1. Introduction

Carriage bolts are an indispensable component in engineering and construction, serving as a fundamental fastening solution for various applications. These bolts are renowned for their robustness, reliability, and ability to provide secure joints in wood-to-wood, wood-to-metal, and even some metal-to-metal assemblies. Impact-Site-Verification: ab2d2592-4118-407e-8024-14203c5d57

Their unique design prevents rotation during tightening, ensuring a steadfast connection. Whether in structural frameworks, heavy-duty furniture, or outdoor installations, carriage bolts offer unparalleled durability and functionality, making them a preferred choice among engineers, builders, and manufacturers.

1.1 Why Carriage Bolts Are Unique

Unlike standard bolts, carriage bolts possess a distinctive round head coupled with a square neck. This square section ensures a non-rotational fit within pre-drilled holes, eliminating the need for additional holding tools during installation. Their smooth, dome-shaped head enhances safety by preventing injuries caused by exposed sharp edges.

Additionally, the lack of protrusions makes them aesthetically appealing, particularly in applications where the bolt remains visible. This unique blend of structural integrity and visual appeal positions carriage bolts as an essential fastening solution in both functional and decorative contexts.

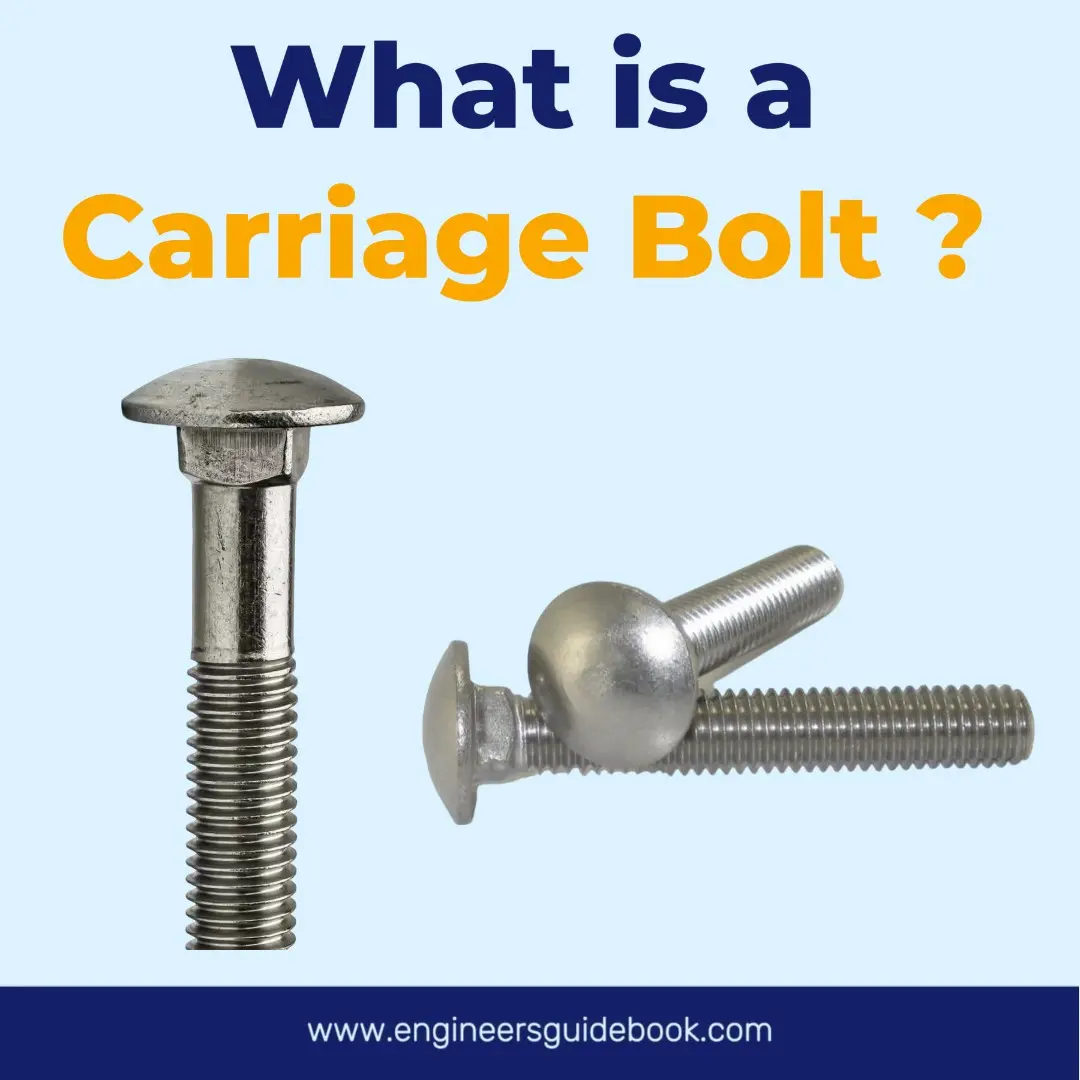

2. What Are Carriage Bolts?

2.1 Defining Carriage Bolts

Carriage bolts, also known as coach bolts, are a specialized type of fastener characterized by their domed or mushroom-shaped head and a square section beneath the head. They are typically used in conjunction with nuts and washers to create secure and stable connections.

