May 28, 2024 By Hassan 6 minutes read

5S is a method used to reduce waste and increase productivity of system by keeping the workplace clean and organized.

In this method we uses visual signs to help everyone follow the same steps and get better results. When a company starts using 5S, they clean out and arrange their workspace without changing its layout.

It’s usually the first Lean method that businesses use to improve their operations.

In this guide we will discuss in detail about What is 5s methodology and how you can implement 5s methodology in any organization.

5S is a methodology for organizing and managing workspaces and workflows. It aims to improve efficiency through the elimination of waste, improvement of flow, and the reduction of unnecessary processes.

5S emphasis on a clean, organized, and efficient work environment. 5s comprises of five fundamental principles:

In the 1980s, Toyota had a large manufacturing plant in Japan. Due to this reason, Toyota faced challenges in manufacturing their process, such as waste, inefficiency, and poor quality.

They prepared a comprehensive approach to handle these issues: the 5S methodology for process improvement, and hence, it would create a culture of continuous improvement for all.

Over time, 5S became a worldwide hot topic in different industries.

One of the most significant benefits of applying 5S is the improvement of efficiency.

The 5S organization saves time, which would otherwise be lost in looking for a tool, equipment, or information.

Everything is where it should be, so the workers can find quickly and easily what they need to work. This results in smooth workflows and more productivity.

5S boosts productivity in a big way. It allows one to focus more on the value-added tasks by removing clutter, things that are not needed, and processes that are redundant and time-wasting.

Setting in order ensures tools and materials are arranged in an optimized way, hence reducing time in unnecessary movements.

This results in better workflow, minimum downtime, and increases in productivity levels.

Safety is a priority in the workplace. The implementation of 5S encourages a safety-conscious environment by eliminating potential hazards and maintaining cleanliness and order in workstations.

The Shine principle maintains cleaning and maintenance, reducing the risk of accidents and injuries.

Besides, the systematic arrangement of tools and equipment in order prevents potential mishaps.

There are mainly 5 pillars of 5s.

In a 5S methodology , the first step is Sort, and it is symbolized by the Japanese word “Seiri” (整理). It involves the cleaning up and organization of the working place through the separation of necessary and unnecessary items. Sorting ensures the most efficient work environment for the organizations.

In 5s it is significant first to analyze the condition of the workspace. Investigate the areas that are cluttered and disorganized, as well as those with excess equipment or products.

The outcome of this assessment indicates the level of sorting that will be done and serves as a baseline for comparisons of improvements.

During analyses of the workspace ask these questions like:

