1. Introduction

A fixed pulley is one of the simplest mechanical devices used to facilitate the movement of loads. Unlike other pulley systems, a fixed pulley does not change the amount of force needed to lift an object but instead alters the direction of the applied force. It serves as a fundamental building block in mechanical engineering, forming the basis for more complex lifting mechanisms. Fixed pulleys are found in various applications, from industrial machinery to household tools, demonstrating their indispensable role in mechanical advantage.

2. The Fundamental Concept of Fixed Pulleys

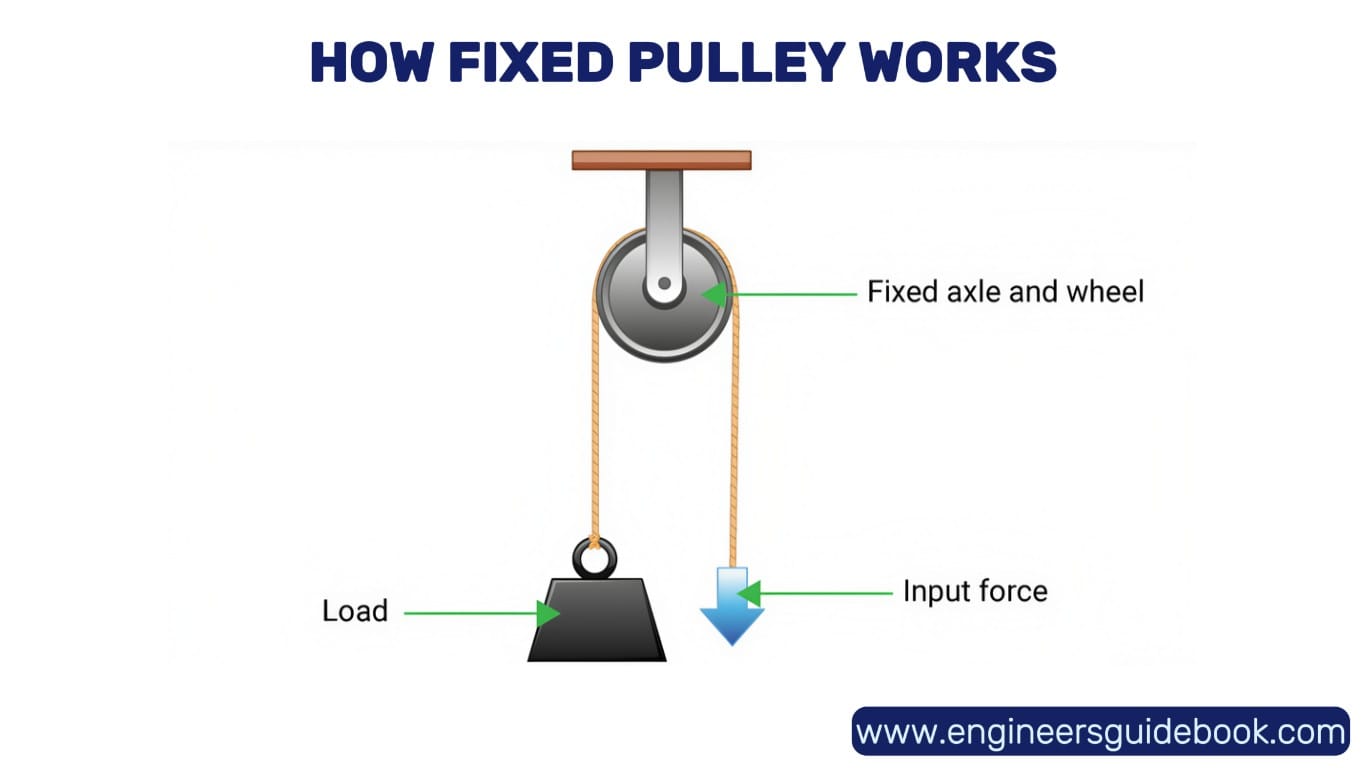

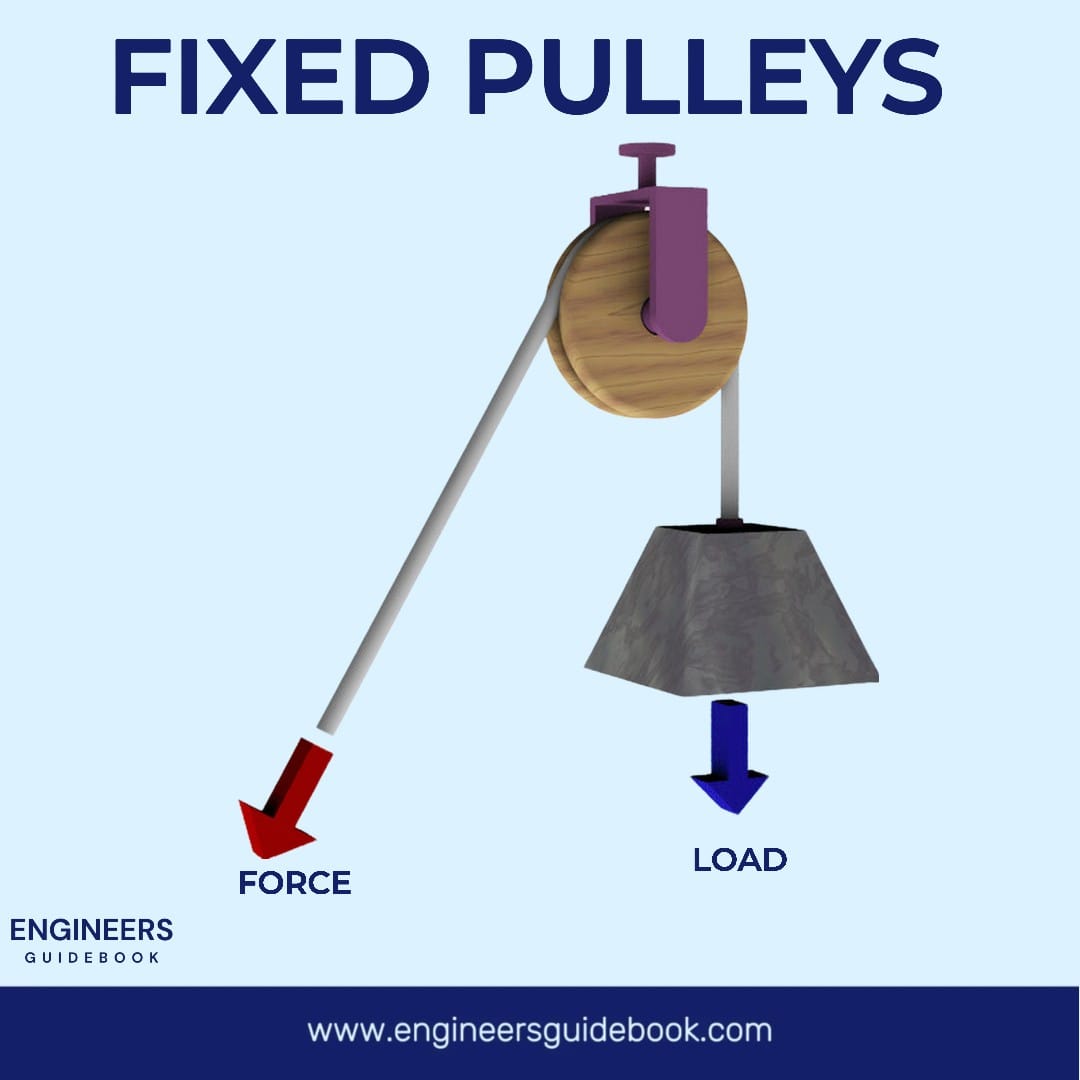

A fixed pulley consists of a wheel mounted on an axle that remains stationary while a rope or cable moves over it. The primary function of a fixed pulley is to redirect force, allowing users to pull down instead of lifting directly upward. While it does not reduce the effort required, it offers convenience and control, making lifting operations more manageable. Fixed pulleys exemplify the principles of classical mechanics, emphasizing efficiency through strategic force redirection.

