1. Introduction

In an era where efficiency and continuous improvement dictate the success of organizations, Kaizen events have emerged as a transformative tool for process optimization. Rooted in Japanese philosophy, Kaizen, which translates to “change for the better,” emphasizes incremental and sustainable improvements that enhance productivity, quality, and workplace culture. These structured events facilitate targeted, rapid improvements by engaging employees at all levels. Understanding and implementing Kaizen events can significantly enhance an organization’s operational efficiency and long-term success.

2. The Concept of Kaizen Events

2.1 Understanding the Philosophy of Continuous Improvement

Kaizen is more than just a methodology; it is a mindset that encourages ongoing refinement of processes, no matter how small. Unlike large-scale changes that require substantial resources, Kaizen promotes incremental enhancements that accumulate into significant benefits over time. By fostering a culture where employees are encouraged to identify inefficiencies and propose solutions, organizations can achieve sustained competitive advantages.

2.2 Kaizen vs. Traditional Problem-Solving Approaches

Traditional problem-solving methods often involve hierarchical decision-making, where management dictates changes with limited employee input. Conversely, Kaizen embraces a bottom-up approach, emphasizing collective intelligence. Rather than waiting for major overhauls, organizations implementing Kaizen continuously tweak and refine their processes, leading to faster, cost-effective, and employee-driven improvements.

2.3 Why Organizations Should Embrace Kaizen Events

Kaizen events offer a structured and results-driven approach to process enhancement. Organizations that integrate these events benefit from improved efficiency, reduced waste, higher employee engagement, and enhanced customer satisfaction. Moreover, by embedding continuous improvement into the corporate culture, companies can respond dynamically to market changes and operational challenges.

3. Key Principles of Kaizen Events

3.1 Focus on Small, Incremental Changes for Big Impact

The essence of Kaizen lies in its cumulative effect. While a single change may seem insignificant, the aggregation of multiple small improvements can lead to remarkable enhancements in efficiency and productivity. By breaking down complex problems into manageable segments, organizations can implement solutions without disrupting daily operations.

3.2 Employee Involvement and Cross-Functional Collaboration

Kaizen events thrive on collective intelligence. Employees who directly interact with processes often possess the most valuable insights into inefficiencies and bottlenecks. By fostering a collaborative environment where teams from various departments contribute, organizations can uncover innovative solutions that might otherwise be overlooked.

3.3 Data-Driven Decision-Making for Sustainable Results

Empirical evidence forms the backbone of effective Kaizen events. By collecting and analyzing relevant data before, during, and after implementation, organizations can ensure that improvements are measurable, replicable, and aligned with strategic objectives. This analytical approach minimizes the risk of subjective decision-making and ensures long-term sustainability.

3.4 Rapid Implementation to Drive Immediate Improvements

Unlike prolonged process improvement initiatives, Kaizen events focus on swift execution. Typically lasting between a few days to a week, these events drive immediate action, ensuring that identified improvements are tested and implemented without unnecessary delays. This rapid deployment encourages momentum and reinforces a culture of proactive problem-solving.

4. Types of Kaizen Events and Their Applications

4.1 Process Improvement Kaizen Events

Designed to streamline workflows, these events target inefficiencies in manufacturing, service delivery, and administrative functions. By mapping current processes and identifying non-value-adding activities, organizations can redesign workflows to enhance efficiency and reduce delays.