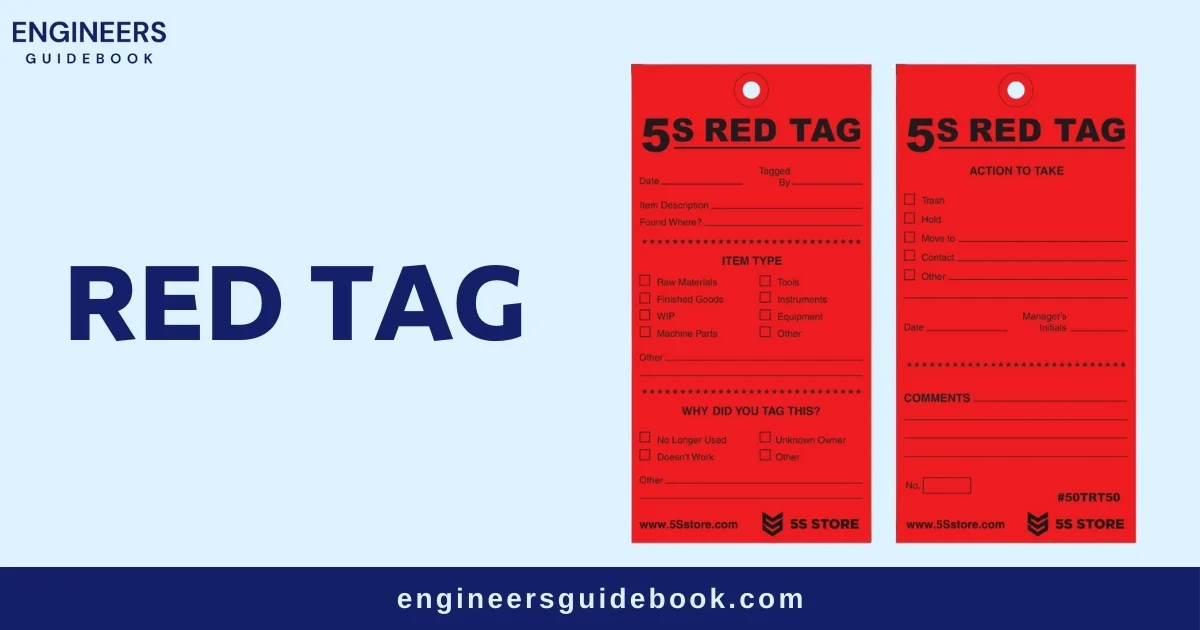

Place red tags on items considered unnecessary so they can be easily identified visually.

Attach red tags to items identified as unnecessary during sorting to differentiate them from necessary items.

Take appropriate action based on the sorting results. Dispose of items that are damaged, expired, or not needed anymore. Move items that are used but less frequently. Rearrange the workspace so that all necessary items can be easily accessed.

Ensure the workspace is visually clean. There should be no clutter. The workspace should be well-organized.

Sorting eliminates clutter, and employee minds can delve into more important things rather than being cluttered with those that will not be in use. This smoothed work and increases overall efficiency.

Employees can find and access the tools and material they need relatively quickly ᅳ minimizing any downtimes and increasing productivity.

Unnecessary items can be eliminated, thus saving organizations the costs of storage, maintenance, and the procurement of redundant or unused peripherals.

Properly arranged workspaces promote safety by removing possible risks for accidents or injury. It helps to do away with accidents attributed to clutter and ensure clear paths.

The second step in the 5S methodology is Set in Order, represented by the Japanese term “Seiton” (整頓). This step focuses on organizing the workspace in a logical and efficient manner.

By arranging items systematically, it becomes easier to access and use them, leading to improved productivity and a safer work environment.

Improved Safety

Set in Order enhances productivity by ensuring items are easily located and retrieved, thus optimizing workspace, and minimizing clutter.

It also improves safety by reducing accident risks through clear labeling and proper item placement, preventing misplaced items and cluttered pathways. Following are some ways to establish set in order.

Identify and designate specific areas for different tasks or processes within the workspace.

This provides clarity and helps in organizing items according to their respective work areas.

Categorize and group similar items together. This facilitates easy identification, efficient storage, and streamlined access.

Select appropriate storage methods such as shelves, cabinets, or tool racks based on the type, size, and quantity of items.

Ensure that storage solutions are suitable for the specific needs of the items being stored.

