1. Introduction

1.1 Overview of Circuit Breakers and Their Importance

Circuit breakers are indispensable components in electrical networks, designed to protect circuits from damage caused by overloads or short circuits. By automatically interrupting the flow of electricity upon detecting faults, these devices prevent catastrophic failures, equipment damage, and potential fire hazards. Their importance extends to residential, commercial, and industrial power systems, ensuring safe and reliable electricity distribution.

1.2 Role of Oil Circuit Breakers in Electrical Systems

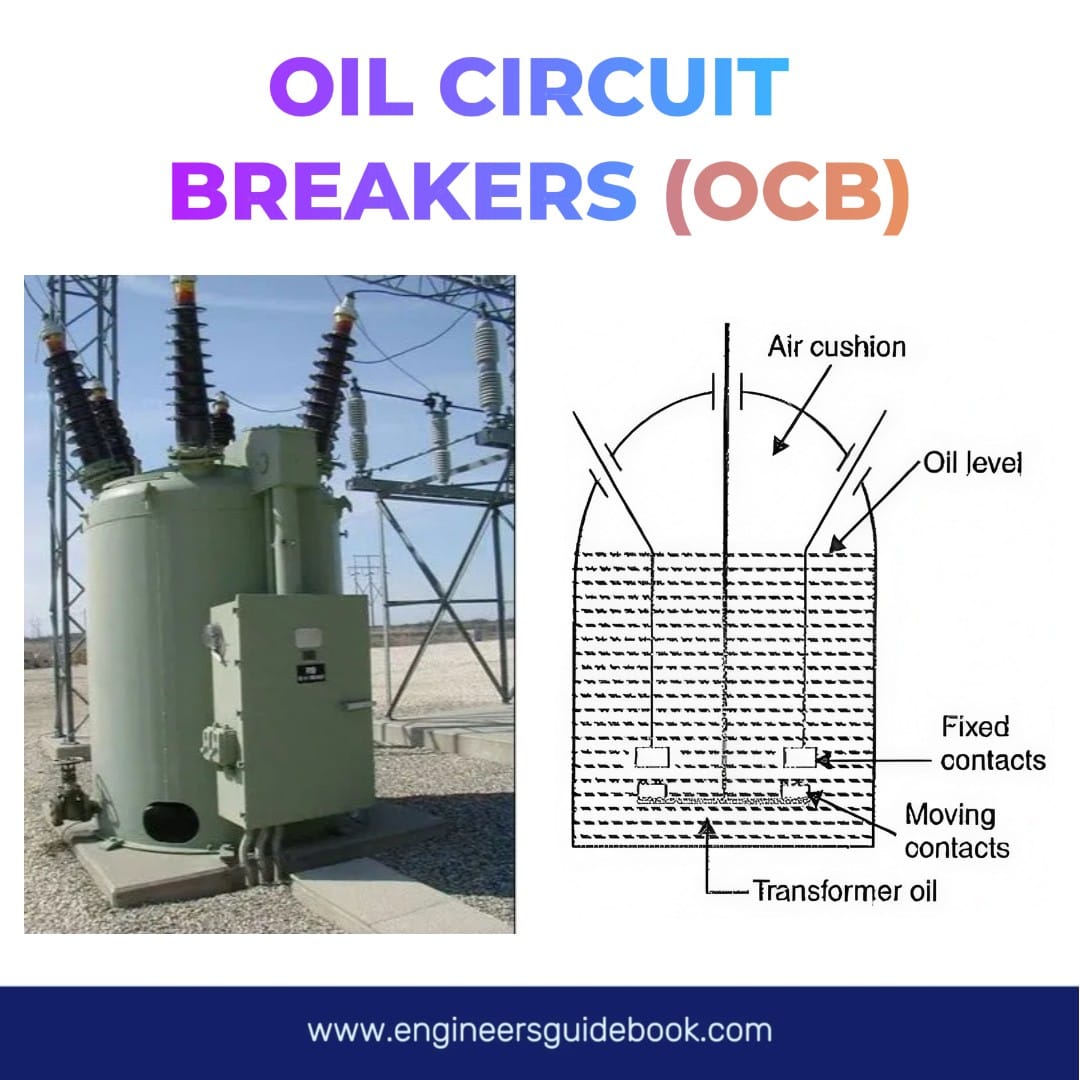

Among the various types of circuit breakers, oil circuit breakers (OCBs) hold a significant place in high-voltage applications. They utilize insulating oil both as a dielectric medium and as an arc-quenching agent, effectively suppressing electrical discharges.