The square neck is designed to fit snugly into corresponding square holes, thereby preventing the bolt from spinning as it is tightened. This feature makes carriage bolts particularly useful in applications where access to the head is limited or when a smooth finish is desired.

2.2 Key Features of Carriage Bolts

Several key attributes set carriage bolts apart from conventional fasteners. Their round head eliminates the need for a wrench or screwdriver during tightening, as the square neck self-locks into the material.

This makes installation more efficient and less cumbersome. Additionally, carriage bolts distribute load evenly across the surface, reducing stress concentration and enhancing structural integrity.

Their compatibility with a variety of materials, including wood, metal, and composites, further broadens their utility in engineering and construction projects.

3. History and Evolution of Carriage Bolts

3.1 Origins of the Carriage Bolt

The origins of carriage bolts can be traced back to the early 19th century, where they were primarily used in the construction of wooden carriages—hence their name.

These bolts provided a secure fastening mechanism for wooden frames, ensuring structural stability while withstanding mechanical stresses from movement and load-bearing.

Over time, their effectiveness in securing wooden joints led to their widespread adoption in architectural and industrial applications.

3.2 How Carriage Bolts Have Evolved Over Time

As engineering and manufacturing techniques advanced, carriage bolts evolved to accommodate new materials and structural demands. Modern variants are now available in an array of materials and coatings, enhancing their strength, corrosion resistance, and adaptability.

Today, carriage bolts are extensively used in metalworking, heavy machinery, bridge construction, and furniture assembly, showcasing their transition from traditional carriage-building fasteners to indispensable components in contemporary engineering.

