1. Introduction

Electrical systems rely on transformers to regulate voltage levels, ensuring the efficient and safe transmission of electricity. Transformers serve as the linchpin of modern power distribution networks by stepping up or stepping down voltage as required.

High-voltage transmission minimizes power losses over long distances, while low-voltage levels are necessary for safe and efficient end-user consumption. Transformers operate on the principle of electromagnetic induction, enabling seamless energy transfer between circuits without direct electrical connection.

1.1 Importance of Step Down Transformers

Step down transformers play a crucial role in delivering usable voltage to households, commercial facilities, and industrial setups. Electrical power generated at power stations is often at an extremely high voltage, making it unsuitable for direct usage.

Step down transformers reduce these voltages to safer, functional levels for appliances and machinery. Without step down transformers, the risks of electrical hazards, equipment damage, and energy inefficiencies would be significantly heightened.

1.2 Objectives of This Article

This article aims to provide a comprehensive understanding of step down transformers, exploring their definition, construction, working principle, and applications. It delves into the fundamental differences between step up and step down transformers while also examining their efficiency and operational limitations.

2. What is a Step Down Transformer?

2.1 Definition and Basic Concept

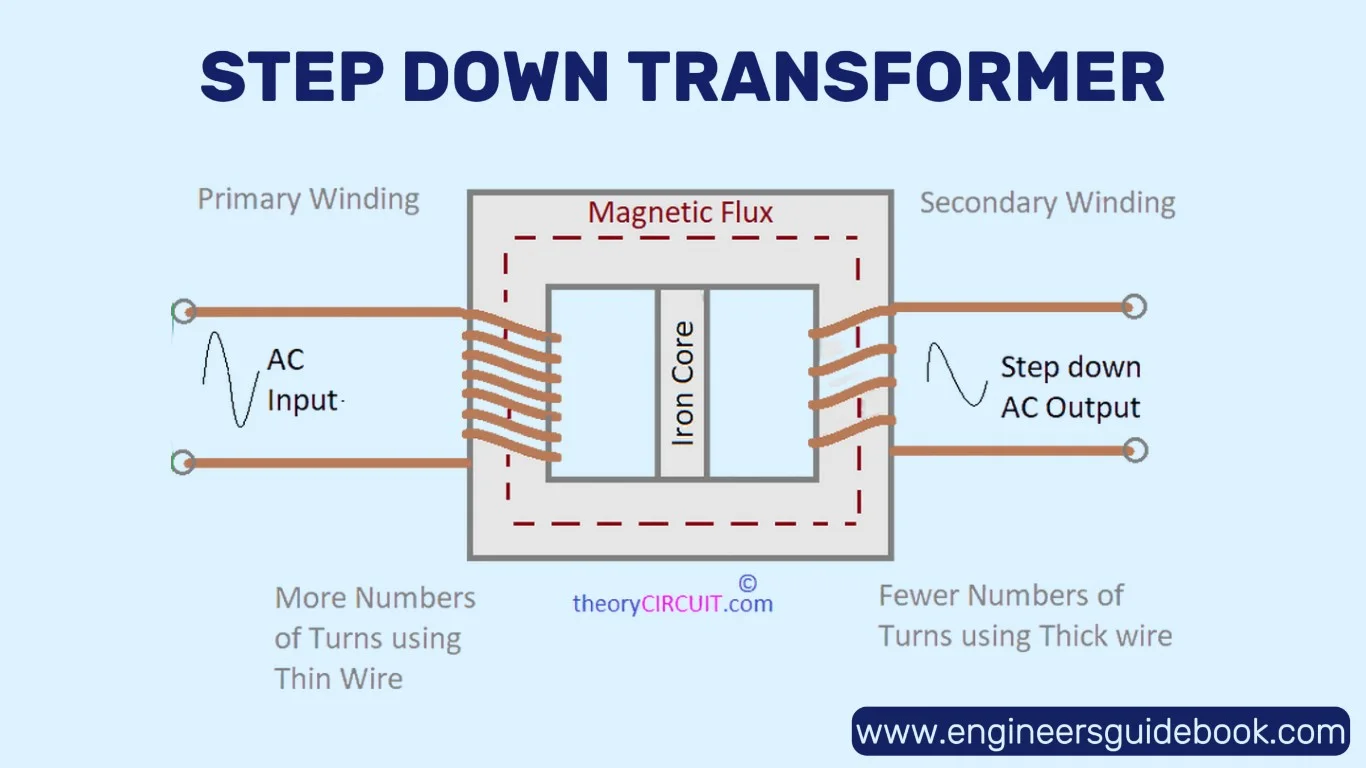

A step down transformer is an electrical device that reduces voltage from a higher level to a lower level while maintaining the power balance, aside from minor losses. It consists of primary and secondary windings wrapped around a core, with the number of windings determining the voltage transformation.

These transformers are indispensable in ensuring that electrical energy is safely delivered at appropriate levels for various applications.

2.2 Key Characteristics of a Step Down Transformer

- Voltage Reduction: Designed to lower the voltage while increasing current proportionally.

- Turns Ratio Dependency: The primary coil has more turns than the secondary, determining the degree of voltage reduction.

- AC Operation: Functions exclusively with alternating current (AC), leveraging electromagnetic induction.

- Efficiency Optimization: Minimizes energy losses through high-quality core materials and advanced insulation.

- Wide-Scale Application: Used in power grids, electronic devices, and industrial machinery to regulate voltage.