3. How Fixed Pulleys Differ from Other Pulley Types

Pulleys are classified based on their mobility and mechanical advantage. Fixed pulleys, as the name suggests, remain stationary, while movable pulleys adjust their position relative to the applied force. Unlike movable and compound pulley systems, which decrease the amount of force required, fixed pulleys serve primarily to enhance directional control. Understanding these distinctions is crucial when designing mechanical systems that require precise force application and load management.

4 Key Components of a Fixed Pulley System

4.1 The Wheel

The wheel in a fixed pulley system is typically composed of durable materials such as steel, aluminum, or high-strength polymers. The choice of material depends on the intended load capacity and environmental conditions. The wheel’s diameter affects the ease of movement, with larger wheels providing smoother operation due to reduced frictional resistance.

4.2 The Groove

The groove in a fixed pulley serves as a guiding channel for the rope or cable, ensuring alignment and minimizing slippage. The depth and shape of the groove are carefully designed to accommodate specific rope diameters, reducing wear and tear. Properly engineered grooves enhance operational efficiency by maintaining a consistent path for force transmission.

4.3 The Axle

The axle is the central support structure that holds the pulley wheel in place. It must be robust and well-secured to withstand repeated force application without loosening. High-quality bearings are often incorporated to reduce friction, ensuring smooth rotation and prolonged system longevity.

5. The Science Behind Fixed Pulleys

5.1 Mechanical Advantage

Unlike movable pulleys, fixed pulleys do not decrease the amount of effort required to lift a load. Instead, they change the direction of applied force, allowing users to leverage their body weight effectively. This principle simplifies lifting tasks, especially when combined with additional mechanical systems.

5.2 How Force is Transmitted Through the System

When a user pulls down on the rope of a fixed pulley, the force is transmitted through the rope and directed upward. The applied force remains constant throughout the system, but the redirection enables more ergonomic lifting techniques. This transmission mechanism is foundational in mechanical engineering and physics.

5.3 The Role of Tension and Load Distribution

Tension plays a critical role in maintaining equilibrium within a fixed pulley system. Properly balanced tension ensures efficient load handling and prevents undue stress on the rope or cable. Load distribution is equally significant, as uneven force application can lead to premature wear or mechanical failure.

6. Real-world applications of Fixed Pulleys

6.1 Fixed Pulleys in Construction and Heavy Lifting

Fixed pulleys are integral to construction sites, where they assist in lifting heavy materials to elevated locations. Cranes and hoists often incorporate fixed pulleys to streamline material handling processes.

6.2 Everyday Uses

In everyday life, fixed pulleys are commonly found in flagpoles, allowing easy hoisting and lowering of flags. Similarly, window blinds utilize fixed pulleys to control movement with minimal effort.

6.3 Industrial and Engineering Applications

Factories and warehouses employ fixed pulleys in conveyor systems and assembly lines, optimizing efficiency in material transport. These applications demonstrate the pulley’s versatility in various mechanical contexts.

7. Fixed Pulleys in Physics and Engineering Principles

7.1 Newton’s Laws and Fixed Pulleys in Motion

Fixed pulleys operate under Newton’s laws of motion, particularly the third law, which states that every action has an equal and opposite reaction. This principle governs the interaction between force, mass, and acceleration within the system.

7.2 Energy Conservation in Pulley Systems

Energy conservation is paramount in pulley mechanisms, ensuring minimal energy loss through friction or inefficient force application. Proper lubrication and material selection contribute to improved energy efficiency.

7.3 The Relationship Between Fixed and Movable Pulleys

When combined with movable pulleys, fixed pulleys enhance overall mechanical advantage, creating compound pulley systems that reduce lifting effort significantly. This synergy is widely utilized in complex machinery.

8. Advantages of Using Fixed Pulleys

8.1 Simplicity and Ease of Use

Fixed pulleys offer straightforward operation, making them accessible for various applications without extensive training.