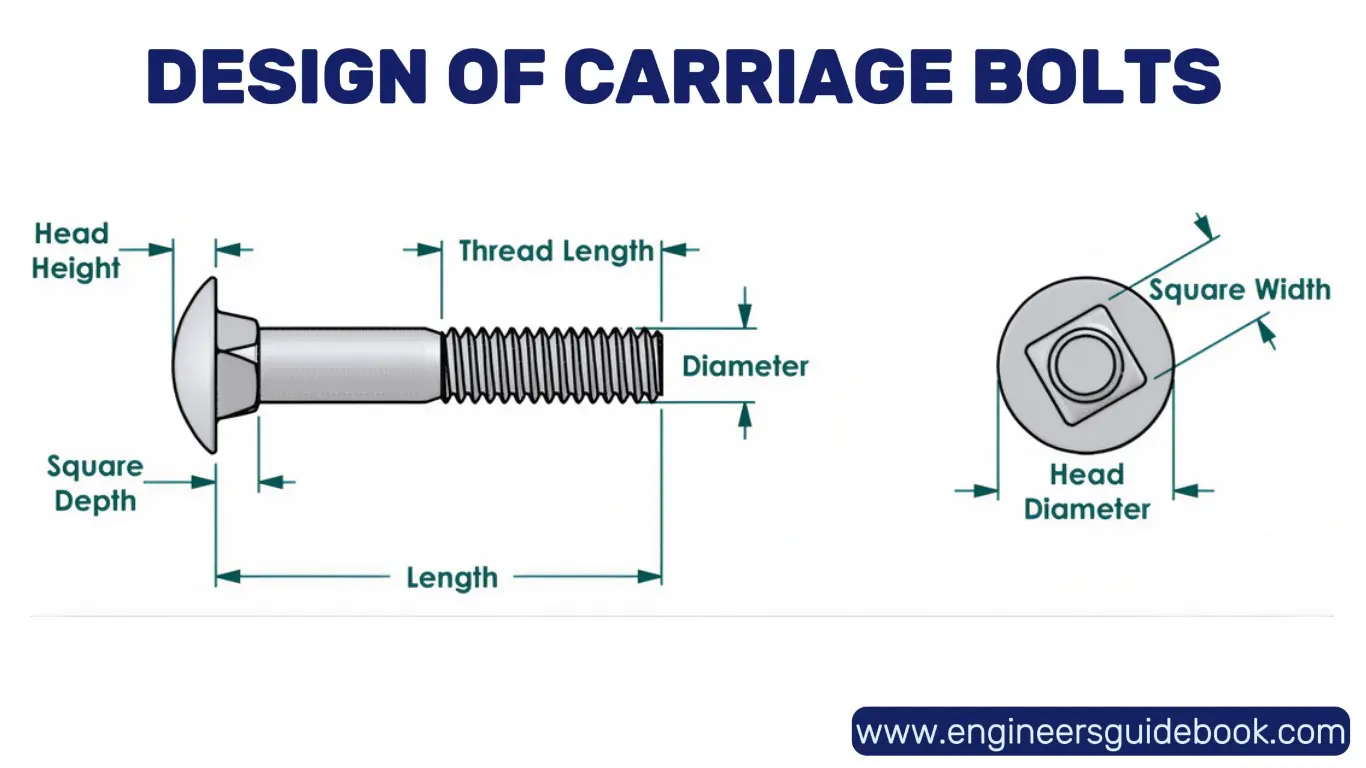

4. Design and Structure of Carriage Bolts

4.1 The Round Head

The round head of a carriage bolt is more than just a design feature; it serves multiple functional purposes. Its smooth, low-profile surface minimizes the risk of injury, making it an ideal choice for applications where exposed fasteners might pose safety concerns.

Moreover, the rounded shape distributes pressure evenly across the material surface, preventing localized damage or indentation. In addition to its functional benefits, the round head enhances the bolt’s visual appeal, particularly in applications where fasteners remain visible.

4.2 The Square Neck

The defining characteristic of a carriage bolt is its square neck, strategically designed to fit into pre-drilled square holes or embed itself into softer materials like wood. This prevents the bolt from rotating during tightening, eliminating the need for a secondary holding tool.

The square neck also enhances the bolt’s grip strength, ensuring a firm and stable connection. This unique mechanism is particularly advantageous in woodworking and construction projects where secure fastening is paramount.

