May 28, 2024 By Muhammad Ali 8 minutes read

Chain drive, belt drive, gear drive, and rope drive are all mechanisms used to transmit power and motion between different components. One similarity among these drives is their ability to transfer energy from a driving source to a driven element. While each drive has its unique characteristics and applications, they all share the fundamental function of power transmission in various mechanical systems.

In this article we will discuss in detail about TYPES OF GEARS ADDVANTAGES, DISADVANTAGES AND USES.

So, let us first define what is a gear ?

Gears are wheels that have projections (called teeth) as shown in fig are provided on the periphery of wheel A which will fit into the corresponding recesses on the periphery of wheel B. A friction wheel with teeth cut on it is known as gear or toothed wheel.

There are 2 basic functions of gears due to which gears are fundamental components in a wide range of mechanical systems, from simple machines to complex industrial equipment.

By altering the size and number of teeth on the gears, engineers can control the speed and direction of the equipment. Gears are essential in ensuring the smooth and efficient operation of various machines and devices.

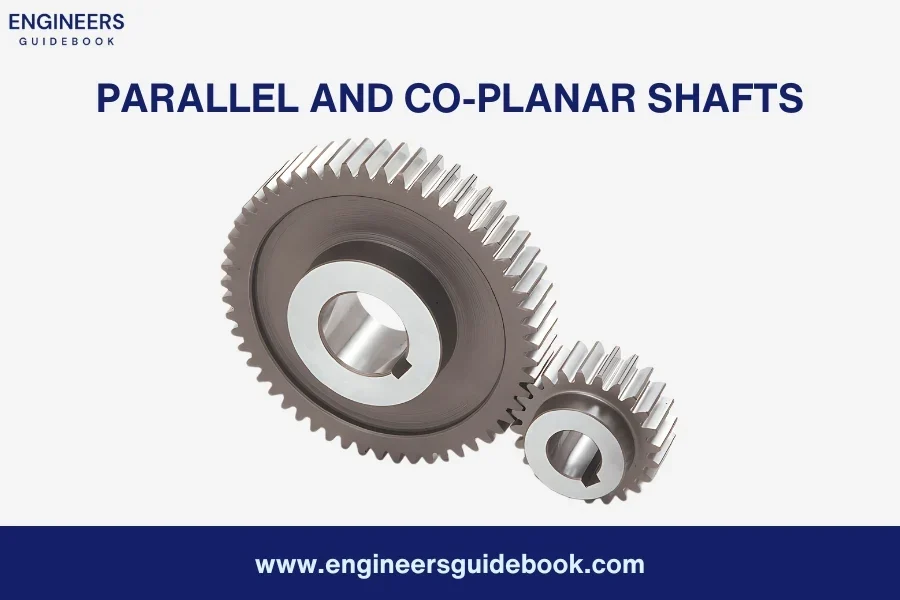

In below Figure, you can see a visual representation of two shafts that run parallel and lie within the same plane (co-Planar) . These shafts are connected by gears known as spur gears. Spur gears have teeth that are aligned parallel to the axis of the wheel, providing efficient power transmission. Additionally, when the teeth of spur gears are inclined to the axis, they are referred to as helical gears, which offer distinct advantages in certain applications.

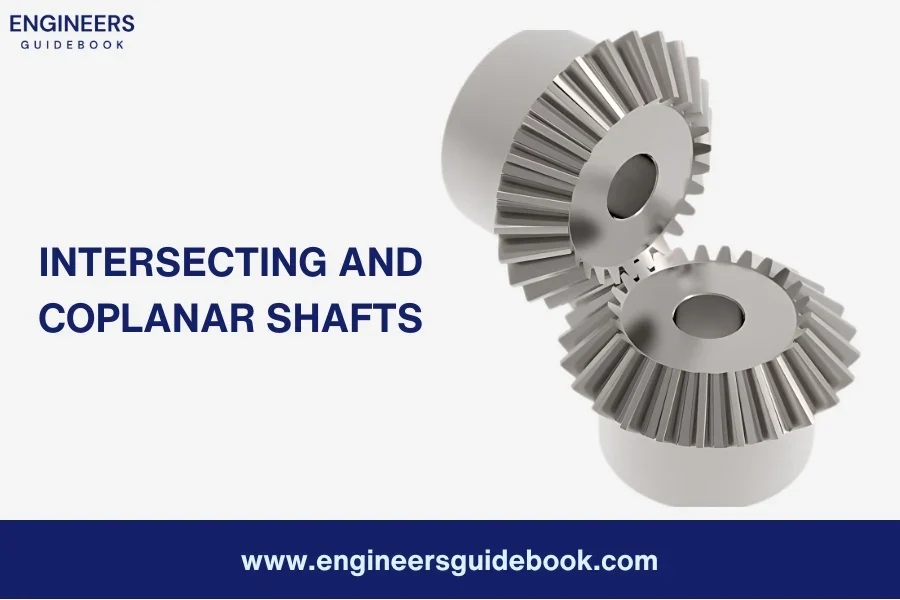

In the figure, you can observe two shafts that are not parallel but intersect each other within the same plane. Gears connecting these shafts are called bevel gears, and the arrangement is known as bevel gearing. Bevel gears, similar to spur gears, can have their teeth inclined to the face of the bevel, and in such cases, they are referred to as helical bevel gears.