2.3 How It Differs from a Step-Up Transformer

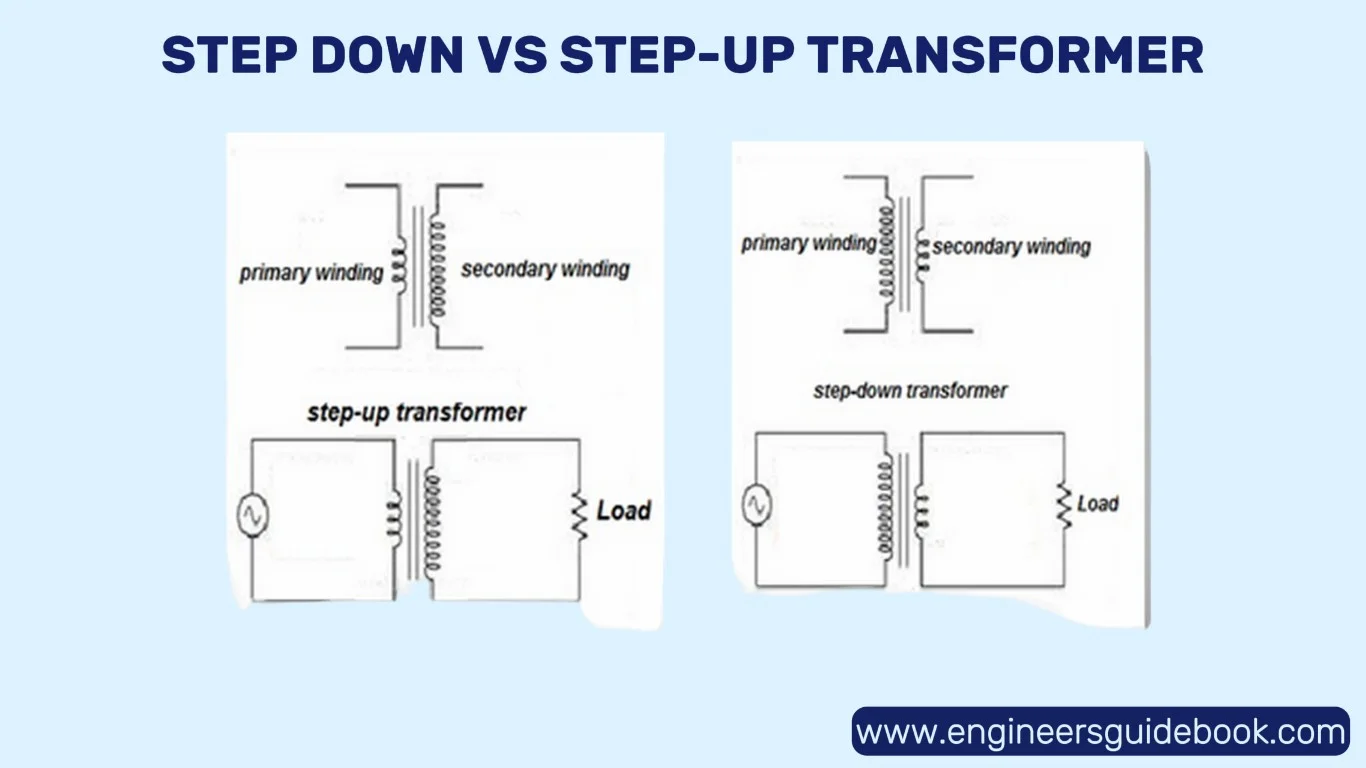

While step down transformers decrease voltage, step-up transformers perform the opposite function—raising voltage for efficient transmission. The primary winding of a step-up transformer contains fewer turns than the secondary, resulting in voltage amplification.

Step-up transformers are typically utilized in power plants to elevate voltage for long-distance transmission, whereas step-down transformers are used at substations and end-user locations to bring voltage to safe levels.