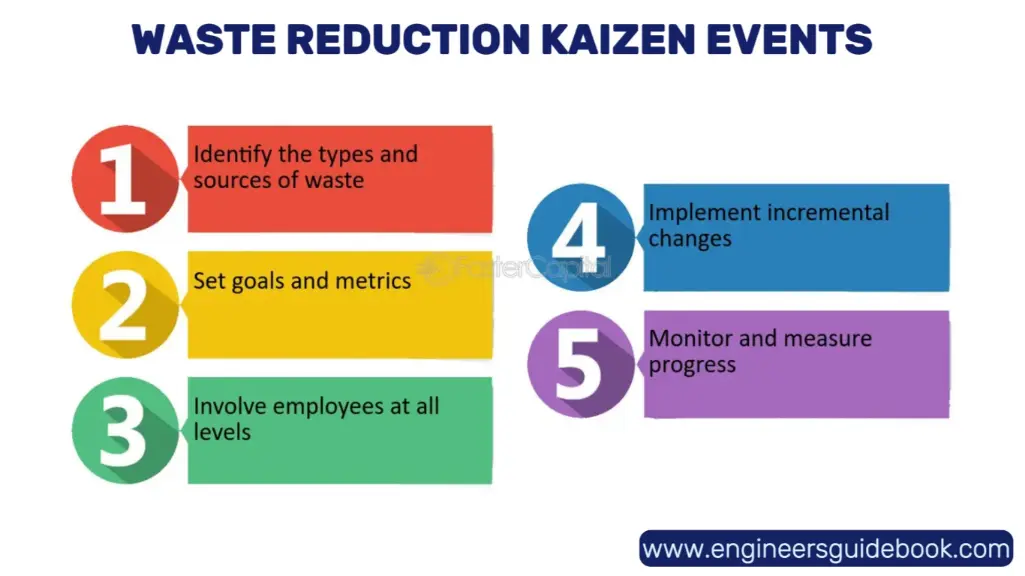

4.2 Waste Reduction Kaizen Events

Waste, in the context of Lean methodology, includes excess inventory, overproduction, waiting times, and unnecessary transportation. Kaizen events focused on waste reduction systematically identify and eliminate such inefficiencies, leading to cost savings and optimized resource utilization.

4.3 Safety and Workplace Organization Kaizen Events

A well-organized workplace fosters productivity and minimizes risks. These events often incorporate the 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—to create an efficient, clean, and hazard-free environment. Enhanced workplace organization translates to improved employee morale and reduced workplace incidents.

4.4 Customer-Focused Kaizen Events

Customer satisfaction is the cornerstone of business success. Kaizen events centered on customer experience analyze feedback, streamline service delivery, and improve product quality. By continuously refining customer interactions, businesses can strengthen brand loyalty and market competitiveness.

5. Preparing for a Successful Kaizen Event

5.1 Identifying the Right Problem and Setting Clear Objectives

A successful Kaizen event begins with pinpointing a specific problem that aligns with organizational goals. Clearly defined objectives ensure that teams remain focused and measurable outcomes are achieved. Organizations should prioritize areas with the most significant potential for improvement to maximize impact.

5.2 Selecting the Right Team: Roles and Responsibilities

A cross-functional team ensures diverse perspectives and comprehensive problem-solving. A typical Kaizen event team includes:

- Team Leader: Guides the event and ensures alignment with objectives.

- Facilitator: Provides expertise in Kaizen methodologies.

- Process Owner: Offers in-depth knowledge of the targeted process.

- Operators and Employees: Bring frontline insights and hands-on experience.

- Data Analyst: Tracks progress and measures results.

5.3 Gathering Preliminary Data and Conducting Process Mapping

Before initiating a Kaizen event, organizations must gather relevant data to establish baseline performance metrics. Process mapping, such as value stream mapping, helps visualize workflows, identify bottlenecks, and determine where improvements can be made. Data-driven insights facilitate precise problem identification and solution formulation.

5.4 Securing Leadership Buy-In and Organizational Support

Leadership support is crucial for the success of a Kaizen event. Management must provide necessary resources, reinforce a culture of continuous improvement, and encourage employee participation. By demonstrating commitment to Kaizen principles, leadership fosters a positive environment where employees feel empowered to contribute to meaningful change.

