In manufacturing, construction, and engineering industries, accurate material calculations are crucial for project success, cost estimation, and resource planning. Among the most common materials used in these fields are square bars –

versatile metal components with equal sides that form a square cross-section. Calculating the weight of square bars manually can be time-consuming and error-prone, which is why a specialized Square Bar Weight Calculator has become an indispensable tool for professionals.

A Square Bar Calculator is a digital solution designed to instantly compute the weight of square cross-section bars based on their dimensions and material composition.

Square bars are long metal pieces with a uniform square cross-section along their entire length. They’re manufactured from various materials including mild steel, stainless steel, aluminum, brass, and copper. These bars are characterized by their:

Equal side dimensions

90-degree angles at all corners

Consistent cross-sectional area

Straightness and uniformity

Square bars serve as fundamental components across multiple industries due to their structural integrity and versatility:

Construction Industry: Used for building frames, supports, and reinforcement structures

Manufacturing: Essential for machinery frames, jigs, fixtures, and tooling

Fabrication: Basis for creating brackets, frames, and custom metal products

Architecture: Decorative elements, railings, and structural accents

Automotive: Chassis components, supports, and custom modifications

Before the advent of digital tools like the Square Bar Calculator, professionals relied on manual calculations that presented numerous challenges:

The weight calculation for square bars involves multiple variables:

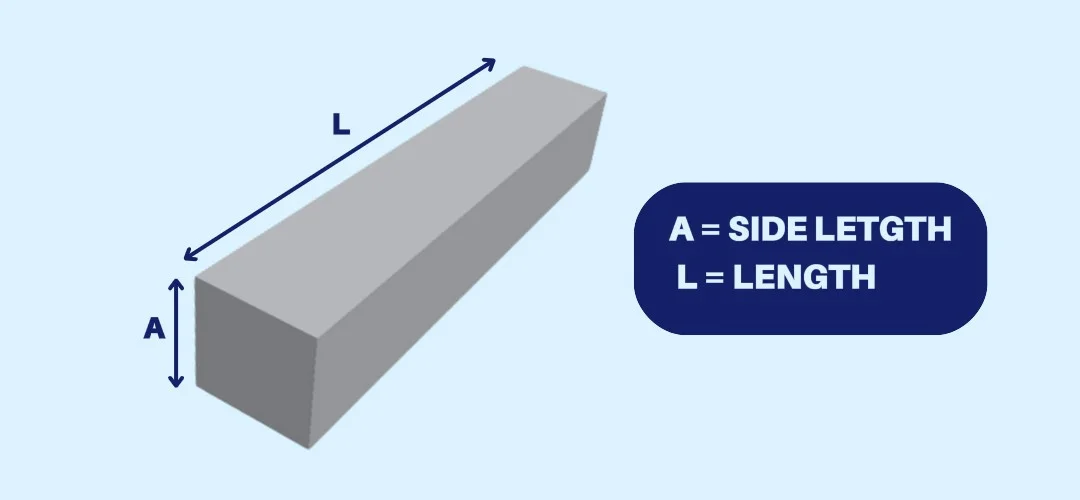

Weight = Side² × Length × DensityWhere:

Side is the dimension of one side of the square

Length is the bar length

Density is the material-specific weight per unit volume

Professionals often work with measurements in different units (mm, cm, m, inches, feet), requiring error-prone conversions:

1 meter = 1000 millimeters

1 foot = 12 inches

1 inch = 25.4 millimeters

A single conversion mistake can lead to significant calculation errors that compound throughout a project.

Different materials have substantially different densities:

Aluminum: ≈2720 kg/m³

Mild Steel: ≈7850 kg/m³

Stainless Steel: ≈8030 kg/m³

Copper: ≈8940 kg/m³

Remembering exact density values for various materials adds another layer of complexity to manual calculations.