These breakers are commonly deployed in substations, power plants, and industrial grids where robust performance and reliability are paramount.

1.3 Evolution of Oil Circuit Breakers in Power Engineering

The development of OCBs can be traced back to the early 20th century when engineers sought more efficient methods to extinguish arcs. Initially, air-break and simple mechanical circuit breakers dominated, but as voltage levels increased, their limitations became apparent.

The introduction of oil as a medium for arc extinction revolutionized circuit breaker technology, leading to the widespread adoption of bulk oil and minimum oil circuit breakers.

2. Fundamentals of Oil Circuit Breakers

2.1 Basic Working Principle of Oil Circuit Breakers

An oil circuit breaker operates by immersing its electrical contacts in insulating oil. When a fault occurs, the breaker separates its contacts, generating an electrical arc. The surrounding oil absorbs the arc’s energy, vaporizing into gas, which further helps quench the arc by cooling it and creating a dielectric barrier. Once the arc is extinguished and the circuit is de-energized, the breaker is ready to restore normal operation.

2.2 Types of Oils Used in Circuit Breakers

The performance of an OCB heavily depends on the quality and characteristics of its insulating oil. Commonly used oils include:

- Mineral Oil: The most prevalent choice due to its excellent dielectric strength and thermal stability.

- Synthetic Oils: Engineered for enhanced performance, particularly in extreme operating conditions.

- Biodegradable Oils: Environmentally friendly alternatives designed to reduce ecological impact without compromising efficiency.