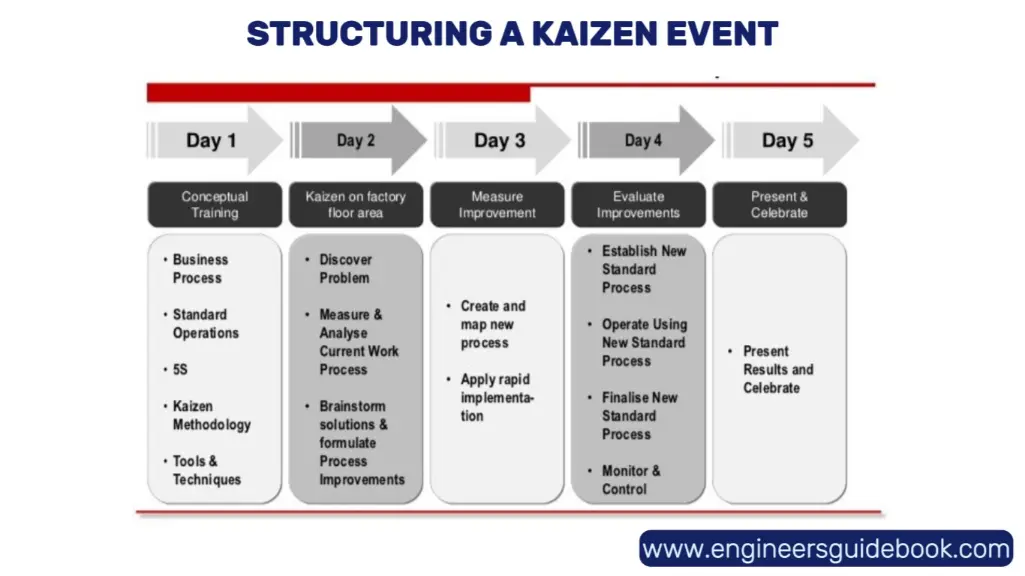

6. Structuring a Kaizen Event for Maximum Effectiveness

6.1 The Five Phases of a Kaizen Event

A well-structured Kaizen event follows five distinct phases: preparation, kickoff, analysis, implementation, and follow-up. The preparation phase involves defining objectives, selecting the right team, and gathering necessary data. The kickoff phase sets expectations and aligns team members on the goals. Analysis focuses on identifying inefficiencies and brainstorming potential solutions. Implementation involves testing and executing the proposed changes. The follow-up phase ensures that improvements are sustained and further refined if necessary.

6.2 Creating a Timeline and Action Plan

A structured timeline is crucial for an effective Kaizen event. Clearly defining tasks, setting milestones, and assigning responsibilities prevent delays and inefficiencies. A typical timeline includes pre-event planning, an intensive improvement workshop lasting several days, and a post-event review. The action plan should outline specific tasks, responsible personnel, and deadlines to ensure accountability and track progress.

6.3 Tools and Techniques Used in Kaizen Events

Kaizen events employ various Lean tools and techniques to facilitate process improvements. Some of the most effective tools include Value Stream Mapping (VSM) for identifying bottlenecks, the 5 Whys technique for root cause analysis, and the PDCA (Plan-Do-Check-Act) cycle for iterative improvements. Visual management tools, such as Kanban boards, also enhance efficiency by providing real-time tracking of tasks and progress.

7. The Kaizen Event Process: Step-by-Step Execution

7.1 Defining the Problem and Establishing Baseline Metrics

The first step in any Kaizen event is to define the problem clearly. This involves analyzing existing processes and identifying inefficiencies. Establishing baseline metrics, such as cycle time, defect rates, or resource utilization, provides a reference point to measure the impact of improvements.

7.2 Brainstorming Solutions Using Lean Methodologies

Once the problem is identified, the team engages in structured brainstorming sessions. Lean methodologies such as Kaizen Blitz, Gemba Walks, and Just-in-Time (JIT) principles help in developing practical and achievable solutions. Prioritization tools, like the impact-effort matrix, guide teams in selecting the most effective improvements.

7.3 Testing and Implementing Improvements in Real Time

Kaizen events emphasize rapid implementation. Small-scale tests or pilot programs validate the effectiveness of proposed changes before full-scale deployment. This iterative process ensures that solutions are practical and deliver measurable benefits without disrupting operations.

7.4 Measuring the Results and Refining the Approach

After implementation, performance metrics are reassessed to determine the success of the Kaizen event. Comparing post-event data with baseline metrics helps quantify improvements. If necessary, further refinements are made to optimize the process continuously.

8. Essential Lean Tools for Kaizen Events

8.1 Value Stream Mapping for Process Visualization

Value Stream Mapping (VSM) is a powerful tool used in Kaizen events to visualize current workflows, identify inefficiencies, and design optimized processes. It provides a holistic view of material and information flow, enabling teams to eliminate waste and enhance value creation.

8.2 5S Methodology for Workplace Organization

The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—improves workplace organization and efficiency. Implementing 5S in Kaizen events ensures that workspaces are systematically arranged, reducing time wasted on searching for tools, materials, or information.

8.3 Root Cause Analysis and the 5 Whys Technique

Root Cause Analysis (RCA) helps uncover the underlying reasons for inefficiencies. The 5 Whys technique is a simple yet effective approach to identifying root causes by repeatedly asking “Why?” until the fundamental issue is revealed. This prevents superficial fixes and promotes long-term solutions.