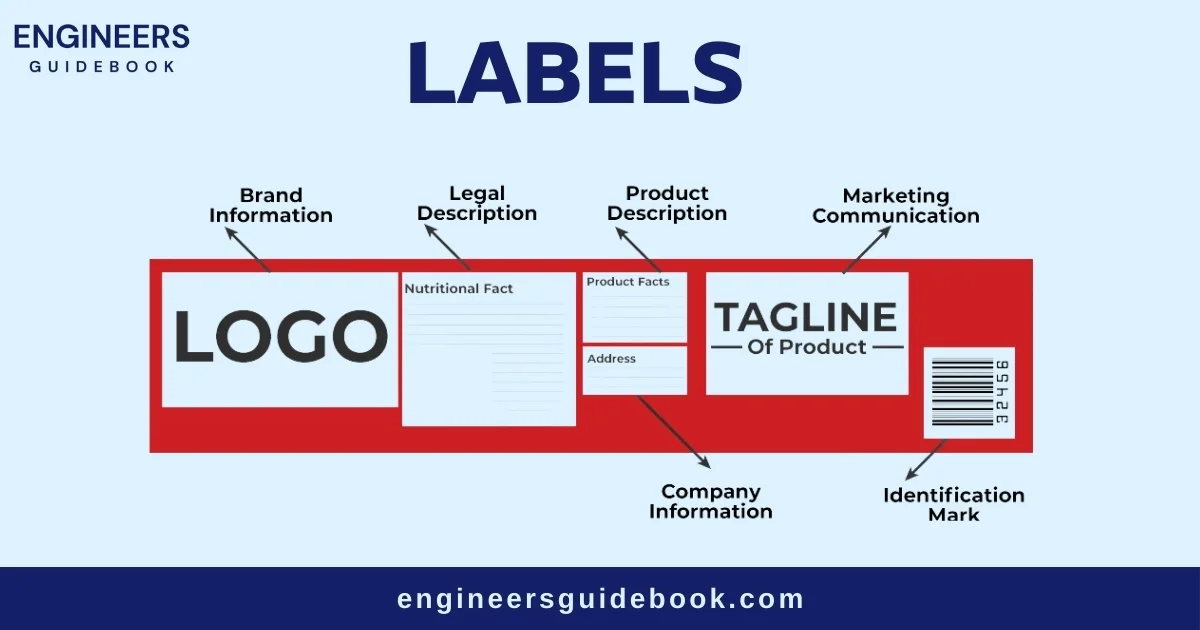

Develop a consistent labelling system to identify storage locations and item categories. Clearly label shelves, containers, and storage areas to eliminate confusion and aid in locating items quickly.

Employees can quickly locate and retrieve items, reducing time wasted on searching and improving overall workflow efficiency.

By having a well-organized workspace, employees can focus on their tasks without distractions and complete them more efficiently, leading to increased productivity.

Set in Order maximizes the utilization of available space, allowing for better workflow and creating a more spacious and orderly work environment.

Setting things in order eliminates clutter by providing a designated place for each item. This reduces visual distractions and creates a cleaner and more organized workspace.

With items properly organized and labelled, inventory management becomes more efficient. It becomes easier to track and maintain stock levels, preventing overstocking or shortages.

The third step in the 5S methodology, is known as Shine “Seiso” in Japanese. It emphasizes the importance of cleanliness and inspection in maintaining a well-organized and efficient workspace. By regularly cleaning and inspecting the work area and equipment, organizations can ensure a safe, visually appealing, and productive environment.