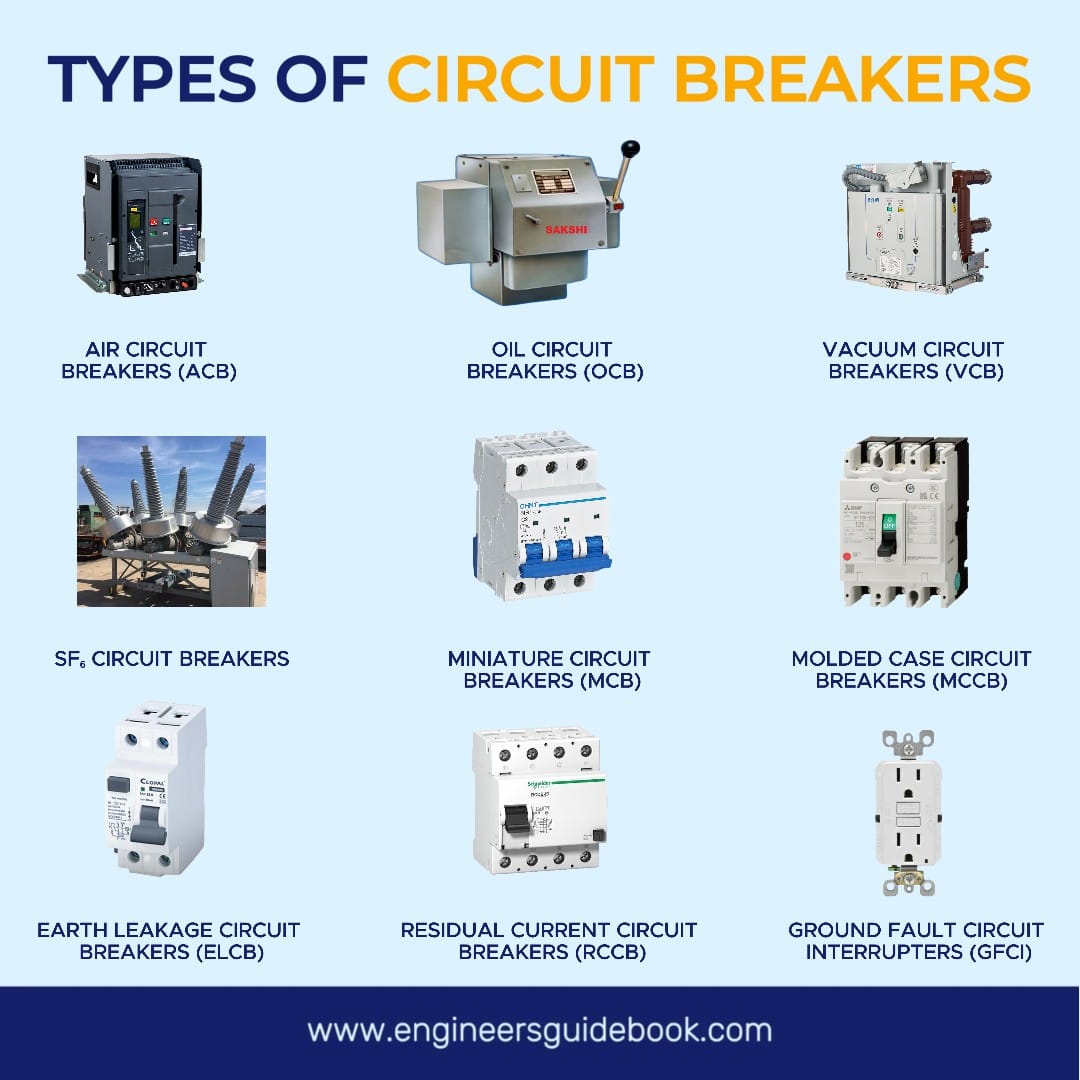

2.3 Comparison Between Oil Circuit Breakers and Other Breaker Types

While OCBs are effective, they are not the only available technology. Comparisons with other breakers include:

- Oil vs. SF6 Circuit Breakers: SF6 breakers offer superior insulation and arc-quenching capabilities but require careful handling due to environmental concerns.

- Oil vs. Vacuum Circuit Breakers: Vacuum breakers provide a cleaner and maintenance-free solution, though they may not be ideal for extremely high-voltage applications.

- Oil vs. Air Circuit Breakers: Air breakers are commonly used in low-voltage applications, whereas oil breakers excel in medium- to high-voltage scenarios.

3. Types of Oil Circuit Breakers

3.1 Bulk Oil Circuit Breakers (BOCB)

BOCBs utilize a large volume of oil for both arc extinction and insulation. They are suited for high-voltage applications where greater insulation is required.