8.4 Standard Work and Visual Management

Standard Work involves documenting best practices and establishing repeatable processes to maintain efficiency. Visual management tools, such as shadow boards and Andon systems, provide real-time information, enabling employees to monitor and respond to process deviations promptly.

9. Common Challenges in Kaizen Events

9.1 Resistance to Change

Change resistance is a common hurdle in Kaizen events. Employees may fear increased workload or job insecurity. Addressing concerns through transparent communication, involving employees in decision-making, and demonstrating the benefits of improvements fosters acceptance and engagement.

9.2 Poor Data Collection

Accurate data collection is vital for successful Kaizen events. Misinterpreting data can lead to ineffective solutions. Using reliable data sources, training employees on data analysis, and employing statistical tools minimize errors and ensure data-driven decision-making.

9.3 Difficulty in Sustaining Improvements Post-Kaizen Event

Sustaining improvements is challenging without proper follow-up. Embedding continuous improvement into organizational culture, conducting regular audits, and integrating changes into standard operating procedures (SOPs) help maintain long-term gains.

10. The Role of Leadership in Kaizen Events

10.1 Creating a Culture of Continuous Improvement

Leadership plays a pivotal role in fostering a Kaizen mindset. Encouraging innovation, recognizing employee contributions, and reinforcing the importance of continuous improvement create a culture where efficiency and quality enhancements become second nature.

10.2 Encouraging Open Communication

Effective communication ensures that employees understand the objectives and benefits of Kaizen events. Open dialogue, active listening, and feedback loops empower employees to share ideas, report inefficiencies, and contribute to meaningful improvements.

10.3 Providing Necessary Resources

Leadership must allocate resources—time, budget, and training—to ensure the success of Kaizen events. Supporting cross-functional collaboration, investing in Lean training, and providing access to improvement tools empower teams to execute and sustain process enhancements effectively.

11. Sustaining the Gains: Ensuring Long-Term Success

Kaizen events yield transformative improvements, but the true challenge lies in maintaining these gains over time. Without a structured approach to sustainability, the initial momentum can dissipate, leading to a regression of inefficiencies. Organizations must institutionalize continuous improvement by embedding standard practices, tracking performance, and fostering a culture that perpetuates refinement.

11.1 Implementing Standard Operating Procedures (SOPs)

Documenting the improvements achieved through a Kaizen event is critical to ensuring their longevity. Standard Operating Procedures (SOPs) serve as a blueprint for maintaining newly established processes. These protocols must be clear, concise, and actionable, allowing employees at all levels to follow best practices consistently. Establishing SOPs involves:

- Defining Process Standards: Detailing optimal workflows and expected outcomes.

- Training Employees: Conducting comprehensive training sessions to ensure adherence to new standards.

- Regular Audits: Reviewing compliance with SOPs to identify deviations and corrective actions.

11.2 Continuous Monitoring and Performance Tracking

Monitoring the impact of a Kaizen event through performance tracking ensures sustained progress. Organizations must establish measurable benchmarks that provide real-time insights into operational efficiency. Key strategies include:

- Utilizing Key Performance Indicators (KPIs): Tracking productivity, quality, and cycle time metrics.

- Implementing Digital Dashboards: Leveraging automation for real-time data analysis and visualization.

- Conducting Periodic Reviews: Holding review meetings to discuss performance trends and improvement opportunities.

11.3 Scheduling Follow-Up Kaizen Events for Continuous Refinement

Kaizen is not a one-time endeavor but an iterative process. Scheduling follow-up events allows organizations to build upon previous improvements, address emerging inefficiencies, and reinforce a culture of continuous enhancement. Effective follow-up practices include:

- Feedback Loops: Encouraging employees to suggest refinements based on real-world application.

- Kaizen Checkpoints: Scheduling structured assessments at defined intervals.

- Cross-Functional Collaboration: Engaging different departments to share insights and replicate successful methodologies.

12. Real-World Examples of Successful Kaizen Events

Examining real-world applications of Kaizen highlights its transformative potential across industries. These case studies illustrate the adaptability and impact of structured continuous improvement initiatives.

12.1 Case Study: Reducing Lead Time in Manufacturing

A global automotive manufacturer implemented a Kaizen event to address excessive lead times in production. By analyzing the value stream and eliminating non-value-adding activities, the company:

- Reduced cycle time by 30% through workflow reconfiguration.

