expanding their applications.

14. FAQS

1. What is a movable pulley, and how does it work?

A movable pulley is a type of pulley that moves along with the load, reducing the force required to lift it by distributing the weight across multiple support points.

2. How does a movable pulley differ from a fixed pulley?

A fixed pulley is stationary and only changes the direction of force, whereas a movable pulley moves with the load, providing a mechanical advantage by reducing effort.

3. What is the mechanical advantage of a movable pulley?

A movable pulley provides a mechanical advantage of 2:1, meaning it reduces the required lifting force by half, making it easier to lift heavy loads.

4. Where are movable pulleys commonly used?

Movable pulleys are used in construction cranes, elevators, gym equipment, rescue hoists, and various industrial and mechanical lifting systems.

5. What are the advantages of using a movable pulley?

Movable pulleys reduce lifting effort, improve load distribution, increase mechanical efficiency, and can be integrated into compound pulley systems for greater effectiveness.

6. What are the main disadvantages of movable pulleys?

They require more components, increase system complexity, demand higher maintenance, generate friction over time, and may not be ideal for compact spaces.

7. Can movable pulleys be combined with other pulley types?

Yes, they are often integrated with fixed pulleys to create compound pulley systems, further enhancing mechanical advantage and reducing effort.

8. How does tension affect the performance of a movable pulley?

Tension distributes force across the rope, reducing strain on individual sections and making it easier to lift loads with minimal applied effort.