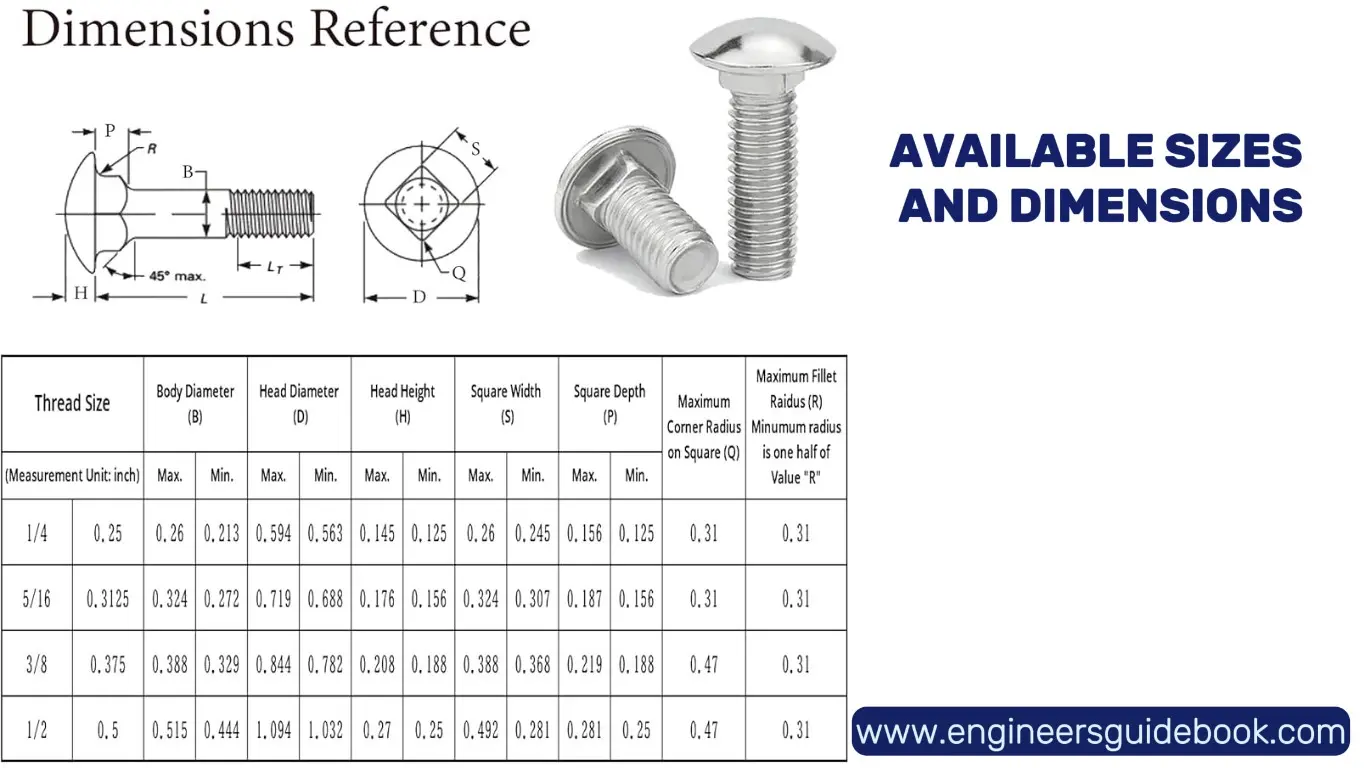

4.3 Available Sizes and Dimensions

Carriage bolts are available in a variety of sizes and dimensions, catering to diverse application requirements. Common diameters range from 1/4 inch to 1 inch, with lengths extending from 1/2 inch to several inches.

Selecting the appropriate size depends on factors such as material thickness, load-bearing capacity, and intended application. Understanding these variables ensures optimal fastening performance and longevity, preventing premature wear or structural instability.