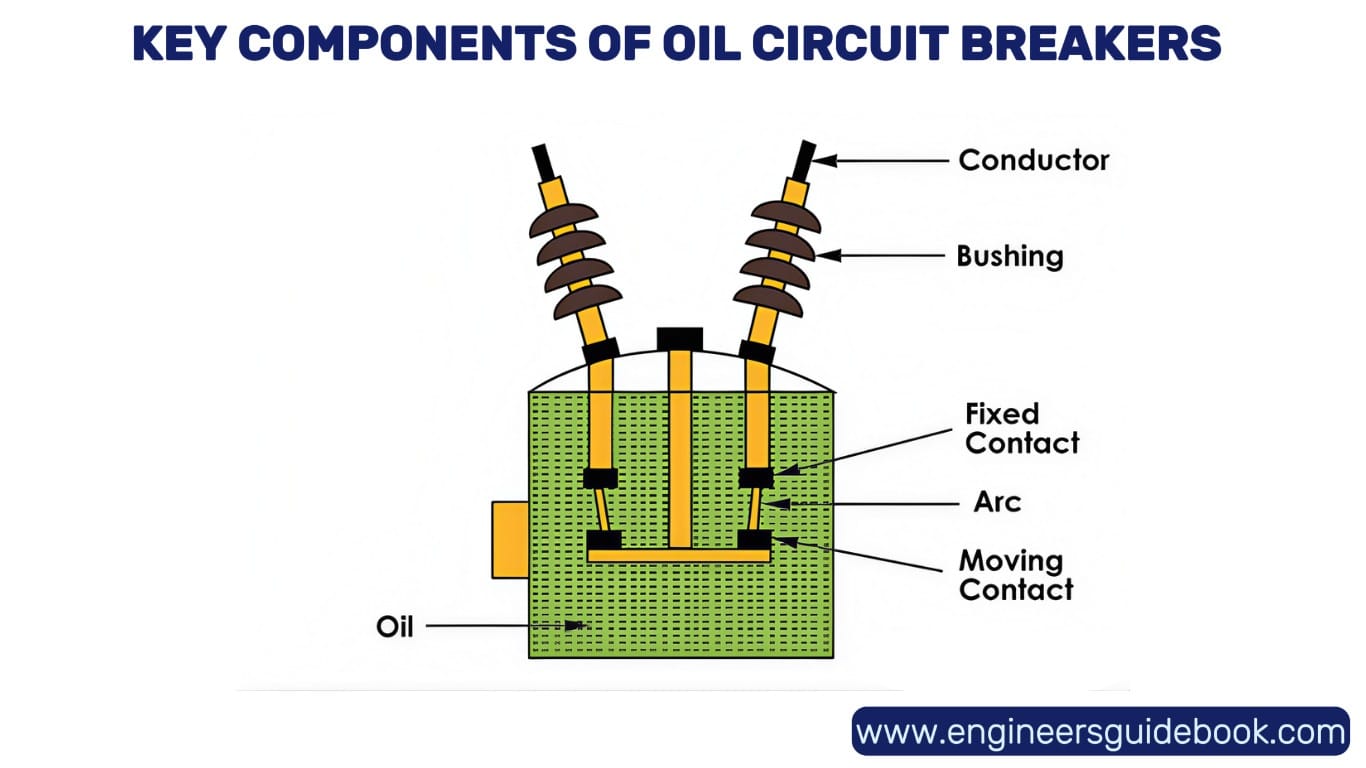

3.1.1 Structure and Components

A typical BOCB consists of:

- Tank: Houses the insulating oil and breaker components.

- Moving and Fixed Contacts: Conductive elements responsible for circuit continuity.

- Arc Control Devices: Facilitate efficient arc quenching.

- Operating Mechanism: Manages contact movement during switching operations.

3.1.2 Applications and Limitations

BOCBs are widely used in substations and industrial grids. However, their bulky nature and high maintenance requirements pose challenges, leading to a gradual shift toward more compact alternatives.

3.2 Minimum Oil Circuit Breakers (MOCB)

MOCBs were developed to address the shortcomings of bulk oil breakers by reducing the amount of oil used while maintaining performance.

3.2.1 Compact Design and Mechanism

Unlike BOCBs, MOCBs isolate the arc-extinction function from the insulation function, leading to a more compact and efficient design. This makes them more suitable for modern substations with space constraints.

3.2.2 Advantages Over Bulk Oil Circuit Breakers

- Reduced Oil Volume: This minimizes fire hazards and environmental risks.

- Lower Maintenance Requirements: Less frequent oil replacement and monitoring.

- Enhanced Operational Efficiency: Faster arc extinction due to improved arc control chambers.

4. Construction and Components of Oil Circuit Breakers

4.1 Arc Interruption Chamber and Its Role

The arc interruption chamber is designed to contain and extinguish electrical arcs swiftly. It regulates the flow of vaporized gases generated during arc formation, facilitating efficient cooling and deionization of the arc path.

4.2 Insulating Oil: Properties and Requirements

The insulating oil used in OCBs must possess:

- High Dielectric Strength: To prevent electrical breakdown.

- Low Viscosity: For efficient circulation and cooling.