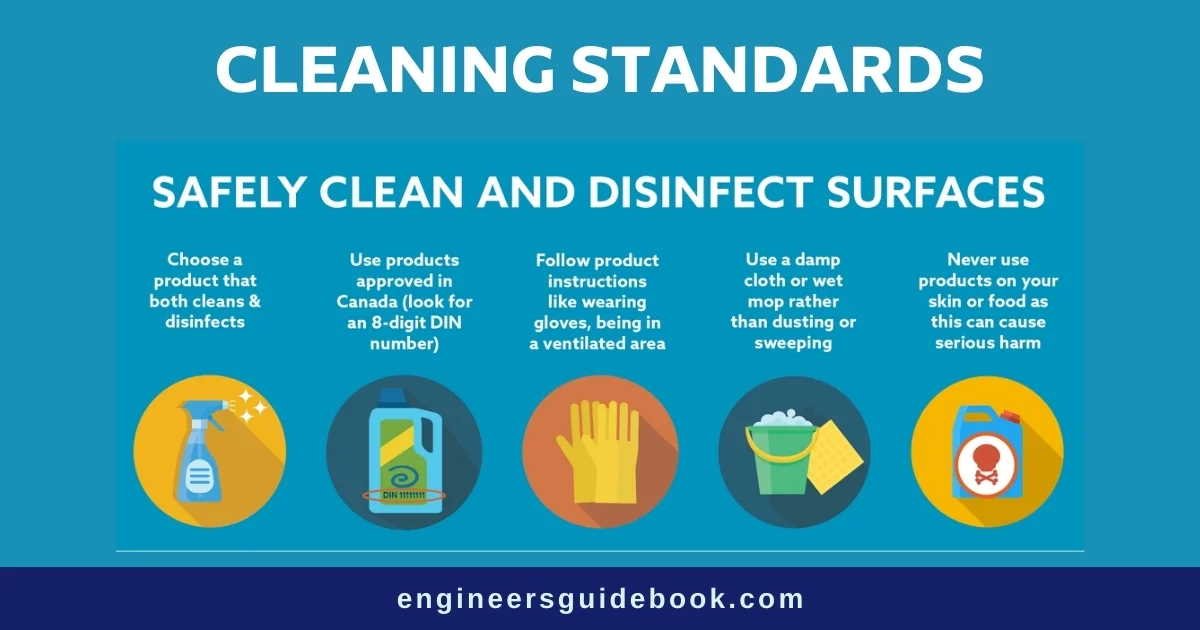

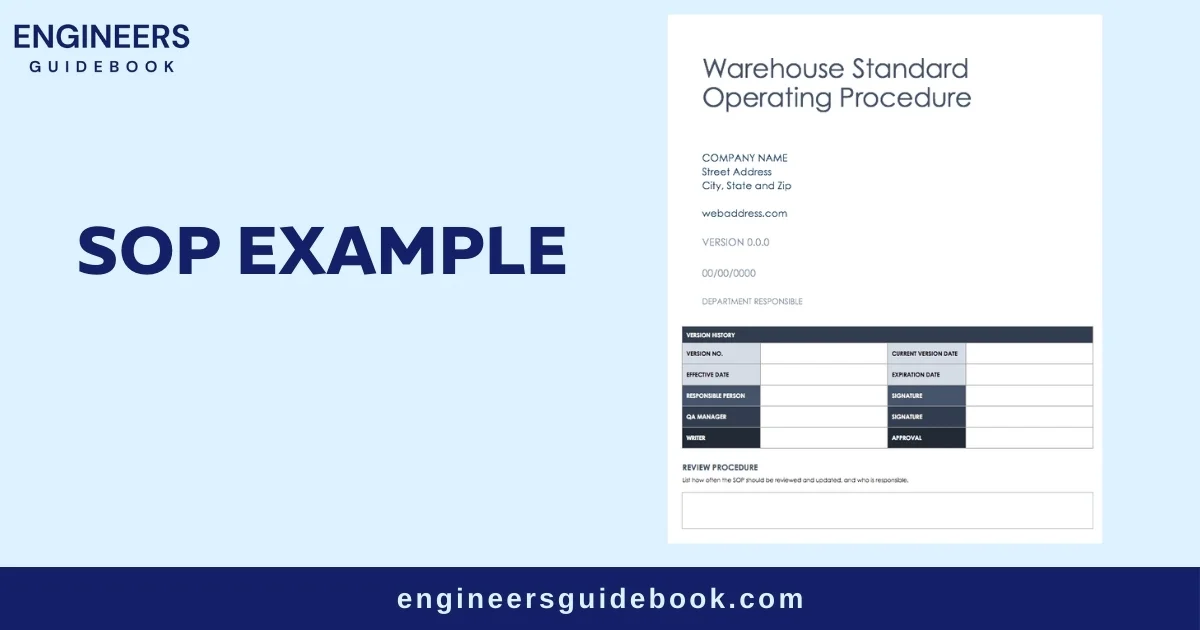

Define clear cleaning standards for different areas, equipment, and tools. Create guidelines specifying the frequency, methods, and materials to be used for cleaning. Ensure that these standards are communicated to all employees. like this example given below.

Allocate cleaning responsibilities to individuals or teams. Clearly define who is responsible for cleaning specific areas, equipment, or workstations. Regularly review and update the assignments as needed.

Ensure that employees have access to appropriate cleaning tools, equipment, and supplies. This may include brooms, mops, vacuum cleaners, cleaning agents, wipes, and personal protective equipment (PPE) as required.

Develop cleaning schedules to ensure regular and systematic cleaning. Determine the frequency and timing of cleaning activities based on the specific needs of the workspace and equipment. Incorporate these schedules into daily, weekly, and monthly routines.

A clean and organized workspace facilitates smooth workflow and efficient operations. Employees can locate tools and equipment quickly in an organized workplace which hence reducing downtime and enhancing productivity.