- Minimized material waste by optimizing inventory levels.

- Enhanced worker efficiency through ergonomic workstation redesign.

12.2 Case Study: Streamlining Hospital Operations for Better Patient Care

A hospital facing bottlenecks in patient admissions employed Kaizen to improve service delivery. The initiative led to:

- A 25% reduction in patient wait times by refining triage protocols.

- Improved staff coordination through standardization of communication procedures.

- Enhanced patient satisfaction scores by addressing inefficiencies in scheduling and resource allocation.

12.3 Case Study: Enhancing Customer Service Efficiency in Retail

A leading retail chain leveraged Kaizen to improve customer service operations. By redesigning the checkout process, they achieved:

- A 40% reduction in transaction times through better queue management.

- Higher employee engagement via incentive-based performance tracking.

- Increased customer retention rates by streamlining product returns and exchanges.

13. Measuring the Impact of Kaizen Events

Assessing the effectiveness of Kaizen initiatives is essential for validating improvements and justifying future investments. Key measurement frameworks ensure objective evaluation and ongoing refinement.

13.1 Key Performance Indicators (KPIs) for Assessing Success

Determining the right KPIs is crucial for tracking progress. Common Kaizen KPIs include:

- Process Efficiency Metrics: Cycle time, lead time, and throughput.

- Quality Indicators: Defect rates and first-pass yield.

- Employee Engagement Metrics: Participation rates in improvement initiatives.

13.2 Cost Savings, Productivity Gains, and Quality Improvements

Quantifiable benefits from Kaizen events reinforce their value proposition. Key impact areas include:

- Operational Cost Reduction: Lower material and labor costs through process optimization.

- Productivity Enhancement: Higher output with the same or fewer resources.

- Quality Improvement: Reduced rework and defects leading to superior customer satisfaction.

13.3 Employee Satisfaction and Workplace Morale Boost

Engaged employees are instrumental in sustaining Kaizen-driven improvements. Metrics to assess workplace morale include:

- Employee Surveys: Measuring satisfaction and perception of workplace efficiency.

- Turnover Rates: Lower attrition indicating a positive work environment.

- Suggestion Box Utilization: High participation reflecting an active improvement culture.

14. Integrating Kaizen Events into Organizational Strategy

For Kaizen to yield long-term benefits, it must be seamlessly integrated into an organization’s strategic framework. A holistic approach ensures alignment with business goals and fosters widespread adoption.

14.1 Aligning Kaizen with Business Objectives and Goals

Kaizen initiatives must be directly linked to organizational priorities to maximize their strategic impact. Alignment strategies include:

- Defining Clear Objectives: Ensuring Kaizen goals support overarching business targets.

- Resource Allocation: Investing in training, technology, and personnel to sustain improvements.

- Leadership Endorsement: Securing executive sponsorship for continuous improvement initiatives.

14.2 Combining Kaizen with Other Continuous Improvement Initiatives

Integrating Kaizen with complementary methodologies enhances its effectiveness. Synergistic approaches include:

- Lean Manufacturing: Eliminating waste and optimizing value streams.

- Six Sigma: Leveraging data-driven problem-solving for defect reduction.

- Agile Principles: Applying iterative cycles for rapid adaptation and innovation.

14.3 Establishing a Kaizen Mindset Across All Departments

A company-wide commitment to Kaizen fosters a unified culture of continuous improvement. Effective integration strategies include:

- Training Programs: Educating employees on Kaizen principles and methodologies.

- Recognition and Rewards: Incentivizing contributions to process enhancement.

- Cross-Departmental Collaboration: Encouraging knowledge sharing and best practice dissemination.

15. Conclusion

Kaizen events represent a powerful mechanism for driving operational excellence, but their true value lies in their sustainability. By embedding standardized practices, continuously monitoring progress, and institutionalizing a culture of improvement, organizations can ensure lasting benefits. Real-world success stories illustrate the profound impact of Kaizen across diverse industries, reinforcing its adaptability and effectiveness.

Measuring success through KPIs, cost savings, and employee engagement metrics provides tangible evidence of Kaizen’s contributions. Integrating these initiatives into broader business strategies ensures their alignment with organizational goals, fostering a company-wide commitment to excellence.