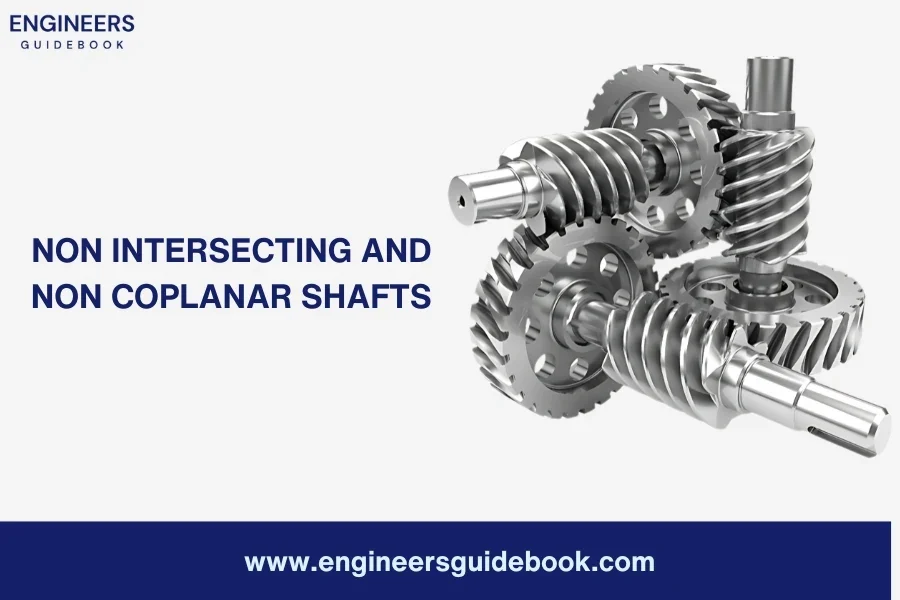

The figure illustrates two shafts that do not intersect and are neither parallel nor coplanar. Gears connecting these shafts are called skew bevel gears or spiral gears, and the arrangement is known as skew bevel gearing or spiral gearing. This type of gearing also involves a line contact, where the rotation of the gears generates two pitch surfaces called hyperboloids.

Low-velocity gears are those gears that operate at a velocity of less than 3 m/s. These gears are designed to handle slower speeds and are commonly used in applications where precise control and reduced wear are important factors.

Medium-velocity gears are gears that operate at a velocity ranging from 3 to 15 m/s. These gears are suitable for applications that require moderate speeds. They offer a balance between power transmission efficiency and wear resistance, making them versatile for various mechanical systems.

High-velocity gears are gears that operate at a velocity exceeding 15 m/s. These gears are specifically designed to handle high-speed applications. They are engineered to withstand the forces and stresses associated with rapid motion, ensuring reliable performance and durability.

In external gearing, the gears of two shafts engage with each other on the outer surface, as illustrated in Figure. The larger gear in this arrangement is known as the spur gear or gear wheel, while the smaller gear is called the pinion. External gearing is commonly used in various mechanical systems to transmit power and motion efficiently.

In internal gearing, the gears of two shafts mesh internally within each other, as depicted in Figure. The larger gear in this configuration is referred to as the annular gear, while the smaller gear is known as the pinion. Internal gearing is employed in applications where compactness and smooth operation are desired, allowing the gears to mesh on the inside of the gear teeth.

Sometimes, a combination of external and internal gears is used, resulting in a straight-line gear arrangement known as rack and pinion, as shown in Figure. In this setup, the gear on the shaft meshes externally with a linear gear called the rack, while internally engaging with the circular gear called the pinion. Rack and pinion systems are commonly used to convert rotary motion into linear motion, facilitating precise control and efficient power transmission.

Read More: Spur gears: Types, Advantages, Disadvantages & Applications

Spur gears are gear wheels with straight teeth that are mounted on parallel shafts. These gears are designed to mesh with each other, transferring rotational motion and torque between the shafts. The teeth of spur gears are evenly spaced and cut straight across the gear’s face.