- Thermal Stability: To withstand high-temperature conditions without degradation.

4.3 Moving and Fixed Contacts: Materials and Functionality

Contacts in OCBs are typically made of copper or copper alloys due to their high conductivity and resistance to wear. Their movement is carefully controlled to minimize arcing and ensure quick disconnection under fault conditions.

4.4 Tank Design and Oil Containment System

The oil tank must be robust and leak-proof, designed to withstand internal pressure changes during switching operations. Some designs incorporate oil filtration systems to prolong operational life.

5. Operational Mechanism of Oil Circuit Breakers

5.1 Arc Formation and Its Effect on Oil

When the breaker contacts separate, an arc forms due to ionized air and residual current. This arc rapidly heats the surrounding oil, causing it to decompose into hydrogen and other gases, which aid in arc extinction.

5.2 Arc Extinction Process in Oil Medium

The arc extinction mechanism involves:

- Ionization: Initial arc formation between contacts.

- Gas Bubble Formation: Rapid decomposition of oil into gases, creating a high-pressure environment.

- Cooling and Quenching: Gas expansion displaces the arc path, cooling it and restoring insulation properties.

- Recombination: The oil reabsorbs gases, stabilizing the breaker for the next operation.

5.3 Role of Gas Generation in Interruption Efficiency

Gas formation plays a critical role in improving the dielectric strength between contacts. The hydrogen released during arc extinction helps dissipate heat and prevents re-ignition, making OCBs highly effective in high-voltage applications.

By leveraging the principles of dielectric insulation and arc quenching, oil circuit breakers remain a cornerstone in electrical power protection, ensuring the safe and reliable operation of energy networks worldwide.

6. Advantages and Disadvantages of Oil Circuit Breakers

6.1 Key Benefits of Oil Circuit Breakers

6.1.1 High Insulation Properties

Oil serves as an excellent insulating medium, preventing electrical discharge and ensuring stable operation. Due to its high dielectric strength, oil significantly reduces the risk of flashovers, which is crucial in high-voltage applications.

6.1.2 Effective Arc Quenching Capability

The primary advantage of oil in circuit breakers is its ability to efficiently quench electric arcs. Upon arc formation, the surrounding oil decomposes into hydrogen gas, which rapidly cools and dissipates the arc energy, leading to quick and reliable interruption.

6.1.3 Reliability in High Voltage Applications

Oil circuit breakers have been widely employed in high-voltage applications due to their robustness and ability to withstand electrical stress. They are particularly effective in handling large fault currents, ensuring uninterrupted power distribution.

6.2 Challenges and Limitations

6.2.1 Fire and Explosion Hazards

One of the significant drawbacks of oil circuit breakers is the potential fire hazard. During arc interruption, excessive gas accumulation may lead to tank rupture, posing a severe explosion risk. This necessitates stringent safety measures in installation and operation.

6.2.2 High Maintenance Requirements

Regular maintenance is crucial to ensure the proper functioning of oil circuit breakers. The insulating oil must be periodically tested and replaced to maintain its dielectric properties, adding to operational costs and downtime.

6.2.3 Environmental Concerns and Oil Leakage

The use of mineral oil in circuit breakers raises environmental concerns. Oil leakage can contaminate soil and water, requiring proper containment systems. Additionally, the disposal of used oil must comply with environmental regulations to mitigate ecological impact.

7. Applications of Oil Circuit Breakers

7.1 Use in High Voltage Transmission and Distribution Networks

Oil circuit breakers are extensively utilized in electrical transmission and distribution systems. They provide reliable protection against short circuits and overloads in high-voltage lines, ensuring system stability and safety.

7.2 Industrial and Commercial Power Systems

Industries and commercial facilities often rely on oil circuit breakers to safeguard electrical equipment. Their ability to handle heavy electrical loads makes them indispensable in factories, processing plants, and large commercial buildings.

7.3 Integration in Substations and Power Plants

Power generation facilities and substations incorporate oil circuit breakers as primary protective devices. Their high interrupting capacity allows them to manage electrical faults efficiently, reducing downtime and damage to critical infrastructure.