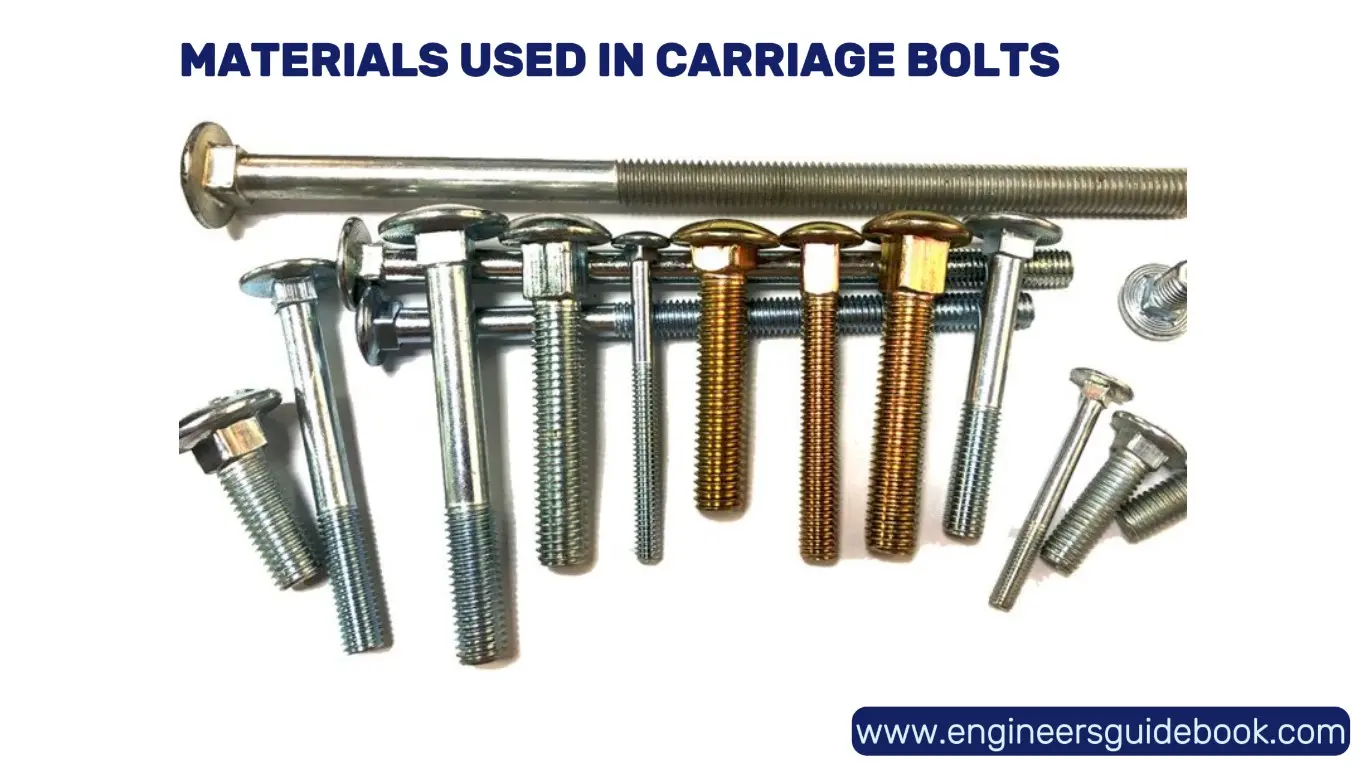

5. Materials and Coatings Used in Carriage Bolts

5.1 Carbon Steel, Stainless Steel, and Other Materials Explained

Carriage bolts are manufactured from a range of materials, each offering unique mechanical properties suited to specific applications.

Carbon steel is a popular choice due to its high strength and affordability, making it ideal for general-purpose fastening. Stainless steel variants provide excellent corrosion resistance, making them suitable for outdoor and marine environments.

Additionally, specialized alloys such as brass and titanium are used in niche applications requiring enhanced durability or electrical conductivity.

5.2 Protective Coatings: Galvanized, Zinc-Plated, and More for Durability

To extend their lifespan and enhance resistance to environmental factors, carriage bolts are often coated with protective finishes.

Galvanization, a process involving the application of a zinc layer, provides robust corrosion protection, particularly in humid or marine conditions.

Zinc plating offers similar benefits but with a thinner coating, making it ideal for indoor applications. Other coatings, such as black oxide or polymer-based finishes, provide additional resistance to wear, moisture, and chemical exposure.

The choice of coating depends on the intended application and environmental conditions, ensuring longevity and optimal performance.