Spur gears find applications in various industries and mechanical systems, including:

Bevel gears are gear wheels with teeth that are cut on conical surfaces. Unlike spur gears, which have teeth parallel to the axis, bevel gears have teeth that are angled and mesh with each other at the point of intersection. This design allows bevel gears to transmit motion between shafts that are not parallel but intersecting.

Bevel gears find wide-ranging applications in various industries and mechanical systems, including:

Helical gears are gear wheels with angled teeth that are cut in a helix shape around the gear’s circumference. Unlike spur gears with straight teeth, helical gears have a twisted tooth profile that allows for smoother engagement and quieter operation.

Helical gears are widely used in various industries and mechanical systems due to their advantages in power transmission. Some notable applications include:

Double helical gears are gear wheels that feature two sets of teeth with a V-shaped groove in the middle, forming a unique herringbone pattern. This design allows for improved load distribution, reduced axial thrust, and enhanced performance compared to traditional helical gears.

Double helical gears find applications in various industries and mechanical systems where precise and reliable power transmission is required. Some notable applications include:

Screw gears, or worm gears, consist of a cylindrical screw-like gear called the worm and a toothed gear called the worm wheel. The worm has a spiral thread that meshes with the teeth of the worm wheel, allowing for efficient power transfer with a high gear ratio.

Screw gears find extensive applications in various industries and mechanical systems. Some notable applications include:

Mitre gears are a type of gear mechanism with conically shaped teeth designed to mesh at a 90-degree angle. They are used to transfer rotational motion and torque between two intersecting shafts while maintaining a constant speed ratio. Mitre gears are commonly used in applications where a change in shaft direction is required.

Mitre gears find wide applications in various mechanical systems across different industries. Some common applications include:

A worm gear consists of a cylindrical gear called a worm and a toothed wheel known as a worm wheel or worm gear. The worm has a helical thread that meshes with the teeth of the worm wheel. This unique configuration allows the worm gear to convert rotational motion between non-intersecting and perpendicular shafts.

Worm gears find applications in various industries and mechanical systems where precise motion control and high gear reduction are essential. Some common applications include:

Internal gears are gear wheels with teeth positioned on the inner surface of the gear rim. Unlike external gears where the teeth are on the outer surface, internal gears have teeth facing inward. They are designed to mesh with external gears, allowing for smooth and efficient power transmission between parallel or concentric shafts.

Internal gears find a wide range of applications in various industries and mechanical systems. Some notable applications include:

External gears are gear wheels that mesh with each other externally. They consist of two gears, namely the larger gear known as the spur wheel or gear, and the smaller gear called the pinion. The teeth of the gears are located on the outer circumference, allowing them to engage and transmit power.

External gears are utilized in a wide range of applications across various industries. Some notable applications include:

Herringbone gears are gear wheels that feature a unique double helical design, resembling the letter “V” or the shape of a herringbone fish’s skeleton. The gears have teeth that are cut in a zigzag pattern, with each tooth having a convex and concave side. This design allows for improved load-carrying capacity, reduced noise and vibration, and enhanced efficiency in power transmission.

Herringbone gears find a wide range of applications in various industries and mechanical systems that require high-performance power transmission and motion control. Some notable applications include:

Hypoid gears are gear wheels that have offset axes and non-intersecting shafts. Unlike bevel gears, which have intersecting axes, hypoid gears have a slight offset between the axes of the driving and driven gears. This unique design allows for efficient power transmission between non-parallel shafts, while also providing compactness and versatility.

Hypoid gears find wide applications in various industries and mechanical systems that require efficient and reliable power transmission. Some notable applications include:

Crown gears, also known as bevel gears, are a type of gear where the teeth are cut on a conical surface. These gears are designed to transmit motion between shafts that are not parallel. Typically, they connect shafts that are at right angles (90 degrees) to each other.

Marine Propulsion Systems: Crown gears are used in marine propulsion systems to transfer power from the engine to the propeller shafts, allowing for efficient direction changes.

Winches: In winching systems, crown gears help in transferring motion between non-parallel shafts, facilitating the lifting and pulling of heavy loads.

Automotive Differentials: Crown gears are essential components in automotive differentials, enabling wheels to rotate at different speeds while turning.

Aerospace Control Systems: These gears are used in aerospace control systems to change the direction of motion and manage the precise movement of control surfaces.

Industrial Machinery: Crown gears are widely used in various types of industrial machinery, such as conveyors and material handling equipment, where direction changes are necessary.

Non-circular gears are a type of gear whose shape is not round. Unlike traditional circular gears, these gears have varying radii and are designed to achieve specific motion profiles. They work by meshing together and transmitting torque and rotational motion in a way that results in non-uniform speed and torque outputs. This unique capability allows them to meet specific mechanical requirements that circular gears cannot.