Regular cleaning and maintenance prevent dust and debris build-up, ensuring equipment operates at optimal performance levels.

Cleaning and inspection activities help identify defects, malfunctions, or abnormalities early on. This enables timely corrective actions, minimizing the production of faulty or defective products.

A well-maintained workspace promotes employee safety and reduces the likelihood of injuries or incidents.

A clean and orderly work environment contributes to a positive atmosphere and fosters employee morale. It reflects a commitment to professionalism.

The fourth step in the 5S methodology is Standardize, known as “Seiketsu” in Japanese. Standardization aims to establish consistent practices and procedures throughout the organization, ensuring that the improvements made in the previous steps are sustained in the long term.

Consistency

Sustaining Improvements

Reduced Variability

Improved Communication

Enhanced Training and on boarding

Standardization means making sure everyone follows the same rules and methods at work. This helps keep things running smoothly, reduces mistakes, and makes training easier.

It also keeps improvements in place, reduces differences in how work is done, and helps everyone communicate better with signs and labels. Plus, it makes training new employees faster and easier.

Identify and document the standard operating procedures for each task or process. Clearly define the steps, methods, and requirements to be followed. Make these documents easily accessible to all employees.

Develop visual aids, such as signage, labels, and floor markings, to communicate important information and instructions. Use standardized colors, symbols, and formats to ensure consistency and easy comprehension.

Provide training to employees on the standardized processes and procedures. Ensure that they understand the importance of following the established standards and the impact it has on overall efficiency and quality.

Conduct regular audits and inspections to verify compliance with the standardized processes. Identify any deviations or opportunities for improvement and take corrective actions as necessary.

Consistency and Efficiency

Quality Control

Streamlined Operation

Training and Cross-Training

Standardization promotes consistency in work practices, resulting in increased efficiency and productivity. It reduces wasted time and effort caused by variations and inconsistencies in processes.

Standardized processes help maintain consistent quality standards. By following predefined procedures, organizations can minimize errors, defects, and rework, leading to improved product or service quality.

Standardization simplifies and streamlines operations by providing clear guidelines and expectations. It reduces confusion, eliminates redundancies, and improves coordination between different teams or departments.

Standardized procedures facilitate training and cross-training efforts. New employees can quickly learn and adapt to established processes.

The fifth and final step in the 5S methodology is Sustain, known as “Shitsuke” in Japanese. Sustain focuses on maintaining and continuously improving the achieved results of the previous steps—Sort, Set in Order, Shine, and Standardize. It aims to embed the 5S principles into the organization’s culture and ensure long-term success.

The goal of Sustain is to keep things working well for a long time by following 5S rules. It helps everyone always look for ways to make things better.

Workers get involved, take care of their workspace, and feel proud of their job. Sustain also helps companies change and improve to stay ahead of others.

Overall, it keeps work areas clean, organized, and efficient, making sure everything stays productive and high-quality.

In sustain we have to follow these guideline for proper effectiveness of 5s technique.

Leadership must demonstrate a strong commitment to the 5S principles and set an example for others to follow. They should actively participate in the implementation of Sustain and provide the necessary resources and support.

Provide ongoing training and education to employees on the importance of sustaining the improvements and the benefits it brings to the organization.

Conduct regular audits and assessments to evaluate the adherence to 5S principles and identify areas for improvement.

Use the findings to develop action plans and address any deviations or opportunities for enhancement.

Recognize and reward employees who actively contribute to sustaining the improvements.

This could include acknowledging their efforts, celebrating successes, and providing incentives to encourage ongoing commitment to the 5S principles.

Sustaining the improvements leads to consistent performance and operational excellence. It establishes a foundation for predictable and reliable outcomes, allowing organizations to meet or exceed customer expectations consistently.

Sustaining the improvements results in cost savings through increased efficiency, reduced waste, and minimized downtime. By optimizing processes and eliminating unnecessary steps, organizations can achieve higher productivity levels while using fewer resources.