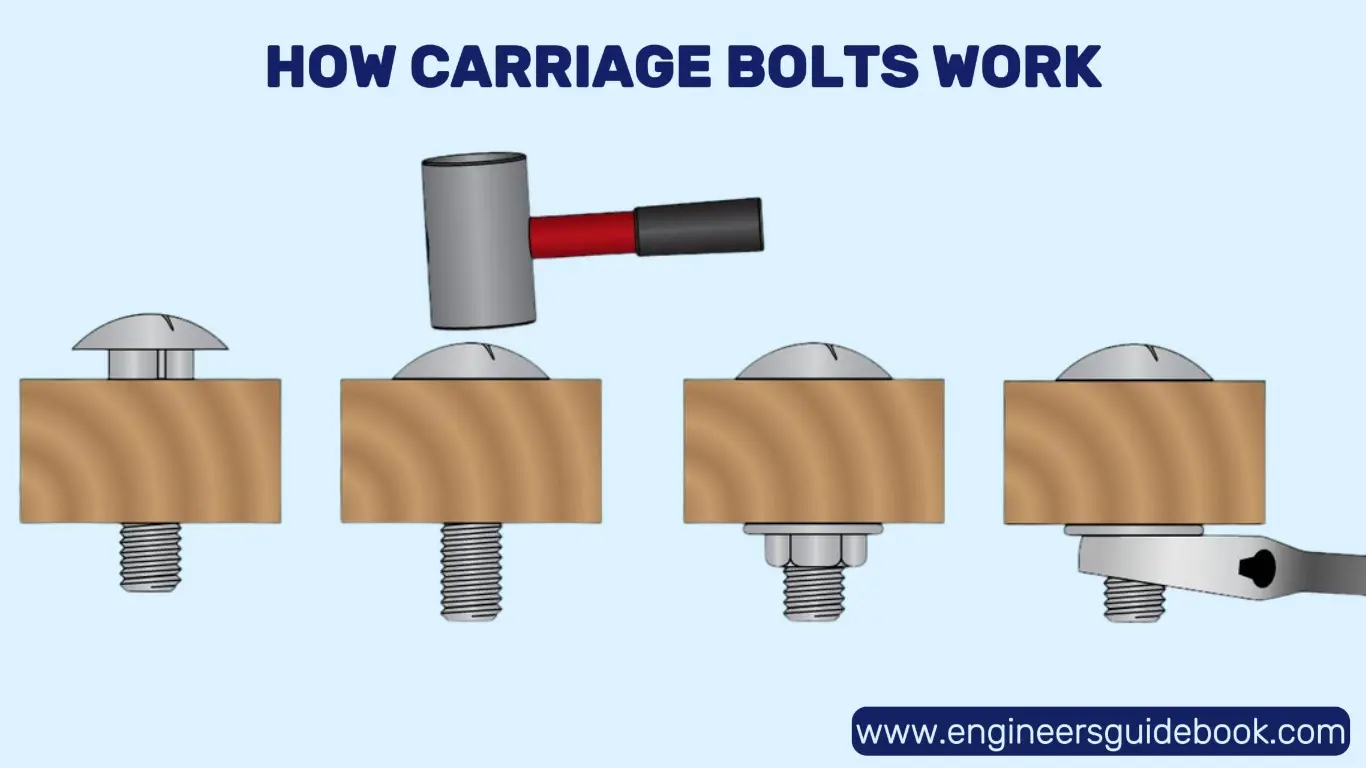

6. How Carriage Bolts Work

6.1 The Self-Locking Mechanism

Carriage bolts possess an inherent self-locking mechanism that makes them uniquely effective in fastening applications. The defining feature of this bolt is its square neck, which sits directly beneath the round, dome-shaped head.

When inserted into a pre-drilled hole—typically in wood or a square slot in metal—the square section bites into the material, preventing the bolt from spinning when torque is applied to the nut. This feature eliminates the need for an additional holding tool during installation, ensuring a secure and hassle-free fastening process.

The self-locking nature of carriage bolts makes them particularly advantageous in applications requiring vibration resistance and structural integrity.

6.2 Pairing with Nuts and Washers for Maximum Effectiveness

While the square neck of a carriage bolt prevents rotation, pairing it with the appropriate nut and washer enhances its overall effectiveness. Standard hex nuts or locknuts are typically used to secure the bolt in place, providing a firm grip and resistance against loosening due to vibrations or load shifts.

Washers play a crucial role in distributing pressure evenly across the fastening surface, reducing the likelihood of material damage or compression. Using a washer also helps prevent the nut from digging into softer materials, such as wood, thereby preserving the integrity of the structure.

7. Common Applications of Carriage Bolts

7.1 Woodworking and Timber Construction

One of the most prevalent applications of carriage bolts is in woodworking and timber construction. Due to their ability to lock into place without requiring additional tools, they are extensively used in assembling wooden frameworks, furniture, and outdoor decking.

Additionally, their compatibility with treated wood and structural beams makes them ideal for heavy-duty wooden constructions.

7.2 Metal-to-Metal Connections

Although traditionally associated with wood, carriage bolts are also widely used in metal-to-metal fastening. Industrial applications, such as bridge construction, steel frameworks, and machinery assembly, often utilize these bolts due to their ability to maintain structural stability under extreme conditions.

7.3 Automotive and Machinery

In the automotive and machinery sectors, carriage bolts are essential for ensuring secure and stable assemblies. They are frequently employed in chassis construction, engine mounting, and agricultural equipment, where durability and vibration resistance are paramount.

7.4 DIY and Home Improvement

Carriage bolts are a valuable asset in home improvement projects and DIY applications. From building furniture and assembling play structures to installing fences and securing gates, these bolts provide an easy-to-use and reliable fastening solution.

Their clean and polished appearance also makes them suitable for visible installations where aesthetics matter as much as functionality.