3. Construction and Components of a Step Down Transformer

3.1 Core

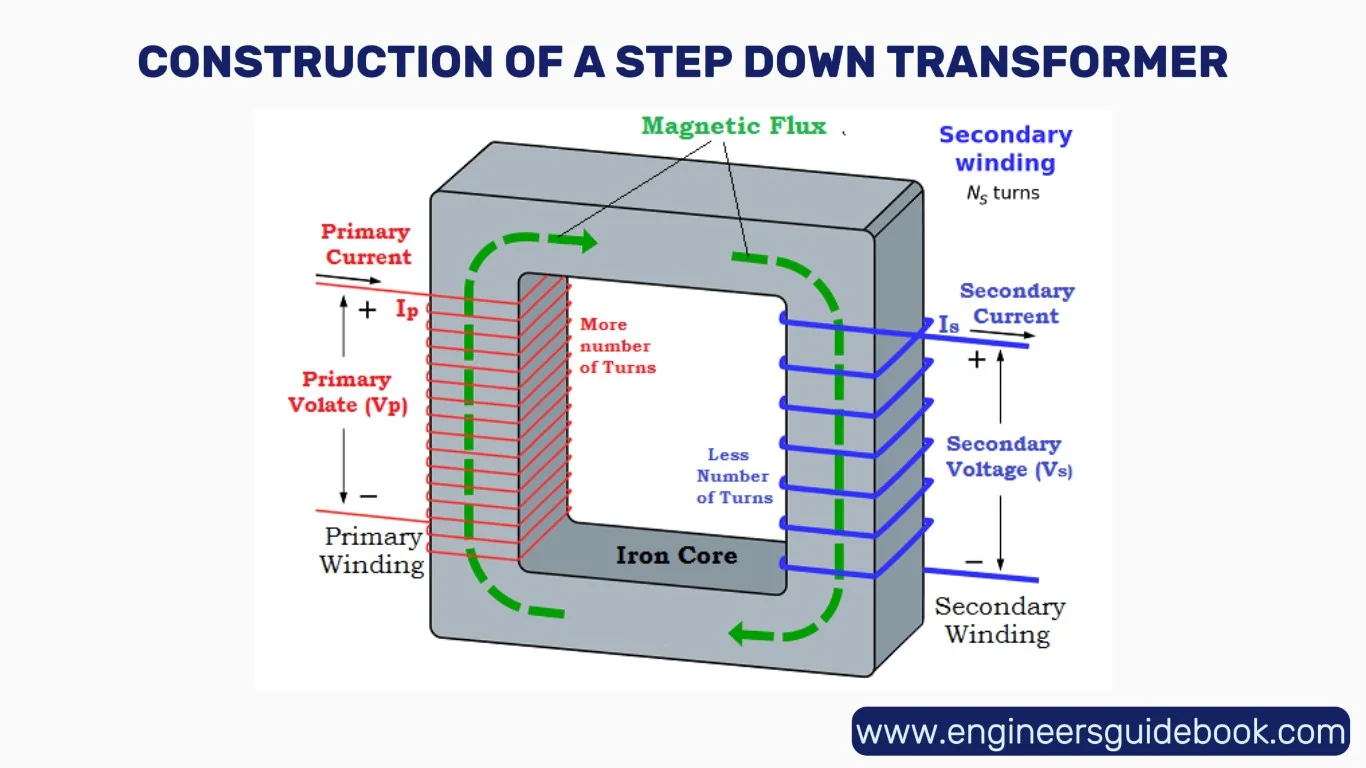

The core is the structural and functional nucleus of the transformer, facilitating the magnetic flux necessary for voltage transformation. Typically made of laminated silicon steel, the core minimizes eddy current losses and enhances efficiency. The laminated structure reduces heat buildup, preventing energy dissipation and ensuring longevity.

3.2 Primary and Secondary Windings

The windings consist of insulated copper or aluminum wires wrapped around the core. The primary winding is connected to the high-voltage input source, while the secondary winding delivers the stepped-down voltage to the output circuit.

The ratio of the number of turns in these windings directly dictates the voltage transformation according to the formula:

where and are the voltages, and and are the number of turns in the primary and secondary windings, respectively.

3.3 Insulation and Cooling Mechanisms for Efficiency

Transformers generate heat during operation, necessitating robust insulation and cooling methods. Insulation materials such as varnish, resin, or oil-impregnated paper protect windings from electrical breakdown.

Cooling techniques include air cooling, oil cooling, and forced ventilation, all of which ensure thermal stability and optimal performance. Large transformers often incorporate oil-filled tanks for efficient heat dissipation.

3.4 Types of Step Down Transformers Based on Construction

- Core Type Transformer: Features separate windings on opposite limbs of the core, enhancing magnetic coupling.

- Shell Type Transformer: Windings are placed on the central limb, providing better leakage flux control.

- Toroidal Transformer: Utilizes a donut-shaped core, improving efficiency by reducing stray losses.

- Autotransformer: A single winding acts as both primary and secondary, offering compactness but with limited isolation.