16. FAQS

1. What is a Kaizen event, and how does it differ from regular continuous improvement initiatives?

A Kaizen event is a focused, time-bound workshop designed to identify and implement process improvements rapidly. Unlike regular continuous improvement initiatives, which may be ongoing and incremental, a Kaizen event has a defined scope, dedicated team, and a structured timeline (typically lasting a few days to a week). It aims for immediate and measurable improvements rather than long-term gradual changes.

2. How do you determine if a process is suitable for a Kaizen event?

Processes with inefficiencies such as bottlenecks, excessive waste, long cycle times, or quality defects are ideal candidates for Kaizen events. Additionally, areas where employees frequently encounter operational challenges or where customer feedback highlights recurring issues are strong contenders. Selecting a process with clear improvement potential ensures a successful outcome.

3. What are the key roles in a Kaizen event team?

A Kaizen event typically involves:

- Team Leader – Oversees the event and ensures objectives are met.

- Facilitator – Provides expertise in Kaizen methodologies and Lean tools.

- Process Owner – Has in-depth knowledge of the current process.

- Operators & Employees – Bring firsthand experience and insights into process inefficiencies.

- Data Analyst – Measures baseline performance and tracks improvements.

A cross-functional team ensures diverse perspectives and innovative solutions.

4. How long does a typical Kaizen event last?

A Kaizen event usually lasts between three to five days, depending on the complexity of the process being improved. Some organizations conduct mini-Kaizen events in a single day, while larger-scale events can extend up to a week. The key is maintaining momentum and ensuring quick, actionable results.

5. What Lean tools are commonly used in Kaizen events?

Several Lean tools are instrumental in Kaizen events, including:

- Value Stream Mapping (VSM) – Visualizes workflows to identify waste and inefficiencies.

- 5S Methodology – Enhances workplace organization through Sort, Set in Order, Shine, Standardize, and Sustain.

- Root Cause Analysis & 5 Whys – Helps identify the underlying causes of problems.

- Standard Work & Visual Management – Ensures consistency and transparency in processes.

These tools facilitate data-driven decision-making and sustainable improvements.

6. How do you sustain the improvements made during a Kaizen event?

To ensure long-term success, organizations should:

- Implement Standard Operating Procedures (SOPs) for new processes.

- Continuously monitor Key Performance Indicators (KPIs) to track performance.

- Schedule follow-up Kaizen events to address new challenges and reinforce improvements.

- Foster a culture of continuous improvement, where employees actively seek out and implement incremental changes.

Sustainability depends on leadership support, employee engagement, and ongoing refinement.

7. What are the most common challenges in conducting a Kaizen event?

Some common challenges include:

- Resistance to Change – Employees may be reluctant to adopt new processes.

- Lack of Data Accuracy – Poor data collection can lead to misguided decisions.

- Inconsistent Implementation – Without follow-up, improvements may not be sustained.

- Limited Leadership Support – If management does not prioritize Kaizen, its impact diminishes.

Overcoming these challenges requires strong leadership, clear communication, and a structured approach.

8. How do Kaizen events impact employee morale and engagement?

Kaizen events empower employees by giving them a voice in process improvement. When workers actively contribute to problem-solving and see their ideas implemented, they feel valued and engaged. Additionally, the reduction of inefficiencies and workplace frustrations leads to improved job satisfaction. Organizations that consistently involve employees in Kaizen initiatives tend to have higher morale and a more motivated workforce.

8 Responses

I believe that is among the such a lot vital information for me.

And i am glad reading your article. But should statement on few normal issues,

The website style is great, the articles is really excellent : D.

Good job, cheers

This article on “Kaizen Events: How to Conduct and Benefit” offers a highly practical and insightful guide to continuous improvement.

It clearly outlines the principles, steps, and benefits of conducting successful Kaizen events, making it an invaluable resource for any organization aiming for operational excellence.

The emphasis on employee involvement and sustainable change truly resonates. Excellent content for process improvement enthusiasts!

We often talk about continuous improvement, but posts like this help turn the talk into action. Thanks for sharing

Short, effective, and straight to the point. Great read!

Nice explanation! I appreciate how you broke it down into practical steps—makes it easier to apply in real situations.

Kaizen events have been a turning point for our team. Glad to see more awareness around structured improvement like this

Really helpful post! We recently started implementing Kaizen events at our facility, and seeing this step-by-step guide gives me more confidence in the process.

very good article on kizen events.