Harmonic drive gears, also known as strain wave gears, are a type of mechanical gear system that delivers high precision, excellent torque capacity, and zero backlash. These gears consist of three main components:

Gears have been essential components in machinery for centuries. From clocks to cars, gears help transfer motion and power efficiently. As technology advances, gear technology also evolves. Here’s a look at the future trends and advancements in gear technology that are set to shape industries.

3D printing allows for the creation of highly precise and customized gears. This technology enables manufacturers to produce complex shapes that were previously impossible or too costly with traditional methods.

With 3D printing, prototypes can be produced quickly and tested for functionality. This accelerates the development process and allows for faster iteration and improvement of gear designs.

Nanotechnology is being used to develop lubricants that significantly reduce friction and wear. These advanced lubricants can enhance the efficiency and lifespan of gears by providing better protection against heat and pressure.

Materials that incorporate self-lubricating properties are being developed. These gears can reduce the need for regular maintenance and improve the reliability of machinery.

Advanced software tools now allow for detailed simulation and analysis of gear performance. Engineers can predict how gears will behave under different conditions and optimize their designs accordingly.

Artificial intelligence and machine learning are being integrated into gear design software. These technologies can analyze vast amounts of data to identify patterns and suggest improvements, leading to more efficient and innovative gear designs.

There is a growing focus on using eco-friendly materials in gear manufacturing. These materials reduce the environmental impact and align with the global push towards sustainability.

Engineers are developing gears that operate more efficiently, reducing energy consumption. This is particularly important in industries like automotive and industrial machinery, where energy efficiency is crucial for cost savings and environmental protection.

Gears are mechanical components used to transmit motion and torque between machine parts. There are several types of gears, each designed for specific applications and mechanical advantages. The eight common types of gears are:

Gears are wheels that have projections (called teeth) as shown in fig are provided on the periphery of wheel A which will fit into the corresponding recesses on the periphery of wheel B. A friction wheel with teeth cut on it is known as gear or toothed wheel.

The most common type of gear is the spur gear. Spur gears are widely used due to their simple design, ease of manufacture, and efficiency in transmitting motion and torque between parallel shafts. They are commonly found in various applications, including clocks, washing machines, and industrial machinery.

There are 2 basic functions of gears:

By altering the size and number of teeth on the gears, engineers can control the speed and direction of the equipment.

There are 2 basic functions of gears:

By altering the size and number of teeth on the gears, engineers can control the speed and direction of the equipment.

Spur gears are gear wheels with straight teeth that are mounted on parallel shafts. These gears are designed to mesh with each other, transferring rotational motion and torque between the shafts. The teeth of spur gears are evenly spaced and cut straight across the gear’s face.

Low-velocity gears are those gears that operate at a velocity of less than 3 m/s. These gears are designed to handle slower speeds and are commonly used in applications where precise control and reduced wear are important factors.

Medium-velocity gears are gears that operate at a velocity ranging from 3 to 15 m/s. These gears are suitable for applications that require moderate speeds.

High-velocity gears are gears that operate at a velocity exceeding 15 m/s. These gears are specifically designed to handle high-speed applications.

Sometimes, a combination of external and internal gears is used, resulting in a straight-line gear arrangement known as rack and pinion, as shown in Figure. In this setup, the gear on the shaft meshes externally with a linear gear called the rack, while internally engaging with the circular gear called the pinion. Rack and pinion systems are commonly used to convert rotary motion into linear motion, facilitating precise control and efficient power transmission.

Helical gears are gear wheels with angled teeth that are cut in a helix shape around the gear’s circumference. Unlike spur gears with straight teeth, helical gears have a twisted tooth profile that allows for smoother engagement and quieter operation.

Gear are mostly used for :

Gears are mostly used in :

Herringbone gears are gear wheels that feature a unique double helical design, resembling the letter “V” or the shape of a herringbone fish’s skeleton. The gears have teeth that are cut in a zigzag pattern, with each tooth having a convex and concave side. This design allows for improved load-carrying capacity, reduced noise and vibration, and enhanced efficiency in power transmission.

Hypoid gears are gear wheels that have offset axes and non-intersecting shafts. Unlike bevel gears, which have intersecting axes, hypoid gears have a slight offset between the axes of the driving and driven gears. This unique design allows for efficient power transmission between non-parallel shafts, while also providing compactness and versatility.

Mitre gears are a type of gear mechanism with conically shaped teeth designed to mesh at a 90-degree angle. They are used to transfer rotational motion and torque between two intersecting shafts while maintaining a constant speed ratio. Mitre gears are commonly used in applications where a change in shaft direction is required.

Muhammad Ali holds a PhD in Mechanical Engineering from MIT and is a writing specialist. His groundbreaking research on sustainable energy systems and renewable energy integration has earned him numerous accolades. His passion for innovation and education shines through in his insightful and inspiring writings.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.