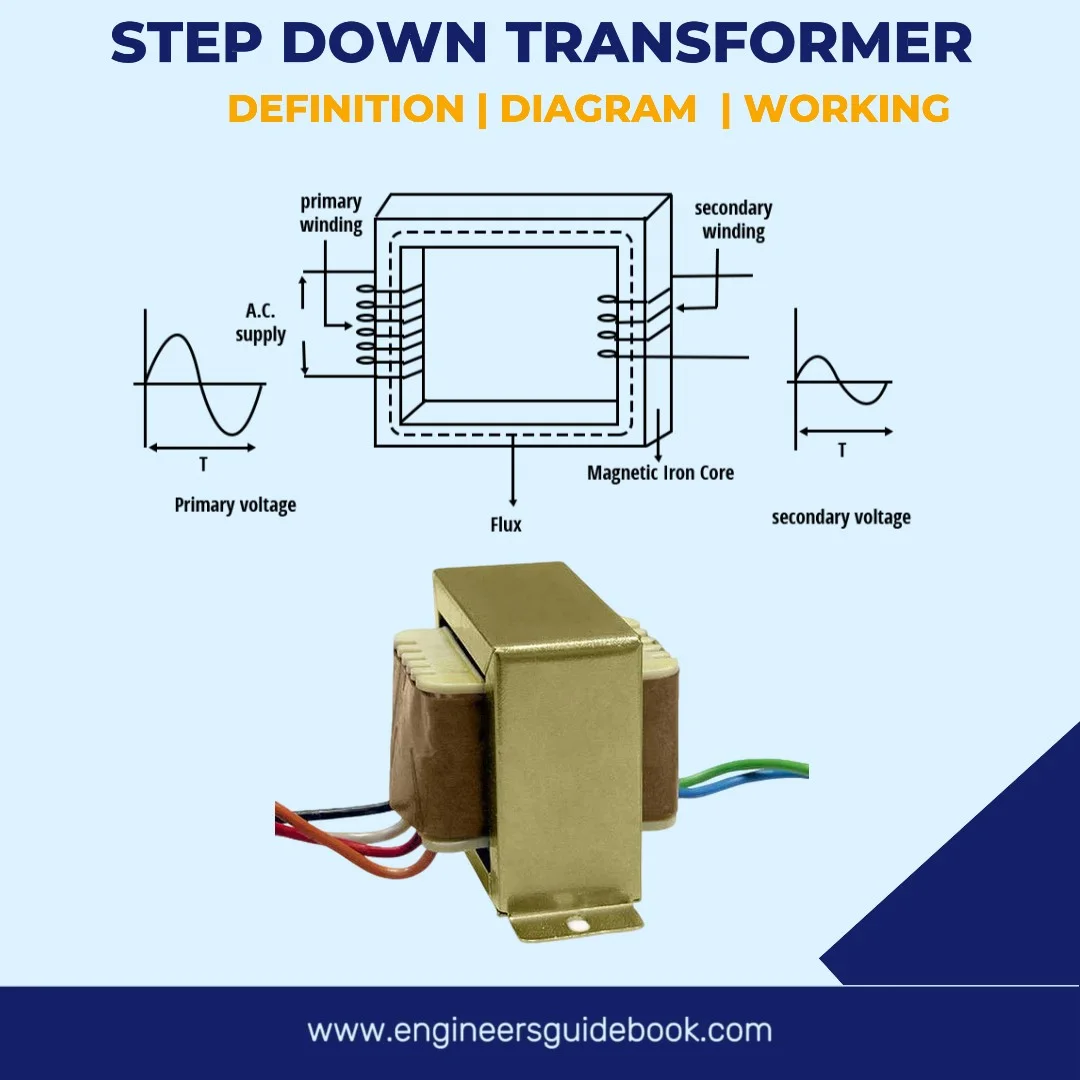

4. Diagram of a Step Down Transformer

4.1 Visual Representation of Key Components

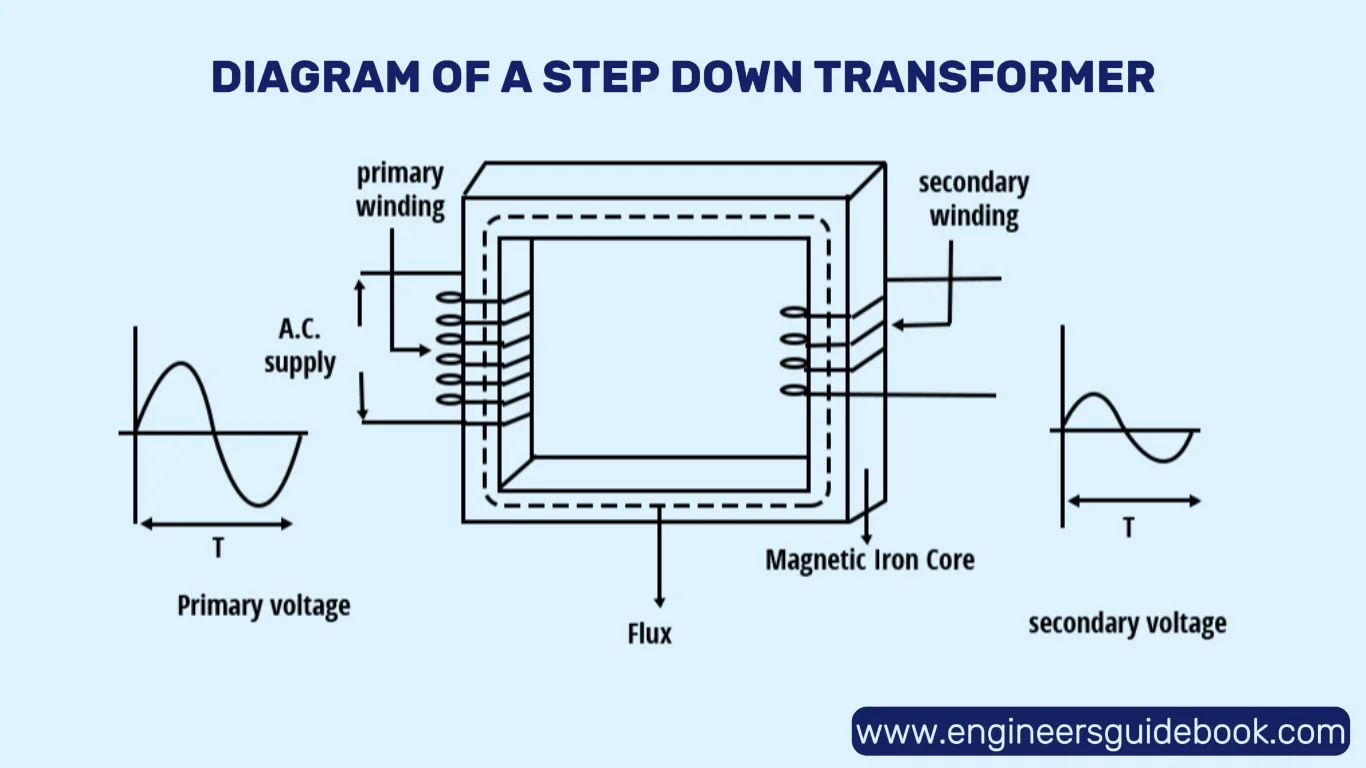

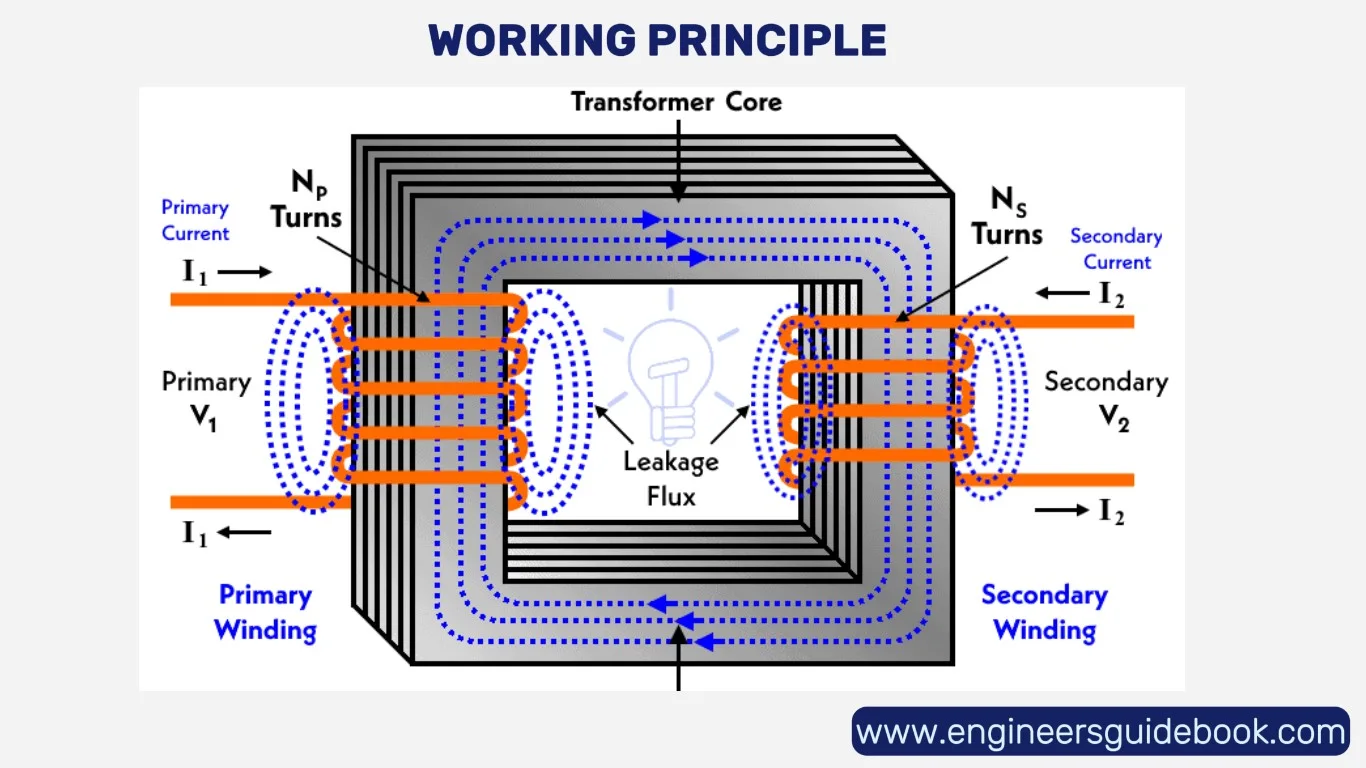

A step down transformer consists of a laminated core, primary and secondary windings, insulation materials, and cooling mechanisms. A schematic representation illustrates how voltage transformation occurs and how components interact within the system.

4.2 Labeling and Explanation of Each Part

- Primary Winding: Connected to the high-voltage source, initiates magnetic flux generation.

- Secondary Winding: Receives the induced voltage, providing the stepped-down output.

- Magnetic Core: Guides magnetic flux between windings, improving efficiency.

- Insulation: Prevents short circuits and enhances safety.

- Cooling System: Dissipates excess heat, preventing performance degradation.

4.3 Simplified vs. Detailed Schematic Diagram