Sustain contributes to improved product or service quality by maintaining standardized processes, preventing deviations, and reducing the risk of errors or defects. This leads to higher customer satisfaction and loyalty.

Sustaining the improvements fosters a positive workplace culture characterized by discipline, organization.

The 5S methodology can be applied in various settings to improve organization, efficiency, and productivity. Let’s explore how 5S is implemented in different environments:

Organizing tools and equipment, establishing visual controls, and implementing standardized procedures streamline workflows and reduce errors.

By organizing medical supplies, maintaining clean and sterile environments, and standardizing procedures, healthcare professionals can provide better patient care.

Organizing files, establishing visual management systems, and implementing standardized filing and storage methods promote a clean and productive office environment.

Organizing classrooms, libraries, and study areas, implementing visual cues for resource locations, and establishing consistent routines enhance learning experiences.

Organizing merchandise, establishing visual merchandising standards, and implementing standardized service procedures create a positive impression and improve the overall customer experience.

Toyota, a renowned automotive manufacturer, has effectively utilized 5S principles to optimize their production processes and achieve high-quality standards.

The implementation of 5S at Toyota has streamlined workflows, reduced waste, and improved efficiency in their manufacturing operations.

Virginia Mason Medical Center, a hospital, has implemented 5S to improve patient safety and enhance efficiency in healthcare delivery.

By organizing and standardizing their processes, they have been able to provide better care to patients and improve overall hospital operations.

In the office environment, Google has adopted 5S principles to create organized and collaborative workspaces.

This approach has promoted employee productivity and creativity by ensuring that workspaces are clean, organized, and conducive to teamwork.

Educational institutions, such as the Tokyo Metropolitan Government Board of Education, have implemented 5S to enhance learning environments and improve student outcomes.

The application of 5S in schools has led to more organized classrooms, better resource management, and an improved focus on learning.

5S is a methodology for organizing and managing workspaces and workflows. It aims to improve efficiency through the elimination of waste, improvement of flow, and the reduction of unnecessary processes.

5S is a method used to reduce waste and increase productivity of system by keeping the workplace clean and organized. In this method we uses visual signs to help everyone follow the same steps and get better results.

5S is called 5S because it is based on five Japanese words that all start with the letter “S.” These words represent the five principles of the methodology:

There are mainly 5 pillars of 5s.

In a 5S methodology , the first step is Sort, and it is symbolized by the Japanese word “Seiri” (整理). It involves the cleaning up and organization of the working place through the separation of necessary and unnecessary items. Sorting ensures the most efficient work environment for the organizations.

The second step in the 5S methodology is Set in Order, represented by the Japanese term “Seiton” (整頓). This step focuses on organizing the workspace in a logical and efficient manner.

The third step in the 5S methodology, is known as Shine “Seiso” in Japanese. It emphasizes the importance of cleanliness and inspection in maintaining a well-organized and efficient workspace. By regularly cleaning and inspecting the work area and equipment, organizations can ensure a safe, visually appealing, and productive environment.

The fourth step in the 5S methodology is Standardize, known as “Seiketsu” in Japanese. Standardization aims to establish consistent practices and procedures throughout the organization, ensuring that the improvements made in the previous steps are sustained in the long term.

The fifth and final step in the 5S methodology is Sustain, known as “Shitsuke” in Japanese. Sustain focuses on maintaining and continuously improving the achieved results of the previous steps—Sort, Set in Order, Shine, and Standardize. It aims to embed the 5S principles into the organization’s culture and ensure long-term success.

5S is a workplace organization method that improves efficiency and productivity by maintaining an orderly workplace. It consists of five steps:

These steps help create a clean, organized, and efficient work environment.

5S is a method to organize the workplace:

Hasan, an Industrial Engineer with a PhD from Georgia Tech, specializes in operational efficiency and lean manufacturing. His research on optimizing production workflows has significantly impacted the manufacturing industry.

Explore the Engineer’s Guidebook! Find the latest engineering tips, industry insights, and creative projects. Get inspired and fuel your passion for engineering.

© 2023-2024 Engineer’s Guidebook. All rights reserved. Explore, Innovate, Engineer.