8.2 Durability and Low Maintenance

Constructed from high-quality materials, fixed pulleys require minimal upkeep, ensuring longevity and reliability in demanding environments.

8.3 Reliable Load Control in Various Applications

Fixed pulleys provide precise control over load movement, reducing the likelihood of accidental drops or erratic force distribution.

9. Limitations of Fixed Pulleys

9.1 No Direct Reduction in Required Force

Unlike movable pulleys, fixed pulleys do not lessen the effort needed to lift heavy loads, limiting their effectiveness in high-load scenarios.

9.2 Limited Mechanical Advantage Compared to Other Systems

While they facilitate directional force application, fixed pulleys lack the mechanical efficiency of compound pulley systems.

9.3 Constraints in Certain Industrial Uses

Fixed pulleys may not be suitable for high-torque or automated lifting systems where mechanical advantage is crucial.

10. How to Set Up a Fixed Pulley System

10.1 Choosing the Right Pulley for the Task

Selecting the appropriate pulley involves evaluating load capacity, material durability, and environmental factors.

10.2 Proper Installation for Maximum Efficiency

Ensuring secure mounting and proper alignment optimizes performance and reduces operational friction.

10.3 Safety Considerations in Fixed Pulley Applications

Adhering to safety protocols, such as load capacity limits and regular inspections, minimizes risks associated with pulley operation.

11. Conclusion

Fixed pulleys play an essential role in mechanical systems, offering directional control and ease of use in various applications. While they do not reduce the effort required to lift loads, their integration into compound systems enhances efficiency. Understanding their principles, advantages, and limitations allows for informed implementation in both everyday and industrial settings.

12. FAQs

1. What is a fixed pulley and how does it work?

A fixed pulley is a simple mechanical device consisting of a wheel mounted on a stationary axle with a rope or cable running through its groove. It changes the direction of the applied force, allowing users to pull downward instead of lifting directly upward. However, it does not reduce the effort required to lift a load.

2. How does a fixed pulley differ from a movable pulley?

A fixed pulley remains stationary while redirecting force, whereas a movable pulley moves along with the load, reducing the amount of force required. Movable pulleys provide mechanical advantage, making it easier to lift heavy objects.

3. Can a fixed pulley provide a mechanical advantage?

No, a fixed pulley does not provide a mechanical advantage because it does not reduce the force needed to lift a load. It only changes the direction of the applied force, making lifting more convenient.

4. What are the common applications of fixed pulleys?

Fixed pulleys are used in flagpoles, window blinds, cranes, elevators, well systems, and various industrial and construction applications where force direction needs to be controlled.

5. What materials are used to make fixed pulleys?

Fixed pulleys are typically made of durable materials such as steel, aluminum, cast iron, or high-strength plastic, depending on the intended application and load capacity.

6. Why is the groove in a fixed pulley important?

The groove ensures that the rope or cable remains in place, preventing slippage and ensuring smooth operation. Its depth and shape are designed to match the specific rope diameter for efficiency and longevity.

7. What are the advantages of using a fixed pulley?

Fixed pulleys are simple to use, durable, and require minimal maintenance. They provide reliable load control and are widely applicable in lifting systems, despite not reducing the required effort.

8. What are the limitations of fixed pulleys?

Fixed pulleys do not reduce the force required to lift a load, limiting their mechanical advantage. They are also less effective in industrial applications that require significant force reduction.

9. How can fixed pulleys be used in combination with other pulleys?

Fixed pulleys are often combined with movable pulleys in compound pulley systems to enhance mechanical advantage and reduce lifting effort. Systems like block and tackle use multiple pulleys to distribute force efficiently.

10. What safety considerations should be taken when using fixed pulleys?

Users should ensure the pulley is securely mounted, inspect the rope or cable for wear and tear, and adhere to weight limits. Regular maintenance and proper alignment are essential for safe operation.

One Response

You have brought up a very wonderful points, appreciate it for the post.