A simplified diagram typically illustrates basic transformer function, showing input and output connections, windings, and the core. A detailed schematic, however, includes internal construction elements such as insulation layers, cooling systems, and material specifications. Both representations are crucial in understanding transformer operation at different levels of complexity.

5. Working Principle of a Step Down Transformer

5.1 Electromagnetic Induction

The operational foundation of a step-down transformer is rooted in the principle of electromagnetic induction. This phenomenon, first elucidated by Michael Faraday, describes how a varying magnetic field induces an electromotive force (EMF) in a conductor.

In a transformer, alternating current (AC) passing through the primary winding generates a fluctuating magnetic field around the core. This dynamic field then induces a voltage in the secondary winding, adhering to Faraday’s Law of Electromagnetic Induction.

The magnitude of the induced voltage depends on the turns ratio between the primary and secondary windings.

5.2 Step-by-Step Voltage Transformation Process

- Primary Coil Activation: An AC voltage is applied to the primary winding, creating an alternating magnetic flux in the transformer core.

- Magnetic Field Generation: The iron or ferrite core facilitates the transfer of magnetic flux from the primary winding to the secondary winding.

- Induced EMF in Secondary Winding: Due to electromagnetic induction, a voltage is induced in the secondary winding, whose magnitude is determined by the turns ratio.

- Voltage Reduction: If the number of turns in the secondary winding is lower than in the primary, the output voltage is proportionally reduced.

- Power Transmission: The transformed voltage is then delivered to the connected load, ensuring the required voltage level for safe operation.