8. Installation Techniques for Carriage Bolts

8.1 Preparing the Material

Proper installation of carriage bolts begins with accurate hole preparation. The diameter of the drilled hole should match the bolt’s size to ensure a snug fit without excessive play.

For wood applications, a slightly undersized hole may be used to allow the square neck to bite into the material securely.

When installing in metal, a pre-punched or laser-cut square hole is ideal for accommodating the square neck, preventing rotation during tightening.

8.2 Proper Tightening Methods

Tightening carriage bolts correctly ensures longevity and structural stability. A wrench or socket is typically used to tighten the nut from the opposite side while the bolt head remains stationary due to the embedded square neck.

For added security, a locking nut or thread-locking compound can be applied to prevent loosening over time. It is advisable to avoid over-tightening, as excessive force may damage the material or strip the threads.

8.3 Avoiding Common Installation Mistakes

Several common mistakes can compromise the effectiveness of a carriage bolt installation. Using an incorrectly sized hole may lead to improper engagement of the square neck, causing the bolt to spin.

Over-tightening can damage the bolt threads or distort the material, leading to weakened structural integrity.

Additionally, neglecting to use washers in load-bearing applications may result in uneven force distribution, increasing the risk of material failure over time.

9. Strength and Load Capacity of Carriage Bolts

9.1 Understanding Tensile Strength and Shear Strength

The strength of carriage bolts is determined by two critical factors: tensile strength and shear strength. Tensile strength refers to the bolt’s ability to withstand axial loads without stretching or breaking.

Shear strength, on the other hand, measures the bolt’s capacity to resist forces that attempt to slide one section of material past another.

High-strength carriage bolts, often made from hardened steel or alloy materials, are designed to withstand substantial mechanical loads, making them suitable for demanding applications.

9.2 Factors That Influence the Load-Bearing Capacity of Carriage Bolts

Several factors influence the load-bearing capacity of carriage bolts, including material composition, diameter, thread pitch, and environmental conditions.

Bolts made from high-carbon steel or stainless steel typically offer greater load resistance compared to standard mild steel variants. Additionally, the use of protective coatings can enhance durability by mitigating corrosion, particularly in outdoor or high-moisture environments.

10. Advantages of Using Carriage Bolts

10.1 Enhanced Security

One of the primary advantages of carriage bolts is their tamper-resistant design. Unlike traditional bolts that can be loosened from either end, the round head of a carriage bolt lacks a gripping surface for tools.

This prevents unauthorized removal from the exposed side, making them an ideal choice for securing fences, outdoor furniture, and public infrastructure components.

10.2 Aesthetic Appeal

Carriage bolts offer a sleek and professional appearance, making them preferable for applications where visible fasteners are an integral part of the design. The smooth, dome-shaped head eliminates protrusions that could detract from the overall aesthetic of a project.

Whether used in decorative woodworking, architectural installations, or public seating, their visually appealing design enhances the final product.

10.3 Corrosion Resistance

Durability is a crucial factor in fastener selection, and carriage bolts excel in this regard. The availability of corrosion-resistant coatings such as galvanized zinc, black oxide, and stainless steel ensures prolonged service life even in harsh environmental conditions. These protective treatments prevent rust formation, reduce material degradation, and maintain structural integrity over time, making them ideal for outdoor and industrial applications.

11. Carriage Bolts vs. Other Types of Bolts

11.1 Comparing Carriage Bolts to Hex Bolts, Lag Bolts, and Machine Bolts

Carriage bolts, hex bolts, lag bolts, and machine bolts all serve distinct functions in engineering and construction. Carriage bolts stand out due to their smooth, rounded heads and square necks, which provide a self-locking mechanism when used with wood or metal.

In contrast, hex bolts feature six-sided heads, allowing for easy tightening with a wrench.

Lag bolts, often used in heavy-duty applications, have coarse threads and do not require a nut, instead driving directly into wood.

Machine bolts, typically threaded along their entire length, are used in precise mechanical assemblies. Each type of bolt has specific advantages, but carriage bolts excel in situations requiring tamper resistance and aesthetic appeal.

11.2 Why Carriage Bolts May Be the Superior Choice for Certain Applications

Carriage bolts offer unique benefits that make them the preferred choice in various applications. Their self-locking square neck prevents spinning, eliminating the need for an additional tool when tightening the nut. This feature is particularly valuable in woodworking, where a secure grip is essential.