8. Maintenance and Safety Considerations

8.1 Routine Inspection and Testing Procedures

Regular inspections help detect potential faults in oil circuit breakers. Key tests include dielectric strength measurement of oil, contact resistance checks, and insulation resistance testing to ensure optimal performance.

8.2 Oil Quality Monitoring and Replacement Strategies

Oil degradation can compromise the breaker’s efficiency. Monitoring oil purity, moisture content, and acidity levels helps determine the right time for oil replacement, preventing operational failures.

8.3 Common Faults and Troubleshooting Methods

Issues such as carbonization of contacts, gas accumulation, and leakage are common in oil circuit breakers. Effective troubleshooting involves visual inspections, thermographic analysis, and pressure monitoring to preempt failures.

8.4 Safety Precautions for Handling and Operation

The proper handling of oil circuit breakers requires adherence to safety protocols. Operators must use protective gear, follow proper oil-disposal methods, and ensure adequate ventilation in confined spaces to minimize health risks.

9. Comparison with Modern Circuit Breaker Technologies

9.1 Oil Circuit Breakers vs. SF6 Circuit Breakers

While oil circuit breakers rely on insulating oil for arc quenching, SF6 circuit breakers use sulfur hexafluoride gas, which offers superior performance and minimal maintenance. However, SF6 gas is a potent greenhouse gas, raising environmental concerns.

9.2 Oil Circuit Breakers vs. Vacuum Circuit Breakers

Vacuum circuit breakers provide arc extinction in a sealed vacuum chamber, eliminating the need for oil. They offer longer service life and reduced maintenance but are more expensive compared to oil circuit breakers.

9.3 Future Trends in Circuit Breaker Technology

Advancements in circuit breaker technology are shifting toward eco-friendly and low-maintenance solutions. Solid-state breakers and hybrid designs are emerging as viable alternatives, promising improved efficiency and environmental sustainability.

10. Conclusion

Oil circuit breakers play a vital role in power systems, offering effective arc quenching, high insulation, and reliability in high-voltage applications. However, they also pose challenges, such as fire risks, environmental concerns, and maintenance demands.

Despite the emergence of modern alternatives, oil circuit breakers remain relevant in specific applications. Research into biodegradable oils and enhanced safety measures may prolong their usability in the industry.

Selecting the right circuit breaker depends on operational requirements, maintenance considerations, and environmental impact. While oil circuit breakers have served the industry for decades, newer technologies offer promising advantages in safety and sustainability.

11. FAQs

1. What is the primary function of an oil circuit breaker?

Oil circuit breakers interrupt fault currents by using insulating oil as a medium for arc extinction, ensuring electrical safety and protection.

2. How often should the oil in an oil circuit breaker be replaced?

Oil replacement depends on operational conditions, but periodic testing should be conducted annually to determine its dielectric strength and contamination levels.

3. What are the main hazards associated with oil circuit breakers?

Fire and explosion risks due to excessive gas buildup, as well as environmental contamination from oil leaks, are the primary hazards.

4. How do oil circuit breakers compare to SF6 breakers?

SF6 breakers offer superior insulation and lower maintenance but pose environmental risks due to greenhouse gas emissions.

5. Why are oil circuit breakers still in use today?

They remain cost-effective for high-voltage applications where alternative technologies are not economically viable.

6. Can oil circuit breakers be retrofitted with modern alternatives?

Yes, many industries are replacing old oil circuit breakers with vacuum or SF6 models for improved efficiency and safety.

7. What safety measures should be followed when maintaining an oil circuit breaker?

Proper ventilation, protective equipment, and adherence to maintenance protocols are essential to prevent accidents and ensure longevity.

8. Are there eco-friendly alternatives to mineral oil in circuit breakers?

Yes, research is ongoing into biodegradable and synthetic oils that offer similar insulating properties with reduced environmental impact.

One Response

Enjoyed reading through this, very good stuff, appreciate it.