5.3 The Role of Turns Ratio in Voltage Reduction

The transformation of voltage in a step-down transformer is governed by the turns ratio formula: where:

- = Secondary Voltage

- = Primary Voltage

- = Number of Turns in Secondary Winding

- = Number of Turns in Primary Winding A higher number of turns in the primary winding compared to the secondary ensures that the voltage is stepped down proportionally while maintaining power equivalence (disregarding minor losses).

5.4 Energy Losses and Efficiency Considerations

Despite its efficiency, a step-down transformer is subject to certain energy losses:

- Copper Losses: Resulting from resistance in the windings, leading to heat dissipation.

- Iron Losses: Including hysteresis and eddy current losses within the core, impacting efficiency.

- Leakage Flux: Some magnetic field lines do not link both windings, causing minor energy inefficiencies. High-grade materials and improved design techniques mitigate these losses, optimizing efficiency beyond 95% in well-engineered transformers.

6. Applications of Step Down Transformers

6.1 Power Distribution

Electrical power is transmitted over long distances at high voltages to minimize transmission losses. Before reaching households, step-down transformers reduce the voltage to safe, usable levels (e.g., 11kV to 230V or 120V). This ensures electrical appliances receive a stable and safe power supply.

6.2 Industrial Applications

Industries rely on step-down transformers to convert high transmission voltages to operational voltages suitable for heavy machinery. Many industrial machines operate at specific voltage levels, necessitating transformers to ensure compatibility with standard power grid voltages.

6.3 Electronics

Many electronic devices, such as laptops, televisions, and chargers, require lower voltages than supplied by the grid. Step-down transformers integrated within power adapters convert the high AC voltage to safer DC levels, preventing circuit damage.

6.4 Renewable Energy

Renewable energy systems, such as solar panels and wind turbines, generate electricity at varying voltage levels. Step-down transformers play a crucial role in voltage regulation, ensuring the generated electricity is compatible with household or industrial usage.

7. Advantages and Limitations of Step Down Transformers

7.1 Advantages

- Voltage Regulation: Reduces high transmission voltages to safe levels for different applications.

- Energy Efficiency: Operates with minimal energy loss when properly designed.

- Low Maintenance: Requires minimal upkeep compared to other voltage conversion methods.

- Cost-Effective: Provides a reliable and economical solution for voltage transformation.

7.2 Limitations

- Energy Dissipation: Heat losses occur due to resistance in windings and core material inefficiencies.

- Size Constraints: Larger transformers can be bulky and space-consuming.

- Maintenance Needs: Periodic inspection and insulation checks are necessary to ensure longevity.

8. Common Faults and Troubleshooting

8.1 Overheating Issues and Their Causes

Overheating in transformers can arise due to excessive load, poor ventilation, or insulation degradation. This can accelerate insulation breakdown, leading to operational failure.

8.2 Winding Faults and Insulation Failures

Short circuits or open circuits within the windings can disrupt transformer functionality. Insulation failures, often due to aging or moisture ingress, can cause dangerous voltage leakages.

8.3 Voltage Fluctuations and Load Imbalances

Uneven distribution of electrical loads can lead to voltage instability. Proper load management and ensuring balanced phase connections help mitigate this issue.

8.4 Preventive Maintenance and Best Practices

Routine inspections, thermal imaging for hotspot detection, and periodic oil analysis (for oil-immersed transformers) help in early fault detection. Proper ventilation and adherence to rated load capacities extend operational lifespan.

9. Conclusion

Step-down transformers play an indispensable role in electrical distribution and industrial applications. By leveraging electromagnetic induction, they ensure voltage levels are adapted to various needs efficiently and safely.

Advancements in solid-state transformers, improved insulation materials, and AI-based monitoring systems are set to enhance transformer efficiency, durability, and predictive maintenance capabilities.

From household appliances to industrial machinery, step-down transformers serve as the backbone of electrical safety and efficiency. As electrical infrastructure evolves, these transformers will continue to play a crucial role in power regulation and distribution worldwide.