Their corrosion-resistant coatings further enhance their durability, making them an ideal selection for outdoor and high-moisture environments. When considering security, functionality, and visual appeal, carriage bolts often surpass their counterparts.

12. How to Choose the Right Carriage Bolt for Your Project

12.1 Factors to Consider

Selecting the appropriate carriage bolt involves careful evaluation of length, diameter, and material. The length should be sufficient to pass through the materials being fastened while allowing enough space for the nut and washer.

Diameter selection depends on load requirements; thicker bolts provide greater strength and stability.

Material choice is equally crucial—stainless steel offers superior corrosion resistance, carbon steel provides strength for heavy loads, and galvanized coatings ensure longevity in outdoor applications.

12.2 Matching Carriage Bolts with the Right Nuts

Pairing carriage bolts with the appropriate nuts and washers is essential for a secure and lasting installation. Standard hex nuts or lock nuts can be used, depending on whether vibration resistance is required.

Washers help distribute pressure evenly, preventing damage to the material surface and ensuring a firm grip.

For outdoor projects, corrosion-resistant nuts and washers should be chosen to complement the bolt material. Proper selection enhances both structural integrity and long-term reliability.

13. Conclusion

Carriage bolts have stood the test of time due to their robust design, reliability, and versatility. Their unique combination of a rounded head and self-locking square neck makes them indispensable in construction, furniture manufacturing, and heavy machinery.

The evolution of materials and coatings has only strengthened their reputation as a durable and secure fastening option.

When selecting carriage bolts, it is essential to consider factors such as material, size, and application-specific requirements. Proper installation, including drilling the right hole size and pairing bolts with compatible nuts and washers, ensures structural integrity.

Routine maintenance, such as checking for corrosion or loosening in high-vibration environments, prolongs the bolt’s lifespan. By understanding their advantages and best practices for use, carriage bolts continue to be a fundamental component in modern engineering and construction.

14. FAQs

1. What makes carriage bolts different from regular bolts?

Carriage bolts have a unique round head and a square neck beneath it, which prevents the bolt from rotating when installed in wood or metal. This feature distinguishes them from standard bolts like hex bolts, which require a wrench for tightening from both ends.

2. What are the most common uses of carriage bolts?

Carriage bolts are widely used in woodworking, furniture assembly, metal-to-metal fastening, machinery, automotive applications, and outdoor structures such as decks and fences. Their tamper-resistant design makes them ideal for public and high-security installations.

3. Do carriage bolts require special tools for installation?

No, carriage bolts do not require special tools. The square neck locks into place in pre-drilled holes, preventing the bolt from spinning while tightening the nut with a standard wrench or socket. A washer may be used for even pressure distribution.

4. What materials are carriage bolts made from?

Carriage bolts are commonly made from carbon steel, stainless steel, and alloy steel. They may also have protective coatings such as galvanized zinc plating or black oxide to improve corrosion resistance, especially in outdoor or high-moisture environments.

5. How do I choose the right size of carriage bolt for my project?

Selecting the right carriage bolt depends on the thickness of the materials being fastened. The length should allow enough space for the nut and washer, while the diameter should match the strength requirements of the application. Common diameters range from 1/4-inch to 1 inch.

6. Can carriage bolts be used for metal-to-metal connections?

Yes, although they are primarily designed for wood, carriage bolts can be used for metal-to-metal fastening when combined with square or slotted holes that accommodate the square neck, preventing rotation.

7. Are carriage bolts rust-resistant?

The resistance to rust depends on the material and coating. Stainless steel and galvanized carriage bolts offer excellent corrosion resistance, making them suitable for outdoor and marine applications. Uncoated carbon steel bolts are more prone to rust.

8. What is the best way to prevent a carriage bolt from loosening over time?

To prevent loosening, use lock nuts or washers such as split-lock washers. Regularly inspecting and tightening bolts in high-vibration environments, such as machinery or vehicles, also helps maintain a secure connection.

4 Responses

I go to see every day some web sites and websites to read articles, except

this blog offers quality based writing.

excellent article on carrige bolt. good to see your knowledge on this topic

not so many people know about these bolts and there importance in industry, mindfull and good data that you give.

not much people know about these bolts in industry. but they are very useful