The Square Bar Calculator is specifically designed to overcome these common calculation obstacles through:

The calculator instantly processes the complex weight formula, eliminating manual computation errors. By simply entering the side dimension, length, and selecting the material, users receive accurate weight calculations in multiple units.

Built-in unit conversion algorithms automatically handle any measurement system:

Metric (mm, cm, m)

Imperial (inches, feet)

Combination of both systems

This functionality ensures consistent accuracy regardless of the input units.

A robust material database contains precise density values for common metals:

Mild Steel (7850 kg/m³)

Stainless Steel (8030 kg/m³)

Aluminum (2720 kg/m³)

Carbon Steel (7800 kg/m³)

Copper (8940 kg/m³)

Brass (8700 kg/m³)

And 6 other common materials

This eliminates the need to memorize or look up density values during calculations.

Using a Square Bar Calculator involves three simple steps:

Material Selection: Choose the appropriate material from the dropdown menu

Dimension Entry:

Enter the side length of the square bar

Enter the bar length

Unit Selection:

Choose measurement units for side length (mm, cm, m, in, ft)

Choose measurement units for bar length

Once inputs are entered:

The calculator converts all dimensions to meters

It retrieves the material density from its database

It calculates the volume (side² × length)

It computes weight (volume × density)

It converts results to multiple units

The calculator provides weight in four useful formats:

Kilograms (kg): Standard metric unit

Pounds (lbs): Common imperial unit

Metric Tons: For large-scale projects

Grams (g): For precision applications

A professional-grade Square Bar Calculator accepts inputs and provides outputs in:

Millimeters (mm)

Centimeters (cm)

Meters (m)

Inches (in)

Feet (ft)

Kilograms (kg)

Pounds (lbs)

Grams (g)

Metric tons

This flexibility allows seamless integration into any workflow regardless of measurement preferences.

The calculator should support at least 12 common materials with precise density values:

Mild Steel

Stainless Steel

Aluminum

Carbon Steel

Copper

Brass

Titanium

Cast Iron

Tool Steel

Aluminum Alloy

Bronze

Lead

A dedicated reset button allows users to:

Clear all inputs instantly

Restore default settings

Prepare for new calculations

Prevent data carryover errors

Built-in validation checks prevent common input errors:

Detection of negative numbers

Identification of non-numeric entries

Prevention of zero values

Clear error messaging for correction

In manufacturing environments, accurate weight calculations enable:

Precise material ordering

Production planning

Cost estimation

Machine load calculations

Quality control verification

Structural engineers rely on bar weight data for:

Load-bearing calculations

Structural integrity analysis

Stress distribution modeling

Safety factor determinations

Foundation requirements

Transportation professionals use weight calculations for:

Container loading optimization

Shipping cost estimation

Vehicle load balancing

Compliance with weight restrictions

Freight documentation

Project managers depend on accurate calculations for:

Material cost projections

Budget allocation

Resource planning

Quotation preparation

Profit margin analysis

Implementing a Square Bar Calculator in your workflow delivers significant advantages:

Time Savings: Reduce calculation time from minutes to seconds

Error Reduction: Eliminate manual computation mistakes

Cost Efficiency: Prevent material waste from incorrect orders

Consistency: Ensure standardized calculations across teams

Versatility: Handle any material or measurement system

Accessibility: Available 24/7 without specialized software

When selecting a Square Bar Calculator, consider these essential features:

Comprehensive Material Library (12+ materials)

Multi-unit Support for inputs and outputs

Responsive Design that works on all devices

Intuitive Interface with clear instructions

Error Prevention with validation checks

Instant Results in multiple units

No Installation Required (web-based)

Completely Free with no hidden costs

The Square Bar Calculator represents a significant advancement in material calculation technology, providing professionals across industries with a reliable, efficient, and accurate solution for determining bar weights.

By eliminating complex manual calculations and error-prone unit conversions, this specialized tool enhances productivity, reduces material waste, and improves project outcomes.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.